Controlled atmosphere storage extends the shelf life of fruits and vegetables by precisely regulating oxygen, carbon dioxide, and humidity levels within large storage facilities, slowing respiration and delaying ripening. Modified atmosphere packaging achieves similar preservation by adjusting the gas composition inside sealed packages, creating an optimal microenvironment at a smaller scale. Both techniques reduce spoilage and maintain quality, but controlled atmosphere storage suits bulk storage and long-term preservation, whereas modified atmosphere packaging is ideal for retail-ready products and shorter supply chains.

Table of Comparison

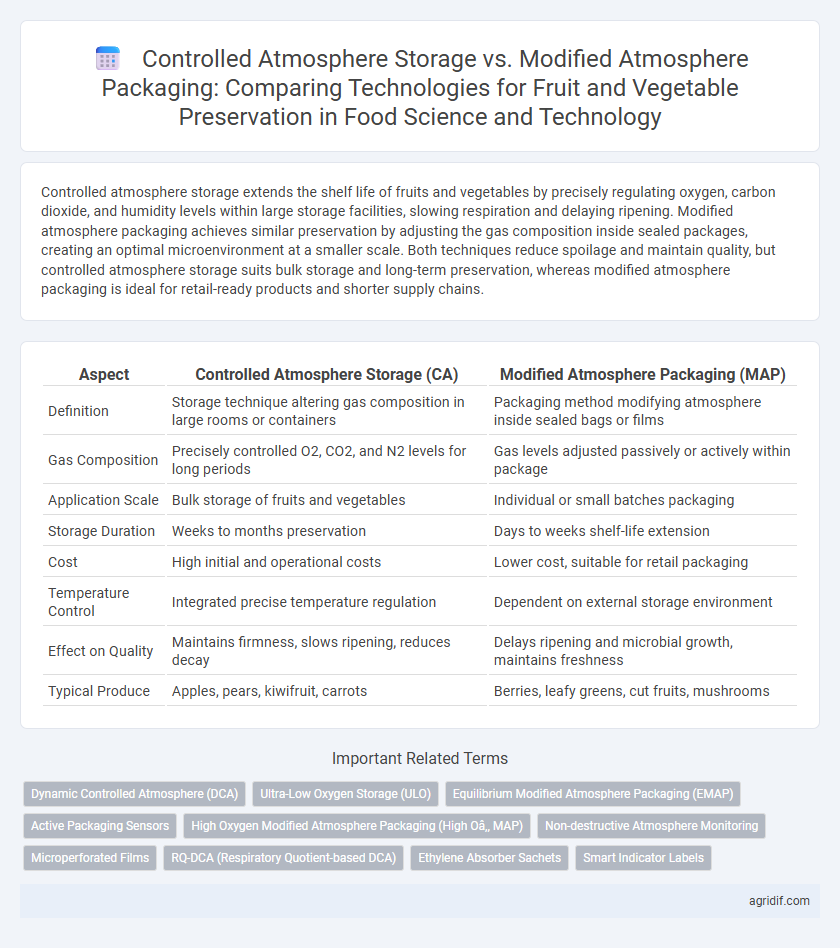

| Aspect | Controlled Atmosphere Storage (CA) | Modified Atmosphere Packaging (MAP) |

|---|---|---|

| Definition | Storage technique altering gas composition in large rooms or containers | Packaging method modifying atmosphere inside sealed bags or films |

| Gas Composition | Precisely controlled O2, CO2, and N2 levels for long periods | Gas levels adjusted passively or actively within package |

| Application Scale | Bulk storage of fruits and vegetables | Individual or small batches packaging |

| Storage Duration | Weeks to months preservation | Days to weeks shelf-life extension |

| Cost | High initial and operational costs | Lower cost, suitable for retail packaging |

| Temperature Control | Integrated precise temperature regulation | Dependent on external storage environment |

| Effect on Quality | Maintains firmness, slows ripening, reduces decay | Delays ripening and microbial growth, maintains freshness |

| Typical Produce | Apples, pears, kiwifruit, carrots | Berries, leafy greens, cut fruits, mushrooms |

Introduction to Postharvest Atmosphere Management

Controlled atmosphere storage regulates oxygen, carbon dioxide, and humidity levels within large storage facilities to slow respiration and extend shelf life of fruits and vegetables. Modified atmosphere packaging alters the gas composition inside sealed packages to maintain freshness during transportation and retail display. Both techniques optimize postharvest atmosphere management by reducing oxidative stress, delaying ripening, and minimizing microbial growth.

Fundamentals of Controlled Atmosphere (CA) Storage

Controlled atmosphere (CA) storage regulates oxygen, carbon dioxide, and humidity levels to slow respiration and delay ripening in fruits and vegetables, extending shelf life and preserving quality. Unlike modified atmosphere packaging (MAP), which alters the gas composition inside a package, CA storage controls the entire storage environment, enabling precise management of atmospheric conditions at scale. Key gas concentrations typically maintained are oxygen levels around 1-3% and carbon dioxide levels between 2-5%, optimizing metabolic rates and minimizing microbial growth.

