Modified Atmosphere Packaging (MAP) and Vacuum Packaging are two effective methods for extending the shelf life of fresh produce by altering the atmospheric conditions surrounding the product. MAP controls the balance of gases such as oxygen, carbon dioxide, and nitrogen to slow respiration and delay spoilage, optimizing freshness and retaining nutritional quality. Vacuum Packaging removes air entirely, reducing oxidation and microbial growth, but may cause physical damage to delicate produce due to pressure changes.

Table of Comparison

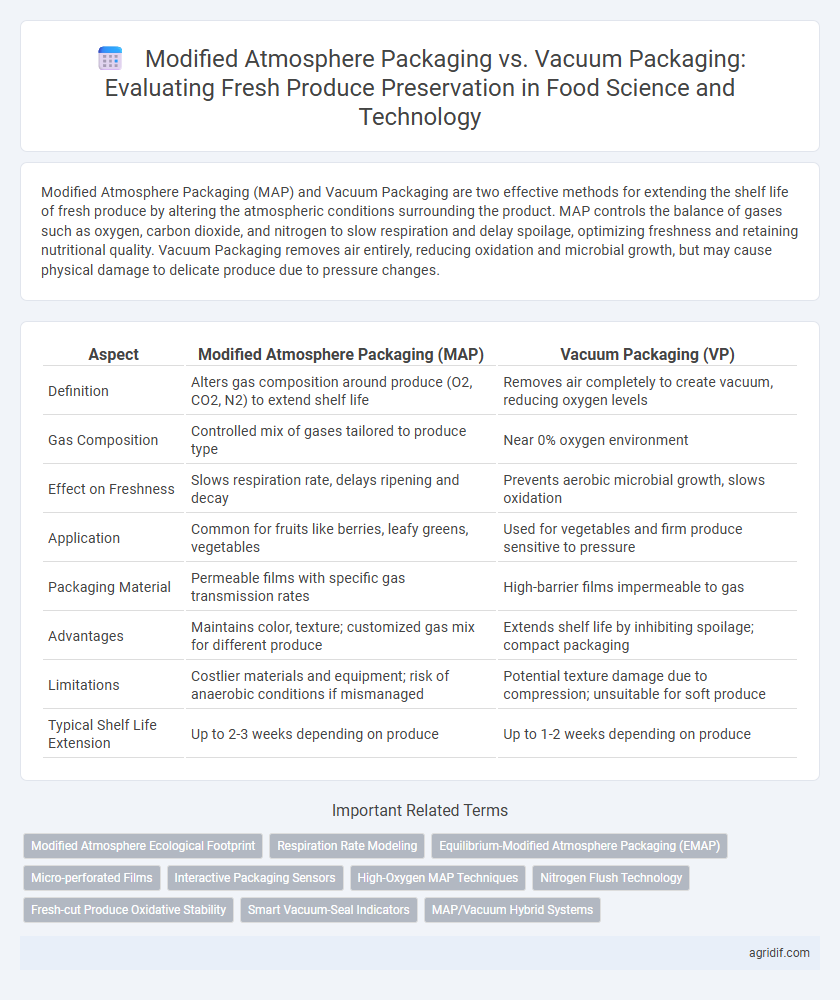

| Aspect | Modified Atmosphere Packaging (MAP) | Vacuum Packaging (VP) |

|---|---|---|

| Definition | Alters gas composition around produce (O2, CO2, N2) to extend shelf life | Removes air completely to create vacuum, reducing oxygen levels |

| Gas Composition | Controlled mix of gases tailored to produce type | Near 0% oxygen environment |

| Effect on Freshness | Slows respiration rate, delays ripening and decay | Prevents aerobic microbial growth, slows oxidation |

| Application | Common for fruits like berries, leafy greens, vegetables | Used for vegetables and firm produce sensitive to pressure |

| Packaging Material | Permeable films with specific gas transmission rates | High-barrier films impermeable to gas |

| Advantages | Maintains color, texture; customized gas mix for different produce | Extends shelf life by inhibiting spoilage; compact packaging |

| Limitations | Costlier materials and equipment; risk of anaerobic conditions if mismanaged | Potential texture damage due to compression; unsuitable for soft produce |

| Typical Shelf Life Extension | Up to 2-3 weeks depending on produce | Up to 1-2 weeks depending on produce |

Introduction to Fresh Produce Packaging Technologies

Modified Atmosphere Packaging (MAP) and Vacuum Packaging (VP) are critical technologies in fresh produce preservation, designed to extend shelf life and maintain quality by controlling the packaging atmosphere. MAP modifies the gas composition around the produce, typically reducing oxygen and increasing carbon dioxide levels to slow respiration and microbial growth, which is highly effective for leafy greens and berries. Vacuum Packaging removes air entirely, creating an anaerobic environment that inhibits aerobic spoilage organisms but may accelerate anaerobic fermentation in some fruits and vegetables.

