Enzymatic browning in fruit products occurs when polyphenol oxidase enzymes catalyze the oxidation of phenolic compounds, leading to undesirable color changes that affect visual quality and consumer acceptance. Non-enzymatic browning, such as the Maillard reaction or caramelization, involves chemical reactions between amino acids and reducing sugars, resulting in flavor and color development that can enhance product appeal if controlled properly. Understanding the differences between enzymatic and non-enzymatic browning is crucial for optimizing processing techniques to maintain fruit freshness and sensory attributes.

Table of Comparison

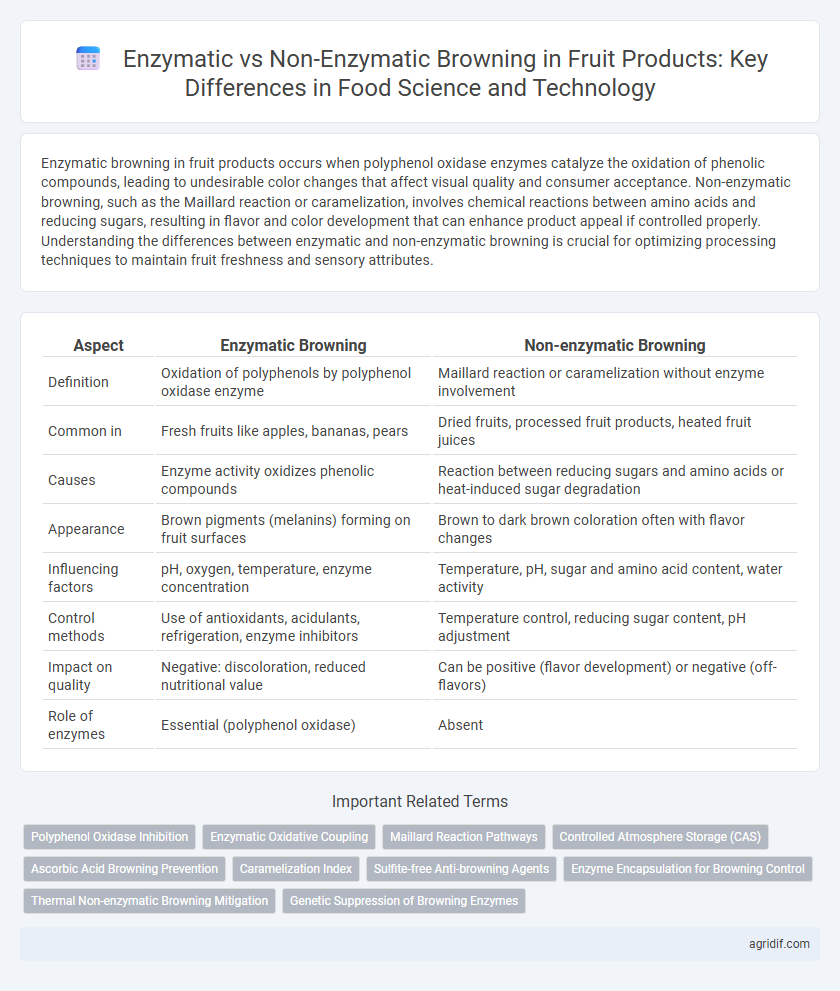

| Aspect | Enzymatic Browning | Non-enzymatic Browning |

|---|---|---|

| Definition | Oxidation of polyphenols by polyphenol oxidase enzyme | Maillard reaction or caramelization without enzyme involvement |

| Common in | Fresh fruits like apples, bananas, pears | Dried fruits, processed fruit products, heated fruit juices |

| Causes | Enzyme activity oxidizes phenolic compounds | Reaction between reducing sugars and amino acids or heat-induced sugar degradation |

| Appearance | Brown pigments (melanins) forming on fruit surfaces | Brown to dark brown coloration often with flavor changes |

| Influencing factors | pH, oxygen, temperature, enzyme concentration | Temperature, pH, sugar and amino acid content, water activity |

| Control methods | Use of antioxidants, acidulants, refrigeration, enzyme inhibitors | Temperature control, reducing sugar content, pH adjustment |

| Impact on quality | Negative: discoloration, reduced nutritional value | Can be positive (flavor development) or negative (off-flavors) |

| Role of enzymes | Essential (polyphenol oxidase) | Absent |

Understanding Browning: Enzymatic vs Non-enzymatic Processes

Enzymatic browning in fruit products occurs when polyphenol oxidase enzymes catalyze the oxidation of phenolic compounds to quinones, which polymerize into brown pigments, often affecting visual quality and flavor. Non-enzymatic browning, primarily involving the Maillard reaction and caramelization, progresses through chemical reactions between reducing sugars and amino acids under heat, contributing to flavor development and color changes independent of enzymatic activity. Controlling factors such as temperature, pH, and substrate availability is crucial to managing both browning types for optimal fruit product quality in food processing.

