Pulsed electric field (PEF) technology preserves juice by applying short bursts of high voltage to inactivate microorganisms while maintaining fresh flavor and nutrient retention. High-pressure processing (HPP) uses intense pressure to achieve microbial safety and extend shelf life without heat, preserving vitamins and antioxidants effectively. Both methods offer non-thermal alternatives to traditional pasteurization, with PEF excelling in energy efficiency and HPP ensuring broader microbial inactivation.

Table of Comparison

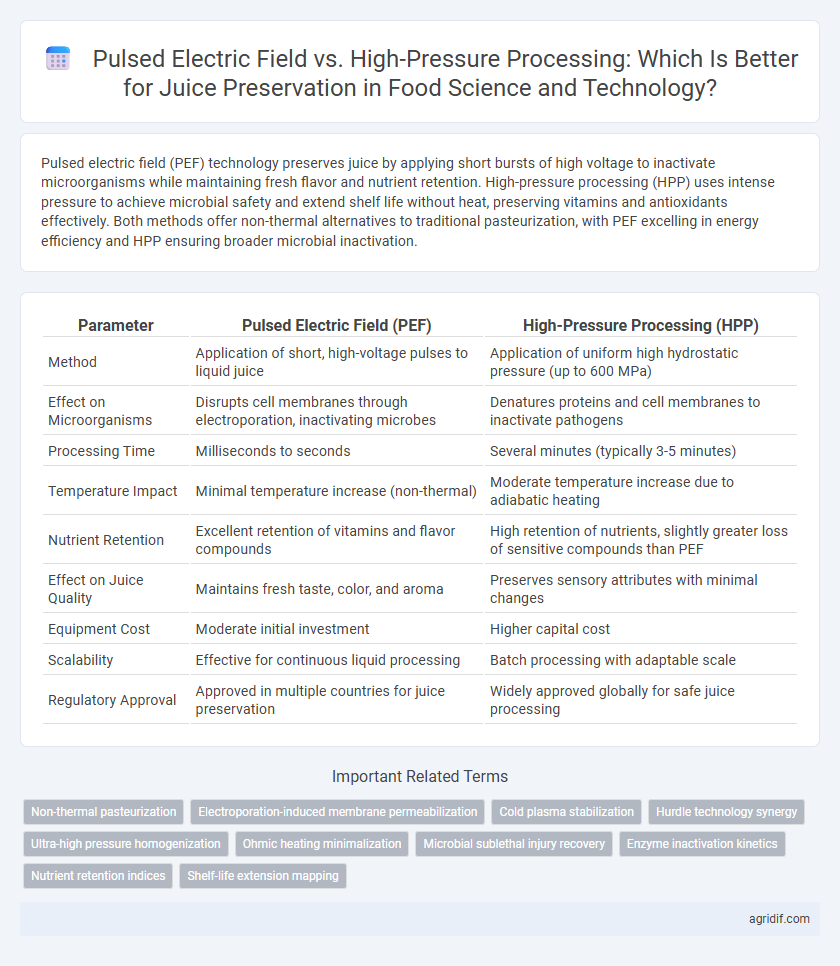

| Parameter | Pulsed Electric Field (PEF) | High-Pressure Processing (HPP) |

|---|---|---|

| Method | Application of short, high-voltage pulses to liquid juice | Application of uniform high hydrostatic pressure (up to 600 MPa) |

| Effect on Microorganisms | Disrupts cell membranes through electroporation, inactivating microbes | Denatures proteins and cell membranes to inactivate pathogens |

| Processing Time | Milliseconds to seconds | Several minutes (typically 3-5 minutes) |

| Temperature Impact | Minimal temperature increase (non-thermal) | Moderate temperature increase due to adiabatic heating |

| Nutrient Retention | Excellent retention of vitamins and flavor compounds | High retention of nutrients, slightly greater loss of sensitive compounds than PEF |

| Effect on Juice Quality | Maintains fresh taste, color, and aroma | Preserves sensory attributes with minimal changes |

| Equipment Cost | Moderate initial investment | Higher capital cost |

| Scalability | Effective for continuous liquid processing | Batch processing with adaptable scale |

| Regulatory Approval | Approved in multiple countries for juice preservation | Widely approved globally for safe juice processing |

Introduction to Non-Thermal Juice Preservation Technologies

Pulsed electric field (PEF) and high-pressure processing (HPP) are prominent non-thermal technologies for juice preservation, maintaining nutritional quality and sensory attributes better than traditional thermal methods. PEF employs short bursts of high voltage to inactivate microorganisms by disrupting cell membranes, while HPP applies intense hydrostatic pressure uniformly to achieve microbial inactivation without significant heat generation. These methods effectively extend shelf life, retain vitamins, antioxidants, and flavor compounds, positioning them as innovative solutions in food science and technology for fresh juice stabilization.

