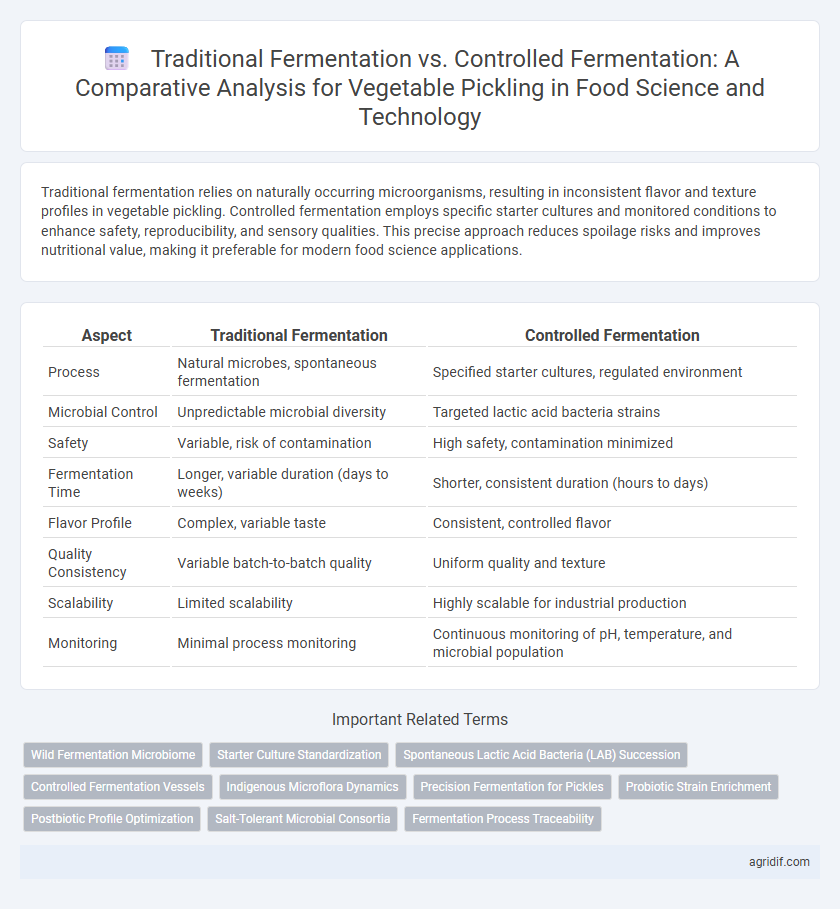

Traditional fermentation relies on naturally occurring microorganisms, resulting in inconsistent flavor and texture profiles in vegetable pickling. Controlled fermentation employs specific starter cultures and monitored conditions to enhance safety, reproducibility, and sensory qualities. This precise approach reduces spoilage risks and improves nutritional value, making it preferable for modern food science applications.

Table of Comparison

| Aspect | Traditional Fermentation | Controlled Fermentation |

|---|---|---|

| Process | Natural microbes, spontaneous fermentation | Specified starter cultures, regulated environment |

| Microbial Control | Unpredictable microbial diversity | Targeted lactic acid bacteria strains |

| Safety | Variable, risk of contamination | High safety, contamination minimized |

| Fermentation Time | Longer, variable duration (days to weeks) | Shorter, consistent duration (hours to days) |

| Flavor Profile | Complex, variable taste | Consistent, controlled flavor |

| Quality Consistency | Variable batch-to-batch quality | Uniform quality and texture |

| Scalability | Limited scalability | Highly scalable for industrial production |

| Monitoring | Minimal process monitoring | Continuous monitoring of pH, temperature, and microbial population |

Introduction to Vegetable Pickling Processes

Vegetable pickling processes involve biochemical transformations driven by microbial activity, where traditional fermentation relies on naturally occurring microorganisms and environmental conditions, resulting in diverse flavors and textures. Controlled fermentation employs specific starter cultures and regulated parameters such as temperature, pH, and salt concentration to achieve consistent product quality and enhanced safety. Understanding these methods is crucial for optimizing fermentation efficiency and maintaining nutritional value in fermented vegetables.

