Pasteurization involves heating liquid foods to moderate temperatures to kill pathogenic microorganisms while preserving flavor and nutrients, making it suitable for products like milk and fruit juices. Sterilization applies higher temperatures to eliminate all microorganisms, extending shelf life significantly but potentially altering taste and nutritional quality. Choosing between pasteurization and sterilization depends on the desired shelf life, safety requirements, and sensory attributes of the liquid food product.

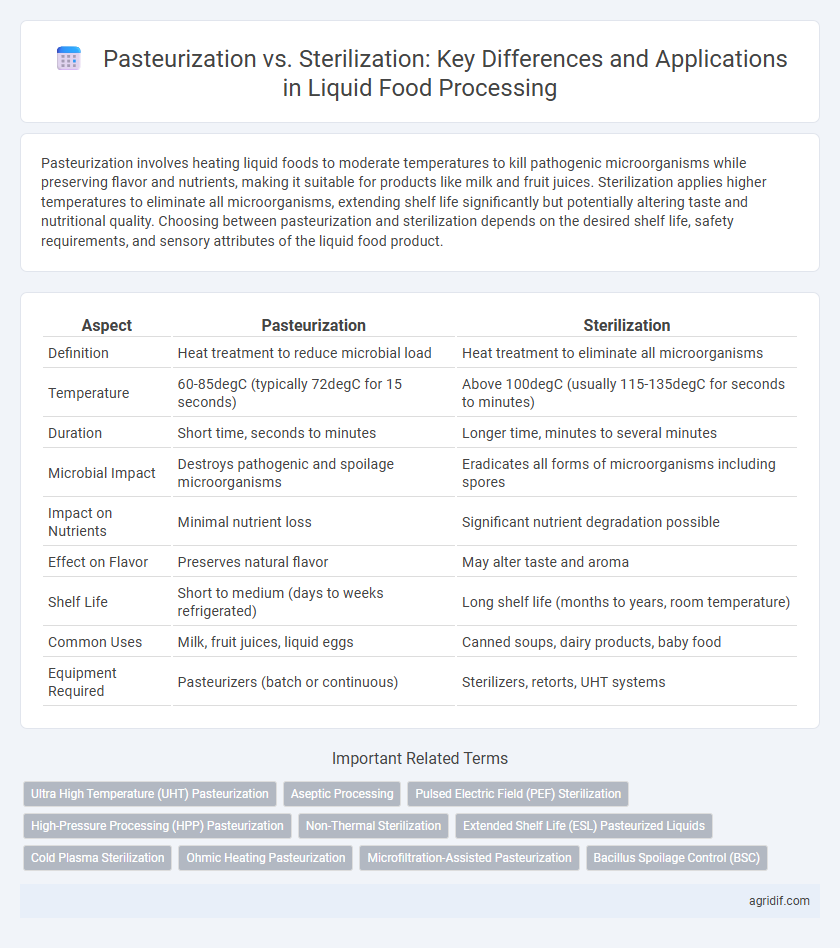

Table of Comparison

| Aspect | Pasteurization | Sterilization |

|---|---|---|

| Definition | Heat treatment to reduce microbial load | Heat treatment to eliminate all microorganisms |

| Temperature | 60-85degC (typically 72degC for 15 seconds) | Above 100degC (usually 115-135degC for seconds to minutes) |

| Duration | Short time, seconds to minutes | Longer time, minutes to several minutes |

| Microbial Impact | Destroys pathogenic and spoilage microorganisms | Eradicates all forms of microorganisms including spores |

| Impact on Nutrients | Minimal nutrient loss | Significant nutrient degradation possible |

| Effect on Flavor | Preserves natural flavor | May alter taste and aroma |

| Shelf Life | Short to medium (days to weeks refrigerated) | Long shelf life (months to years, room temperature) |

| Common Uses | Milk, fruit juices, liquid eggs | Canned soups, dairy products, baby food |

| Equipment Required | Pasteurizers (batch or continuous) | Sterilizers, retorts, UHT systems |

Introduction to Liquid Food Preservation Methods

Pasteurization involves heating liquid foods to a specific temperature below boiling point for a short time to eliminate pathogenic microorganisms while preserving nutritional and sensory qualities. Sterilization uses higher temperatures for longer durations, ensuring complete microbial destruction for extended shelf life but can cause changes in flavor and nutrient content. Both methods are essential in liquid food preservation, balancing food safety with quality retention.

