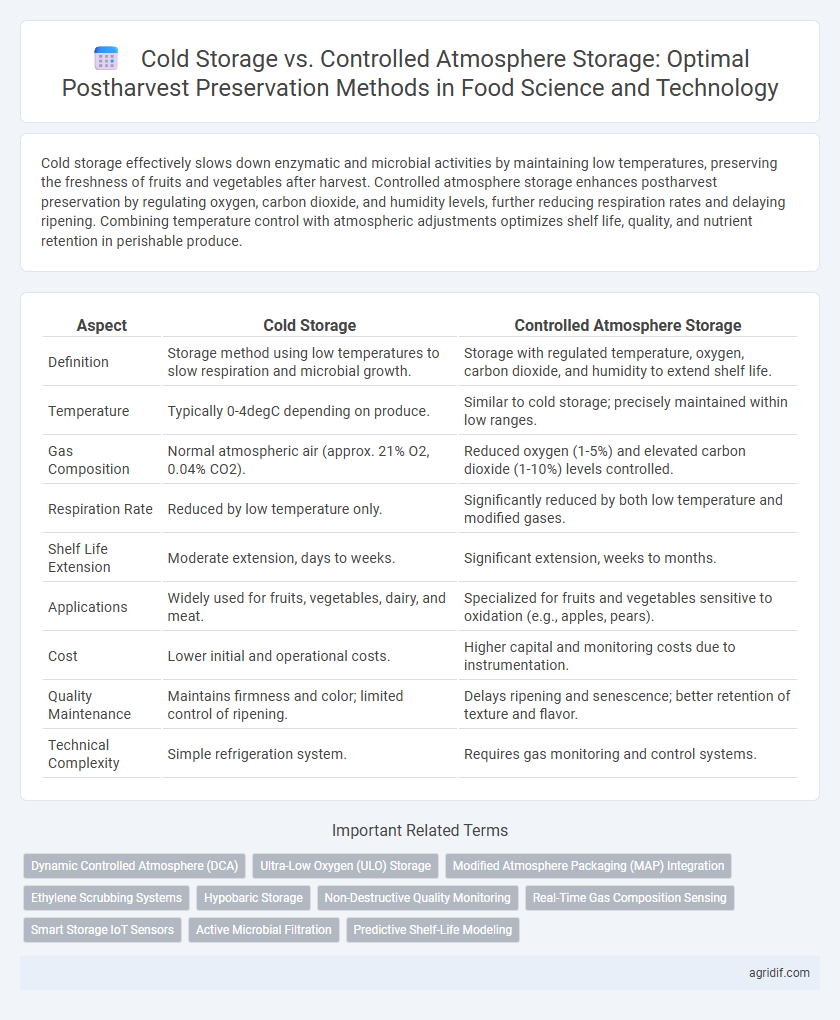

Cold storage effectively slows down enzymatic and microbial activities by maintaining low temperatures, preserving the freshness of fruits and vegetables after harvest. Controlled atmosphere storage enhances postharvest preservation by regulating oxygen, carbon dioxide, and humidity levels, further reducing respiration rates and delaying ripening. Combining temperature control with atmospheric adjustments optimizes shelf life, quality, and nutrient retention in perishable produce.

Table of Comparison

| Aspect | Cold Storage | Controlled Atmosphere Storage |

|---|---|---|

| Definition | Storage method using low temperatures to slow respiration and microbial growth. | Storage with regulated temperature, oxygen, carbon dioxide, and humidity to extend shelf life. |

| Temperature | Typically 0-4degC depending on produce. | Similar to cold storage; precisely maintained within low ranges. |

| Gas Composition | Normal atmospheric air (approx. 21% O2, 0.04% CO2). | Reduced oxygen (1-5%) and elevated carbon dioxide (1-10%) levels controlled. |

| Respiration Rate | Reduced by low temperature only. | Significantly reduced by both low temperature and modified gases. |

| Shelf Life Extension | Moderate extension, days to weeks. | Significant extension, weeks to months. |

| Applications | Widely used for fruits, vegetables, dairy, and meat. | Specialized for fruits and vegetables sensitive to oxidation (e.g., apples, pears). |

| Cost | Lower initial and operational costs. | Higher capital and monitoring costs due to instrumentation. |

| Quality Maintenance | Maintains firmness and color; limited control of ripening. | Delays ripening and senescence; better retention of texture and flavor. |

| Technical Complexity | Simple refrigeration system. | Requires gas monitoring and control systems. |

Introduction to Postharvest Preservation in Agriculture

Postharvest preservation in agriculture is essential for reducing losses and maintaining the quality of harvested fruits and vegetables. Cold storage slows down metabolic processes by maintaining low temperatures, thereby extending shelf life, while controlled atmosphere storage further optimizes preservation by regulating oxygen, carbon dioxide, and humidity levels to inhibit spoilage and physiological deterioration. Combining these techniques enhances postharvest longevity, ensuring fresh produce reaches consumers with minimal quality degradation.

