Pasteurization involves heating milk to a moderate temperature for a short time to kill harmful bacteria while preserving flavor and nutrients, resulting in a shorter shelf life compared to UHT milk. Ultra-High Temperature (UHT) processing heats milk to a much higher temperature for a few seconds, effectively sterilizing it and extending shelf life significantly without refrigeration until opened. Both methods ensure safety, but pasteurization maintains more fresh milk characteristics, whereas UHT offers convenience and longer storage stability.

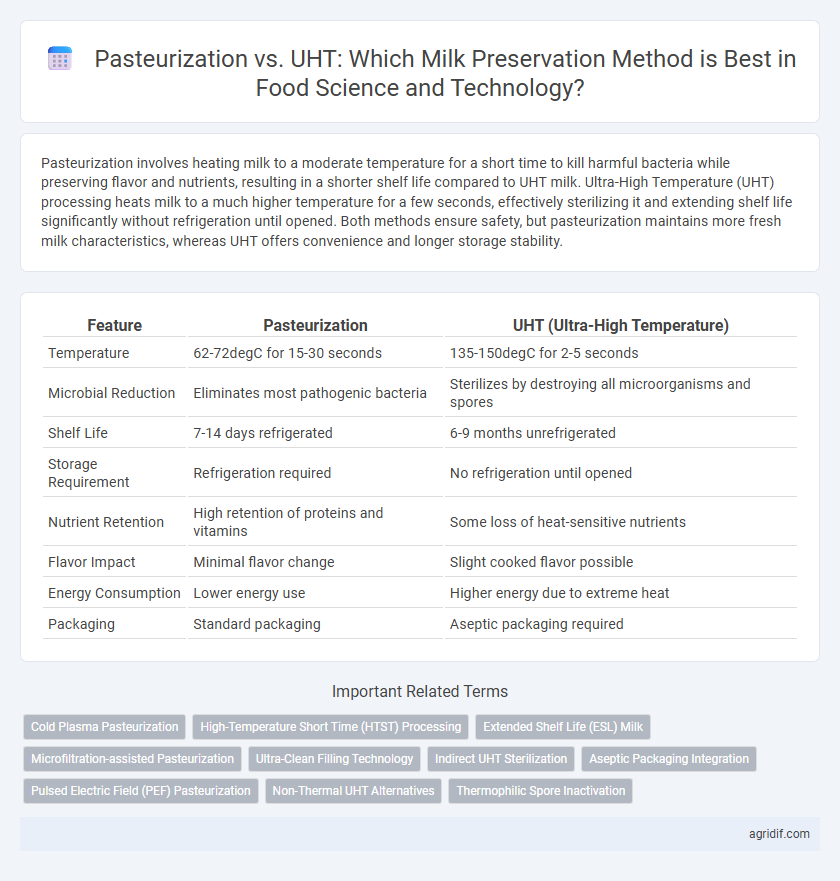

Table of Comparison

| Feature | Pasteurization | UHT (Ultra-High Temperature) |

|---|---|---|

| Temperature | 62-72degC for 15-30 seconds | 135-150degC for 2-5 seconds |

| Microbial Reduction | Eliminates most pathogenic bacteria | Sterilizes by destroying all microorganisms and spores |

| Shelf Life | 7-14 days refrigerated | 6-9 months unrefrigerated |

| Storage Requirement | Refrigeration required | No refrigeration until opened |

| Nutrient Retention | High retention of proteins and vitamins | Some loss of heat-sensitive nutrients |

| Flavor Impact | Minimal flavor change | Slight cooked flavor possible |

| Energy Consumption | Lower energy use | Higher energy due to extreme heat |

| Packaging | Standard packaging | Aseptic packaging required |

Introduction to Milk Preservation Techniques

Pasteurization involves heating milk to 72degC for 15 seconds to eliminate pathogenic bacteria while preserving flavor and nutritional quality. UHT (Ultra-High Temperature) processing heats milk to 135-150degC for 2-5 seconds, extending shelf life up to six months without refrigeration. Milk preservation techniques like pasteurization and UHT ensure microbiological safety, maintain sensory properties, and support distribution logistics in the dairy industry.

