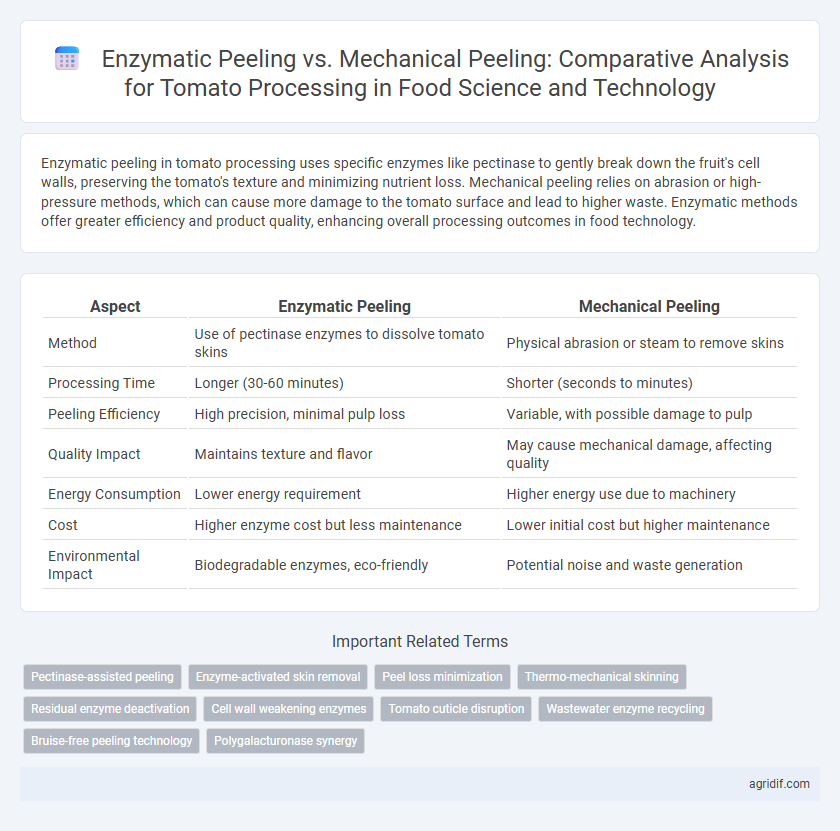

Enzymatic peeling in tomato processing uses specific enzymes like pectinase to gently break down the fruit's cell walls, preserving the tomato's texture and minimizing nutrient loss. Mechanical peeling relies on abrasion or high-pressure methods, which can cause more damage to the tomato surface and lead to higher waste. Enzymatic methods offer greater efficiency and product quality, enhancing overall processing outcomes in food technology.

Table of Comparison

| Aspect | Enzymatic Peeling | Mechanical Peeling |

|---|---|---|

| Method | Use of pectinase enzymes to dissolve tomato skins | Physical abrasion or steam to remove skins |

| Processing Time | Longer (30-60 minutes) | Shorter (seconds to minutes) |

| Peeling Efficiency | High precision, minimal pulp loss | Variable, with possible damage to pulp |

| Quality Impact | Maintains texture and flavor | May cause mechanical damage, affecting quality |

| Energy Consumption | Lower energy requirement | Higher energy use due to machinery |

| Cost | Higher enzyme cost but less maintenance | Lower initial cost but higher maintenance |

| Environmental Impact | Biodegradable enzymes, eco-friendly | Potential noise and waste generation |

Introduction to Tomato Peeling Methods

Enzymatic peeling of tomatoes utilizes proteolytic and pectolytic enzymes to break down cell wall components, offering precise removal of skins with minimal pulp damage and improved processing efficiency. Mechanical peeling relies on abrasive or steam methods to physically separate the skin, often causing higher wastage and potential quality degradation due to harsh treatment. Comparing enzymatic and mechanical peeling reveals significant differences in yield, texture preservation, and scalability in tomato processing operations.