Principles of Modified Atmosphere Packaging (MAP)

Modified Atmosphere Packaging (MAP) involves altering the composition of gases within a sealed package to slow down respiration and delay ripening in fruits and vegetables, typically by reducing oxygen levels and increasing carbon dioxide concentrations. This technique leverages the principle that controlled gas mixtures inhibit microbial growth and enzymatic reactions, maintaining product freshness and extending shelf life while retaining sensory and nutritional quality. MAP differs from controlled atmosphere storage by applying these gas modifications on a product-specific scale within individual packages rather than through environmental control of entire storage rooms.

Key Differences Between CA Storage and MAP

Controlled atmosphere (CA) storage regulates oxygen, carbon dioxide, and humidity levels in large, sealed rooms to extend the shelf life of fruits and vegetables by slowing respiration and delaying ripening. Modified atmosphere packaging (MAP) modifies gas composition within a package, using films that adjust permeability to maintain an optimal atmosphere around the produce, enhancing freshness during transportation and retail display. CA storage is ideal for long-term bulk storage with precise atmospheric control, whereas MAP offers flexibility for smaller quantities by providing tailored microenvironments within packaging.

Impact on Shelf Life Extension for Fruits and Vegetables

Controlled atmosphere storage uses precise regulation of oxygen, carbon dioxide, and humidity levels, significantly slowing respiration rates and delaying ripening in fruits and vegetables, thereby extending shelf life by weeks to months. Modified atmosphere packaging adjusts gas composition within sealed packaging, reducing oxygen and increasing carbon dioxide around produce, which slows metabolic processes and microbial growth but typically extends shelf life for days to weeks. The choice between controlled atmosphere storage and modified atmosphere packaging depends on the type of produce, desired shelf life duration, and cost considerations, with controlled atmosphere storage often preferred for long-term preservation in commercial supply chains.

Effects on Nutritional and Sensory Quality

Controlled atmosphere storage significantly slows respiration rates and enzymatic activity in fruits and vegetables by regulating oxygen, carbon dioxide, and humidity levels, thus preserving vitamin C content and maintaining firmness over extended periods. Modified atmosphere packaging alters gas composition in sealed packages, reducing oxidative degradation and microbial growth, which helps retain color, flavor, and antioxidants like polyphenols. Both technologies improve shelf life while balancing sensory attributes and nutrient retention, yet controlled atmosphere storage is more effective for bulk storage, whereas modified atmosphere packaging is ideal for retail-ready produce.

Technical Requirements and Scalability

Controlled atmosphere storage demands advanced gas regulation systems and extensive infrastructure to maintain precise oxygen, carbon dioxide, and humidity levels, ensuring long-term preservation of fruits and vegetables. Modified atmosphere packaging relies on selectively permeable films that adjust gas exchange at the package level, offering flexibility but limited control compared to centralized systems. Scalability favors controlled atmosphere storage for large-scale operations due to its capacity to handle bulk volumes, whereas modified atmosphere packaging suits smaller or diverse product lines with rapid turnover.

Cost Analysis and Economic Considerations

Controlled atmosphere storage requires significant upfront investment in specialized facilities and continuous monitoring systems, resulting in higher fixed costs compared to modified atmosphere packaging (MAP), which involves lower initial capital but recurring material expenses. MAP offers greater flexibility and scalability for small- to medium-sized operations, reducing overall operational costs by limiting the need for extensive infrastructure. Economic considerations also include product shelf-life extension and reduced spoilage rates, which vary between the two technologies and directly impact return on investment and profit margins in the fresh produce supply chain.

Sustainability and Environmental Impacts

Controlled atmosphere storage extends the shelf life of fruits and vegetables by regulating oxygen, carbon dioxide, and humidity levels in large-scale facilities, reducing food waste but requiring significant energy consumption for climate control systems. Modified atmosphere packaging uses gas-permeable films to alter the internal atmosphere around individual products, minimizing the need for extensive energy use but generating additional plastic waste, which challenges sustainability efforts. Balancing energy efficiency with packaging waste management is crucial for minimizing the overall environmental impact of these preservation methods in the food supply chain.

Choosing the Right Technology for Specific Crops

Controlled atmosphere storage maintains precise levels of oxygen, carbon dioxide, and humidity to extend the shelf life of high-value fruits like apples and pears by slowing respiration and delaying ripening. Modified atmosphere packaging, using gas-permeable films tailored to specific fruits and vegetables such as berries and leafy greens, optimizes gas exchange to reduce spoilage during distribution. Selecting the right technology depends on crop respiration rates, storage duration, and supply chain requirements to maximize freshness and minimize post-harvest losses.

