High-pressure processing (HPP) preserves juice by inactivating spoilage microorganisms and enzymes without significant heat, maintaining fresh flavor, color, and nutritional quality better than traditional thermal processing. Thermal processing relies on heat to extend shelf life but often causes nutrient degradation and sensory changes due to protein denaturation and Maillard reactions. HPP offers a non-thermal alternative that enhances shelf stability while retaining vitamins and bioactive compounds more effectively than thermal pasteurization.

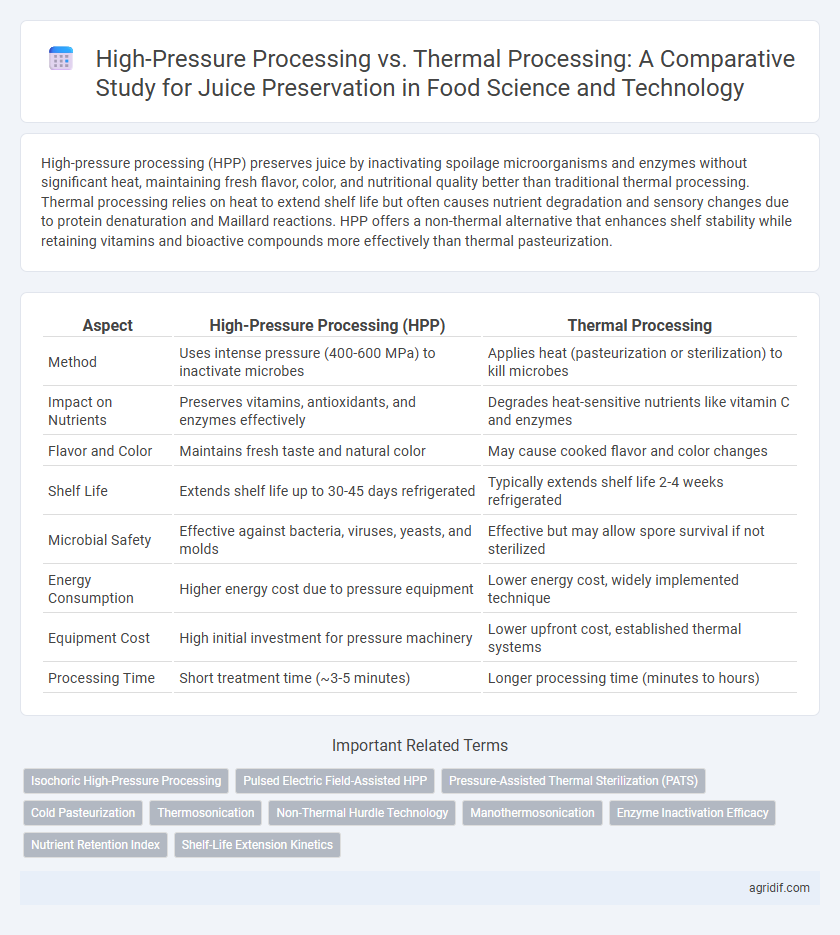

Table of Comparison

| Aspect | High-Pressure Processing (HPP) | Thermal Processing |

|---|---|---|

| Method | Uses intense pressure (400-600 MPa) to inactivate microbes | Applies heat (pasteurization or sterilization) to kill microbes |

| Impact on Nutrients | Preserves vitamins, antioxidants, and enzymes effectively | Degrades heat-sensitive nutrients like vitamin C and enzymes |

| Flavor and Color | Maintains fresh taste and natural color | May cause cooked flavor and color changes |

| Shelf Life | Extends shelf life up to 30-45 days refrigerated | Typically extends shelf life 2-4 weeks refrigerated |

| Microbial Safety | Effective against bacteria, viruses, yeasts, and molds | Effective but may allow spore survival if not sterilized |

| Energy Consumption | Higher energy cost due to pressure equipment | Lower energy cost, widely implemented technique |

| Equipment Cost | High initial investment for pressure machinery | Lower upfront cost, established thermal systems |

| Processing Time | Short treatment time (~3-5 minutes) | Longer processing time (minutes to hours) |

Overview of Juice Preservation Methods

High-pressure processing (HPP) preserves juice by applying intense pressure, effectively inactivating microorganisms while retaining nutritional and sensory qualities better than traditional thermal processing. Thermal processing uses heat to eliminate pathogens and enzymes but often causes nutrient degradation and alters flavor and color. Both methods aim to extend shelf life, with HPP favored for maintaining freshness and bioactive compounds in juice products.

