Brix measurement and refractometry are essential techniques in food science for accurately determining sugar content in juices. Brix measurement quantifies the percentage of soluble solids, primarily sugars, offering a quick assessment of sweetness and concentration. Refractometry, which measures the refractive index of juice, provides precise and non-destructive analysis, making it highly reliable for quality control in juice production.

Table of Comparison

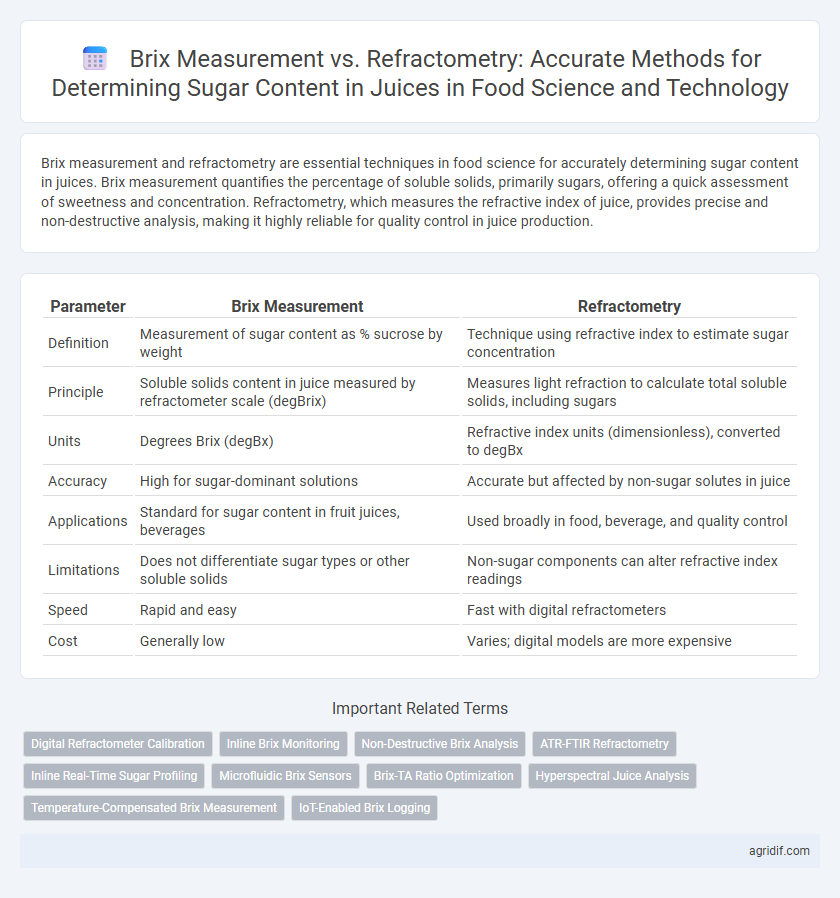

| Parameter | Brix Measurement | Refractometry |

|---|---|---|

| Definition | Measurement of sugar content as % sucrose by weight | Technique using refractive index to estimate sugar concentration |

| Principle | Soluble solids content in juice measured by refractometer scale (degBrix) | Measures light refraction to calculate total soluble solids, including sugars |

| Units | Degrees Brix (degBx) | Refractive index units (dimensionless), converted to degBx |

| Accuracy | High for sugar-dominant solutions | Accurate but affected by non-sugar solutes in juice |

| Applications | Standard for sugar content in fruit juices, beverages | Used broadly in food, beverage, and quality control |

| Limitations | Does not differentiate sugar types or other soluble solids | Non-sugar components can alter refractive index readings |

| Speed | Rapid and easy | Fast with digital refractometers |

| Cost | Generally low | Varies; digital models are more expensive |

Introduction to Sugar Content Analysis in Juices

Brix measurement quantifies the sugar content in juices by determining the percentage of sucrose equivalents in a solution, providing a direct indication of sweetness levels. Refractometry uses the refractive index of juice samples to infer sugar concentration, offering a rapid and non-destructive analytical method favored in food science. Accurate sugar content analysis through these techniques is essential for quality control, product consistency, and consumer satisfaction in juice manufacturing.

Understanding Brix Measurement in Food Science

Brix measurement in food science quantifies the sugar content in juices by representing the percentage of sucrose by weight, facilitating quality control and standardization in beverage production. Refractometry, the primary method for Brix determination, uses the refractive index of a liquid to estimate soluble solids concentration, ensuring rapid and accurate sugar content analysis. Precise Brix values are critical for optimizing fermentation, sweetness consistency, and shelf-life stability in food and beverage manufacturing.

Principles of Refractometry in Juice Analysis

Refractometry in juice analysis measures the refractive index to determine sugar content by evaluating how light bends when passing through the juice sample, correlating with dissolved solids concentration. The Brix scale quantifies sucrose concentration as a percentage by weight, derived from the refractive index, providing a rapid and non-destructive estimation of sweetness. Refractometers require temperature compensation to ensure accuracy, as temperature variations affect the refractive index and consequently the Brix value.

Comparing Brix and Refractometry Techniques

Brix measurement directly quantifies the percentage of sucrose in juice, providing a straightforward indication of sweetness and sugar content. Refractometry uses the refractive index to estimate dissolved solids, including sugars, offering rapid, non-destructive analysis but varying in accuracy depending on juice composition. Comparing these techniques, Brix measurement delivers specificity for sucrose, while refractometry offers broader applicability with potential interference from other soluble substances in juices.

