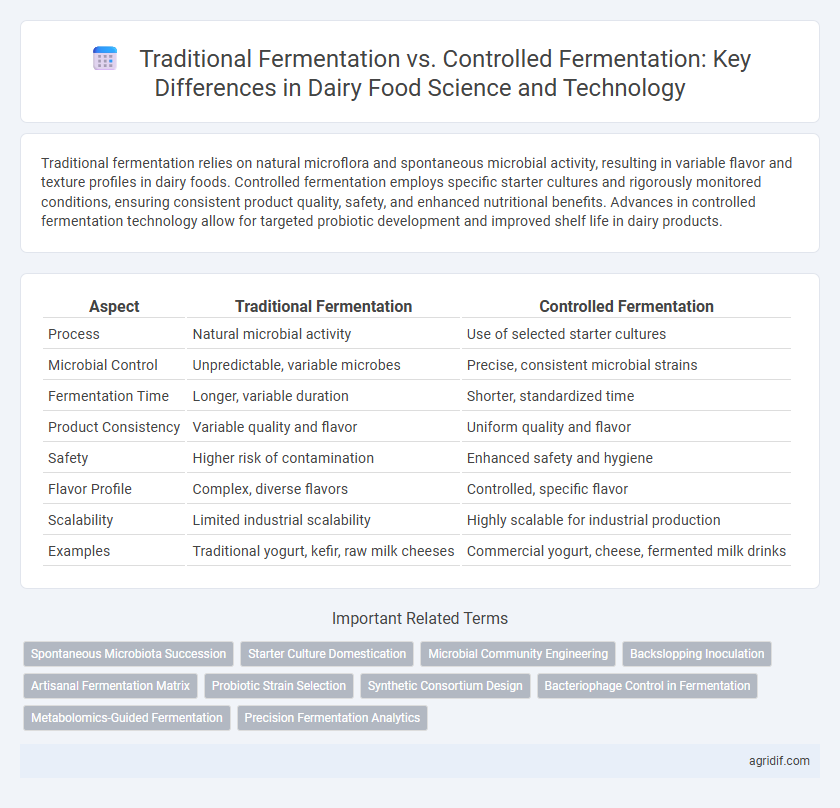

Traditional fermentation relies on natural microflora and spontaneous microbial activity, resulting in variable flavor and texture profiles in dairy foods. Controlled fermentation employs specific starter cultures and rigorously monitored conditions, ensuring consistent product quality, safety, and enhanced nutritional benefits. Advances in controlled fermentation technology allow for targeted probiotic development and improved shelf life in dairy products.

Table of Comparison

| Aspect | Traditional Fermentation | Controlled Fermentation |

|---|---|---|

| Process | Natural microbial activity | Use of selected starter cultures |

| Microbial Control | Unpredictable, variable microbes | Precise, consistent microbial strains |

| Fermentation Time | Longer, variable duration | Shorter, standardized time |

| Product Consistency | Variable quality and flavor | Uniform quality and flavor |

| Safety | Higher risk of contamination | Enhanced safety and hygiene |

| Flavor Profile | Complex, diverse flavors | Controlled, specific flavor |

| Scalability | Limited industrial scalability | Highly scalable for industrial production |

| Examples | Traditional yogurt, kefir, raw milk cheeses | Commercial yogurt, cheese, fermented milk drinks |

Overview of Fermentation in Dairy Food Processing

Fermentation in dairy food processing transforms lactose into lactic acid through microbial activity, enhancing flavor, texture, and safety. Traditional fermentation relies on spontaneous microbial flora, resulting in variable product quality and inconsistent shelf life. Controlled fermentation utilizes specific starter cultures and precise environmental conditions to ensure reproducibility, improved safety, and targeted sensory properties in dairy products.

Defining Traditional Fermentation Methods

Traditional fermentation methods in dairy foods rely on naturally occurring microorganisms present in raw milk or the environment, fostering spontaneous microbial growth without standardized starter cultures. These techniques often utilize indigenous strains, resulting in unique organoleptic properties and cultural variations in taste, texture, and aroma. The lack of microbial control can lead to variable fermentation times and inconsistent product quality compared to controlled fermentation processes.