Overview of Enzymatic Peeling in Tomato Processing

Enzymatic peeling in tomato processing involves the use of pectinases and cellulases to selectively degrade the tomato skin, enhancing peel removal efficiency while preserving fruit integrity. This method reduces mechanical damage and minimizes nutrient loss compared to traditional mechanical peeling techniques. Industrial applications demonstrate that enzymatic peeling improves yield, texture, and overall product quality in tomato-based products.

Mechanical Peeling Techniques for Tomatoes

Mechanical peeling techniques for tomatoes primarily include abrasion peeling, steam peeling, and lye peeling, each offering distinct advantages in efficiency and quality retention. Abrasion peeling uses friction to remove skins rapidly, minimizing tissue damage and preserving tomato firmness and flavor. Steam peeling provides an eco-friendly alternative, utilizing high-temperature steam to loosen skins for easier removal, while lye peeling employs alkaline solutions to facilitate rapid skin separation, though it requires thorough washing to prevent chemical residues.

Efficiency Comparison: Enzymatic vs Mechanical Peeling

Enzymatic peeling in tomato processing offers higher precision and reduces fruit damage compared to mechanical peeling, leading to improved yield and product quality. The use of pectinase and cellulase enzymes specifically targets cell wall components, resulting in cleaner skin removal and less waste. Mechanical peeling, while faster, often causes higher pulp loss and increased energy consumption, making enzymatic methods more efficient in preserving tomato integrity.

Impact on Tomato Quality: Texture, Color, and Flavor

Enzymatic peeling enhances tomato quality by preserving the fruit's natural texture, maintaining a firmer and less damaged surface compared to mechanical peeling, which often causes skin tearing and mushiness. Enzymes such as pectinases selectively break down the tomato's skin without affecting the flesh, resulting in vibrant color retention and superior flavor preservation due to minimal heat generation. Mechanical peeling can lead to color degradation and flavor loss from physical abrasion and oxidation, making enzymatic peeling the preferred method for high-quality tomato processing.

Nutritional Retention in Different Peeling Methods

Enzymatic peeling in tomato processing preserves higher levels of vitamins, antioxidants, and phenolic compounds compared to mechanical peeling, which often causes nutrient losses due to heat and abrasion. Studies show enzymatic methods maintain better retention of lycopene and vitamin C, crucial for the nutritional quality of tomato products. This method also reduces damage to the delicate tomato tissues, enhancing overall nutrient bioavailability in processed tomatoes.

Environmental and Economic Considerations

Enzymatic peeling of tomatoes significantly reduces water consumption and energy use compared to mechanical peeling, lowering the environmental footprint of processing plants. Economically, enzymatic methods minimize equipment wear and decrease processing time, leading to cost savings through enhanced throughput and reduced maintenance expenses. Waste generated from enzymatic peeling is biodegradable and more easily treated, further supporting sustainable and cost-effective tomato processing operations.

Industrial Scalability of Peeling Technologies

Enzymatic peeling in tomato processing offers high precision and reduced tissue damage, enhancing product quality and yield in large-scale operations. Mechanical peeling provides faster throughput and lower initial costs but often results in higher waste and inconsistent peel removal at industrial volumes. Industrial scalability favors enzymatic peeling for its ability to maintain uniformity and minimize damage, despite higher enzyme costs compared to traditional mechanical methods.

Challenges and Limitations in Tomatos Peeling

Enzymatic peeling of tomatoes offers precision and reduced mechanical damage but faces challenges such as high enzyme cost, limited shelf-life, and sensitivity to processing conditions like pH and temperature. Mechanical peeling is more cost-effective and faster yet often results in higher product loss, inconsistent peel removal, and increased risk of pulp damage due to abrasive forces. Both methods struggle with tomato variety variability and scale-up issues impacting efficiency and final product quality in industrial processing.

Future Trends in Tomato Peeling Technologies

Enzymatic peeling in tomato processing offers precise cell wall degradation, enhancing peel removal efficiency while preserving fruit integrity and minimizing waste, positioning it as a sustainable alternative to traditional mechanical peeling methods. Emerging technologies integrate enzyme cocktails optimized for specific tomato cultivars, leveraging biotechnological advances to reduce processing time and energy consumption. Future trends emphasize combining enzymatic methods with automation and real-time monitoring systems to improve throughput, quality control, and environmental impact in large-scale tomato peeling operations.

