Crossflow microfiltration offers continuous filtration by flowing juice tangentially across the membrane surface, reducing particle buildup and extending membrane life during juice clarification. Dead-end filtration forces juice directly through the membrane, causing rapid clogging and frequent cleaning, which limits processing efficiency. Choosing crossflow microfiltration enhances clarity, yield, and operational stability in juice processing compared to dead-end filtration.

Table of Comparison

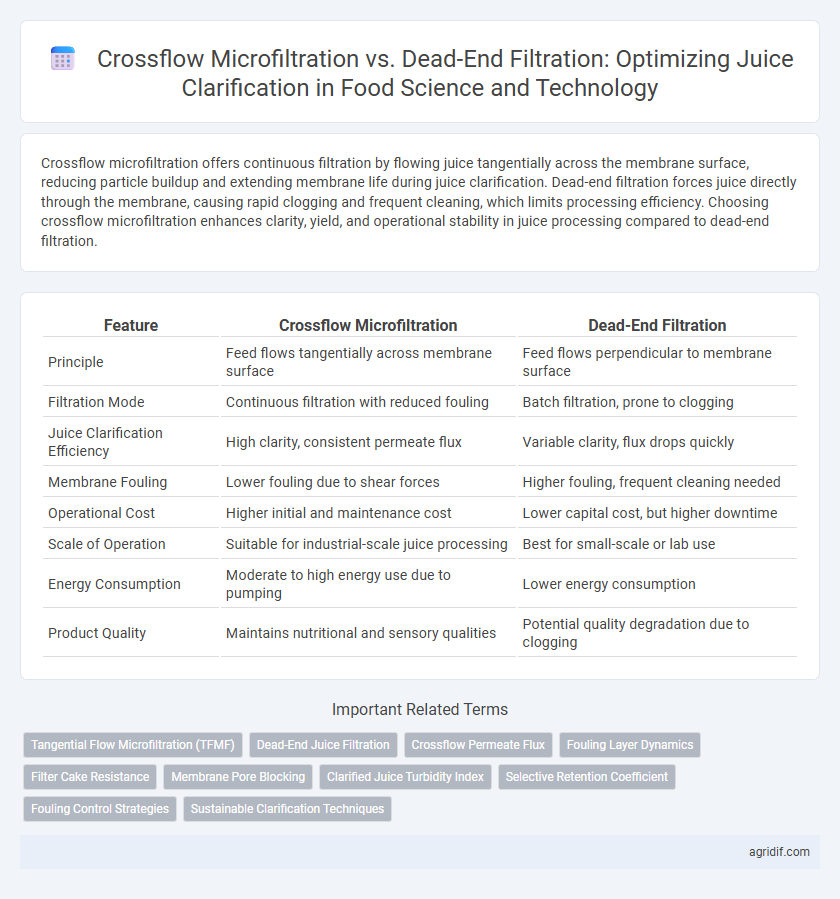

| Feature | Crossflow Microfiltration | Dead-End Filtration |

|---|---|---|

| Principle | Feed flows tangentially across membrane surface | Feed flows perpendicular to membrane surface |

| Filtration Mode | Continuous filtration with reduced fouling | Batch filtration, prone to clogging |

| Juice Clarification Efficiency | High clarity, consistent permeate flux | Variable clarity, flux drops quickly |

| Membrane Fouling | Lower fouling due to shear forces | Higher fouling, frequent cleaning needed |

| Operational Cost | Higher initial and maintenance cost | Lower capital cost, but higher downtime |

| Scale of Operation | Suitable for industrial-scale juice processing | Best for small-scale or lab use |

| Energy Consumption | Moderate to high energy use due to pumping | Lower energy consumption |

| Product Quality | Maintains nutritional and sensory qualities | Potential quality degradation due to clogging |

Introduction to Juice Clarification Techniques

Crossflow microfiltration offers superior juice clarification by continuously removing suspended solids while minimizing membrane fouling, compared to dead-end filtration where particles accumulate on the membrane surface, leading to rapid clogging. Juice clarification techniques aim to enhance clarity, stability, and shelf life by efficiently separating suspended solids, pectin, and yeast cells without compromising flavor and nutritional quality. Crossflow microfiltration operates under tangential flow, maintaining consistent filtration rates and extending membrane lifespan in juice processing industries.

