Aseptic packaging extends the shelf life of ready-to-eat meals by sterilizing food and packaging separately, preserving nutritional quality and flavor without refrigeration. Retort packaging involves sealing meals in pouches or cans and applying high heat to sterilize, ensuring safety but potentially altering texture and taste. Both methods enhance convenience and food safety, with aseptic packaging favored for fresh-like quality and retort packaging preferred for durability in diverse distribution conditions.

Table of Comparison

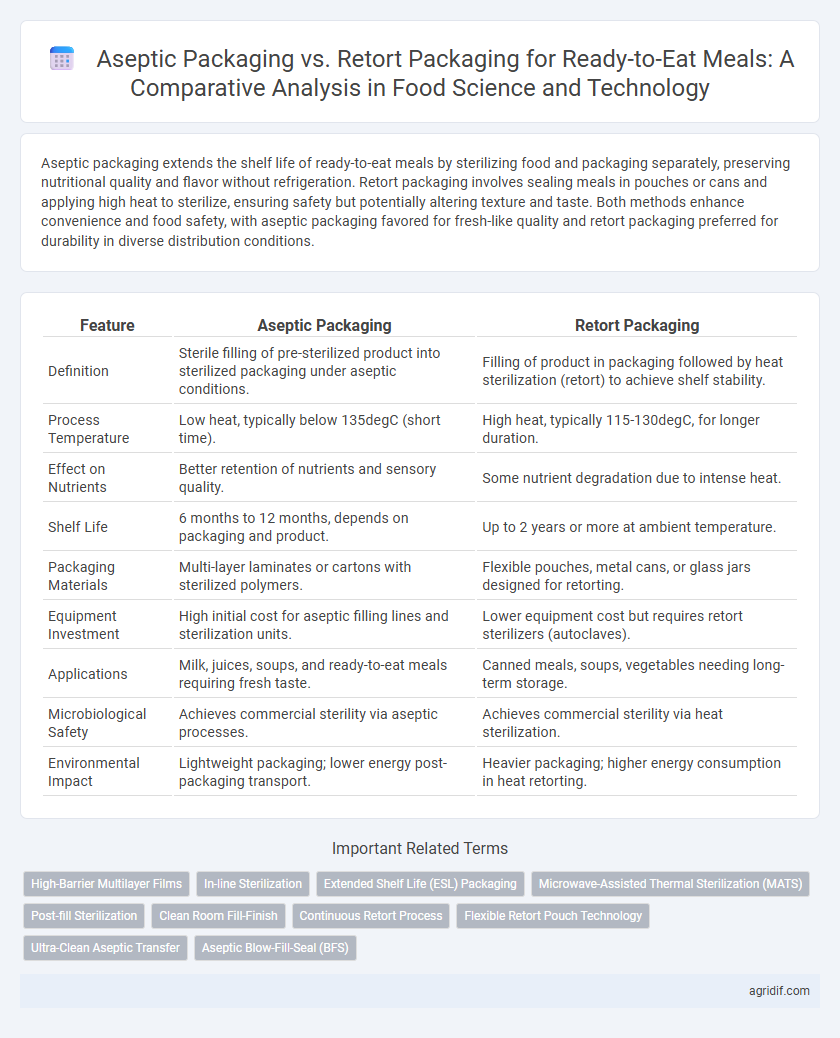

| Feature | Aseptic Packaging | Retort Packaging |

|---|---|---|

| Definition | Sterile filling of pre-sterilized product into sterilized packaging under aseptic conditions. | Filling of product in packaging followed by heat sterilization (retort) to achieve shelf stability. |

| Process Temperature | Low heat, typically below 135degC (short time). | High heat, typically 115-130degC, for longer duration. |

| Effect on Nutrients | Better retention of nutrients and sensory quality. | Some nutrient degradation due to intense heat. |

| Shelf Life | 6 months to 12 months, depends on packaging and product. | Up to 2 years or more at ambient temperature. |

| Packaging Materials | Multi-layer laminates or cartons with sterilized polymers. | Flexible pouches, metal cans, or glass jars designed for retorting. |

| Equipment Investment | High initial cost for aseptic filling lines and sterilization units. | Lower equipment cost but requires retort sterilizers (autoclaves). |

| Applications | Milk, juices, soups, and ready-to-eat meals requiring fresh taste. | Canned meals, soups, vegetables needing long-term storage. |

| Microbiological Safety | Achieves commercial sterility via aseptic processes. | Achieves commercial sterility via heat sterilization. |

| Environmental Impact | Lightweight packaging; lower energy post-packaging transport. | Heavier packaging; higher energy consumption in heat retorting. |

Introduction to Aseptic and Retort Packaging in Ready-to-Eat Meals

Aseptic packaging involves sterilizing the food and packaging separately before filling in a sterile environment, preserving the nutritional quality and extending shelf life without refrigeration. Retort packaging uses heat treatment after sealing, applying high temperature and pressure to sterilize the product within the sealed container, ensuring microbial safety and long shelf stability. Both methods enable ready-to-eat meals to maintain safety and quality, but aseptic packaging offers better retention of flavor and nutrients due to lower thermal exposure.