Understanding Pasteurization: Principles and Applications

Pasteurization involves heating liquid foods to a specific temperature below boiling, typically 60-85degC, for a defined period to reduce pathogenic microorganisms and extend shelf life while preserving nutritional and sensory qualities. This process targets vegetative bacteria and enzymes without significantly impacting heat-sensitive vitamins, making it ideal for dairy products, fruit juices, and beverages. Unlike sterilization, which uses higher temperatures above 100degC and longer exposure times to achieve commercial sterility, pasteurization balances microbial safety with quality retention in liquid foods.

Sterilization in Liquid Foods: An Overview

Sterilization in liquid foods involves the application of intense heat or other treatments to eliminate all forms of microbial life, ensuring extended shelf life and safety without refrigeration. Common methods include ultra-high temperature (UHT) processing and aseptic packaging, which preserve nutritional quality and sensory attributes while preventing spoilage. This technique is crucial for milk, fruit juices, and liquid eggs, offering a robust alternative to pasteurization by achieving commercial sterility.

Key Differences Between Pasteurization and Sterilization

Pasteurization involves heating liquid foods to temperatures between 60degC and 85degC for a short time to eliminate pathogenic microorganisms while preserving flavor and nutrients. Sterilization subjects liquids to much higher temperatures, typically above 121degC, for extended periods to achieve commercial sterility by destroying all microbial life, including spores. Pasteurization maintains more natural taste and nutrition but has a shorter shelf life compared to sterilization, which ensures longer shelf stability but may alter sensory and nutritional qualities.

Effects on Nutritional Quality of Liquid Foods

Pasteurization preserves most heat-sensitive vitamins such as vitamin C and B-complex by using moderate temperatures (typically 60-85degC) for short durations, minimizing nutrient degradation in liquid foods. Sterilization applies higher temperatures (above 100degC) for longer times, causing significant losses in heat-labile nutrients and altering flavor profiles due to Maillard reactions. Choosing pasteurization over sterilization enhances retention of antioxidants, enzymes, and essential amino acids, maintaining better nutritional quality in liquid dairy and fruit products.

Microbial Safety: Pasteurization vs. Sterilization

Pasteurization reduces microbial load by heating liquid foods to a specific temperature for a short time, effectively inactivating pathogenic microorganisms without significantly affecting nutritional quality. Sterilization involves higher temperatures and longer exposure to eliminate all viable microorganisms, including spores, thereby ensuring complete microbial safety and extending shelf life. While pasteurization is suitable for products requiring freshness and minimal flavor alteration, sterilization is preferred for commercially sterile products with longer storage stability.

Impact on Flavor, Texture, and Sensory Properties

Pasteurization preserves the natural flavor and texture of liquid foods by using lower temperatures, minimizing sensory changes while extending shelf life through microbial reduction. Sterilization applies higher heat, which can alter flavor profiles, degrade texture, and reduce sensory quality due to protein denaturation and Maillard reactions. Selecting pasteurization or sterilization depends on balancing microbial safety with maintaining desirable sensory attributes in products like milk, juices, and soups.

Technological Advances in Heat Treatment Processes

Technological advances in heat treatment processes have enhanced pasteurization and sterilization for liquid foods, improving microbial safety while preserving nutritional quality. Innovative methods such as ultra-high temperature (UHT) processing and pulsed electric fields allow precise control over time-temperature profiles to minimize nutrient degradation and sensory changes. Integration of real-time monitoring systems and advanced heat exchangers ensures consistent product quality and energy efficiency in large-scale production.

Industry Applications and Regulatory Standards

Pasteurization in liquid foods involves heating to temperatures below 100degC to eliminate pathogenic microorganisms while preserving sensory and nutritional qualities, and is widely applied in dairy, juice, and beverage industries under standards such as the FDA Pasteurized Milk Ordinance. Sterilization uses higher temperatures, often above 121degC, to achieve commercial sterility by destroying all microbial life including spores, essential for shelf-stable products like canned soups and UHT milk regulated by agencies like the USDA and Codex Alimentarius. Industry applications select pasteurization for refrigerated products requiring shorter shelf life, whereas sterilization supports long-term storage at ambient temperatures, balancing microbial safety, product quality, and compliance with food safety regulations.