Overview of Traditional Fermentation Methods

Traditional fermentation methods for vegetable pickling rely on natural microbial populations present on raw materials and in the environment, promoting spontaneous lactic acid fermentation without added starter cultures. These methods typically use open-air fermentation in containers such as earthenware jars, relying on ambient temperature and conditions to drive microbial activity, which can lead to variability in flavor and safety. The process duration ranges from several days to weeks, allowing diverse indigenous bacteria, primarily Lactobacillus species, to dominate and produce characteristic tangy flavors and enhanced preservation.

Advances in Controlled Fermentation Techniques

Advances in controlled fermentation techniques for vegetable pickling have significantly improved product consistency, safety, and flavor profiles by utilizing precise microbial cultures and environmental monitoring. Modern approaches employ starter cultures such as Lactobacillus plantarum to ensure predictable lactic acid production, reducing spoilage and enhancing shelf life. Integration of sensors and automated systems enables real-time control of temperature, pH, and oxygen levels, optimizing fermentation kinetics and improving nutritional quality.

Microbial Diversity in Traditional Fermentation

Traditional fermentation for vegetable pickling harnesses a broad spectrum of naturally occurring microbial communities, including lactic acid bacteria, yeasts, and molds, which contribute to diverse and complex flavor profiles. This microbial diversity enhances product safety through competitive exclusion of pathogens while enriching probiotic content that can benefit gut health. Unlike controlled fermentation, which utilizes selected starter cultures, traditional methods rely on environmental microbes, resulting in variable but unique ferment characteristics essential for regional culinary heritage.

Precision Microbial Management in Controlled Systems

Precision microbial management in controlled fermentation systems ensures consistent product quality by regulating specific microbial strains and environmental parameters such as temperature, pH, and oxygen levels. This targeted approach reduces the risk of spoilage and undesirable microbial growth commonly observed in traditional fermentation methods. Advanced monitoring technologies and starter cultures optimize the biochemical pathways, enhancing flavor development and safety in vegetable pickling processes.

Flavor Development: Traditional vs Controlled Pickling

Traditional fermentation in vegetable pickling relies on naturally occurring microorganisms, producing complex, spontaneous flavor profiles with variable acidity and texture. Controlled fermentation uses specific starter cultures and regulated environmental conditions, resulting in consistent flavor development, optimized sourness, and improved safety. Flavor complexity in traditional pickles often surpasses controlled methods due to diverse microbial interactions, while controlled fermentation offers predictability and reduced spoilage risk.

Safety and Consistency Concerns in Pickling Methods

Traditional fermentation in vegetable pickling relies on natural microbial populations, resulting in variable safety and product consistency due to uncontrolled microbial growth and environmental factors. Controlled fermentation employs selected starter cultures and regulated conditions, significantly reducing the risk of pathogenic contamination and ensuring uniform flavor profiles and texture. Implementing controlled fermentation enhances food safety standards and meets industrial demands for consistent quality in pickled vegetables.

Nutritional Impact of Fermentation Techniques

Traditional fermentation of vegetables relies on naturally occurring microbes, enhancing probiotic content and increasing bioavailability of vitamins such as B-complex and C while producing beneficial organic acids. Controlled fermentation employs specific starter cultures and optimized environmental conditions, ensuring consistent nutrient retention and higher levels of functional compounds like antioxidants and peptides. Both methods improve mineral absorption and promote gut health, but controlled fermentation offers greater precision in maximizing nutrient preservation and enhancing food safety.

Scalability and Commercial Viability

Traditional fermentation relies on natural microbial populations, resulting in variable product quality and limited scalability for vegetable pickling. Controlled fermentation employs specific starter cultures and standardized conditions to ensure consistent flavor, texture, and safety, enhancing commercial viability. Industrial pickling operations benefit from controlled processes that reduce batch inconsistencies and extend shelf life, supporting large-scale production and market distribution.

Future Trends in Vegetable Fermentation Technology

Future trends in vegetable fermentation technology emphasize the integration of controlled fermentation processes using precision microbiome engineering to enhance flavor profiles, ensure safety, and improve shelf life. Advances in sensor technology and artificial intelligence enable real-time monitoring and optimization of fermentation parameters, reducing batch variability and increasing production efficiency. Emerging research on probiotic enrichment and bioactive compound amplification aims to create functional fermented vegetables with enhanced health benefits and tailored nutritional content.

