Freezing preserves fruit by lowering temperatures to inhibit microbial growth and enzymatic activity, maintaining texture and nutritional quality with minimal processing. Freeze-drying removes moisture through sublimation, producing lightweight, shelf-stable fruits with intense flavor and nutrient retention but requires higher energy and cost. Choosing between freezing and freeze-drying depends on storage conditions, desired shelf life, texture, and economic factors in fruit preservation.

Table of Comparison

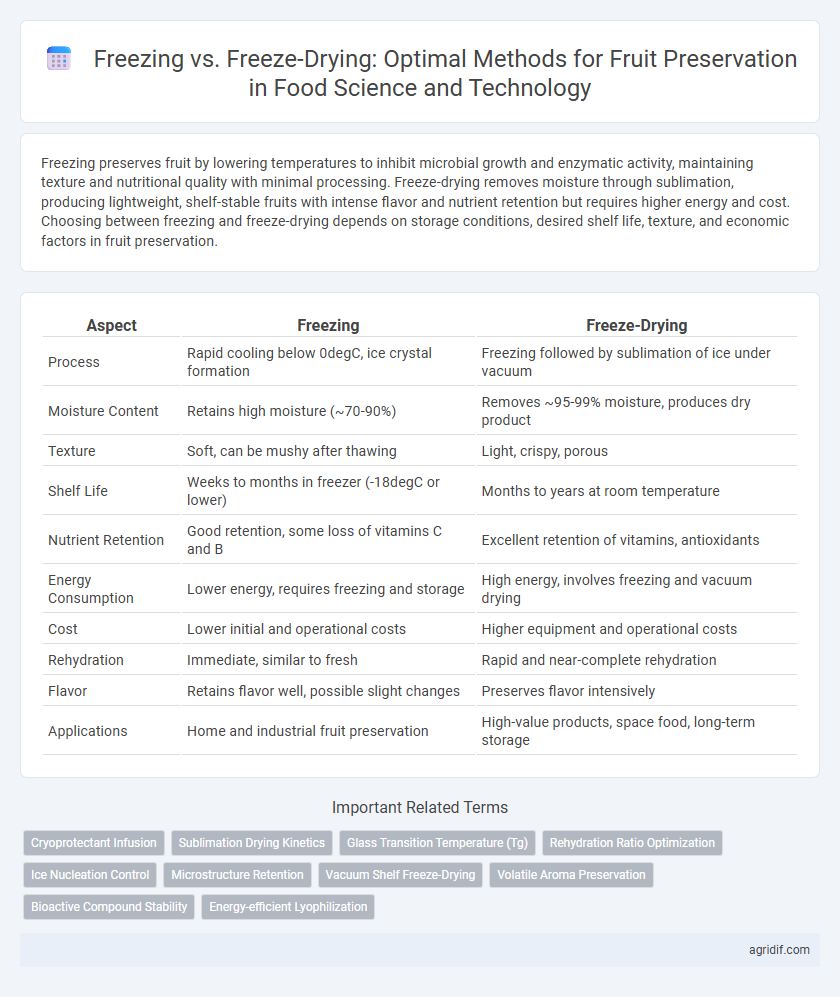

| Aspect | Freezing | Freeze-Drying |

|---|---|---|

| Process | Rapid cooling below 0degC, ice crystal formation | Freezing followed by sublimation of ice under vacuum |

| Moisture Content | Retains high moisture (~70-90%) | Removes ~95-99% moisture, produces dry product |

| Texture | Soft, can be mushy after thawing | Light, crispy, porous |

| Shelf Life | Weeks to months in freezer (-18degC or lower) | Months to years at room temperature |

| Nutrient Retention | Good retention, some loss of vitamins C and B | Excellent retention of vitamins, antioxidants |

| Energy Consumption | Lower energy, requires freezing and storage | High energy, involves freezing and vacuum drying |

| Cost | Lower initial and operational costs | Higher equipment and operational costs |

| Rehydration | Immediate, similar to fresh | Rapid and near-complete rehydration |

| Flavor | Retains flavor well, possible slight changes | Preserves flavor intensively |

| Applications | Home and industrial fruit preservation | High-value products, space food, long-term storage |

Introduction to Fruit Preservation Methods

Freezing and freeze-drying are pivotal techniques in fruit preservation, each leveraging distinct physical principles to extend shelf life and retain nutritional quality. Freezing halts microbial activity and enzymatic reactions by lowering temperatures below the freezing point, while freeze-drying removes moisture through sublimation under low pressure, drastically reducing water activity. Understanding these methods' impacts on texture, flavor, and nutrient retention is essential for optimizing fruit preservation in food science and technology.

