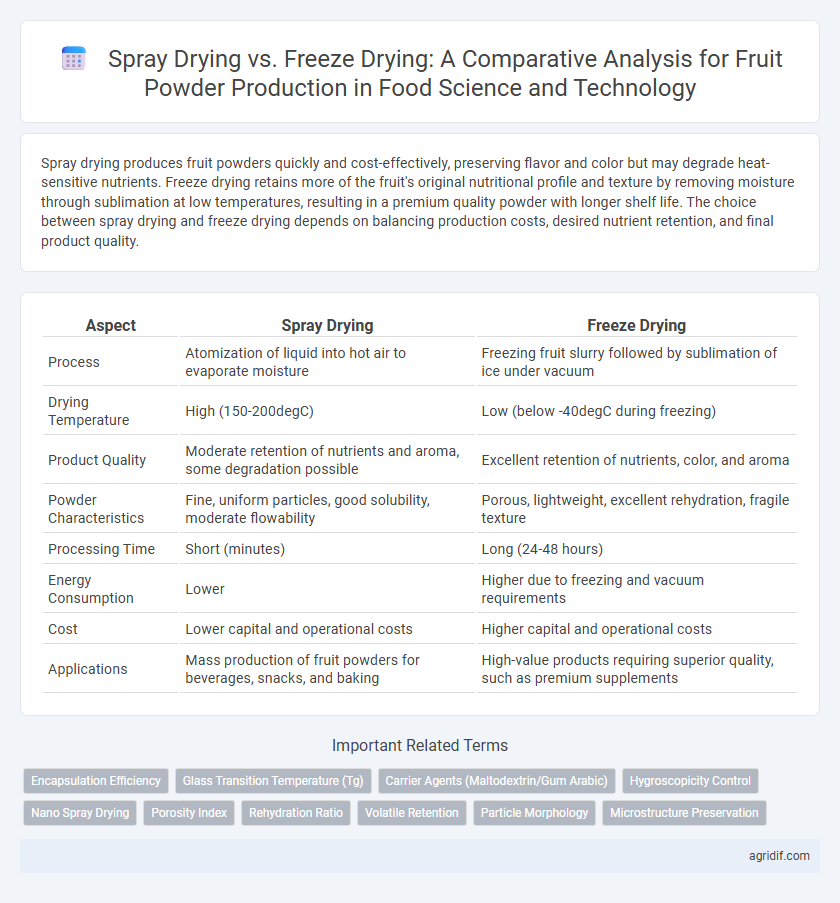

Spray drying produces fruit powders quickly and cost-effectively, preserving flavor and color but may degrade heat-sensitive nutrients. Freeze drying retains more of the fruit's original nutritional profile and texture by removing moisture through sublimation at low temperatures, resulting in a premium quality powder with longer shelf life. The choice between spray drying and freeze drying depends on balancing production costs, desired nutrient retention, and final product quality.

Table of Comparison

| Aspect | Spray Drying | Freeze Drying |

|---|---|---|

| Process | Atomization of liquid into hot air to evaporate moisture | Freezing fruit slurry followed by sublimation of ice under vacuum |

| Drying Temperature | High (150-200degC) | Low (below -40degC during freezing) |

| Product Quality | Moderate retention of nutrients and aroma, some degradation possible | Excellent retention of nutrients, color, and aroma |

| Powder Characteristics | Fine, uniform particles, good solubility, moderate flowability | Porous, lightweight, excellent rehydration, fragile texture |

| Processing Time | Short (minutes) | Long (24-48 hours) |

| Energy Consumption | Lower | Higher due to freezing and vacuum requirements |

| Cost | Lower capital and operational costs | Higher capital and operational costs |

| Applications | Mass production of fruit powders for beverages, snacks, and baking | High-value products requiring superior quality, such as premium supplements |

Introduction to Fruit Powder Production Technologies

Spray drying and freeze drying are two prominent technologies in fruit powder production, each offering unique advantages in preserving flavor, nutrients, and color. Spray drying is a cost-effective method that rapidly dries fruit juices through hot air, yielding fine powders with good solubility but potential nutrient degradation. Freeze drying, involving sublimation of frozen fruit, produces high-quality powders with superior retention of bioactive compounds and texture, though with higher operational costs and longer processing times.