Principles of Controlled Fermentation in Dairy Industry

Controlled fermentation in the dairy industry relies on precise regulation of microbial strains, temperature, pH, and incubation time to ensure consistent product quality and safety. This method employs selected starter cultures to accelerate fermentation, enhance flavor development, and inhibit undesirable microorganisms. By monitoring fermentation parameters, controlled fermentation optimizes yield, texture, and shelf life of dairy products compared to traditional spontaneous methods.

Microbial Diversity in Traditional vs. Controlled Fermentation

Traditional fermentation in dairy foods relies on spontaneous microbial communities from raw materials and environment, resulting in rich microbial diversity that enhances unique flavors and potential probiotic benefits. Controlled fermentation employs selected starter cultures with defined microbial strains, ensuring consistent product quality, safety, and targeted functional properties but often reduces microbial diversity. This difference in microbial profiles influences the sensory attributes, shelf life, and health-promoting qualities of fermented dairy products.

Impact on Flavor and Texture: A Comparative Analysis

Traditional fermentation in dairy foods relies on naturally occurring microorganisms, resulting in unique and complex flavors with variable textures influenced by regional microbial diversity. Controlled fermentation employs selected microbial strains under standardized conditions, ensuring consistent flavor profiles and uniform texture across batches. The comparative analysis highlights that traditional methods offer distinct sensory characteristics favored for artisanal products, while controlled fermentation provides reliability and scalability essential for industrial dairy production.

Nutritional Differences Between Traditional and Controlled Dairy Ferments

Traditional fermentation of dairy foods relies on naturally occurring microbes, resulting in diverse microbial populations that enhance bioavailability of nutrients and produce beneficial metabolites like vitamins and organic acids. Controlled fermentation employs selected starter cultures, leading to consistent nutrient profiles and higher levels of specific probiotics known to improve gut health and immune function. Nutritional differences include variations in protein digestibility, vitamin B complex concentration, and production of bioactive peptides, with controlled fermentation often yielding more standardized and potentially enhanced nutritional benefits.

Food Safety Considerations in Both Fermentation Approaches

Traditional fermentation in dairy foods relies on naturally occurring microorganisms, which may pose a risk of contamination by pathogenic bacteria, compromising food safety. Controlled fermentation utilizes selected starter cultures under monitored conditions, enhancing microbial consistency and significantly reducing the risk of harmful pathogens. Rigorous control of temperature, pH, and hygiene practices in controlled fermentation ensures safer dairy products compared to the variability inherent in traditional methods.

Scalability and Industrial Applications

Traditional fermentation in dairy foods relies on naturally occurring microbes, providing unique flavors but facing challenges in scalability and consistency for industrial applications. Controlled fermentation employs selected microbial strains and standardized conditions, enhancing product uniformity, safety, and efficiency critical for large-scale dairy production. Industrial use of controlled fermentation allows precise manipulation of parameters such as temperature and pH, optimizing yield and meeting regulatory standards essential for commercial dairy manufacturing.

Consumer Perspectives and Market Trends

Traditional fermentation in dairy foods is often valued by consumers for its natural flavor complexity and cultural authenticity, appealing to niche markets focused on artisanal and heritage products. Controlled fermentation, driven by advances in food technology, offers consistent quality, safety, and scalability, meeting the growing demand for reliable and standardized dairy products in mainstream markets. Market trends indicate a rising consumer preference for products that combine traditional sensory attributes with modern safety standards, pushing dairy producers to innovate fermentation processes to balance authenticity and control.

Future Directions in Dairy Fermentation Technology

Future directions in dairy fermentation technology emphasize the integration of precision microbiology and advanced bioprocessing to enhance controlled fermentation, ensuring consistent product quality and safety. Innovations in metagenomics and metabolomics enable the selection and optimization of specific microbial strains for improved flavor, texture, and nutritional profiles in dairy foods. Smart fermentation systems incorporating real-time monitoring and AI-driven control promise to revolutionize large-scale dairy production while preserving traditional sensory attributes.