Future Trends in Liquid Food Processing Techniques

Emerging trends in liquid food processing emphasize non-thermal technologies such as high-pressure processing (HPP) and pulsed electric fields (PEF) to enhance microbial safety while preserving nutritional and sensory qualities. Advances in membrane filtration and ultraviolet (UV) irradiation are increasingly integrated with pasteurization and sterilization protocols to optimize energy efficiency and reduce chemical usage. Artificial intelligence and real-time monitoring systems enable precise control of processing parameters, driving innovation in sustainable, high-quality liquid food production.

Related Important Terms

Ultra High Temperature (UHT) Pasteurization

Ultra High Temperature (UHT) pasteurization heats liquid foods such as milk to 135-150degC for 2-5 seconds, effectively destroying pathogenic microorganisms while preserving nutritional quality and flavor better than traditional sterilization methods. Unlike sterilization, which involves longer heating times and higher temperatures causing altered taste and nutrient degradation, UHT enables extended shelf life without refrigeration through aseptic packaging.

Aseptic Processing

Aseptic processing combines high-temperature short-time pasteurization with sterile packaging to extend shelf life of liquid foods without refrigeration. This method preserves nutritional quality and flavor better than traditional sterilization, which uses higher temperatures but can degrade sensory and nutritional attributes.

Pulsed Electric Field (PEF) Sterilization

Pulsed Electric Field (PEF) sterilization uses short bursts of high voltage to inactivate microorganisms in liquid foods, preserving flavor and nutrients more effectively than traditional thermal pasteurization. This non-thermal technology extends shelf life while maintaining the sensory and nutritional quality of juices and dairy products.

High-Pressure Processing (HPP) Pasteurization

High-Pressure Processing (HPP) pasteurization preserves the nutritional quality and sensory characteristics of liquid foods by inactivating spoilage microorganisms and pathogens without heat, offering an alternative to traditional thermal pasteurization. Unlike sterilization, which uses high temperatures to achieve commercial sterility but can degrade taste and nutrients, HPP maintains freshness while extending shelf life through pressure levels typically ranging from 400 to 600 MPa.

Non-Thermal Sterilization

Non-thermal sterilization methods such as high-pressure processing, pulsed electric fields, and ultraviolet light inactivate pathogens in liquid foods without compromising nutritional quality or sensory attributes, unlike traditional pasteurization and thermal sterilization that rely on heat. These innovative techniques preserve vitamins, enzymes, and flavor compounds while ensuring microbial safety and extending shelf life in juice, milk, and other liquid food products.

Extended Shelf Life (ESL) Pasteurized Liquids

Extended Shelf Life (ESL) pasteurization employs moderate heat treatment combined with microfiltration or gas flushing to reduce microbial load in liquid foods, preserving fresh taste while extending shelf stability to several weeks under refrigeration. Compared to sterilization, which uses high heat causing nutrient degradation and altered flavor, ESL pasteurization retains higher nutritional quality and sensory attributes with reduced thermal damage.

Cold Plasma Sterilization

Cold plasma sterilization offers a non-thermal alternative to traditional pasteurization and sterilization methods for liquid foods, effectively inactivating pathogens and spoilage microorganisms while preserving nutritional and sensory qualities. This emerging technology uses reactive species generated at low temperatures, enabling enhanced microbial safety and extended shelf life without the detrimental effects associated with heat treatments.

Ohmic Heating Pasteurization

Ohmic heating pasteurization rapidly inactivates pathogens and spoilage microorganisms in liquid foods by passing electric current through the product, preserving sensory and nutritional qualities better than conventional pasteurization. This method achieves effective microbial reduction with lower thermal damage compared to sterilization, ensuring extended shelf life while maintaining product quality.

Microfiltration-Assisted Pasteurization

Microfiltration-assisted pasteurization enhances liquid food safety by removing microorganisms through physical filtration, reducing the thermal load needed compared to traditional pasteurization and preserving nutritional and sensory qualities better than sterilization. This technique achieves microbial inactivation at lower temperatures while maintaining product stability and extending shelf life, positioning it as an effective alternative for heat-sensitive liquid foods.

Bacillus Spoilage Control (BSC)

Pasteurization effectively reduces Bacillus spoilage bacteria in liquid foods by applying moderate heat (typically 60-85degC) for a short time, preserving sensory and nutritional qualities while controlling Bacillus subtilis and Bacillus cereus. Sterilization uses higher temperatures (above 100degC, often 121degC) to achieve commercial sterility, eliminating Bacillus spores but potentially affecting the taste and nutrient profile of liquid products.

Pasteurization vs sterilization for liquid foods Infographic

agridif.com

agridif.com