Aflatoxin detection in grain quality control is critical due to its high toxicity and widespread occurrence, requiring sensitive methods such as ELISA and HPLC for accurate quantification. Ochratoxin detection also plays a vital role, especially because of its nephrotoxic effects and prevalence in stored grains, with techniques like immunoaffinity columns enhancing specificity. Comparing both, aflatoxin detection often demands more stringent regulatory limits and rapid testing protocols due to its immediate health risks, while ochratoxin analysis focuses on long-term exposure monitoring and contamination prevention.

Table of Comparison

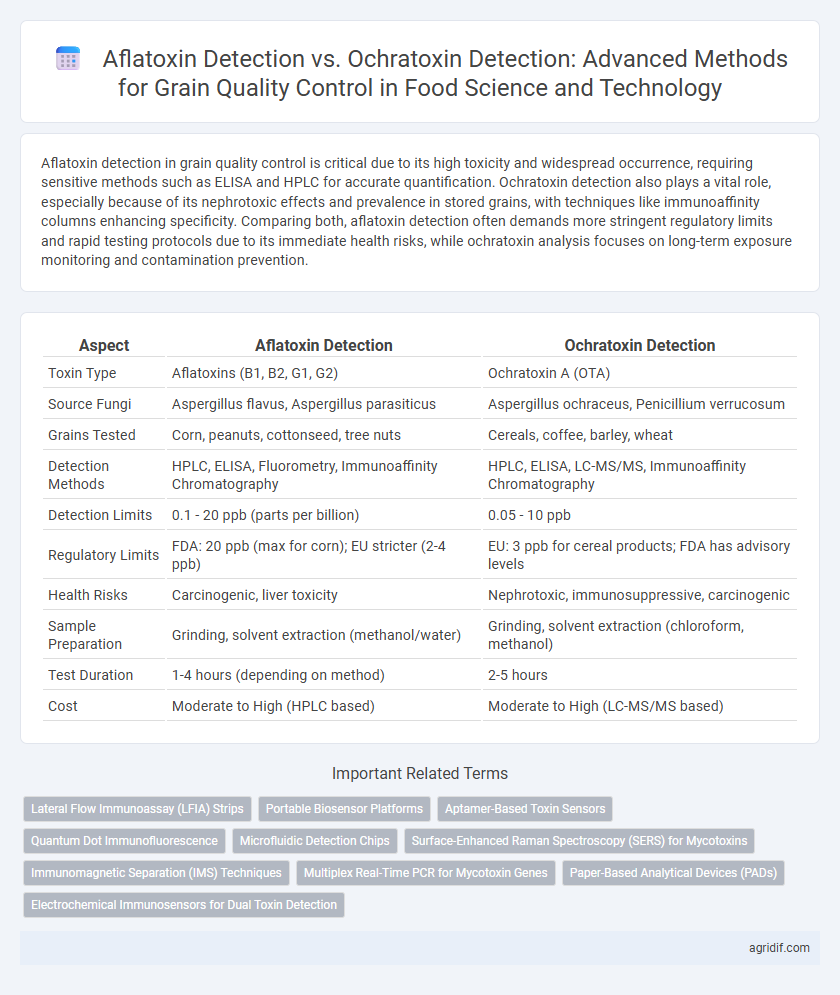

| Aspect | Aflatoxin Detection | Ochratoxin Detection |

|---|---|---|

| Toxin Type | Aflatoxins (B1, B2, G1, G2) | Ochratoxin A (OTA) |

| Source Fungi | Aspergillus flavus, Aspergillus parasiticus | Aspergillus ochraceus, Penicillium verrucosum |

| Grains Tested | Corn, peanuts, cottonseed, tree nuts | Cereals, coffee, barley, wheat |

| Detection Methods | HPLC, ELISA, Fluorometry, Immunoaffinity Chromatography | HPLC, ELISA, LC-MS/MS, Immunoaffinity Chromatography |

| Detection Limits | 0.1 - 20 ppb (parts per billion) | 0.05 - 10 ppb |

| Regulatory Limits | FDA: 20 ppb (max for corn); EU stricter (2-4 ppb) | EU: 3 ppb for cereal products; FDA has advisory levels |

| Health Risks | Carcinogenic, liver toxicity | Nephrotoxic, immunosuppressive, carcinogenic |

| Sample Preparation | Grinding, solvent extraction (methanol/water) | Grinding, solvent extraction (chloroform, methanol) |

| Test Duration | 1-4 hours (depending on method) | 2-5 hours |

| Cost | Moderate to High (HPLC based) | Moderate to High (LC-MS/MS based) |

Introduction to Mycotoxins in Grain: Aflatoxins vs Ochratoxins

Aflatoxins and ochratoxins are toxic secondary metabolites produced by Aspergillus and Penicillium species, respectively, that pose significant threats to grain quality and safety. Aflatoxin detection methods often prioritize high sensitivity due to their potent carcinogenic effects, while ochratoxin detection focuses on identifying contamination that impacts both human health and grain marketability. Effective grain quality control involves rapid, accurate detection techniques such as immunoassays and chromatography to mitigate the risks associated with these mycotoxins.