Fundamentals of Aseptic Packaging Technology

Aseptic packaging technology involves sterilizing both the food product and packaging separately before filling and sealing in a sterile environment, preserving sensory and nutritional qualities of ready-to-eat meals. This method relies on ultra-high temperature (UHT) treatment and hermetic sealing with multilayer polymer or foil laminate materials to prevent microbial contamination and extend shelf life without refrigeration. In contrast to retort packaging, which sterilizes the filled package as a unit, aseptic packaging reduces thermal damage and processing time, enhancing product quality and energy efficiency in food processing.

Fundamentals of Retort Packaging Technology

Retort packaging technology involves placing ready-to-eat meals in flexible pouches or rigid containers, which are then sealed and subjected to high-temperature sterilization inside pressurized retort vessels, ensuring microbial safety and shelf stability without refrigeration. This method differs from aseptic packaging, where sterilization of food and packaging occurs separately before filling in sterile environments. Retort processing retains nutritional quality and texture better than traditional canning, making it a preferred choice for extended shelf life in convenience foods.

Shelf Life Comparison: Aseptic vs Retort Packaging

Aseptic packaging significantly extends the shelf life of ready-to-eat meals by sterilizing food and packaging separately before sealing, maintaining quality for 6 to 12 months without refrigeration. Retort packaging involves sealing the product in sterilized containers and heating to high temperatures, offering a shelf life of up to 1 to 3 years but may cause slight nutritional and sensory degradation. The choice between aseptic and retort packaging depends on the desired balance between shelf life extension, product quality, and thermal processing impact.

Impact on Nutritional Quality and Food Safety

Aseptic packaging preserves the nutritional quality of ready-to-eat meals by minimizing heat exposure, maintaining higher levels of vitamins and antioxidants compared to retort packaging, which involves high-temperature sterilization that can degrade sensitive nutrients. Food safety in aseptic packaging is ensured through sterile filling and sealing processes that prevent microbial contamination without compromising texture and flavor. Retort packaging offers proven microbial inactivation through intense heat treatment, providing a long shelf life but often at the expense of nutritional and sensory characteristics.

Packaging Materials and Environmental Sustainability

Aseptic packaging for ready-to-eat meals typically uses multi-layered materials such as polyethylene, aluminum foil, and paperboard, enabling lightweight, shelf-stable, and energy-efficient storage, reducing carbon footprint compared to retort packaging. Retort packaging relies on thicker flexible pouches or metal cans made from aluminum or steel, which require high thermal processing, increasing energy consumption and environmental impact. The recyclability of aseptic cartons is improving but remains challenged by composite layers, while retort pouches often have limited recyclability due to mixed polymers, affecting sustainability efforts in both packaging systems.

Processing Efficiency and Cost Considerations

Aseptic packaging enables rapid sterilization and filling processes that significantly reduce processing time and energy consumption compared to retort packaging, which relies on slower, high-temperature batch sterilization. The initial investment cost for aseptic systems is higher due to complex equipment and sterile environments, but it offers lower operational costs and extended shelf life without preservatives, enhancing overall cost efficiency. Retort packaging involves lower upfront costs but incurs higher energy use, longer cycle times, and increased labor, impacting throughput and manufacturing expenses adversely in high-volume ready-to-eat meal production.

Consumer Acceptance and Market Trends

Consumer acceptance of aseptic packaging for ready-to-eat meals is rising due to its superior ability to preserve taste, texture, and nutritional quality without the need for preservatives. Retort packaging remains popular for its extended shelf life and cost-effectiveness, but its impact on product flavor and texture can limit consumer preference. Market trends indicate a growing demand for aseptic-packaged meals driven by health-conscious buyers and a shift towards premium, fresh-tasting convenience foods.

Regulatory Standards and Compliance

Aseptic packaging for ready-to-eat meals must comply with FDA's 21 CFR Part 113, ensuring commercial sterility through precise temperature and time controls during sterilization. Retort packaging follows similar regulatory frameworks but often requires validation under stringent thermal processing standards to prevent microbial contamination. Both methods necessitate thorough documentation and adherence to HACCP plans to meet global food safety regulations and maintain product shelf stability.