Overview of Spray Drying and Freeze Drying Methods

Spray drying involves atomizing fruit pulp into a hot-air chamber, rapidly evaporating moisture to produce fine, stable fruit powders with high solubility and low moisture content. Freeze drying preserves bioactive compounds and flavor by sublimating frozen fruit puree under low temperature and pressure, resulting in porous powders with excellent rehydration properties. Both methods balance quality attributes and processing costs, with spray drying favored for cost-efficiency and freeze drying for superior nutrient retention.

Mechanisms of Spray Drying in Fruit Powders

Spray drying in fruit powder production involves atomizing fruit puree into fine droplets, which are then exposed to hot air, causing rapid moisture evaporation and the formation of dry particles. The mechanism relies on the heat and mass transfer between the droplets and drying air, preserving flavor and nutritional compounds while producing uniform, free-flowing powder. Unlike freeze drying, spray drying operates at higher temperatures but offers faster processing times and cost-effective scalability for fruit powders with controlled particle size and moisture content.

Principles of Freeze Drying for Fruit Processing

Freeze drying for fruit powder production relies on sublimation, where frozen fruit undergoes low-pressure conditions allowing ice to convert directly into vapor without passing through the liquid phase. This preserves cellular structure, nutrients, and flavor compounds by minimizing heat exposure and oxidation compared to spray drying. The resulting fruit powder retains superior rehydration properties, color stability, and bioactive compounds, making freeze drying ideal for high-quality fruit powders in food science and technology.

Comparative Analysis of Nutrient Retention

Spray drying of fruit powders provides rapid moisture removal at high temperatures, which can cause moderate nutrient degradation, particularly of heat-sensitive vitamins like vitamin C and some polyphenols. Freeze drying preserves nutrient content more effectively by sublimating ice under low temperature and pressure, retaining up to 90-95% of antioxidants and vitamins. However, spray drying offers greater cost-efficiency and faster processing times, making the choice dependent on balancing nutrient retention against operational scalability.

Effects on Flavor, Color, and Sensory Attributes

Spray drying preserves the bright color and fruity aroma of fruit powders due to rapid moisture removal but may cause slight flavor degradation from heat exposure. Freeze drying better retains the original flavor profile and vibrant color by sublimating moisture under low temperatures, resulting in superior sensory attributes like texture and aroma intensity. Both methods impact the final product's sensory quality, with freeze drying often preferred for premium fruit powders requiring high flavor and color fidelity.

Energy Consumption and Cost Efficiency

Spray drying consumes significantly less energy compared to freeze drying, making it more cost-efficient for large-scale fruit powder production. Freeze drying, while offering superior nutrient retention and flavor preservation, involves higher operational costs due to prolonged drying times and energy-intensive freezing processes. The choice between these methods hinges on balancing energy consumption constraints with desired product quality and budget considerations.

Impact on Microbial Stability and Shelf Life

Spray drying exposes fruit powders to high temperatures briefly, effectively reducing microbial load and extending shelf life by inhibiting microbial growth. Freeze drying preserves nutritional and sensory qualities while maintaining low moisture content, resulting in superior microbial stability and longer shelf life under proper storage conditions. Selection between spray drying and freeze drying depends on the desired balance between microbial safety, product quality, and cost efficiency in fruit powder production.

Industrial Applications and Scale-up Considerations

Spray drying offers rapid processing and cost-effective scalability for large-scale fruit powder production, making it ideal for industrial applications requiring continuous operation. Freeze drying preserves nutritional value and flavor more effectively but involves higher energy consumption and longer processing times, limiting its use to premium product lines or smaller batch sizes. Scale-up considerations favor spray drying due to simpler equipment and lower operational costs, while freeze drying demands careful control of freezing and vacuum conditions, impacting throughput and capital investment.