Related Important Terms

Wild Fermentation Microbiome

Traditional fermentation relies on a diverse wild fermentation microbiome, naturally present on vegetable surfaces and in the environment, which promotes the growth of beneficial lactic acid bacteria and enhances flavor complexity through spontaneous microbial interactions. Controlled fermentation, by contrast, utilizes selected starter cultures to standardize microbial populations and fermentation outcomes, potentially limiting the microbial diversity and unique sensory profiles associated with wild fermentation microbiota.

Starter Culture Standardization

Starter culture standardization in controlled fermentation enhances the consistency, safety, and flavor profile of pickled vegetables by using specific microbial strains, unlike traditional fermentation which relies on spontaneous microbial activity leading to variable results. This standardized approach reduces spoilage risks and allows precise control over fermentation parameters, improving product quality and shelf life in vegetable pickling processes.

Spontaneous Lactic Acid Bacteria (LAB) Succession

Traditional fermentation relies on spontaneous lactic acid bacteria (LAB) succession driven by indigenous microbial populations, resulting in variable fermentation outcomes and flavor profiles. Controlled fermentation utilizes selected LAB starter cultures to standardize the succession process, enhancing safety, consistency, and desired sensory attributes in vegetable pickling.

Controlled Fermentation Vessels

Controlled fermentation vessels for vegetable pickling enhance microbial consistency and flavor development by maintaining precise temperature, pH, and oxygen levels, reducing the risk of spoilage compared to traditional open-air methods. Stainless steel and food-grade plastic fermenters equipped with airlocks and sensors facilitate reproducible fermentation cycles, improving product safety, shelf life, and overall quality in commercial food production.

Indigenous Microflora Dynamics

Traditional fermentation of vegetables relies on indigenous microflora that naturally present on raw materials, promoting diverse bacterial growth and complex flavor development. Controlled fermentation, however, uses selected starter cultures to standardize microflora dynamics, ensuring consistent product safety, quality, and accelerated fermentation time.

Precision Fermentation for Pickles

Precision fermentation for pickles enhances consistency, flavor, and safety by monitoring specific microbial strains and environmental parameters, unlike traditional fermentation which relies on spontaneous microbial activity. Controlled fermentation reduces spoilage risks and accelerates production times, ensuring standardized quality and improved shelf life in vegetable pickling.

Probiotic Strain Enrichment

Traditional fermentation of vegetable pickling relies on naturally occurring microbial communities that can vary widely in probiotic strain composition, often resulting in inconsistent enrichment of beneficial bacteria such as Lactobacillus plantarum and Leuconostoc mesenteroides. Controlled fermentation utilizes selected probiotic starter cultures to ensure targeted enrichment of specific health-promoting strains, enhancing the nutritional and functional qualities of pickled vegetables while maintaining safety and reproducibility.

Postbiotic Profile Optimization

Traditional fermentation of vegetable pickling relies on spontaneous microbial activity, resulting in variable postbiotic profiles with inconsistent health benefits. Controlled fermentation employs selected starter cultures and monitored conditions to optimize postbiotic compounds such as organic acids, bacteriocins, and exopolysaccharides, enhancing functional properties and shelf-life.

Salt-Tolerant Microbial Consortia

Salt-tolerant microbial consortia play a crucial role in both traditional and controlled fermentation methods for vegetable pickling, enhancing flavor development and preservation by selectively promoting lactic acid bacteria such as Lactobacillus plantarum. Controlled fermentation utilizes precise salt concentrations and inoculated starter cultures to consistently harness these halotolerant microbes, improving product safety and reducing spoilage compared to the variable microbial communities in traditional spontaneous fermentations.

Fermentation Process Traceability

Traditional fermentation relies on spontaneous microbial activity, resulting in less predictable fermentation outcomes and limited traceability of microbial strains involved, whereas controlled fermentation employs selected starter cultures and monitored environmental parameters, enhancing process traceability and ensuring consistent quality in vegetable pickling. Traceable fermentation workflows facilitate optimization of flavor profiles, safety standards, and shelf life by allowing precise tracking of microbial dynamics and biochemical transformations throughout the pickling process.

Traditional Fermentation vs Controlled Fermentation for Vegetable Pickling Infographic

agridif.com

agridif.com