Principles of Modified Atmosphere Packaging (MAP)

Modified Atmosphere Packaging (MAP) for fresh produce involves altering the gas composition within the packaging to slow down respiration rates and delay spoilage, typically by reducing oxygen and increasing carbon dioxide levels. This controlled environment minimizes microbial growth and oxidation, preserving texture, flavor, and nutritional quality. MAP differs from vacuum packaging by maintaining a specific gas balance rather than removing air entirely, allowing for better management of product freshness and shelf life.

Understanding Vacuum Packaging in Food Preservation

Vacuum packaging involves removing air from the package before sealing, significantly reducing oxygen levels that promote microbial growth and enzymatic spoilage in fresh produce. This method extends shelf life by maintaining product freshness, texture, and nutritional quality, while minimizing oxidative damage and moisture loss. Compared to modified atmosphere packaging, vacuum packaging offers a simpler, cost-effective solution for preserving sensitive fruits and vegetables with a lean, oxygen-free environment.

Comparative Benefits: MAP vs Vacuum Packaging

Modified Atmosphere Packaging (MAP) extends the shelf life of fresh produce by altering gas composition, reducing oxygen levels, and increasing carbon dioxide to slow respiration and delay spoilage. Vacuum Packaging removes air completely, minimizing oxidation and microbial growth, which enhances freshness but may sometimes cause anaerobic conditions unsuitable for certain produce. MAP offers more tailored gas environments for specific fruits and vegetables, enabling better preservation of texture and flavor compared to the uniform air removal in vacuum packaging.

Impact on Freshness and Shelf Life of Produce

Modified Atmosphere Packaging (MAP) enhances the shelf life of fresh produce by altering the gas composition inside the packaging, typically reducing oxygen and increasing carbon dioxide levels to slow respiration and microbial growth. Vacuum Packaging removes air completely, effectively reducing oxidation and moisture loss, but may cause anaerobic conditions that can affect the texture and flavor of certain fresh produce. Both techniques significantly extend freshness and shelf life compared to conventional packaging, with MAP often preferred for maintaining color and firmness in fruits and vegetables.

Effects on Nutritional Quality and Sensory Attributes

Modified Atmosphere Packaging (MAP) extends shelf life and preserves the nutritional quality of fresh produce by controlling oxygen and carbon dioxide levels, which slows down respiration and reduces nutrient degradation. Vacuum Packaging (VP) effectively limits oxygen exposure, reducing enzymatic browning and maintaining sensory attributes such as texture and flavor, but may cause anaerobic conditions that affect certain nutrients. Both MAP and VP optimize freshness retention, yet MAP offers superior control over gas composition, enhancing sensory quality and preserving vitamins like vitamin C more effectively in fresh fruits and vegetables.

Applications for Different Types of Fruits and Vegetables

Modified Atmosphere Packaging (MAP) enhances shelf life by adjusting oxygen, carbon dioxide, and nitrogen levels, making it ideal for fruits like berries and leafy greens that require controlled respiration rates. Vacuum Packaging (VP) removes air to inhibit microbial growth, better suited for firm produce such as mushrooms and root vegetables, where preventing oxidation is crucial. Selecting MAP or VP depends on produce respiration characteristics, moisture content, and sensitivity to anaerobic conditions for optimal freshness retention.

Packaging Materials and Sustainability Considerations

Modified Atmosphere Packaging (MAP) for fresh produce utilizes specialized films with tailored gas permeability to regulate oxygen and carbon dioxide levels, enhancing shelf life while requiring multilayer polymer materials that can challenge recyclability. Vacuum Packaging employs flexible barrier films that remove air to inhibit microbial growth, often using simpler single-polymer materials that offer improved recyclability but may not control internal gas composition as precisely as MAP. Sustainability considerations emphasize the development of biodegradable or recyclable packaging materials for both MAP and Vacuum Packaging to reduce environmental impact while maintaining functional performance for fresh produce preservation.

Economic and Operational Implications for Producers

Modified Atmosphere Packaging (MAP) enhances shelf life and reduces food waste by controlling oxygen and carbon dioxide levels around fresh produce, leading to potentially higher market value but increased packaging costs and need for specialized equipment. Vacuum Packaging (VP) offers cost-effective sealing with extended freshness by removing air, lowering oxidation rates, and simplifying logistics, yet may cause product deformation and limits gas exchange benefits. Producers must balance MAP's higher operational complexity and expense against VP's affordability and simplicity when optimizing supply chain efficiency and product quality retention.