Sustainability and Environmental Impacts

Spray drying uses higher energy consumption due to elevated temperatures but offers faster drying rates and lower operational costs compared to freeze drying. Freeze drying, while consuming more energy mainly from prolonged freezing and sublimation processes, maintains superior nutrient retention and reduces chemical degradation in fruit powders. Evaluating environmental impacts requires balancing energy use with product quality and shelf stability, where advancements in renewable energy integration improve sustainability for both methods.

Related Important Terms

Encapsulation Efficiency

Spray drying offers higher encapsulation efficiency for fruit powder production by rapidly converting liquid extracts into stable powders with minimal nutrient loss. Freeze drying maintains better retention of volatile compounds and bioactive nutrients but generally exhibits lower encapsulation efficiency due to longer processing times and higher porosity in the final powder structure.

Glass Transition Temperature (Tg)

Spray drying fruit powders typically requires careful control of inlet temperature to stay below the glass transition temperature (Tg) of sugars and acids, preventing stickiness and caking during processing. Freeze drying preserves fruit powder quality by operating below Tg, minimizing molecular mobility and maintaining structural integrity, but it is more energy-intensive and costly compared to spray drying.

Carrier Agents (Maltodextrin/Gum Arabic)

Spray drying and freeze drying both utilize carrier agents like maltodextrin and gum arabic to improve powder yield, enhance solubility, and protect sensitive fruit bioactives; maltodextrin offers low viscosity and cost efficiency, while gum arabic provides superior emulsification and encapsulation properties. In spray drying, maltodextrin prevents stickiness and improves drying efficiency, whereas freeze drying benefits from gum arabic's film-forming abilities to maintain powder stability and preserve flavor compounds.

Hygroscopicity Control

Spray drying produces fruit powders with higher hygroscopicity due to the retention of amorphous sugars, requiring effective moisture barrier coatings to enhance shelf life. Freeze drying results in powders with lower hygroscopicity by preserving cellular integrity and reducing surface area exposed to moisture, making it optimal for long-term hygroscopicity control in fruit powder storage.

Nano Spray Drying

Nano spray drying offers superior control over particle size and morphology compared to conventional spray drying and freeze drying, enhancing the solubility and bioavailability of fruit powders. This technology operates at lower temperatures, preserving heat-sensitive bioactive compounds, making it ideal for producing high-quality fruit powders with improved nutritional and functional properties.

Porosity Index

Spray drying produces fruit powders with a lower porosity index due to rapid moisture evaporation creating denser particles, while freeze drying yields powders with a higher porosity index because sublimation preserves the porous cellular structure. The increased porosity in freeze-dried fruit powders enhances solubility and rehydration rates compared to the more compact spray-dried powders.

Rehydration Ratio

Spray drying produces fruit powders with a lower rehydration ratio due to high temperature exposure causing partial cell structure collapse, resulting in reduced water absorption capacity. Freeze drying preserves cell integrity better, yielding fruit powders with a higher rehydration ratio and improved retention of flavor and nutrients.

Volatile Retention

Spray drying rapidly removes moisture by hot air, often resulting in significant volatile compound loss, which affects aroma and flavor in fruit powder. Freeze drying preserves volatile retention more effectively by sublimation under low temperature and pressure, maintaining the fruit's sensory and nutritional qualities.

Particle Morphology

Spray drying produces fruit powders with spherical, smooth particles that exhibit uniform size distribution suitable for quick reconstitution. Freeze drying generates porous, irregularly shaped particles with higher surface area, enhancing solubility and retention of volatile compounds in fruit powders.

Microstructure Preservation

Spray drying often results in smaller, more uniform particles but can cause significant microstructural changes due to high temperatures, leading to loss of volatile compounds and altered cellular integrity. Freeze drying preserves the microstructure of fruit powders more effectively by sublimating water under low temperature and pressure, maintaining the porous structure and nutrient retention critical for high-quality fruit powder production.

Spray drying vs freeze drying for fruit powder production Infographic

agridif.com

agridif.com