Overview of Pulsed Electric Field (PEF) Processing

Pulsed Electric Field (PEF) processing is a non-thermal food preservation technique that uses short bursts of high voltage to inactivate microorganisms in juice, thereby extending shelf life while maintaining nutritional and sensory qualities. This method disrupts microbial cell membranes through electroporation without significant heating, preserving heat-sensitive vitamins and flavors. Compared to high-pressure processing, PEF offers rapid treatment times and energy efficiency, making it a promising technology for fresh juice preservation.

Fundamentals of High-Pressure Processing (HPP) in Juice Preservation

High-Pressure Processing (HPP) in juice preservation utilizes isostatic pressure typically ranging from 400 to 600 MPa to inactivate spoilage microorganisms and enzymes without significant heat application, preserving the nutritional and sensory qualities of fresh juice. The non-thermal nature of HPP disrupts cellular membranes and enzyme structures, enhancing microbial safety while maintaining vitamin C, antioxidants, and flavor compounds. Compared to Pulsed Electric Field (PEF), HPP offers deeper penetration and uniform pressure distribution, ensuring effective pathogen inactivation and extended shelf life in a wide range of juice types.

Microbial Inactivation: PEF vs HPP

Pulsed electric field (PEF) technology effectively inactivates microorganisms in juice by disrupting cell membranes through high-voltage pulses, preserving nutritional and sensory qualities. High-pressure processing (HPP) achieves microbial inactivation by applying intense hydrostatic pressure, causing protein denaturation and membrane disruption, with broad-spectrum effectiveness against bacteria, yeasts, and molds. Comparative studies show HPP often delivers higher log reductions of pathogens like Escherichia coli and Listeria monocytogenes, while PEF maintains better retention of heat-sensitive vitamins and bioactive compounds.

Nutritional Retention and Quality Attributes

Pulsed electric field (PEF) technology preserves juice nutritional content more effectively by maintaining higher levels of vitamin C and antioxidants compared to high-pressure processing (HPP), which can cause slight nutrient degradation due to pressure-induced changes. PEF also better retains sensory qualities such as color, flavor, and texture, offering minimal thermal impact and preserving fresh juice characteristics. High-pressure processing guarantees microbial safety but may alter juice viscosity and color, impacting overall quality attributes.

Impact on Juice Sensory Properties

Pulsed electric field (PEF) treatment preserves juice sensory properties such as color, flavor, and freshness more effectively than high-pressure processing (HPP) by minimizing thermal degradation and enzymatic browning. HPP may cause slight changes in texture and taste due to pressure-induced modifications affecting volatile aroma compounds. Both technologies maintain nutritional quality, but PEF offers superior retention of natural juice characteristics preferred by consumers.

Processing Efficiency and Energy Consumption

Pulsed electric field (PEF) technology offers higher processing efficiency than high-pressure processing (HPP) by enabling rapid microbial inactivation at lower temperatures, preserving juice quality while reducing treatment time. PEF consumes significantly less energy per liter processed due to shorter processing cycles and lower pressure requirements compared to HPP, which demands high hydraulic pressure up to 600 MPa for several minutes. This energy efficiency positions PEF as a cost-effective and environmentally sustainable alternative for juice preservation in industrial applications.

Industrial Scalability and Economic Considerations

Pulsed electric field (PEF) technology offers rapid microbial inactivation with lower energy consumption, facilitating easier integration into existing juice production lines and reducing operational costs in large-scale settings. High-pressure processing (HPP) provides superior preservation of sensory and nutritional qualities but requires substantial initial capital investment and higher maintenance expenses, challenging cost-effectiveness for small to medium enterprises. Industrial scalability favors PEF for continuous processing and lower footprint, whereas HPP's batch mode and equipment size limit throughput, influencing economic viability based on production volume demands.

Regulatory and Safety Aspects of PEF and HPP

Pulsed Electric Field (PEF) and High-Pressure Processing (HPP) are both recognized as non-thermal preservation technologies with distinct regulatory frameworks depending on regional food safety authorities such as the FDA and EFSA. PEF is often subject to stringent electrical safety standards and validation of inactivation mechanisms for microbial safety, while HPP benefits from extensive global regulatory acceptance due to its proven capability to maintain juice quality and eliminate pathogens without chemical additives. Compliance with Good Manufacturing Practices (GMP) and validated critical control points are essential for both methods to ensure consumer safety and adherence to regulatory requirements in juice preservation.