Understanding Pasteurization: Process and Benefits

Pasteurization involves heating milk to 72degC for 15 seconds, effectively reducing pathogenic microorganisms while preserving essential nutrients and flavor. This process enhances milk safety and extends shelf life without significantly affecting its sensory qualities. Compared to UHT, pasteurization maintains a fresher taste and a higher nutritional value, making it preferred for daily consumption.

UHT Treatment: How It Works and Its Advantages

UHT (Ultra-High Temperature) treatment involves heating milk to approximately 135-150degC for 2-5 seconds, effectively sterilizing it by destroying all microorganisms and spores. This method extends milk shelf life up to six months without refrigeration, maintaining nutritional quality and taste better than traditional pasteurization. UHT milk's aseptic packaging prevents contamination, making it highly advantageous for long-term storage and distribution in regions with limited cold chain infrastructure.

Key Differences Between Pasteurization and UHT

Pasteurization involves heating milk to 72degC for 15 seconds to kill pathogenic bacteria while preserving nutritional value and taste, whereas UHT (Ultra High Temperature) processing heats milk to 135-150degC for 2-5 seconds, resulting in longer shelf life without refrigeration. Pasteurized milk typically lasts 7-10 days under refrigeration, while UHT milk can be stored unopened for 6-9 months at room temperature. The thermal exposure in UHT causes slight changes in flavor and minor nutrient loss compared to pasteurization, which better retains milk's original characteristics.

Impact on Nutritional Quality of Milk

Pasteurization retains most of the vitamins, minerals, and proteins in milk by heating it to moderate temperatures (typically 72degC for 15 seconds), preserving the nutritional quality effectively. UHT (Ultra-High Temperature) processing involves heating milk to approximately 135degC for 2-5 seconds, which extends shelf life but slightly reduces some heat-sensitive nutrients like vitamin B12 and thiamine. Both methods ensure microbial safety, yet pasteurization generally offers better preservation of nutritional components compared to UHT milk.

Shelf Life Comparison: Pasteurized vs UHT Milk

Pasteurized milk typically has a shelf life of 7 to 10 days when refrigerated, due to the mild heat treatment that reduces pathogenic bacteria but leaves some spoilage microbes intact. UHT (Ultra-High Temperature) milk undergoes heating at 135-150degC for 2-5 seconds, extending its shelf life to 6 to 9 months without refrigeration by inactivating nearly all microbial contaminants. The extended shelf stability of UHT milk makes it ideal for long-term storage and distribution in areas lacking cold chain infrastructure.

Safety and Microbial Control in Both Methods

Pasteurization effectively reduces pathogenic microorganisms in milk by heating it to 72degC for 15 seconds, ensuring safety while maintaining nutritional quality. Ultra-High Temperature (UHT) treatment sterilizes milk at 135-150degC for 2-5 seconds, achieving commercial sterility and extending shelf life without refrigeration. Both methods control microbial growth, but UHT provides a higher level of microbial safety due to its more intense heat treatment.

Taste and Sensory Changes: Consumer Perspectives

Pasteurization preserves milk's natural taste and creamy texture, leading to higher consumer preference for freshness and flavor authenticity. UHT treatment extends shelf life significantly but often results in a cooked or caramelized flavor, which can be less appealing to some consumers. Sensory evaluations indicate that while UHT milk is convenient, many consumers detect and prefer the subtle sweetness and aroma retained in pasteurized milk.

Economic and Environmental Considerations

Pasteurization requires lower energy consumption than UHT, resulting in reduced operational costs and a smaller carbon footprint for milk preservation. UHT milk's longer shelf life reduces packaging waste and transportation frequency, which can offset its higher initial energy use. Economically, pasteurization suits local markets with quick turnover, while UHT supports broader distribution, balancing environmental impact with supply chain efficiency.

Future Trends in Milk Preservation Technologies

Emerging milk preservation technologies emphasize high-pressure processing (HPP) and pulsed electric fields (PEF) as alternatives to traditional pasteurization and UHT methods, offering enhanced microbial safety while retaining nutritional and sensory qualities. Innovations in membrane filtration and cold plasma treatment promise to extend shelf life without thermal degradation, aligning with consumer demand for fresh-tasting, minimally processed milk. Integration of smart packaging with biosensors is poised to revolutionize shelf-life monitoring, ensuring real-time quality control throughout the supply chain.