Principles of High-Pressure Processing (HPP)

High-Pressure Processing (HPP) preserves juice by applying uniform pressures between 100 and 600 MPa, inactivating spoilage microorganisms and enzymes while maintaining nutritional quality. This non-thermal method disrupts microbial cell membranes and denatures proteins without significant heat generation, retaining fresh flavor and color. HPP enhances juice shelf life and safety compared to traditional thermal pasteurization, which uses high temperatures that can degrade sensory and nutritional attributes.

Fundamentals of Thermal Processing in Juice Industry

Thermal processing in the juice industry involves applying heat to inactivate spoilage microorganisms and enzymes, ensuring microbial safety and extending shelf life. Typical methods such as pasteurization and sterilization operate at specific time-temperature combinations optimized to preserve sensory and nutritional qualities while preventing pathogen growth. The thermal resistance of target microorganisms and enzymes guides process parameters to achieve efficient microbial inactivation with minimum quality degradation.

Microbial Safety: HPP vs Thermal Processing

High-Pressure Processing (HPP) effectively inactivates pathogenic microorganisms in juices while preserving sensory and nutritional qualities, using pressures up to 600 MPa without heat. Thermal processing ensures microbial safety by applying heat, typically above 85degC, which eradicates spoilage and pathogenic microbes but may degrade flavor, color, and nutrients. Comparative studies show HPP extends shelf life with minimal quality loss, whereas thermal methods offer more cost-effective microbial control but at the expense of juice quality.

Impact on Nutritional Quality and Phytochemicals

High-pressure processing (HPP) preserves more vitamins, antioxidants, and phytochemicals in juice compared to thermal processing, which often leads to nutrient degradation and flavor loss due to high temperatures. Studies show that HPP maintains the bioavailability of vitamin C and preserves phenolic compounds that contribute to antioxidant capacity. Thermal pasteurization, while effective for microbial safety, significantly reduces heat-sensitive nutrients and phytochemicals, diminishing the overall nutritional quality of juice.

Effects on Juice Flavor and Sensory Attributes

High-pressure processing (HPP) preserves juice flavor by effectively inactivating microbes without significant heat, maintaining the fresh, natural taste and vibrant sensory attributes. Thermal processing, involving heat pasteurization, often induces flavor degradation and off-notes due to Maillard reactions and volatile compound loss, impacting overall sensory quality. Studies show HPP-treated juices retain higher levels of aroma compounds and antioxidants, contributing to superior flavor profiles compared to thermally processed juices.

Shelf Life Extension: Comparative Analysis

High-Pressure Processing (HPP) preserves juice by inactivating spoilage microorganisms while maintaining flavor and nutrient integrity, extending shelf life up to 30-45 days under refrigeration. Thermal Processing uses heat pasteurization to degrade enzymes and pathogens but often causes nutrient loss and flavor alteration, providing a shelf life of 14-28 days. Comparative analyses reveal HPP's superior ability to maintain sensory qualities and nutritional value with longer shelf stability compared to conventional thermal methods.

Energy Consumption and Environmental Sustainability

High-Pressure Processing (HPP) for juice preservation significantly reduces energy consumption compared to traditional thermal processing due to its shorter treatment times and lower temperature requirements. HPP maintains nutrient quality and flavor integrity while minimizing greenhouse gas emissions associated with energy use in thermal pasteurization. This method supports environmental sustainability by reducing the carbon footprint of juice production and lowering water usage in heat exchange systems.

Consumer Acceptance and Market Trends

High-pressure processing (HPP) preserves juice freshness and nutritional quality without heat-induced flavor changes, leading to higher consumer acceptance compared to thermal processing, which often results in altered taste and nutrient loss. Market trends indicate a growing demand for minimally processed, clean-label juices, driving increased adoption of HPP technology by beverage manufacturers. Studies reveal consumers are willing to pay premium prices for juices labeled as HPP-treated, reflecting trust in its safety and quality benefits over traditional thermal pasteurization.

Future Prospects in Juice Processing Technologies

High-pressure processing (HPP) offers superior nutrient retention and microbial inactivation compared to traditional thermal processing, making it a promising technology for future juice preservation. Advances in HPP equipment aim to reduce processing times and energy consumption, enhancing sustainability and scalability for commercial applications. Integrating HPP with emerging techniques such as pulsed electric fields and ultrasound may further improve juice quality, safety, and shelf life in innovative processing systems.