Principles of Cold Storage in Food Preservation

Cold storage preserves food quality by maintaining temperatures just above freezing, significantly slowing enzymatic activity and microbial growth. This method reduces metabolic rates, delaying ripening and spoilage in fruits, vegetables, and meats. Uniform low temperatures and proper humidity control are essential to prevent dehydration and maintain texture.

Fundamentals of Controlled Atmosphere (CA) Storage

Controlled Atmosphere (CA) Storage optimizes postharvest preservation by regulating oxygen, carbon dioxide, and humidity levels to slow respiration and delay ripening. Unlike conventional cold storage that primarily reduces temperature, CA storage creates an environment tailored to specific produce, minimizing physiological breakdown and microbial growth. This method significantly extends shelf life and maintains quality by modulating environmental gases alongside temperature control.

Key Differences Between Cold Storage and CA Storage

Cold storage maintains low temperatures to slow metabolic activity and delay spoilage in fruits and vegetables, typically ranging from 0degC to 10degC depending on the produce. Controlled Atmosphere (CA) storage precisely regulates oxygen, carbon dioxide, and humidity levels alongside temperature to further reduce respiration rates and extend shelf life beyond conventional cold storage limits. Unlike cold storage, CA storage is tailored to specific crop requirements, enabling superior preservation quality and minimizing physiological disorders during long-term postharvest storage.

Impact on Shelf Life and Quality of Agricultural Produce

Controlled atmosphere storage significantly extends the shelf life of agricultural produce by precisely regulating oxygen, carbon dioxide, and humidity levels, thereby slowing respiration and delaying ripening and spoilage. Cold storage, while effective in reducing metabolic rates through low temperatures, often does not prevent quality degradation caused by moisture loss, chilling injuries, or oxidative stress. Combining both methods can optimize postharvest preservation by maintaining firmness, color, nutritional value, and flavor, ultimately ensuring higher market value and reduced food waste.

Technological Requirements and Infrastructure

Cold storage requires precise temperature regulation systems, reliable refrigeration units, and insulated facilities to maintain low temperatures essential for slowing metabolic processes in harvested produce. Controlled atmosphere storage demands advanced gas monitoring and modification technologies, including sensors and automated gas injection systems, to regulate oxygen, carbon dioxide, and humidity levels, thereby enhancing shelf life and quality. Both methods necessitate robust infrastructure with uninterrupted power supply, but controlled atmosphere storage involves higher initial investment and more complex maintenance due to the integration of gas control technologies.

Cost-Benefit Analysis of Cold vs. CA Storage

Cold storage offers an economical solution for short-term preservation by maintaining low temperatures that slow metabolic rates and microbial growth, significantly reducing postharvest losses. Controlled Atmosphere (CA) storage, though requiring higher initial investment and operational costs due to precise regulation of oxygen, carbon dioxide, and humidity levels, extends shelf life more effectively and preserves fruit quality over longer durations. Cost-benefit analysis favors cold storage for commodities with shorter market windows, while CA storage maximizes returns for high-value produce needing extended storage periods and superior quality retention.

Suitability for Different Fruits, Vegetables, and Commodities

Cold storage is highly effective for extending the shelf life of many fruits like apples, berries, and leafy vegetables by maintaining low temperatures that slow respiration and microbial growth. Controlled atmosphere storage further optimizes preservation by adjusting oxygen, carbon dioxide, and humidity levels, making it ideal for climacteric fruits such as bananas, avocados, and tomatoes that continue to ripen after harvest. Both methods are critical in food science and technology for tailoring postharvest environments to specific commodities, ensuring quality retention and reducing spoilage.

Environmental Considerations and Energy Efficiency

Cold storage relies on consistent low temperatures to inhibit microbial growth and enzymatic activity, consuming significant electricity and contributing to high carbon footprints. Controlled atmosphere storage optimizes oxygen, carbon dioxide, and humidity levels to extend shelf life, often reducing energy consumption by minimizing refrigeration intensity. Implementing controlled atmospheres can enhance environmental sustainability by lowering greenhouse gas emissions and improving overall energy efficiency in postharvest preservation.