Related Important Terms

Spontaneous Microbiota Succession

Traditional fermentation in dairy foods relies on spontaneous microbiota succession, where indigenous microorganisms naturally dominate and drive flavor and texture development, often resulting in product variability and unique regional characteristics. Controlled fermentation uses selected starter cultures to standardize microbial succession, ensuring consistent quality, enhanced safety, and predictable sensory profiles in dairy products.

Starter Culture Domestication

Starter culture domestication in traditional fermentation relies on naturally occurring microbes adapted over generations, resulting in diverse microbial communities that contribute unique flavors and textures in dairy foods. Controlled fermentation employs selected, standardized starter cultures to ensure consistent microbial activity, enhancing safety, reproducibility, and specific functional properties in dairy product development.

Microbial Community Engineering

Traditional fermentation in dairy foods relies on naturally occurring microbial communities that offer diverse flavors but unpredictable consistency, while controlled fermentation employs selected starter cultures to engineer microbial communities for enhanced safety, uniformity, and targeted biochemical properties. Microbial community engineering in controlled fermentation enables precise modulation of metabolic activities, improving product quality, shelf-life, and functional attributes such as probiotic content and flavor profile.

Backslopping Inoculation

Backslopping inoculation in traditional fermentation involves using a portion of a previous batch to initiate fermentation, promoting complex microbial communities but risking inconsistent product quality. Controlled fermentation employs standardized starter cultures to ensure reproducibility, safety, and specific sensory attributes in dairy foods.

Artisanal Fermentation Matrix

Artisanal fermentation matrix in dairy foods relies on diverse microbial communities from natural environments, promoting unique flavors and textures through uncontrolled metabolic interactions. Controlled fermentation employs specific starter cultures under regulated conditions to ensure consistency, safety, and predictable product characteristics, contrasting with traditional methods' variability and complexity.

Probiotic Strain Selection

Traditional fermentation relies on naturally occurring microbial communities, often resulting in variable probiotic strain profiles and inconsistent health benefits, whereas controlled fermentation employs carefully selected probiotic strains with proven functional properties to enhance the safety, nutritional value, and therapeutic effects of dairy foods. The targeted use of specific Lactobacillus and Bifidobacterium strains in controlled fermentation ensures reproducible probiotic viability and metabolic activity, optimizing gut microbiota modulation and immune system support.

Synthetic Consortium Design

Traditional fermentation in dairy foods relies on naturally occurring microbial communities with variable metabolic activities, leading to inconsistent product quality, while controlled fermentation employs synthetic consortium design to assemble specific strains with known functions, enhancing process stability and flavor profiles. Synthetic consortia optimize microbial interactions, improve acidification rates, and enable targeted production of bioactive compounds, advancing the precision and safety of fermented dairy products.

Bacteriophage Control in Fermentation

Traditional fermentation relies on spontaneous microbial activity, often leading to inconsistent results and increased susceptibility to bacteriophage infections that can disrupt dairy fermentation. Controlled fermentation employs specific starter cultures and bacteriophage-resistant strains, coupled with rigorous monitoring and sanitation protocols, to minimize phage contamination and ensure consistent product quality in dairy processing.

Metabolomics-Guided Fermentation

Metabolomics-guided fermentation in dairy foods leverages comprehensive metabolic profiling to optimize microbial activity, enhancing flavor, texture, and nutritional profiles compared to traditional fermentation methods. Controlled fermentation enables precise regulation of metabolic pathways, reducing undesirable compounds and improving consistency in probiotic viability and bioactive metabolite production.

Precision Fermentation Analytics

Precision fermentation analytics in dairy foods enables real-time monitoring of microbial activity, metabolite production, and enzymatic changes, enhancing product consistency and safety beyond traditional fermentation methods. Advanced sensors and bioinformatics tools provide detailed insights into fermentation kinetics, facilitating optimization of flavor profiles and nutritional content through controlled fermentation processes.

Traditional Fermentation vs Controlled Fermentation for Dairy Foods Infographic

agridif.com

agridif.com