Accuracy and Reliability in Sugar Determination

Brix measurement using refractometry provides rapid and accurate estimation of sugar content in fruit juices by determining the refractive index, which correlates directly with soluble solids concentration. The precision of refractometers in sugar determination depends on calibration quality and temperature compensation, ensuring reliable results in both laboratory and industrial settings. Compared to traditional chemical methods, refractometry enhances reproducibility and efficiency, making it a preferred technique for quality control in the food and beverage industry.

Sample Preparation and Practical Considerations

Accurate Brix measurement in juices relies on meticulous sample preparation, including filtration to remove pulp and debris that can skew refractometry readings. Refractometers require temperature compensation to ensure precise sugar content analysis, as temperature fluctuations affect the refractive index. Practical considerations involve calibrating the device with standard solutions and handling viscous or cloudy samples carefully to maintain measurement consistency and reliability.

Advantages and Limitations of Brix Measurement

Brix measurement quantifies sugar content in juices by determining soluble solids concentration, offering a rapid and non-destructive analysis essential for quality control in food science. Its primary advantage is simplicity, requiring minimal sample preparation and providing immediate results critical for production efficiency. However, Brix measurement may be limited by interference from non-sugar solutes and temperature variations, potentially affecting accuracy compared to more specialized refractometry techniques.

Benefits and Drawbacks of Refractometry

Refractometry offers rapid and non-destructive measurement of sugar content in juices by assessing the refractive index, enabling real-time quality control during food processing. Its benefits include high sensitivity, minimal sample volume requirement, and ease of use without the need for chemical reagents. However, refractometry can be affected by the presence of other soluble solids like acids and salts, leading to potential inaccuracies in Brix measurement if not properly calibrated or compensated.

Applications in Fruit Juice Quality Control

Brix measurement quantifies the sugar content in fruit juices by determining the percentage of sucrose equivalents, essential for assessing sweetness and ripeness. Refractometry utilizes optical principles to measure the refractive index, providing rapid and accurate Brix values critical for quality control in juice production. This technique ensures consistency in flavor profiles, detects adulteration, and monitors fermentation processes in fruit juice manufacturing.

Future Trends in Juice Sugar Content Assessment

Emerging advances in refractometry harness multispectral and digital imaging technologies to enhance the precision of Brix measurement in juice sugar content assessment. Integration of AI algorithms enables real-time data processing and predictive modeling, optimizing quality control in juice production. Future trends emphasize non-invasive, portable refractometers with IoT connectivity, facilitating continuous monitoring and improved product consistency in the beverage industry.

Related Important Terms

Digital Refractometer Calibration

Digital refractometer calibration enhances the accuracy of Brix measurement by compensating for temperature variations and instrument drift, ensuring precise quantification of sugar content in fruit juices. Regular calibration using standard sucrose solutions is critical for maintaining reliable refractometric readings in food science and technology applications.

Inline Brix Monitoring

Inline Brix monitoring using refractometry provides rapid and continuous measurement of sugar content in juices, enhancing real-time process control and product consistency. The technique relies on refractive index changes correlated with sugar concentration, enabling precise Brix level detection without sample extraction.

Non-Destructive Brix Analysis

Non-destructive Brix analysis using refractometry enables rapid, accurate determination of sugar content in juices by measuring the refractive index without altering the sample, preserving its integrity for further testing. This technique enhances quality control in food science by providing real-time data on soluble solids concentration, crucial for optimizing flavor and processing parameters.

ATR-FTIR Refractometry

ATR-FTIR refractometry offers a highly accurate, rapid method for measuring sugar content in juices by analyzing the infrared absorption characteristics of dissolved sugars, outperforming traditional Brix measurement which relies solely on refractive index changes. This technique enables detailed compositional analysis, including detection of sugar types and concentrations, enhancing quality control and product standardization in food science and technology.

Inline Real-Time Sugar Profiling

Inline real-time sugar profiling in juices utilizes refractometry to provide precise Brix measurements, enabling continuous monitoring of sugar content during processing. This method enhances accuracy and efficiency by offering rapid, non-destructive analysis compared to traditional offline Brix measurement techniques.

Microfluidic Brix Sensors

Microfluidic Brix sensors offer enhanced precision and rapid sugar content analysis in juices by miniaturizing traditional refractometry techniques, allowing for real-time monitoring and minimal sample volume. These sensors leverage micro-scale optical components to measure refractive index changes correlated with Brix values, optimizing accuracy in food quality control and process automation.

Brix-TA Ratio Optimization

Brix measurement quantifies total soluble solids, primarily sugars, while refractometry offers rapid, non-destructive analysis essential for precise sugar content determination in juices. Optimizing the Brix-TA ratio enhances juice quality control by balancing sweetness and acidity, crucial for flavor profiling and product consistency in food science and technology.

Hyperspectral Juice Analysis

Hyperspectral juice analysis enhances Brix measurement accuracy by capturing spectral data across multiple wavelengths, enabling precise quantification of sugar content beyond traditional refractometry limits. Integrating hyperspectral imaging with refractive index measurements provides comprehensive insights into juice composition, improving quality control and authentication in food science.

Temperature-Compensated Brix Measurement

Temperature-compensated Brix measurement in refractometry ensures precise sugar content analysis in fruit juices by automatically adjusting for temperature variations, minimizing errors caused by thermal fluctuations. This method enhances accuracy in quality control during juice production, where standard refractometric readings without compensation may lead to inconsistent Brix values affecting product consistency.

IoT-Enabled Brix Logging

IoT-enabled Brix logging revolutionizes sugar content analysis in juices by integrating digital refractometry with real-time data collection, enhancing accuracy and efficiency in food quality control. Continuous monitoring through smart sensors enables precise Brix measurement, facilitating instant adjustments in production and ensuring consistent product sweetness levels.

Brix Measurement vs Refractometry for Sugar Content in Juices Infographic

agridif.com

agridif.com