Cold pasteurization, such as high-pressure processing, preserves milk nutrients and flavor more effectively than thermal pasteurization by inactivating pathogens without heat. Thermal pasteurization uses heat to eliminate harmful microorganisms but can cause slight changes in taste and nutrient content. Both methods ensure milk safety, with cold pasteurization offering a better option for maintaining milk's sensory and nutritional quality.

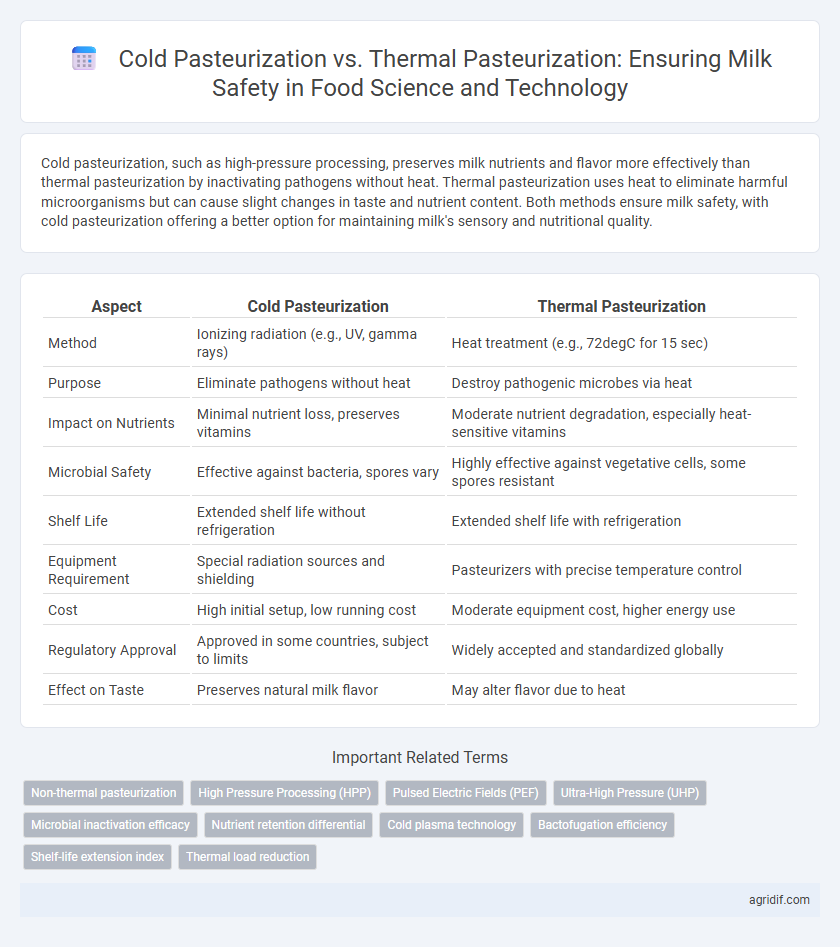

Table of Comparison

| Aspect | Cold Pasteurization | Thermal Pasteurization |

|---|---|---|

| Method | Ionizing radiation (e.g., UV, gamma rays) | Heat treatment (e.g., 72degC for 15 sec) |

| Purpose | Eliminate pathogens without heat | Destroy pathogenic microbes via heat |

| Impact on Nutrients | Minimal nutrient loss, preserves vitamins | Moderate nutrient degradation, especially heat-sensitive vitamins |

| Microbial Safety | Effective against bacteria, spores vary | Highly effective against vegetative cells, some spores resistant |

| Shelf Life | Extended shelf life without refrigeration | Extended shelf life with refrigeration |

| Equipment Requirement | Special radiation sources and shielding | Pasteurizers with precise temperature control |

| Cost | High initial setup, low running cost | Moderate equipment cost, higher energy use |

| Regulatory Approval | Approved in some countries, subject to limits | Widely accepted and standardized globally |

| Effect on Taste | Preserves natural milk flavor | May alter flavor due to heat |

Introduction to Milk Pasteurization Methods

Cold pasteurization, including high-pressure processing (HPP), preserves milk's nutritional and sensory qualities by inactivating pathogens without applying heat. Thermal pasteurization, such as high-temperature short-time (HTST) treatment, effectively eliminates bacteria through controlled heating, ensuring safety and extended shelf life. Both methods balance microbial safety with milk quality, influencing industry choices based on processing efficiency and product characteristics.