Principles of Freezing and Freeze-drying

Freezing preserves fruit by lowering its temperature below the freezing point, causing water inside cells to form ice crystals that inhibit microbial growth and enzymatic activity. Freeze-drying removes moisture through sublimation, where frozen fruit is exposed to low pressure, allowing ice to change directly from solid to vapor without passing through a liquid phase, preserving texture and nutrients. Both methods rely on controlling temperature and pressure to maintain fruit quality, but freeze-drying better preserves cellular structure and nutritional content due to minimal ice crystal formation.

Impact on Nutritional Content

Freezing preserves fruit by slowing enzyme activity and microbial growth, retaining most vitamins like vitamin C and antioxidants, though some water-soluble nutrients may leach during thawing. Freeze-drying removes moisture under low temperature and pressure, maintaining nearly all nutrients including heat-sensitive vitamins and phytochemicals due to minimal thermal degradation. Comparative studies show freeze-dried fruits have superior retention of nutritional quality and longer shelf life compared to frozen counterparts, making freeze-drying preferable for nutrient-rich fruit preservation.

Effects on Fruit Texture and Appearance

Freezing preserves fruit texture by slowing ice crystal formation but can cause cellular damage leading to mushiness upon thawing, while freeze-drying maintains structural integrity by sublimating water, resulting in a dry, porous texture. Freeze-dried fruits retain vivid color and shape better than frozen fruits, which often darken and soften due to enzymatic and oxidative reactions during storage. Texture and appearance stability are closely tied to the preservation method's impact on moisture content and cellular structure integrity.

Flavor Retention and Loss

Freezing preserves fruit flavor by slowing enzymatic reactions and microbial growth, maintaining volatile compounds that contribute to fresh taste. Freeze-drying removes moisture through sublimation, better preserving volatile flavor compounds and aroma compared to freezing, but may lead to slight alterations in texture. Both methods reduce nutrient loss, yet freeze-drying offers superior flavor retention due to minimal cellular damage and reduced ice crystal formation.

Shelf Life Comparison

Freeze-drying extends the shelf life of fruit preservation up to 25 years by removing almost all moisture, which inhibits microbial growth and enzymatic reactions. Freezing typically preserves fruit quality for 6 to 12 months, as ice crystal formation can cause cellular damage and potential spoilage upon thawing. The low moisture content achieved in freeze-drying significantly enhances stability and storage duration compared to conventional freezing methods.

Cost and Energy Efficiency

Freeze-drying fruit offers superior preservation quality but demands significantly higher energy consumption and costs compared to freezing, which relies on lower-energy refrigeration systems. Freezing requires less initial investment and operational expenses, making it more accessible for large-scale, cost-sensitive fruit preservation. Energy-efficient freezing technologies continue to evolve, enhancing cost-effectiveness, while freeze-drying remains ideal for premium, value-added products despite its higher economic footprint.

Storage and Packaging Requirements

Freezing requires airtight, moisture-resistant packaging to prevent ice crystal formation and freezer burn, ensuring fruit quality during storage at temperatures below -18degC. Freeze-drying demands moisture-proof, oxygen-barrier packaging to maintain low water activity and protect against oxidation, enabling storage at room temperature without refrigeration. Controlled humidity and temperature conditions are critical for both methods to maximize shelf life and preserve the fruit's nutritional and sensory properties.

Applications in the Agri-food Industry

Freezing preserves fruit by slowing enzymatic activity and microbial growth, maintaining freshness and nutritional quality, making it ideal for large-scale storage and transportation in the agri-food industry. Freeze-drying removes water through sublimation, resulting in lightweight, shelf-stable fruit products that retain shape, flavor, and bioactive compounds, suitable for high-value snack and ingredient markets. Freeze-drying requires higher investment and energy but offers superior preservation of texture and nutrients compared to freezing, influencing its application based on product type and market demand.