Future Trends in Postharvest Preservation Technology

Emerging trends in postharvest preservation technology emphasize the integration of smart sensors and AI-driven monitoring systems in both cold storage and controlled atmosphere storage to optimize temperature, humidity, and gas composition in real-time. Advances in nanotechnology coatings and biodegradable packaging materials are enhancing the effectiveness of controlled atmosphere storage by reducing respiration rates and microbial growth. Future developments aim to combine IoT connectivity with precision climate control, significantly extending shelf life while minimizing energy consumption and food waste.

Related Important Terms

Dynamic Controlled Atmosphere (DCA)

Dynamic Controlled Atmosphere (DCA) technology enhances postharvest preservation by continuously adjusting oxygen, carbon dioxide, and humidity levels based on real-time fruit respiration rates, significantly extending shelf life compared to conventional cold storage. DCA reduces metabolic activity and delays ripening and senescence more effectively than static controlled atmospheres, optimizing quality and minimizing spoilage in perishable produce such as apples, pears, and berries.

Ultra-Low Oxygen (ULO) Storage

Ultra-Low Oxygen (ULO) storage, a subset of Controlled Atmosphere Storage, maintains oxygen levels below 1%, effectively slowing respiration and delaying ripening in fruits and vegetables for extended postharvest shelf life. Compared to traditional cold storage, ULO storage significantly reduces spoilage and physiological disorders by optimizing gas composition alongside low temperatures, enhancing freshness and quality retention.

Modified Atmosphere Packaging (MAP) Integration

Controlled Atmosphere Storage enhances postharvest preservation by precisely regulating oxygen, carbon dioxide, and humidity levels, minimizing respiration and delaying senescence more effectively than traditional cold storage. Integrating Modified Atmosphere Packaging (MAP) further optimizes the microenvironment around fresh produce, reducing oxidative stress and microbial growth to extend shelf life and maintain quality during distribution and retail.

Ethylene Scrubbing Systems

Ethylene scrubbing systems in controlled atmosphere storage significantly reduce ethylene gas concentration, slowing down fruit ripening and extending shelf life more effectively than traditional cold storage. By incorporating advanced adsorbents or catalytic converters, these systems maintain optimal storage conditions, minimizing physiological disorders and preserving postharvest quality.

Hypobaric Storage

Hypobaric storage, a method within controlled atmosphere storage, reduces air pressure to slow metabolic rates and delay ripening in fruits and vegetables, effectively extending shelf life while maintaining quality. This technique outperforms traditional cold storage by minimizing oxygen exposure and ethylene accumulation, thereby reducing spoilage and preserving nutritional value during postharvest preservation.

Non-Destructive Quality Monitoring

Cold storage maintains low temperatures to slow metabolic rates in fruits and vegetables, effectively reducing spoilage but offering limited real-time quality monitoring capabilities. Controlled atmosphere storage regulates oxygen, carbon dioxide, and humidity levels, enabling advanced non-destructive sensors such as near-infrared spectroscopy and electronic noses to monitor biochemical changes and freshness without compromising produce integrity.

Real-Time Gas Composition Sensing

Real-time gas composition sensing in controlled atmosphere storage enables precise monitoring and adjustment of oxygen, carbon dioxide, and ethylene levels, significantly extending the shelf life and maintaining the quality of perishable produce compared to traditional cold storage. Integrating advanced gas sensors with automated control systems optimizes the microenvironment, reducing spoilage and biochemical degradation during postharvest preservation.

Smart Storage IoT Sensors

Smart Storage IoT sensors enhance postharvest preservation by continuously monitoring and adjusting environmental parameters in both cold storage and controlled atmosphere storage, optimizing temperature, humidity, and gas composition to extend shelf life and maintain quality. These sensors enable precise data-driven management, reducing spoilage and energy consumption while improving traceability and responsiveness in food supply chains.

Active Microbial Filtration

Cold storage slows microbial growth by maintaining low temperatures around 0-4degC, effectively reducing metabolic activity but offering limited control over specific microbial populations. Controlled atmosphere storage enhances postharvest preservation by regulating oxygen, carbon dioxide, and humidity levels, combined with active microbial filtration systems that selectively remove airborne pathogens, thereby extending shelf life and maintaining produce quality.

Predictive Shelf-Life Modeling

Predictive shelf-life modeling in cold storage relies on temperature and humidity data to estimate decay rates and maintain quality by slowing metabolic processes. Controlled atmosphere storage enhances model accuracy by integrating dynamic gas concentration metrics such as oxygen, carbon dioxide, and ethylene levels, effectively extending postharvest freshness and reducing spoilage predictions.

Cold Storage vs Controlled Atmosphere Storage for Postharvest Preservation Infographic

agridif.com

agridif.com