Key Enzymes Involved in Enzymatic Browning

Polyphenol oxidase (PPO) is the primary enzyme responsible for enzymatic browning in fruit products, catalyzing the oxidation of phenolic compounds into quinones, which polymerize into brown pigments. Peroxidase (POD) also contributes by using hydrogen peroxide to oxidize phenolics, enhancing browning under certain conditions. Understanding the activity levels of these enzymes is crucial for developing effective methods to control enzymatic browning and maintain fruit quality.

Chemical Pathways of Non-enzymatic Browning

Non-enzymatic browning in fruit products primarily involves the Maillard reaction and caramelization, where reducing sugars react with amino acids or undergo thermal decomposition under heat. The Maillard reaction begins with the formation of a Schiff base and Amadori rearrangement products, leading to complex melanoidin polymers responsible for brown pigments and flavor changes. Caramelization involves the pyrolysis of sugars, producing volatile compounds and brown pigments through dehydration, isomerization, and fragmentation pathways, significantly influencing the color and taste of processed fruits.

Factors Influencing Browning Reactions in Fruits

Enzymatic browning in fruit products is primarily influenced by factors such as pH, temperature, oxygen availability, and the presence of polyphenol oxidase enzymes, which catalyze the oxidation of phenolic compounds. Non-enzymatic browning, including Maillard reactions and caramelization, depends significantly on sugar concentration, temperature, and water activity, with higher temperatures accelerating these reactions. Controlling these parameters is essential for optimizing fruit product quality and shelf life through the management of browning reactions.

Impact of Browning on Nutritional Quality

Enzymatic browning in fruit products, primarily caused by polyphenol oxidase activity, leads to significant degradation of phenolic compounds and vitamin C, reducing antioxidant capacity and overall nutritional quality. Non-enzymatic browning, such as Maillard reactions, diminishes essential amino acids and may generate advanced glycation end-products, adversely affecting protein bioavailability and healthfulness. Both browning pathways result in color, flavor, and nutrient profile alterations that compromise the functional value and consumer acceptance of fruit-based foods.

Sensory and Aesthetic Changes in Fruit Products

Enzymatic browning in fruit products causes the formation of brown pigments due to polyphenol oxidase activity, leading to noticeable changes in color, texture, and flavor that often reduce consumer appeal. Non-enzymatic browning, including Maillard reactions and caramelization, results in complex flavor development and color changes that can enhance or detract from sensory quality depending on processing conditions. Both browning types significantly impact the sensory attributes and aesthetic quality of fruits, influencing marketability and consumer acceptance.

Technological Approaches to Control Browning

Enzymatic browning in fruit products occurs due to polyphenol oxidase catalyzing the oxidation of phenolic compounds, while non-enzymatic browning primarily involves Maillard reactions between reducing sugars and amino acids. Technological approaches to control enzymatic browning include applying sulfur dioxide, using ascorbic acid as an antioxidant, and employing modified atmosphere packaging to reduce oxygen exposure. Non-enzymatic browning is managed through temperature control, pH adjustment, and reducing sugar content during processing to minimize Maillard reaction rates.

Processing Methods to Minimize Browning

Enzymatic browning in fruit products is primarily controlled through the application of acidulants like citric acid, blanching, or use of antibrowning agents such as ascorbic acid to inhibit polyphenol oxidase activity. Non-enzymatic browning, including Maillard reaction and caramelization, is minimized by regulating processing parameters such as temperature, pH, and storage conditions to reduce sugar degradation and protein-sugar interactions. Controlled atmosphere storage and quick freezing techniques further preserve fruit quality by limiting substrate availability and reaction rates responsible for browning.

Case Studies: Browning in Common Fruit Products

Enzymatic browning in fruit products like apples and bananas occurs due to polyphenol oxidase catalyzing phenolic compounds upon exposure to oxygen, resulting in dark pigments that affect quality. Non-enzymatic browning, such as the Maillard reaction observed in dried fruits and fruit juices, involves sugar-amino acid interactions under heat, leading to color and flavor changes without enzyme involvement. Case studies highlight that controlling storage conditions and using antioxidants can effectively mitigate enzymatic browning, while optimizing heat treatment parameters minimizes non-enzymatic browning in fruit processing.