Principles of Crossflow Microfiltration

Crossflow microfiltration operates by continuously flowing juice tangentially across the membrane surface, minimizing fouling and allowing efficient separation of suspended solids and microorganisms. This method maintains a stable permeate flux by sweeping away retained particles, enhancing membrane longevity and process consistency. Unlike dead-end filtration, which directs flow perpendicular to the membrane and causes rapid clogging, crossflow microfiltration ensures higher clarity and yield in juice clarification.

Fundamentals of Dead-End Filtration

Dead-end filtration operates by forcing juice through a membrane where particles accumulate on the surface, forming a filter cake that increases resistance and reduces permeate flux over time. This method is simpler and less costly but often requires frequent cleaning or replacement due to rapid fouling. In juice clarification, dead-end filtration is effective for removing suspended solids but is limited by lower throughput and shorter operational cycles compared to crossflow microfiltration.

Filtration Efficiency: Crossflow vs Dead-End

Crossflow microfiltration demonstrates higher filtration efficiency compared to dead-end filtration for juice clarification due to its continuous sweeping action that reduces membrane fouling and maintains flux rates. Dead-end filtration often suffers from rapid clogging as particulates accumulate directly on the membrane surface, leading to frequent cleaning and lower throughput. Crossflow systems enable longer operation times and improved retention of flavor and nutritional compounds, making them more suitable for high-quality juice processing.

Impact on Juice Quality and Nutrient Retention

Crossflow microfiltration preserves juice quality by minimizing membrane fouling, ensuring consistent nutrient retention and clarity compared to dead-end filtration, which often leads to rapid clogging and quality degradation. The continuous flow in crossflow microfiltration reduces shear stress on bioactive compounds like vitamins and polyphenols, maintaining antioxidant activity and flavor profiles. Dead-end filtration, while simpler, tends to cause more nutrient loss and turbidity due to particle accumulation on the membrane surface.

Membrane Fouling and Cleaning Strategies

Crossflow microfiltration reduces membrane fouling by continuously sweeping particles away from the membrane surface, maintaining higher permeate flux during juice clarification compared to dead-end filtration, which accumulates particulates directly on the membrane leading to rapid clogging. Effective cleaning strategies for crossflow systems include periodic backflushing and chemical cleaning with alkaline and enzymatic agents to remove organic deposits, while dead-end filters require more frequent replacement or intensive chemical cleaning due to higher fouling rates. Optimizing operational parameters such as crossflow velocity and transmembrane pressure further mitigates fouling and enhances membrane longevity in juice processing applications.

Operational Costs and Energy Consumption

Crossflow microfiltration generally incurs higher initial capital costs due to complex membrane systems but offers lower operational costs and reduced energy consumption by minimizing membrane fouling and allowing continuous processing. Dead-end filtration, while simpler and less expensive upfront, suffers from higher energy use and frequent maintenance as filter clogging demands repeated cleaning and replacement. Evaluating juice clarification processes favors crossflow microfiltration for long-term cost-efficiency and sustainable energy use in industrial applications.

Scalability and Industrial Applications

Crossflow microfiltration offers superior scalability and efficiency for industrial juice clarification by continuously removing suspended solids without clogging, enabling longer operational runs and higher throughput compared to dead-end filtration. Dead-end filtration is typically limited by rapid filter cake accumulation, requiring frequent cleaning and downtime that hinder large-scale production. Industrial applications favor crossflow systems for maintaining consistent juice quality and process stability during extended production cycles.

Environmental Impact and Sustainability

Crossflow microfiltration for juice clarification offers enhanced environmental sustainability by reducing membrane fouling and extending filter lifespan, which decreases waste generation and energy consumption compared to dead-end filtration. Dead-end filtration typically produces higher levels of membrane clogging, requiring more frequent cleaning and replacement, leading to increased chemical use and water waste. The continuous operation and lower resource demands of crossflow systems contribute to a smaller ecological footprint in juice processing applications.

