Batch fermentation offers precise control over yogurt texture and flavor by fermenting a fixed volume under consistent conditions, ideal for small-scale production. Continuous fermentation enhances efficiency and productivity by maintaining constant microbial activity and substrate supply, suitable for large-scale industrial yogurt manufacturing. Optimizing fermentation parameters in both methods directly influences yogurt quality, safety, and probiotic viability.

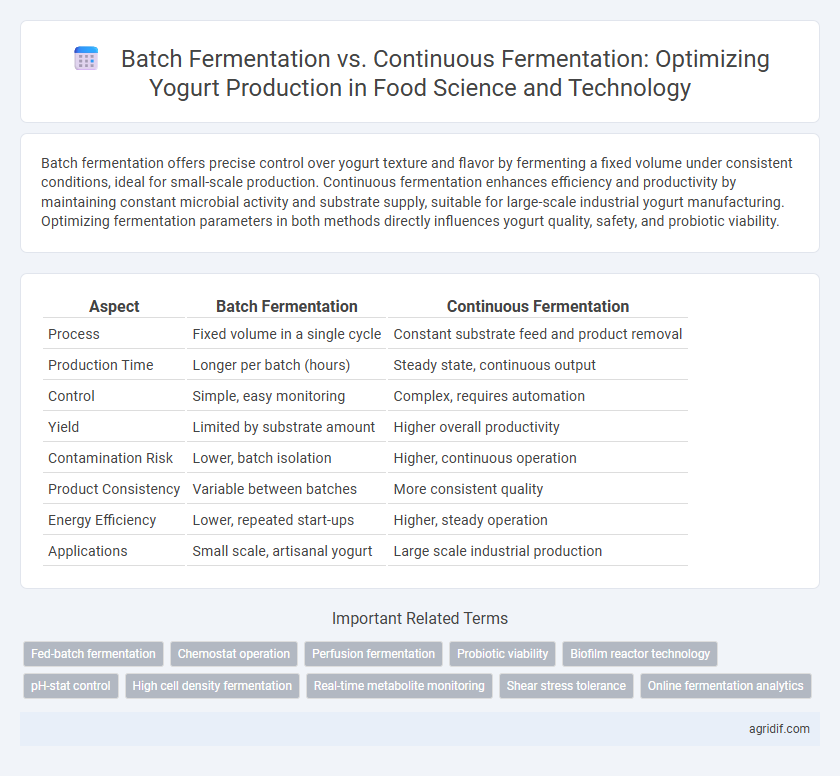

Table of Comparison

| Aspect | Batch Fermentation | Continuous Fermentation |

|---|---|---|

| Process | Fixed volume in a single cycle | Constant substrate feed and product removal |

| Production Time | Longer per batch (hours) | Steady state, continuous output |

| Control | Simple, easy monitoring | Complex, requires automation |

| Yield | Limited by substrate amount | Higher overall productivity |

| Contamination Risk | Lower, batch isolation | Higher, continuous operation |

| Product Consistency | Variable between batches | More consistent quality |

| Energy Efficiency | Lower, repeated start-ups | Higher, steady operation |

| Applications | Small scale, artisanal yogurt | Large scale industrial production |

Introduction to Yogurt Fermentation Methods

Batch fermentation in yogurt production involves fermenting milk in fixed volumes, allowing precise control over parameters and consistent quality with limited contamination risk. Continuous fermentation maintains a steady state by constantly adding fresh milk and removing yogurt, enhancing productivity and reducing downtime but requiring advanced monitoring systems. Understanding these methods enables optimization of microbial activity, acidification rate, and texture development in yogurt manufacturing.

Overview of Batch Fermentation in Yogurt Production

Batch fermentation in yogurt production involves inoculating a fixed volume of milk with starter cultures and allowing the fermentation process to proceed under controlled temperature conditions until the desired acidity and consistency are achieved. This method offers precise control over fermentation time and product characteristics, ensuring consistent flavor and texture in each batch. However, batch fermentation typically requires downtime for cleaning and preparation between cycles, limiting overall production capacity compared to continuous fermentation systems.