Related Important Terms

Pectinase-assisted peeling

Pectinase-assisted enzymatic peeling enhances tomato processing by selectively degrading pectin in the fruit's cell walls, resulting in higher peel removal efficiency and reduced mechanical damage compared to traditional mechanical peeling methods. This enzymatic approach improves process yield, maintains tomato quality, and reduces energy consumption, making it a superior alternative in industrial tomato peeling applications.

Enzyme-activated skin removal

Enzymatic peeling in tomato processing employs pectinase and cellulase enzymes to target and weaken the fruit's skin structure, enabling precise and efficient skin removal without damaging the tomato flesh. This method enhances yield quality and reduces mechanical stress compared to traditional mechanical peeling, which relies on abrasive or thermal forces that often cause product loss and uneven peeling.

Peel loss minimization

Enzymatic peeling in tomato processing uses pectinase and cellulase enzymes to selectively degrade the peel, significantly reducing peel loss compared to mechanical peeling, which often causes excessive fruit damage and higher waste. By preserving tomato flesh integrity, enzymatic methods enhance yield and product quality, making them a preferred choice for minimizing peel loss in food science applications.

Thermo-mechanical skinning

Thermo-mechanical skinning in tomato processing combines controlled heat application with mechanical peeling to enhance skin separation efficiency, reducing damage to the pulp compared to purely mechanical methods. Enzymatic peeling offers gentler skin removal by targeting pectin degradation, improving yield and maintaining fruit integrity, but thermo-mechanical peeling is preferred for faster processing in large-scale operations.

Residual enzyme deactivation

Enzymatic peeling in tomato processing requires precise residual enzyme deactivation to prevent over-softening and preserve fruit integrity, typically achieved through controlled thermal inactivation or pH adjustment. Mechanical peeling eliminates the need for enzyme deactivation but may cause surface damage and reduce yield, making enzymatic methods advantageous for maintaining product quality when residual enzyme control is optimized.

Cell wall weakening enzymes

Enzymatic peeling in tomato processing leverages cell wall weakening enzymes such as pectinases and cellulases to selectively degrade pectin and cellulose, enabling more efficient skin removal while preserving fruit integrity. Mechanical peeling relies on physical abrasion methods that often cause higher tissue damage and yield loss compared to the precise action of enzymes targeting middle lamella dissolution.

Tomato cuticle disruption

Enzymatic peeling of tomatoes utilizes pectinases and cellulases to target and disrupt the tomato cuticle's polysaccharide matrix, resulting in efficient skin removal with minimal damage to the underlying tissue. Mechanical peeling relies on abrasion and pressure, which can cause uneven cuticle disruption and increased waste due to excessive pulp loss.

Wastewater enzyme recycling

Enzymatic peeling of tomatoes significantly reduces wastewater volume and organic load compared to mechanical peeling, facilitating more efficient enzyme recovery and recycling processes. Implementing membrane filtration techniques in enzymatic peeling wastewater systems enhances enzyme reuse, minimizing operational costs and environmental impact in tomato processing industries.

Bruise-free peeling technology

Enzymatic peeling utilizes pectinase and cellulase enzymes to gently degrade tomato skin without causing surface damage, preserving the fruit's integrity and reducing bruising compared to mechanical peeling methods that rely on abrasive forces. This bruise-free peeling technology improves product quality by minimizing cell rupture and maintaining firmness, essential for high-grade tomato processing applications.

Polygalacturonase synergy

Enzymatic peeling using polygalacturonase enhances tomato processing by selectively degrading pectin-rich cell walls, resulting in better peel removal with minimal fruit damage compared to mechanical peeling. Polygalacturonase synergy with other cell wall-degrading enzymes improves peeling efficiency, preserves tomato integrity, and increases processing yield.

Enzymatic peeling vs mechanical peeling for tomato processing Infographic

agridif.com

agridif.com