Future Innovations in Ready-to-Eat Meal Packaging

Future innovations in ready-to-eat meal packaging emphasize aseptic technology for its superior preservation of nutritional quality and extended shelf life without refrigeration, leveraging ultra-high temperature sterilization and microbial control. Retort packaging improvements focus on advanced barrier materials and intelligent sensors to enhance thermal processing efficiency and real-time quality monitoring, reducing nutrient degradation and ensuring food safety. Integration of smart packaging with IoT and biodegradable materials is anticipated to revolutionize sustainability and consumer engagement in food science and technology.

Related Important Terms

High-Barrier Multilayer Films

High-barrier multilayer films in aseptic packaging provide superior oxygen and moisture resistance, preserving the nutritional quality and extending the shelf life of ready-to-eat meals without refrigeration. Retort packaging, while effective for sterilization through heat treatment, often compromises film integrity and texture due to the high-temperature process, making aseptic packaging preferable for maintaining food safety and sensory attributes.

In-line Sterilization

Aseptic packaging employs in-line sterilization by separately sterilizing the food and packaging materials before filling them in a sterile environment, preserving nutritional quality and flavor retention in ready-to-eat meals. Retort packaging uses thermal sterilization after filling, subjecting meals to higher temperatures that can impact texture and nutrient stability but ensure extended shelf life.

Extended Shelf Life (ESL) Packaging

Aseptic packaging uses ultra-high temperature (UHT) sterilization and sterile filling to extend the shelf life of ready-to-eat meals up to 6-12 months without refrigeration, preserving nutritional quality and flavor better than retort packaging. Retort packaging relies on thermal sterilization after sealing, offering extended shelf life of 6-18 months but often causes texture and nutrient degradation due to higher heat exposure during processing.

Microwave-Assisted Thermal Sterilization (MATS)

Microwave-Assisted Thermal Sterilization (MATS) enhances aseptic packaging by rapidly sterilizing ready-to-eat meals at lower temperatures, preserving sensory quality and nutritional value compared to traditional retort packaging. Retort packaging relies on high-temperature, long-duration heating that often compromises texture and flavor, while MATS integrates microwave energy with pressurized hot water to achieve uniform sterilization with minimal thermal damage.

Post-fill Sterilization

Aseptic packaging involves sterilizing food and packaging separately before filling in a sterile environment, preserving sensory and nutritional quality by avoiding heat damage through post-fill sterilization. Retort packaging uses post-fill sterilization by sealing food in containers and subjecting the entire package to high-temperature thermal treatment, ensuring microbial safety but potentially impacting texture and flavor.

Clean Room Fill-Finish

Aseptic packaging employs sterile processing and filling within a clean room environment to maintain product sterility and extend shelf life without refrigeration, ensuring high quality and safety of ready-to-eat meals. Retort packaging involves heat sterilization after filling, which can impact texture and nutrient retention, whereas clean room fill-finish in aseptic processing preserves sensory and nutritional attributes more effectively.

Continuous Retort Process

The continuous retort process in aseptic packaging offers enhanced heat penetration and microbial safety for ready-to-eat meals by maintaining a consistent temperature profile, reducing nutrient degradation compared to traditional retort packaging. This technology improves product shelf life and quality through efficient sterilization while minimizing thermal impact on flavor and texture.

Flexible Retort Pouch Technology

Flexible retort pouch technology offers superior thermal processing efficiency and shelf-life extension for ready-to-eat meals compared to traditional aseptic packaging methods. This packaging innovation enhances nutrient retention, improves flavor profile, and reduces packaging waste through lightweight, durable materials designed to withstand high-temperature sterilization.

Ultra-Clean Aseptic Transfer

Ultra-Clean Aseptic Transfer in aseptic packaging ensures sterilized product and packaging remain contamination-free during filling, preserving the nutritional quality and extending shelf life of ready-to-eat meals without refrigeration. Retort packaging relies on high-temperature sterilization after sealing, which can degrade heat-sensitive nutrients and alter texture compared to aseptic methods.

Aseptic Blow-Fill-Seal (BFS)

Aseptic Blow-Fill-Seal (BFS) technology offers superior sterilization of ready-to-eat meals by forming, filling, and sealing containers in a sterile environment, reducing microbial contamination and preserving nutritional quality better than traditional retort packaging. BFS enables lightweight, high-barrier packaging with extended shelf life without refrigeration, making it ideal for heat-sensitive food matrices compared to the high thermal load and nutrient degradation typical of retort processes.

Aseptic packaging vs retort packaging for ready-to-eat meals Infographic

agridif.com

agridif.com