Understanding Continuous Fermentation for Yogurt

Continuous fermentation for yogurt production maintains a steady-state environment through constant input of fresh milk and simultaneous removal of fermented product, optimizing bacterial growth and acidification rates. This method improves production efficiency by reducing downtime and ensuring consistent product quality compared to batch fermentation. Key parameters such as temperature control, pH monitoring, and oxygen levels are critical for sustaining the activity of Lactobacillus bulgaricus and Streptococcus thermophilus during continuous fermentation.

Key Process Differences: Batch vs Continuous Fermentation

Batch fermentation for yogurt production involves fermenting a fixed volume of milk with starter culture until desired acidity and texture are reached, allowing precise control over fermentation time and product consistency. Continuous fermentation uses a steady input of milk and starter culture with simultaneous product removal, enabling higher production efficiency and reduced downtime but requiring complex control systems to maintain steady-state conditions. Key process differences include batch fermentation's discrete, time-defined cycles offering greater flexibility, while continuous fermentation provides constant operation with increased scalability for industrial yogurt production.

Impact on Yogurt Quality and Consistency

Batch fermentation in yogurt production allows precise control over fermentation time and conditions, resulting in consistent texture and flavor profiles. Continuous fermentation offers higher production efficiency but may introduce variability in acidity and microbial activity, potentially affecting yogurt quality. Optimizing parameters such as temperature, pH, and inoculum concentration is crucial to maintaining the desired sensory attributes and consistency in both methods.

Efficiency and Productivity Analysis

Batch fermentation in yogurt production limits efficiency due to intermittent processing and longer turnaround times, resulting in lower overall productivity. Continuous fermentation enables steady-state operation with consistent microbial activity, significantly enhancing production rates and reducing downtime. Continuous systems also optimize substrate utilization and maintain stable environmental conditions, leading to improved yield and process scalability compared to batch methods.

Equipment and Operational Requirements

Batch fermentation for yogurt production requires simpler equipment such as fermenters that can be easily cleaned and sterilized between batches, with manual loading and unloading processes. Continuous fermentation demands more sophisticated, automated systems with continuous feeding and product discharge mechanisms, requiring precise control of parameters like temperature and pH to maintain steady-state conditions. Operationally, batch processes involve intermittent production with downtime for cleaning, while continuous systems enable consistent output and higher productivity but require advanced monitoring and maintenance.

Cost Comparison: Batch versus Continuous Systems

Batch fermentation for yogurt production typically incurs higher operational costs due to frequent cleaning, sterilization, and downtime between batches. Continuous fermentation systems reduce labor and energy expenses by maintaining a steady production flow, enhancing process efficiency and lowering per-unit costs. Investment in continuous systems involves higher initial capital but offers long-term savings through increased yield and reduced waste.

Microbial Stability and Safety Aspects

Batch fermentation for yogurt production offers enhanced microbial stability due to controlled conditions and limited microbial exposure, reducing contamination risk and ensuring consistent probiotic viability. Continuous fermentation enables higher productivity but requires rigorous monitoring and advanced sterilization to prevent microbial shifts and potential pathogen growth, posing challenges for safety assurance. Balancing microbial stability and safety aspects depends on maintaining stringent hygiene protocols and real-time microbial analysis in both fermentation methods.

Environmental and Sustainability Considerations

Batch fermentation in yogurt production generates higher water and energy consumption per unit due to downtime between cycles, leading to increased resource use and waste generation. Continuous fermentation optimizes substrate utilization and reduces effluent output by maintaining steady-state conditions, enhancing environmental sustainability. Implementing continuous systems can lower greenhouse gas emissions and improve process efficiency, supporting sustainable dairy production practices.

