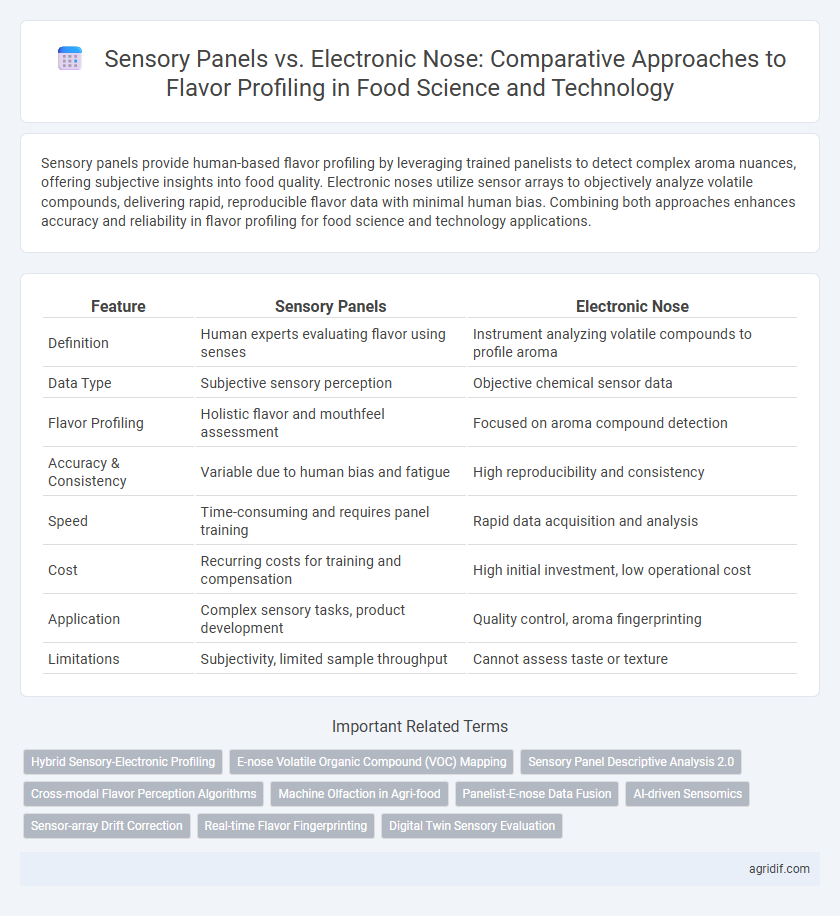

Sensory panels provide human-based flavor profiling by leveraging trained panelists to detect complex aroma nuances, offering subjective insights into food quality. Electronic noses utilize sensor arrays to objectively analyze volatile compounds, delivering rapid, reproducible flavor data with minimal human bias. Combining both approaches enhances accuracy and reliability in flavor profiling for food science and technology applications.

Table of Comparison

| Feature | Sensory Panels | Electronic Nose |

|---|---|---|

| Definition | Human experts evaluating flavor using senses | Instrument analyzing volatile compounds to profile aroma |

| Data Type | Subjective sensory perception | Objective chemical sensor data |

| Flavor Profiling | Holistic flavor and mouthfeel assessment | Focused on aroma compound detection |

| Accuracy & Consistency | Variable due to human bias and fatigue | High reproducibility and consistency |

| Speed | Time-consuming and requires panel training | Rapid data acquisition and analysis |

| Cost | Recurring costs for training and compensation | High initial investment, low operational cost |

| Application | Complex sensory tasks, product development | Quality control, aroma fingerprinting |

| Limitations | Subjectivity, limited sample throughput | Cannot assess taste or texture |

Introduction to Flavor Profiling in Food Science

Flavor profiling in food science involves analyzing and identifying aroma and taste attributes critical for product development and quality control. Sensory panels use trained human assessors to evaluate complex flavor nuances with high sensitivity to subtle differences. Electronic noses employ sensor arrays to detect volatile compounds, offering rapid and objective flavor analysis but often require calibration against human sensory data for accurate interpretation.

Principles of Sensory Panels in Flavor Analysis

Sensory panels in flavor analysis rely on trained human evaluators to detect and describe complex flavor attributes through perception of taste, aroma, and texture, leveraging the human brain's ability to integrate multisensory information. Panelists are systematically trained to use standardized vocabulary and rating scales to ensure consistent and reproducible flavor profiling outcomes. This method serves as a gold standard in flavor analysis due to its capacity to capture subjective sensory nuances that electronic noses may not fully replicate.

Understanding Electronic Nose Technology

Electronic nose technology utilizes sensor arrays to detect volatile organic compounds, enabling precise and rapid flavor profiling in food science. Unlike sensory panels, which rely on human perception subject to variability and fatigue, electronic noses provide consistent, replicable data by analyzing complex aroma patterns. This technology enhances flavor analysis efficiency, supporting quality control and product development in food manufacturing.