Principles of Cold Pasteurization Techniques

Cold pasteurization techniques for milk safety primarily utilize ionizing radiation, such as electron beams or gamma rays, to inactivate pathogenic microorganisms without significantly increasing temperature. These methods disrupt microbial DNA and cellular structures, maintaining nutritional and sensory qualities better than thermal pasteurization. Cold pasteurization offers advantages in preserving heat-sensitive vitamins and proteins while ensuring microbiological safety.

Overview of Traditional Thermal Pasteurization

Traditional thermal pasteurization of milk involves heating milk to temperatures between 63degC and 72degC for 15 to 30 seconds to effectively inactivate pathogenic microorganisms such as Mycobacterium bovis and Listeria monocytogenes. This process ensures microbiological safety while preserving essential nutrients, although some heat-sensitive vitamins like vitamin C may degrade. Thermal pasteurization remains the industry standard due to its proven efficacy and regulatory acceptance for extending milk shelf life and reducing foodborne illness risks.

Microbial Safety: Cold vs. Thermal Pasteurization

Cold pasteurization methods such as high-pressure processing (HPP) and ultraviolet (UV) irradiation effectively reduce microbial load in milk without significantly altering its nutritional and sensory qualities. Thermal pasteurization, including traditional methods like low-temperature long-time (LTLT) and high-temperature short-time (HTST), ensures the inactivation of pathogenic microorganisms but may cause slight degradation of heat-sensitive vitamins and proteins. Both techniques achieve microbial safety, but cold pasteurization offers enhanced retention of milk's natural properties while maintaining effective pathogen control.

Effects on Milk Nutritional Quality

Cold pasteurization techniques, such as high-pressure processing (HPP) and ultraviolet (UV) treatment, preserve milk's nutritional quality by minimizing heat-induced degradation of vitamins and bioactive proteins compared to thermal pasteurization. Thermal pasteurization, involving heat treatments like HTST (High-Temperature Short Time), can cause significant losses of vitamin C, B-complex vitamins, and denaturation of whey proteins, reducing milk's nutritional value. Research indicates cold pasteurization maintains better sensory attributes and bioavailability of essential nutrients, making it a promising alternative for milk safety without compromising nutritional integrity.

Impact on Milk Flavor and Sensory Properties

Cold pasteurization methods such as high-pressure processing (HPP) preserve the natural flavor and sensory attributes of milk by minimizing heat-induced changes, unlike thermal pasteurization which can cause cooked or caramelized off-flavors due to Maillard reactions and protein denaturation. Sensory evaluation studies consistently show that cold pasteurized milk retains fresher taste profiles, improved mouthfeel, and better color stability compared to thermally treated milk. The preservation of volatile compounds and maintenance of native protein structures during cold pasteurization enhance consumer acceptance and perceived freshness.

Shelf-life Extension: Comparative Analysis

Cold pasteurization methods, such as high-pressure processing (HPP) and ultraviolet (UV) treatment, significantly extend milk's shelf life by inactivating spoilage microorganisms without heat-induced nutrient degradation. In contrast, thermal pasteurization relies on heat to eliminate pathogens but often results in shorter shelf life due to heat-sensitive nutrient loss and slight changes in flavor and texture. Comparative studies indicate that cold pasteurization can increase shelf life by up to 30% compared to conventional thermal pasteurization, making it a preferred choice for maintaining milk quality and safety over extended storage periods.

Energy Consumption and Environmental Impact

Cold pasteurization methods, such as high-pressure processing (HPP) and ultraviolet (UV) treatment, significantly reduce energy consumption compared to traditional thermal pasteurization by operating at ambient or low temperatures, thereby minimizing greenhouse gas emissions. Thermal pasteurization requires substantial heat energy input, leading to higher carbon footprints due to fossil fuel combustion and associated environmental pollution. Implementing cold pasteurization technologies in milk safety protocols promotes energy efficiency and environmental sustainability without compromising microbial inactivation.

Regulatory Standards and Industry Adoption

Cold pasteurization techniques like high-pressure processing (HPP) are increasingly recognized under FDA and EU regulatory standards for ensuring milk safety without compromising nutritional value, prompting gradual industry adoption. Thermal pasteurization remains the dominant method, with strict compliance to FDA's 161degF (72degC) for 15 seconds standard for effective pathogen reduction. Regulatory frameworks emphasize validation of microbial kill steps, influencing dairy processors to balance traditional thermal methods with innovative cold technologies for improved shelf life and safety.