Related Important Terms

Fed-batch fermentation

Fed-batch fermentation in yogurt production combines the advantages of batch and continuous processes by allowing controlled nutrient addition, which enhances microbial growth and acidification rate. This method improves product consistency, reduces contamination risk, and optimizes flavor and texture by maintaining optimal fermentation conditions throughout the process.

Chemostat operation

Batch fermentation for yogurt production involves a fixed volume of milk inoculated with starter cultures, resulting in limited control over microbial growth and acidification rates, whereas continuous fermentation using a chemostat maintains constant nutrient levels and waste removal, optimizing bacterial activity and product consistency. Chemostat operation in continuous fermentation allows precise regulation of dilution rate and pH, enhancing the growth of Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus, thereby improving yogurt yield and quality.

Perfusion fermentation

Batch fermentation involves producing yogurt in discrete cycles, ideal for small-scale or experimental runs, while continuous fermentation, particularly perfusion fermentation, allows for the constant removal of waste and supply of fresh nutrients, enhancing microbial productivity and product consistency. Perfusion fermentation optimizes yogurt yield by maintaining steady-state conditions and preventing the accumulation of inhibitory metabolites, crucial for industrial-scale production.

Probiotic viability

Batch fermentation in yogurt production typically results in higher probiotic viability due to controlled nutrient availability and stable environmental conditions, promoting optimal bacterial growth. Continuous fermentation, while offering consistent product output, may experience fluctuations in microbial populations that can reduce the stability and viability of probiotic strains over time.

Biofilm reactor technology

Batch fermentation in yogurt production allows for precise control of fermentation parameters, promoting the development of uniform microbial biofilms essential for high-quality flavor and texture; however, continuous fermentation with biofilm reactor technology enhances productivity by enabling sustained microbial activity and stability, reducing downtime, and improving overall yield through immobilized cell systems. Biofilm reactors optimize mass transfer and maintain cell density, which accelerates fermentation rates and supports consistent probiotic viability, crucial for producing yogurt with enhanced health benefits.

pH-stat control

Batch fermentation for yogurt production involves maintaining pH-stat control by periodically adjusting acidity to optimize microbial activity, ensuring consistent flavor and texture within defined time frames. Continuous fermentation utilizes real-time pH-stat systems to dynamically regulate acid levels, enhancing productivity and product uniformity through sustained microbial growth.

High cell density fermentation

Batch fermentation allows precise control over microbial growth phases, resulting in consistent high cell density and optimal flavor profile for yogurt; continuous fermentation achieves sustained high cell density by maintaining steady-state conditions, increasing productivity and reducing downtime but requires more complex monitoring to prevent contamination and maintain culture stability. High cell density is crucial in both methods to enhance lactic acid bacteria concentration, improve fermentation efficiency, and achieve desired yogurt texture and probiotic benefits.

Real-time metabolite monitoring

Real-time metabolite monitoring in batch fermentation for yogurt production enables precise tracking of acidification and flavor compound synthesis within fixed timeframes, ensuring optimal microbial activity and consistency. Continuous fermentation, integrated with advanced sensor technologies, allows dynamic adjustment of metabolic parameters, enhancing productivity and stability by maintaining steady-state conditions throughout the yogurt manufacturing process.

Shear stress tolerance

Batch fermentation in yogurt production offers higher control over shear stress tolerance, as microbial cultures are exposed to consistent, lower agitation levels, preserving the integrity of lactic acid bacteria. Continuous fermentation faces challenges with increased shear stress from constant mixing, which can damage shear-sensitive probiotic strains, potentially affecting yogurt texture and fermentation efficiency.

Online fermentation analytics

Online fermentation analytics enable real-time monitoring of critical parameters such as pH, temperature, and microbial growth during both batch and continuous fermentation, enhancing process control and product consistency in yogurt production. Continuous fermentation benefits more significantly by integrating advanced sensors and data analytics, allowing for immediate adjustments that optimize yield, reduce downtime, and maintain consistent yogurt texture and flavor profiles.

Batch fermentation vs Continuous fermentation for yogurt production Infographic

agridif.com

agridif.com