Related Important Terms

Cold Plasma Pasteurization

Cold plasma pasteurization employs ionized gas at near-room temperature to inactivate microorganisms in milk, preserving nutritional and sensory qualities better than traditional heat-based methods like pasteurization and UHT. This non-thermal technology extends shelf life while maintaining vitamins and enzymes intact, offering an innovative alternative to thermal milk preservation techniques.

High-Temperature Short Time (HTST) Processing

High-Temperature Short Time (HTST) processing, a common pasteurization method, heats milk to 72degC for 15 seconds to effectively eliminate pathogenic microorganisms while preserving the milk's sensory and nutritional qualities. Compared to Ultra-High Temperature (UHT) processing, HTST pasteurization results in a shorter shelf life of approximately 2-3 weeks under refrigeration but maintains fresher taste and better nutrient retention.

Extended Shelf Life (ESL) Milk

Pasteurization uses moderate heat to destroy pathogens while preserving milk's natural flavor, resulting in a refrigerated shelf life of about 7-14 days, whereas UHT (Ultra High Temperature) treatment employs temperatures above 135degC for a few seconds, enabling milk to remain shelf-stable for 6-9 months without refrigeration. Extended Shelf Life (ESL) milk combines microfiltration with pasteurization, extending refrigerated shelf life to 21-45 days by reducing microbial load more effectively than traditional pasteurization without the flavor changes associated with UHT.

Microfiltration-assisted Pasteurization

Microfiltration-assisted pasteurization enhances milk preservation by removing bacteria and spores through a 1.4-micron membrane, enabling lower pasteurization temperatures that retain more nutrients and fresh taste compared to traditional pasteurization. Unlike UHT processing, which sterilizes milk at 135-150degC for 2-5 seconds causing flavor changes and nutrient degradation, microfiltration combined with mild heat treatment extends shelf life while maintaining superior sensory and nutritional qualities.

Ultra-Clean Filling Technology

Ultra-Clean Filling Technology enhances UHT milk preservation by ensuring aseptic packaging that maintains sterility and extends shelf life without refrigeration, unlike traditional pasteurization which requires cold storage due to limited microbial kill. This technology reduces contamination risk and preserves nutritional and sensory qualities, making UHT milk with Ultra-Clean Filling a superior option for long-term distribution and storage.

Indirect UHT Sterilization

Indirect UHT sterilization of milk involves rapidly heating the product to 135-150degC for 2-5 seconds using heat exchangers, effectively eliminating pathogenic microorganisms while preserving nutritional and sensory qualities better than traditional pasteurization. This method extends milk shelf life up to 6 months without refrigeration, meeting stringent food safety standards and maintaining higher protein solubility and vitamin retention compared to pasteurized milk.

Aseptic Packaging Integration

Pasteurization combined with aseptic packaging extends milk's shelf life by eliminating spoilage microorganisms while preserving sensory and nutritional qualities, making it suitable for refrigerated distribution. UHT processing paired with aseptic packaging achieves longer ambient shelf stability by applying ultra-high temperature treatment to destroy all microorganisms, enabling milk storage without refrigeration for several months.

Pulsed Electric Field (PEF) Pasteurization

Pulsed Electric Field (PEF) pasteurization offers a non-thermal milk preservation technology that inactivates microorganisms while retaining fresh flavor and nutritional quality, unlike traditional pasteurization and UHT methods that rely on heat. PEF extends shelf life comparable to UHT but preserves more heat-sensitive vitamins and bioactive compounds, positioning it as an innovative alternative in milk processing.

Non-Thermal UHT Alternatives

Non-thermal UHT alternatives such as high-pressure processing (HPP) and pulsed electric fields (PEF) effectively inactivate pathogens and spoilage microorganisms in milk while preserving nutritional quality and sensory attributes better than traditional thermal methods. These innovative techniques extend shelf life comparable to UHT pasteurization without the heat-induced loss of vitamins and flavor compounds.

Thermophilic Spore Inactivation

Pasteurization typically heats milk to 72degC for 15 seconds, effectively inactivating most vegetative microbes but often sparing thermophilic spores, which can survive and cause spoilage. UHT (Ultra-High Temperature) processing, heating milk above 135degC for 2-5 seconds, achieves superior inactivation of thermophilic spores, enhancing milk's shelf life by preventing spore germination and spoilage under ambient conditions.

Pasteurization vs UHT for milk preservation Infographic

agridif.com

agridif.com