Future Trends in Juice Filtration Technologies

Crossflow microfiltration offers higher efficiency and longer membrane lifespan compared to dead-end filtration due to continuous removal of solids, reducing fouling in juice clarification. Emerging trends include integration of membrane filtration with enzymatic treatment and advanced nanomaterials to enhance clarity and nutrient retention. Future juice filtration technologies are expected to focus on hybrid systems combining microfiltration with ultrafiltration or reverse osmosis for improved quality and sustainability.

Related Important Terms

Tangential Flow Microfiltration (TFMF)

Tangential Flow Microfiltration (TFMF) enhances juice clarification by continuously sweeping the membrane surface, reducing fouling compared to dead-end filtration where particles accumulate directly on the membrane. This crossflow mechanism increases filtration efficiency, extends membrane lifespan, and improves juice clarity by effectively separating suspended solids and microorganisms while maintaining product quality.

Dead-End Juice Filtration

Dead-end juice filtration utilizes a single-pass approach where juice flows perpendicular to the membrane, leading to rapid fouling and reduced membrane lifespan due to particle accumulation. This method is cost-effective for low-solid juices but requires frequent cleaning and maintenance to maintain filtration efficiency compared to crossflow microfiltration.

Crossflow Permeate Flux

Crossflow microfiltration maintains higher permeate flux rates by continuously sweeping the membrane surface, reducing fouling and concentration polarization compared to dead-end filtration, which suffers from rapid flux decline as solids accumulate. In juice clarification, this results in more efficient separation, longer membrane lifespan, and improved clarity and quality of the permeate.

Fouling Layer Dynamics

Crossflow microfiltration minimizes fouling layer thickness by continuously sweeping the membrane surface, resulting in higher flux and prolonged membrane life during juice clarification. Dead-end filtration leads to rapid buildup of a fouling layer, causing flux decline and frequent membrane cleaning or replacement in juice processing.

Filter Cake Resistance

Crossflow microfiltration significantly reduces filter cake resistance by continuously sweeping away particulates, maintaining higher permeate flux and extending membrane life during juice clarification. In contrast, dead-end filtration causes rapid accumulation of solids on the membrane surface, leading to increased filter cake resistance and frequent membrane fouling.

Membrane Pore Blocking

Crossflow microfiltration minimizes membrane pore blocking by maintaining tangential flow that sweeps away particles, enhancing filtration efficiency and extending membrane lifespan during juice clarification. In contrast, dead-end filtration suffers rapid pore blocking as particles accumulate directly on the membrane surface, causing frequent fouling and reduced permeate flux.

Clarified Juice Turbidity Index

Crossflow microfiltration achieves a significantly lower clarified juice turbidity index of 0.2-0.5 NTU by continuously removing retentate, compared to dead-end filtration, which typically registers turbidity values above 1.0 NTU due to membrane fouling and cake layer formation. This consistent turbidity reduction in crossflow microfiltration enhances juice clarity and shelf-life by minimizing suspended solids and microbial load.

Selective Retention Coefficient

Crossflow microfiltration offers a higher selective retention coefficient compared to dead-end filtration, enabling more efficient separation of suspended solids and macromolecules from fruit juice while minimizing membrane fouling. This selective retention enhances juice clarity and quality by preferentially removing undesirable particles without significant loss of valuable nutrients and flavors.

Fouling Control Strategies

Crossflow microfiltration enhances fouling control in juice clarification by maintaining a tangential flow that continuously sweeps away particles, reducing membrane clogging and extending operational time. Dead-end filtration experiences rapid fouling due to direct particle accumulation on the membrane surface, requiring frequent cleaning and resulting in shorter filtration cycles.

Sustainable Clarification Techniques

Crossflow microfiltration offers sustainable juice clarification by continuously removing solids and reducing membrane fouling, thereby enhancing energy efficiency and membrane lifespan compared to dead-end filtration. Dead-end filtration, while simpler, often requires frequent membrane cleaning and replacement due to rapid clogging, leading to higher operational costs and environmental impact.

Crossflow microfiltration vs dead-end filtration for juice clarification Infographic

agridif.com

agridif.com