Future Prospects and Innovations in Juice Preservation

Pulsed electric field (PEF) and high-pressure processing (HPP) are advancing juice preservation by enhancing microbial inactivation while retaining nutritional and sensory qualities. Innovations in PEF technology include integration with other non-thermal methods, such as ultrasonication, to improve energy efficiency and maximize bioactive compound retention. HPP developments focus on scaling up equipment for industrial use and combining pressure with mild heat to extend shelf life without compromising juice freshness or nutrient profiles.

Related Important Terms

Non-thermal pasteurization

Pulsed electric field (PEF) and high-pressure processing (HPP) are non-thermal pasteurization techniques that effectively inactivate microorganisms in juice while preserving its sensory and nutritional qualities. PEF uses short bursts of high voltage to disrupt microbial cell membranes, whereas HPP applies intense hydrostatic pressure uniformly, both ensuring extended shelf life without heat-induced nutrient degradation.

Electroporation-induced membrane permeabilization

Pulsed electric field (PEF) technology preserves juice by inducing electroporation-induced membrane permeabilization, which disrupts microbial cell membranes without significant heating, maintaining nutritional and sensory qualities. High-pressure processing (HPP) preserves juice by applying uniform pressure to inactivate microorganisms, but PEF offers more precise control over membrane permeabilization, enhancing juice quality and shelf life.

Cold plasma stabilization

Cold plasma stabilization enhances juice preservation by generating reactive species that effectively inactivate microorganisms without heat, complementing pulsed electric field (PEF) and high-pressure processing (HPP) methods. Unlike PEF's electroporation and HPP's uniform pressure application, cold plasma offers rapid microbial reduction while maintaining juice quality and nutrient retention.

Hurdle technology synergy

Pulsed electric field (PEF) and high-pressure processing (HPP) both serve as non-thermal preservation methods that inactivate microorganisms while preserving juice quality, with PEF using short bursts of high voltage to disrupt cell membranes and HPP applying uniform pressure to inactivate pathogens. When combined in hurdle technology, PEF and HPP create synergistic antimicrobial effects, enhancing microbial safety and extending shelf life by targeting different cellular structures and stress responses in juice preservation.

Ultra-high pressure homogenization

Ultra-high pressure homogenization (UHPH) enhances juice preservation by disrupting microbial cells and enzymes at pressures up to 400 MPa, retaining sensory and nutritional qualities better than traditional pulsed electric field (PEF) and high-pressure processing (HPP) methods. UHPH's continuous processing and fine particle size reduction improve juice stability and shelf life while preserving bioactive compounds and vitamins more effectively than batch HPP treatments.

Ohmic heating minimalization

Pulsed electric field (PEF) technology preserves juice by disrupting microbial cell membranes using short bursts of high voltage, effectively maintaining nutritional and sensory qualities while minimizing thermal damage compared to traditional methods. High-pressure processing (HPP) inactivates pathogens through uniform pressure application but often generates heat, whereas PEF's reliance on electrical pulses results in lower ohmic heating, reducing nutrient degradation and preserving juice freshness more efficiently.

Microbial sublethal injury recovery

Pulsed electric field (PEF) treatment induces microbial sublethal injury by permeabilizing cell membranes, which can lead to delayed recovery and reduced spoilage in juice preservation. High-pressure processing (HPP) causes more extensive cell damage, often resulting in irreversible microbial inactivation, but sublethally injured cells may recover under favorable conditions, affecting juice safety and shelf life.

Enzyme inactivation kinetics

Pulsed electric field (PEF) and high-pressure processing (HPP) exhibit distinct enzyme inactivation kinetics in juice preservation, with PEF enabling rapid permeabilization of microbial and enzyme membranes at lower temperatures, thereby preserving sensory and nutritional qualities. In contrast, HPP achieves enzyme inactivation through uniform high pressure that induces conformational changes in enzyme structures, often requiring longer treatment times and potentially affecting juice texture and flavor profiles.

Nutrient retention indices

Pulsed electric field (PEF) processing demonstrates superior nutrient retention indices in juice preservation by maintaining higher levels of vitamin C and phenolic compounds compared to high-pressure processing (HPP), which can cause moderate nutrient degradation. PEF's non-thermal mechanism preserves enzyme activity and antioxidant capacity more effectively, resulting in enhanced nutritional quality and longer shelf life for fruit juices.

Shelf-life extension mapping

Pulsed electric field (PEF) and high-pressure processing (HPP) significantly extend juice shelf-life by inactivating spoilage microorganisms and enzymes, with PEF preserving sensory attributes while allowing shelf stability up to 30 days under refrigeration. HPP achieves longer shelf-life extension, often exceeding 45 days, by applying uniform pressure that maintains nutritional quality and flavor without thermal degradation, making it suitable for premium juice preservation.

Pulsed electric field vs high-pressure processing for juice preservation Infographic

agridif.com

agridif.com