Future Trends in Fresh Produce Packaging Innovations

Modified Atmosphere Packaging (MAP) and Vacuum Packaging (VP) are evolving with advancements in sustainable materials and smart sensor integration to extend the shelf life of fresh produce. Emerging trends emphasize biodegradable films combined with real-time gas composition monitoring to optimize freshness and reduce food waste. Integration of nanotechnology and IoT platforms is expected to revolutionize fresh produce packaging by enhancing quality control and supply chain transparency.

Related Important Terms

Modified Atmosphere Ecological Footprint

Modified Atmosphere Packaging (MAP) for fresh produce reduces oxygen levels and increases carbon dioxide to slow respiration and prolong shelf life, significantly lowering food waste compared to traditional packaging. Despite higher initial material use in MAP films, its overall ecological footprint tends to be lower than Vacuum Packaging due to reduced spoilage and extended freshness, minimizing resource consumption and carbon emissions throughout the supply chain.

Respiration Rate Modeling

Modified Atmosphere Packaging (MAP) controls oxygen, carbon dioxide, and nitrogen levels to slow the respiration rate of fresh produce, effectively extending shelf life by reducing metabolic activity and moisture loss. Vacuum Packaging (VP) removes air to create a low-oxygen environment that inhibits aerobic respiration but may increase anaerobic respiration, influencing the respiration rate model differently based on produce type and storage conditions.

Equilibrium-Modified Atmosphere Packaging (EMAP)

Equilibrium-Modified Atmosphere Packaging (EMAP) regulates gas composition inside packaging by balancing produce respiration rates with gas permeation through the film, extending shelf life while maintaining freshness in fruits and vegetables. EMAP offers advantages over Vacuum Packaging by reducing anaerobic conditions and minimizing quality loss due to off-flavors and texture degradation.

Micro-perforated Films

Micro-perforated films in Modified Atmosphere Packaging (MAP) enhance gas exchange and moisture regulation, extending the shelf life of fresh produce by maintaining optimal oxygen and carbon dioxide levels. Compared to Vacuum Packaging, MAP with micro-perforated films better preserves texture and reduces anaerobic respiration, minimizing spoilage and nutrient loss.

Interactive Packaging Sensors

Interactive packaging sensors in Modified Atmosphere Packaging (MAP) provide real-time monitoring of oxygen, carbon dioxide, and ethylene levels, optimizing the freshness and shelf life of fresh produce more effectively than the static environment maintained by Vacuum Packaging. These advanced sensors enable dynamic adjustments to gas compositions, reducing spoilage and microbial growth while enhancing quality control throughout the supply chain.

High-Oxygen MAP Techniques

High-oxygen Modified Atmosphere Packaging (MAP) enhances the shelf life and visual quality of fresh produce by maintaining oxygen levels typically between 60-80%, delaying senescence and microbial growth more effectively than vacuum packaging. Unlike vacuum packaging, which removes oxygen completely and can cause anaerobic spoilage and off-flavors, high-oxygen MAP supports aerobic respiration, preserving texture and color in oxygen-sensitive fruits and vegetables.

Nitrogen Flush Technology

Modified Atmosphere Packaging (MAP) utilizes Nitrogen Flush Technology to replace oxygen with nitrogen, effectively slowing respiration and microbial growth in fresh produce, thereby extending shelf life and maintaining quality. In contrast, Vacuum Packaging removes air entirely but can cause tissue compression and anaerobic conditions, making Nitrogen Flush MAP a superior choice for preserving texture and freshness in delicate fruits and vegetables.

Fresh-cut Produce Oxidative Stability

Modified Atmosphere Packaging (MAP) enhances fresh-cut produce oxidative stability by adjusting gas compositions to reduce oxygen levels and increase carbon dioxide, thereby slowing enzymatic browning and lipid oxidation. In contrast, Vacuum Packaging (VP) removes air completely, limiting oxygen exposure but may induce anaerobic respiration and off-flavors, impacting product quality differently than MAP.

Smart Vacuum-Seal Indicators

Smart Vacuum-Seal Indicators enhance the effectiveness of vacuum packaging by providing real-time monitoring of oxygen levels and seal integrity, ensuring prolonged freshness and reduced spoilage in fresh produce. Compared to Modified Atmosphere Packaging, these indicators offer a precise, user-friendly solution for maintaining optimal storage conditions and extending shelf life without the need for complex gas mixtures.

MAP/Vacuum Hybrid Systems

Modified Atmosphere Packaging (MAP) and Vacuum Packaging each extend the shelf life of fresh produce by controlling oxygen and carbon dioxide levels; however, MAP/Vacuum hybrid systems combine the benefits of both techniques, optimizing gas compositions while reducing oxidation and microbial growth. This hybrid approach enhances freshness retention, delays ripening, and maintains texture and nutritional quality more effectively than using MAP or vacuum packaging alone.

Modified Atmosphere Packaging vs Vacuum Packaging for Fresh Produce Infographic

agridif.com

agridif.com