Future Perspectives in Milk Pasteurization Technologies

Emerging technologies like high-pressure processing (HPP) and pulsed electric fields (PEF) are revolutionizing milk safety by offering cold pasteurization methods that preserve nutritional and sensory qualities while effectively inactivating pathogens. Thermal pasteurization remains a widely used approach, but advances in non-thermal techniques promise enhanced energy efficiency and retention of bioactive compounds. Future milk pasteurization technologies will likely integrate smart sensors and real-time monitoring systems to ensure optimal microbial safety with minimal quality degradation.

Related Important Terms

Non-thermal pasteurization

Non-thermal pasteurization methods such as high-pressure processing (HPP) and pulsed electric fields (PEF) effectively inactivate pathogens in milk while preserving sensory qualities and nutritional value better than thermal pasteurization. These cold pasteurization techniques reduce heat-induced nutrient degradation and maintain bioactive compounds, enhancing milk safety without compromising quality.

High Pressure Processing (HPP)

High Pressure Processing (HPP) effectively inactivates pathogens in milk without the nutrient degradation and flavor changes typical of thermal pasteurization, preserving quality and freshness. This cold pasteurization technique maintains bioactive proteins and vitamins while ensuring microbial safety, making it a superior alternative to traditional heat-based methods in milk preservation.

Pulsed Electric Fields (PEF)

Pulsed Electric Fields (PEF) technology offers an effective cold pasteurization method for milk by using short bursts of high voltage to inactivate pathogens while preserving sensory and nutritional qualities. Compared to thermal pasteurization, PEF reduces heat-induced changes, retains vitamins and enzymes, and extends shelf life without compromising milk safety.

Ultra-High Pressure (UHP)

Ultra-High Pressure (UHP) pasteurization uses intense pressure up to 600 MPa to inactivate pathogens in milk without heat, preserving nutritional and sensory qualities better than conventional thermal pasteurization. UHP offers extended shelf life and enhanced safety by disrupting microbial cell membranes while minimizing nutrient degradation commonly caused by high temperatures.

Microbial inactivation efficacy

Cold pasteurization techniques, including high-pressure processing (HPP) and ultraviolet (UV) treatment, achieve microbial inactivation by disrupting cell membranes and genetic material without heat, preserving milk's nutritional and sensory qualities. Thermal pasteurization uses controlled heat to denature proteins and enzymes, effectively reducing pathogens such as Listeria monocytogenes and Escherichia coli, but may alter milk's flavor and nutrient profile.

Nutrient retention differential

Cold pasteurization techniques such as high-pressure processing (HPP) preserve higher levels of heat-sensitive vitamins, enzymes, and bioactive compounds in milk compared to thermal pasteurization methods that often degrade these nutrients due to prolonged heat exposure. Studies show cold pasteurization retains 90-95% of vitamin C and B-complex vitamins, whereas traditional thermal pasteurization can reduce these by up to 40%, significantly impacting milk's nutritional profile.

Cold plasma technology

Cold plasma technology offers a non-thermal pasteurization method that preserves milk's nutritional quality while effectively inactivating pathogenic microorganisms. This cold pasteurization approach ensures safer milk products without the heat-induced degradation common in thermal pasteurization.

Bactofugation efficiency

Cold pasteurization through bactofugation efficiently removes bacteria and spores from milk by centrifugal separation without heat damage, preserving nutritional and sensory qualities better than thermal pasteurization. Thermal pasteurization relies on heat to inactivate pathogens but can reduce milk's nutritional value and alter flavor, making bactofugation a preferred method for maintaining milk quality while ensuring safety.

Shelf-life extension index

Cold pasteurization techniques such as high-pressure processing (HPP) significantly extend the shelf-life of milk by inactivating spoilage microorganisms while preserving nutritional and sensory qualities compared to thermal pasteurization, which often shortens shelf-life due to protein denaturation and nutrient loss. The shelf-life extension index for cold-pasteurized milk can be up to 2-3 times higher than that of thermally pasteurized milk, making it a superior method for maintaining milk safety and quality over prolonged storage.

Thermal load reduction

Cold pasteurization methods such as high-pressure processing and ultraviolet treatment achieve milk safety with significantly lower thermal loads compared to traditional thermal pasteurization, preserving heat-sensitive nutrients and sensory qualities. Reducing thermal load prevents protein denaturation and lipid oxidation, enhancing shelf life and maintaining the nutritional profile of milk.

Cold pasteurization vs thermal pasteurization for milk safety Infographic

agridif.com

agridif.com