Related Important Terms

Dynamic Controlled Atmosphere (DCA)

Dynamic Controlled Atmosphere (DCA) technology optimizes oxygen and carbon dioxide levels based on real-time monitoring of fruit and vegetable respiration rates, significantly extending shelf life compared to traditional controlled atmosphere storage. Unlike Modified Atmosphere Packaging (MAP) that relies on passive gas exchange within sealed films, DCA actively adjusts atmospheric conditions to reduce metabolic activity, delay ripening, and maintain texture and nutritional quality.

Ultra-Low Oxygen Storage (ULO)

Ultra-Low Oxygen Storage (ULO) achieves oxygen levels as low as 0.5% to significantly slow respiration and delay ripening in fruits and vegetables, providing superior shelf-life extension compared to conventional Controlled Atmosphere (CA) storage. Modified Atmosphere Packaging (MAP) adjusts gas composition inside sealed packaging but cannot maintain the ultra-low oxygen conditions and precise control characteristic of ULO, making ULO more effective for long-term storage of highly perishable produce.

Equilibrium Modified Atmosphere Packaging (EMAP)

Controlled atmosphere storage precisely regulates oxygen, carbon dioxide, and humidity levels in large storage units to extend the shelf life of fruits and vegetables by slowing respiration rates and delaying ripening. Equilibrium Modified Atmosphere Packaging (EMAP) achieves a balance between gas composition inside the package and produce respiration through selective permeability films, providing a cost-effective and scalable solution that optimizes freshness and quality during retail and distribution.

Active Packaging Sensors

Controlled atmosphere storage utilizes precise gas composition regulation to slow respiration and extend shelf life of fruits and vegetables, enhancing freshness through continuous environmental monitoring. Modified atmosphere packaging incorporates active packaging sensors that detect oxygen, carbon dioxide, and ethylene levels inside sealed packages, providing real-time quality indicators to optimize storage conditions and reduce spoilage.

High Oxygen Modified Atmosphere Packaging (High O₂ MAP)

High Oxygen Modified Atmosphere Packaging (High O2 MAP) extends the shelf life of fruits and vegetables by maintaining oxygen levels typically above 60%, which suppresses anaerobic respiration and microbial growth better than traditional controlled atmosphere storage. This technology optimizes freshness and nutrient retention by combining precise gas regulation with packaging materials that tailor gas permeability, enhancing post-harvest quality and reducing spoilage.

Non-destructive Atmosphere Monitoring

Controlled atmosphere storage employs precise regulation of oxygen, carbon dioxide, and humidity levels in large, sealed environments to extend shelf life, while modified atmosphere packaging adjusts gas composition within flexible packaging to maintain produce freshness. Non-destructive atmosphere monitoring utilizes sensors like infrared spectroscopy and gas sensors to continuously track internal gas concentrations, enabling real-time quality assessment without damaging fruits and vegetables.

Microperforated Films

Microperforated films in modified atmosphere packaging (MAP) offer precise gas exchange control, maintaining optimal O2 and CO2 levels to extend the shelf life of fruits and vegetables by reducing respiration rates and delaying senescence. Unlike controlled atmosphere (CA) storage, which requires large-scale, temperature-regulated facilities, MAP with microperforated films enables cost-effective, scalable preservation by allowing adequate ventilation while preventing moisture loss and microbial growth.

RQ-DCA (Respiratory Quotient-based DCA)

Controlled atmosphere storage utilizes precise regulation of oxygen, carbon dioxide, and humidity levels to slow respiration and delay ripening in fruits and vegetables, with Respiratory Quotient-based Dynamic Controlled Atmosphere (RQ-DCA) technology optimizing gas compositions in real-time based on respiratory activity. Modified atmosphere packaging alters gas composition within packaging films but lacks the dynamic gas regulation of RQ-DCA, making controlled atmosphere storage with RQ-DCA more effective for extending shelf life and maintaining quality by continuously adjusting to metabolic changes.

Ethylene Absorber Sachets

Controlled atmosphere storage regulates oxygen, carbon dioxide, and humidity levels in large-scale environments, effectively slowing fruit and vegetable respiration and ethylene production, while modified atmosphere packaging uses ethylene absorber sachets to actively capture and neutralize ethylene gas within sealed packages, extending shelf life at a product-specific scale. Ethylene absorber sachets, often containing potassium permanganate or zeolite-based materials, are crucial in modified atmosphere packaging for maintaining optimal freshness by significantly reducing ethylene-induced ripening and spoilage in perishable produce.

Smart Indicator Labels

Smart indicator labels in controlled atmosphere storage provide real-time monitoring of oxygen and carbon dioxide levels to optimize fruit and vegetable freshness, enabling precise adjustments to storage conditions. In modified atmosphere packaging, these labels offer immediate quality feedback by detecting gas composition changes inside the packaging, ensuring extended shelf life and reducing spoilage.

Controlled atmosphere storage vs modified atmosphere packaging for fruits and vegetables Infographic

agridif.com

agridif.com