Related Important Terms

Isochoric High-Pressure Processing

Isochoric High-Pressure Processing (HPP) maintains juice quality by applying uniform pressure in a constant-volume system, preserving bioactive compounds and sensory attributes better than traditional thermal processing, which often degrades flavor and nutrients through heat exposure. Studies show isochoric HPP effectively inactivates pathogens and enzymes while retaining vitamin C and antioxidants, offering a superior method for preserving juice freshness and extending shelf life without compromising nutritional value.

Pulsed Electric Field-Assisted HPP

Pulsed Electric Field-Assisted High-Pressure Processing (PEF-HPP) enhances juice preservation by combining the microbial inactivation efficacy of high hydrostatic pressure with the cell membrane permeabilization induced by pulsed electric fields, resulting in superior retention of nutrients, flavor, and color compared to conventional thermal processing. Studies demonstrate that PEF-HPP-treated juices maintain higher levels of vitamin C and phytochemicals while achieving significant shelf-life extension without compromising sensory quality or nutritional value.

Pressure-Assisted Thermal Sterilization (PATS)

Pressure-Assisted Thermal Sterilization (PATS) combines high pressure (up to 600 MPa) with moderate heat (90-121degC) to effectively inactivate microbial spores while preserving essential nutrients and sensory qualities in juice products. This method outperforms conventional thermal processing by reducing thermal degradation and maintaining flavor, color, and vitamin content during juice preservation.

Cold Pasteurization

High-Pressure Processing (HPP) preserves juice quality by inactivating pathogens and enzymes at low temperatures, maintaining fresh flavor, nutrients, and color better than traditional Thermal Processing, which uses heat that can degrade sensory and nutritional properties. Cold pasteurization via HPP extends shelf life while retaining bioactive compounds such as vitamin C and antioxidants, making it an advanced alternative for juice preservation in food science and technology.

Thermosonication

Thermosonication combines ultrasound waves and mild heat to effectively inactivate spoilage enzymes and pathogenic microorganisms in juice, preserving its nutritional quality better than traditional thermal pasteurization. This non-thermal technique enhances microbial safety while maintaining sensory attributes, making it a promising alternative to thermal processing in juice preservation.

Non-Thermal Hurdle Technology

High-Pressure Processing (HPP) preserves juice quality by inactivating pathogens and spoilage microorganisms through pressures up to 600 MPa without heat, retaining vitamins, flavor, and color better than Thermal Processing. This non-thermal hurdle technology synergizes with mild acidification and natural antimicrobials to enhance microbial stability and shelf life while minimizing nutrient degradation.

Manothermosonication

High-pressure processing (HPP) preserves juice quality by inactivating microbes without heat, maintaining nutritional and sensory properties better than traditional thermal methods. Manothermosonication combines mild heat, pressure, and ultrasound, enhancing microbial inactivation and improving juice shelf life while preserving vitamins and phytochemicals more effectively than either high-pressure or thermal processing alone.

Enzyme Inactivation Efficacy

High-Pressure Processing (HPP) achieves superior enzyme inactivation in juice preservation by applying pressures up to 600 MPa, effectively deactivating pectin methylesterase and polyphenol oxidase without significant heat-induced nutrient degradation. In contrast, Thermal Processing relies on high temperatures (typically above 85degC) that can denature enzymes but often compromise juice flavor and vitamin content, resulting in lower overall enzyme inactivation efficacy compared to HPP.

Nutrient Retention Index

High-Pressure Processing (HPP) preserves juice nutrients more effectively than Thermal Processing by inactivating microorganisms at lower temperatures, resulting in a higher Nutrient Retention Index. Studies show HPP-treated juices maintain up to 90-95% of vitamin C and polyphenols, whereas thermal methods often reduce nutrient levels by 30-50%.

Shelf-Life Extension Kinetics

High-pressure processing (HPP) extends juice shelf-life by inactivating spoilage microorganisms and enzymes without significant heat damage, preserving sensory and nutritional qualities better than traditional thermal processing. Shelf-life extension kinetics show HPP achieves microbial stability at lower temperature conditions, slowing quality degradation and retaining bioactive compounds more effectively over time compared to thermal pasteurization.

High-Pressure Processing vs Thermal Processing for Juice Preservation Infographic

agridif.com

agridif.com