Consumer Acceptance and Market Trends

Freeze-drying preserves fruit texture and flavor more effectively than freezing, driving higher consumer acceptance due to its convenience and longer shelf life. Market trends reveal increasing demand for freeze-dried fruits in snacks and nutraceuticals, reflecting a shift towards premium, minimally processed options. Consumer preference aligns with the growing interest in clean-label products, making freeze-dried fruit a lucrative segment in food technology innovation.

Related Important Terms

Cryoprotectant Infusion

Cryoprotectant infusion enhances fruit preservation by reducing ice crystal formation during freezing, maintaining cellular integrity and sensory quality. Freeze-drying with cryoprotectants further improves texture retention and nutrient stability by minimizing structural damage and oxidative degradation in dehydrated fruit products.

Sublimation Drying Kinetics

Sublimation drying kinetics in freeze-drying enable the precise removal of ice from fruit tissues, preserving cellular structure and nutritional content better than conventional freezing methods, which often cause ice crystal formation and cellular damage. Optimizing sublimation parameters such as temperature and pressure accelerates moisture removal while maintaining fruit quality, making freeze-drying a superior technique for long-term fruit preservation.

Glass Transition Temperature (Tg)

Freezing preserves fruit by reducing molecular mobility below the glass transition temperature (Tg), stabilizing cellular structures and enzymatic activity. Freeze-drying removes water under low temperature and pressure, preventing crystallization by maintaining the product below Tg, thus retaining texture and nutrient integrity more effectively than conventional freezing.

Rehydration Ratio Optimization

Freeze-drying preserves fruit texture and nutrients by sublimating ice directly to vapor, resulting in higher rehydration ratios compared to conventional freezing methods where cellular damage reduces water absorption capacity. Optimizing rehydration ratios involves controlling drying parameters such as shelf temperature, chamber pressure, and primary drying duration to maintain porous microstructures that facilitate efficient water uptake during rehydration.

Ice Nucleation Control

Ice nucleation control during freezing preserves fruit cellular structure by promoting uniform ice crystal formation, minimizing cell wall damage and nutrient loss. In contrast, freeze-drying bypasses liquid-to-ice transitions, removing water via sublimation, which preserves fruit texture and bioactive compounds more effectively than uncontrolled freezing processes.

Microstructure Retention

Freeze-drying preserves fruit microstructure more effectively than freezing by sublimating water content while maintaining cell wall integrity and minimizing ice crystal damage. This process results in improved texture, rehydration capacity, and nutrient retention compared to traditional freezing methods.

Vacuum Shelf Freeze-Drying

Vacuum shelf freeze-drying preserves fruit by sublimating ice under low pressure and controlled shelf temperature, maintaining nutrient content and texture better than conventional freezing, which causes cellular damage from ice crystal formation. This method extends shelf life significantly without the need for refrigeration, making it ideal for high-quality fruit preservation in Food Science and Technology.

Volatile Aroma Preservation

Freeze-drying preserves volatile aromas in fruit better than freezing by sublimating moisture at low temperatures, which minimizes aroma compound loss and oxidation. In contrast, freezing can cause ice crystal formation that damages cell structure and leads to volatile aroma degradation during thawing.

Bioactive Compound Stability

Freeze-drying preserves bioactive compounds in fruits more effectively than freezing due to lower temperature stress and minimal enzymatic activity, maintaining higher levels of antioxidants, vitamins, and polyphenols. Frozen fruits often suffer from ice crystal formation that damages cell structure and accelerates degradation of heat-sensitive nutrients during thawing.

Energy-efficient Lyophilization

Freeze-drying (lyophilization) offers superior fruit preservation by removing moisture under low temperature and pressure, maintaining nutritional content and sensory qualities more effectively than conventional freezing. Energy-efficient lyophilization techniques reduce operational costs by optimizing vacuum levels and heat transfer, enabling sustainable, long-term storage without compromising fruit integrity.

Freezing vs Freeze-drying for Fruit Preservation Infographic

agridif.com

agridif.com