Importance of Detecting Aflatoxin and Ochratoxin in Grain Quality Control

Detecting aflatoxin and ochratoxin is crucial for grain quality control due to their potent toxicity and carcinogenic effects on human health. Aflatoxins, primarily produced by Aspergillus species, contaminate staple crops like maize and peanuts, posing severe risks including liver cancer and immune suppression. Ochratoxins, mainly from Penicillium and Aspergillus species, affect grain storage and safety by causing nephrotoxicity and immunotoxicity, making their detection essential to comply with food safety regulations and protect consumer health.

Chemical Structure Differences: Aflatoxins and Ochratoxins

Aflatoxins and ochratoxins differ significantly in their chemical structures, influencing their detection methods in grain quality control. Aflatoxins possess a difuranocoumarin nucleus with a highly reactive lactone ring, while ochratoxins contain an isocoumarin moiety linked to phenylalanine, affecting their fluorescence and binding properties. These distinct molecular frameworks require specific analytical techniques such as HPLC with fluorescence detection for aflatoxins and immunoassays or mass spectrometry optimized for ochratoxins to ensure precise contamination assessment.

Health Risks Posed by Aflatoxins and Ochratoxins in Food Products

Aflatoxins and ochratoxins are two critical mycotoxins monitored in grain quality control due to their significant health risks. Aflatoxins, primarily produced by Aspergillus flavus, are highly carcinogenic and can cause liver cancer, immunosuppression, and acute poisoning, making their detection vital in food safety. Ochratoxins, especially ochratoxin A, produced by Aspergillus and Penicillium species, pose nephrotoxic and immunotoxic risks, necessitating stringent detection to prevent chronic kidney disease and other adverse health effects in humans.

Common Detection Methods for Aflatoxin in Grains

Common detection methods for aflatoxin in grains include high-performance liquid chromatography (HPLC), enzyme-linked immunosorbent assay (ELISA), and lateral flow devices, which offer high sensitivity and specificity for rapid screening. In contrast, ochratoxin detection often relies on similar chromatographic techniques but with different sample preparation due to chemical structure differences. The widespread use of ELISA kits for aflatoxins enables efficient monitoring in grain quality control, supporting regulatory compliance and food safety.

Ochratoxin Detection Techniques: Current Approaches

Ochratoxin detection techniques in grain quality control primarily utilize chromatographic methods such as high-performance liquid chromatography (HPLC) coupled with fluorescence detection or mass spectrometry for precise quantification. Immunoassays, including enzyme-linked immunosorbent assay (ELISA), offer rapid screening solutions with high sensitivity for ochratoxin presence in cereals. Emerging biosensor technologies integrating nanomaterials enhance on-site ochratoxin detection, providing cost-effective and real-time analysis critical for ensuring food safety standards.

Sensitivity and Specificity of Aflatoxin vs Ochratoxin Testing Methods

Aflatoxin detection methods, such as ELISA and HPLC, generally exhibit higher sensitivity levels compared to ochratoxin testing techniques, enabling the identification of lower toxin concentrations in grains which is critical for ensuring food safety. Specificity in aflatoxin assays is enhanced by molecular recognition elements like monoclonal antibodies, reducing cross-reactivity and false positives, whereas ochratoxin detection often faces challenges due to structural analogs. Advanced chromatographic methods combined with mass spectrometry provide robust specificity for both toxins but aflatoxin tests typically deliver faster and more reliable quantitative results for grain quality control.

Regulatory Limits and Standards for Aflatoxin and Ochratoxin in Grains

Regulatory limits for aflatoxins in grains are typically set by agencies such as the FDA and EFSA, often ranging from 2 to 20 parts per billion (ppb) depending on the grain type and intended use. Ochratoxin A regulatory standards are generally lower, with limits usually around 3 to 10 ppb due to its nephrotoxic and carcinogenic properties impacting grain safety. Accurate detection methods for both toxins must comply with these stringent limits to ensure food safety and international trade compliance in grain quality control.

Challenges in Simultaneous Detection of Aflatoxin and Ochratoxin

Simultaneous detection of aflatoxin and ochratoxin in grain quality control faces significant challenges due to their differing chemical structures and diverse physicochemical properties, which complicate extraction and analytical methods. Variations in toxin concentration levels and matrix interferences further hinder accurate simultaneous quantification using conventional techniques like ELISA and HPLC. Advances in multiplex immunoassays and biosensor technologies are essential to overcome these obstacles for more reliable and efficient mycotoxin monitoring in food safety.