Future Trends in Browning Management for Fruit Technology

Future trends in browning management for fruit technology emphasize advanced enzymatic inhibitors derived from natural extracts and genetic modifications to reduce polyphenol oxidase activity. Innovations in non-enzymatic browning involve optimizing storage conditions and atmosphere control to limit Maillard reactions, enhancing fruit quality and shelf life. Integration of nanotechnology for targeted delivery of anti-browning agents and real-time monitoring sensors shows promise in precise browning control during processing and storage.

Related Important Terms

Polyphenol Oxidase Inhibition

Polyphenol oxidase (PPO) inhibition is critical in controlling enzymatic browning in fruit products, which occurs due to the oxidation of phenolic compounds by PPO, leading to undesirable discoloration and quality loss. Non-enzymatic browning, such as Maillard reactions and caramelization, involves sugar-protein interactions under heat and does not depend on PPO activity, requiring different control strategies focused on temperature and pH management.

Enzymatic Oxidative Coupling

Enzymatic oxidative coupling in fruit products involves polyphenol oxidase catalyzing the oxidation of phenolic compounds to quinones, leading to the formation of brown pigments that affect color and quality. This enzymatic browning differs from non-enzymatic browning, which includes Maillard reactions and caramelization, as it specifically requires oxygen and enzyme activity for pigment development.

Maillard Reaction Pathways

Enzymatic browning in fruit products primarily involves polyphenol oxidase catalyzing phenolic compounds to o-quinones, resulting in pigment formation, whereas non-enzymatic browning occurs through Maillard reaction pathways, where reducing sugars react with amino acids producing complex flavor and color compounds. The Maillard reaction progresses via Amadori rearrangement intermediates leading to melanoidin polymers, significantly impacting the sensory qualities and shelf life of processed fruit products.

Controlled Atmosphere Storage (CAS)

Controlled Atmosphere Storage (CAS) significantly reduces enzymatic browning in fruit products by lowering oxygen levels, which inhibits polyphenol oxidase activity responsible for the browning reaction. Non-enzymatic browning, primarily caused by Maillard reactions and caramelization, is less affected by CAS but can be minimized by controlling temperature and humidity during storage.

Ascorbic Acid Browning Prevention

Ascorbic acid effectively prevents enzymatic browning in fruit products by reducing o-quinones back to their original phenolic compounds, thereby inhibiting polyphenol oxidase activity. In contrast, non-enzymatic browning, such as the Maillard reaction and caramelization, is unaffected by ascorbic acid and requires different control strategies like pH adjustment or temperature control.

Caramelization Index

Enzymatic browning in fruit products involves polyphenol oxidase catalyzing phenolic compounds to form brown pigments, whereas non-enzymatic browning, including caramelization, occurs through thermal degradation of sugars without enzymatic action. The caramelization index measures the extent of sugar polymerization and color change during heating, providing a critical parameter for assessing quality and flavor development in processed fruits.

Sulfite-free Anti-browning Agents

Enzymatic browning in fruit products involves polyphenol oxidase catalyzing phenolic compounds into brown pigments, whereas non-enzymatic browning primarily occurs through Maillard reactions and caramelization. Sulfite-free anti-browning agents such as ascorbic acid, citric acid, and calcium chloride effectively inhibit enzymatic browning by reducing oxidative substrates and altering pH without compromising fruit quality or posing allergenic risks.

Enzyme Encapsulation for Browning Control

Enzyme encapsulation in fruit products effectively controls enzymatic browning by isolating polyphenol oxidase enzymes, thereby reducing the oxidative reaction that leads to discoloration and quality degradation. This technology enhances shelf life and maintains nutritional and sensory attributes by preventing direct enzyme-substrate interaction without altering the fruit's natural composition.

Thermal Non-enzymatic Browning Mitigation

Thermal non-enzymatic browning in fruit products primarily results from Maillard reactions and caramelization during heat processing, leading to undesirable color and flavor changes. Implementing controlled thermal treatments, optimizing pH levels, and incorporating antioxidants can effectively mitigate these browning reactions, preserving product quality and nutritional value.

Genetic Suppression of Browning Enzymes

Genetic suppression of polyphenol oxidase (PPO) genes in fruit products significantly reduces enzymatic browning by inhibiting the oxidation of phenolic compounds, enhancing shelf life and visual quality. Non-enzymatic browning, such as Maillard reactions, remains unaffected by gene suppression and requires alternative control strategies like temperature regulation and pH adjustment.

Enzymatic Browning vs Non-enzymatic Browning for Fruit Products Infographic

agridif.com

agridif.com