Future Trends in Mycotoxin Detection for Enhanced Grain Safety

Emerging trends in mycotoxin detection emphasize the integration of advanced biosensors and nanotechnology for improved sensitivity in identifying aflatoxins and ochratoxins in grain samples. Multi-analyte detection platforms harnessing molecularly imprinted polymers and immunoassays enable simultaneous quantification, accelerating grain quality control processes. Future developments focus on real-time, on-site monitoring systems employing portable devices with AI-driven data analysis to enhance preventive measures against mycotoxin contamination.

Related Important Terms

Lateral Flow Immunoassay (LFIA) Strips

Lateral Flow Immunoassay (LFIA) strips offer rapid, sensitive detection of aflatoxins in grains, enabling on-site monitoring critical for food safety compliance and reducing toxin-related health risks. Ochratoxin detection using LFIA strips is also effective but often requires higher specificity optimization due to its structural diversity and lower contamination prevalence in common grains.

Portable Biosensor Platforms

Portable biosensor platforms for aflatoxin detection offer rapid, on-site screening with high sensitivity and selectivity, leveraging immunoassays and electrochemical sensors tailored to detect aflatoxins at parts-per-billion levels. In contrast, ochratoxin detection on portable devices emphasizes multiplexed sensing capabilities and biosensor miniaturization to simultaneously monitor multiple mycotoxins, ensuring comprehensive grain quality control in diverse environmental conditions.

Aptamer-Based Toxin Sensors

Aptamer-based toxin sensors offer high specificity and sensitivity in detecting aflatoxins and ochratoxins, critical mycotoxins affecting grain quality control. Compared to traditional methods, aptamer sensors provide rapid, cost-effective, and portable solutions for real-time monitoring of toxin contamination in grain storage and processing.

Quantum Dot Immunofluorescence

Quantum dot immunofluorescence offers highly sensitive and specific detection for both aflatoxin and ochratoxin in grain quality control, surpassing traditional methods by utilizing semiconductor nanoparticles that emit stable, bright fluorescence. This technology enables simultaneous multiplexed analysis, enhancing early contamination screening and ensuring safer food supply chains.

Microfluidic Detection Chips

Microfluidic detection chips enable rapid, sensitive identification of aflatoxins and ochratoxins in grain samples by integrating micro-scale fluid manipulation with biosensors for real-time analysis. These chips significantly enhance grain quality control by providing lower detection limits for aflatoxins and ochratoxins compared to conventional assays, facilitating timely intervention in food safety management.

Surface-Enhanced Raman Spectroscopy (SERS) for Mycotoxins

Surface-Enhanced Raman Spectroscopy (SERS) enables rapid, sensitive detection of aflatoxins and ochratoxins in grain quality control by enhancing molecular fingerprint signals at trace levels. Compared to traditional methods, SERS offers improved specificity and lower detection limits for multiple mycotoxins simultaneously, facilitating early intervention and minimizing contamination risk.

Immunomagnetic Separation (IMS) Techniques

Immunomagnetic Separation (IMS) techniques provide highly selective and efficient extraction of aflatoxins and ochratoxins from grain samples, enhancing the sensitivity of subsequent analytical methods like HPLC and ELISA. IMS coupled with specific antibody-coated magnetic beads offers rapid purification and concentration of mycotoxins, reducing matrix interference and enabling precise detection critical for grain quality control.

Multiplex Real-Time PCR for Mycotoxin Genes

Multiplex Real-Time PCR enables simultaneous detection of aflatoxin and ochratoxin biosynthesis genes in grain samples, enhancing the precision and speed of mycotoxin contamination assessment in food quality control. This molecular approach targets specific gene clusters such as the aflR gene for aflatoxins and the pks gene for ochratoxins, providing high sensitivity and specificity critical for preventing mycotoxin-related health risks.

Paper-Based Analytical Devices (PADs)

Paper-Based Analytical Devices (PADs) offer rapid, cost-effective detection of aflatoxins and ochratoxins in grains, with aflatoxin detection often leveraging immunoassays for higher specificity and sensitivity. Ochratoxin detection on PADs typically utilizes enzymatic or fluorescence-based methods, providing effective screening tools for ensuring grain quality and safety in food science applications.

Electrochemical Immunosensors for Dual Toxin Detection

Electrochemical immunosensors enable sensitive and simultaneous detection of aflatoxin and ochratoxin, enhancing grain quality control through rapid, selective, and cost-effective monitoring. These sensors leverage antibody-antigen interactions on electrode surfaces, providing high specificity and low detection limits critical for ensuring food safety in food science and technology applications.

Aflatoxin detection vs ochratoxin detection for grain quality control Infographic

agridif.com

agridif.com