Methodological Differences: Sensory Panels vs Electronic Nose

Sensory panels rely on human evaluators to detect and describe flavor attributes using taste, smell, and cognitive interpretation, providing subjective, nuanced insights into food flavor profiles. In contrast, the electronic nose employs sensor arrays and pattern recognition algorithms to objectively analyze volatile compounds, offering rapid and reproducible chemical fingerprint data. Methodological differences include variability in human perception versus standardized sensor responses, with sensory panels capturing complex flavor interactions and electronic noses excelling in high-throughput volatile analysis.

Accuracy and Reliability in Flavor Detection

Sensory panels provide nuanced flavor profiling through human perception, capturing complex taste and aroma interactions with high sensitivity but may suffer from variability and fatigue-induced errors. Electronic noses utilize sensor arrays and pattern recognition algorithms to deliver consistent and objective flavor detection, offering superior repeatability but sometimes lacking the subtlety to differentiate closely related odors. Combining both approaches enhances accuracy and reliability by leveraging human sensory intuition alongside precise electronic measurement in food flavor analysis.

Applications in Food Quality Assurance

Sensory panels provide human perception and nuanced flavor evaluation essential for assessing product acceptability and detecting subtle taste variations in food quality assurance. Electronic noses utilize sensor arrays and machine learning algorithms to offer rapid, objective, and consistent flavor profiling, enabling real-time monitoring and control in production processes. Combining both methods enhances accuracy and efficiency in detecting flavor defects, ensuring product consistency and consumer satisfaction.

Advantages and Limitations of Sensory Panels

Sensory panels excel in capturing complex flavor nuances through human perception, enabling the detection of subtle taste and aroma attributes that electronic noses might miss. These panels provide contextual insights based on cultural and experiential factors, which are crucial for product development and consumer acceptance studies. However, sensory panels are subject to variability due to human fatigue, bias, and inconsistent sensitivity, limiting reproducibility and scalability compared to electronic nose technology.

Pros and Cons of Electronic Nose Systems

Electronic nose systems offer rapid, objective, and reproducible flavor profiling by detecting volatile organic compounds through sensor arrays, minimizing human bias and sensory fatigue inherent in traditional sensory panels. These devices excel in high-throughput screening and standardization but struggle with complex flavor matrices and lack the nuanced interpretation of human sensory perception. Limitations include sensor drift, calibration challenges, and difficulty distinguishing overlapping aromas, which can affect reliability in diverse food applications.

Integrating Sensory and Electronic Methods for Enhanced Profiling

Integrating sensory panels with electronic nose technology enhances flavor profiling by combining human perceptual accuracy with objective chemical analysis. Sensory panels provide nuanced descriptions and detect subtle aroma variations, while electronic noses offer rapid, reproducible, and quantifiable data on volatile compounds. This hybrid approach improves reliability and depth in flavor characterization, accelerating product development and quality control in food science.

Future Trends in Flavor Profiling Technologies for Agriculture

Sensory panels provide nuanced human perception essential for flavor profiling but face limitations in consistency and scalability, whereas electronic noses offer rapid, objective, and reproducible analysis using sensor arrays detecting volatile compounds. Future trends in flavor profiling technologies for agriculture emphasize integrating electronic noses with machine learning algorithms and high-throughput phenotyping to enhance crop flavor selection and breeding programs. Emerging developments focus on miniaturized, portable devices enabling real-time, on-site flavor assessment, significantly advancing precision agriculture and quality control.

Related Important Terms

Hybrid Sensory-Electronic Profiling

Hybrid sensory-electronic profiling combines human sensory panels with electronic nose technology to enhance accuracy and reproducibility in flavor profiling, leveraging the nuanced perception of trained tasters alongside rapid, objective chemical detection. Integrating volatile compound analysis from electronic noses with sensory panel feedback enables a comprehensive evaluation of complex flavor profiles, advancing food quality control and product development in Food Science and Technology.

E-nose Volatile Organic Compound (VOC) Mapping

Sensory panels rely on human perception to evaluate flavor profiles, while electronic noses utilize sensor arrays to detect and map volatile organic compounds (VOCs) with high precision and reproducibility. Electronic nose VOC mapping enables rapid, quantitative analysis of complex aroma patterns, providing objective data crucial for flavor consistency and quality control in food science and technology.

Sensory Panel Descriptive Analysis 2.0

Sensory Panel Descriptive Analysis 2.0 enhances flavor profiling by combining trained human evaluators' nuanced perception with advanced statistical tools, improving accuracy and reproducibility in identifying subtle flavor attributes. Compared to electronic noses, this method captures complex sensory experiences and emotional responses, providing richer data for product development and quality control in food science.

Cross-modal Flavor Perception Algorithms

Sensory panels provide nuanced human perception data critical for capturing subjective flavor experiences, while electronic noses deliver objective chemical signature analysis essential for reproducible flavor profiling. Cross-modal flavor perception algorithms integrate these datasets to enhance predictive accuracy by correlating volatile compound patterns detected by electronic noses with sensory panel feedback, optimizing flavor development and quality control in Food Science and Technology.

Machine Olfaction in Agri-food

Machine olfaction systems, such as electronic noses, offer rapid, objective, and reproducible flavor profiling by detecting volatile compounds with sensor arrays, enhancing precision in agri-food quality control compared to traditional sensory panels. While sensory panels provide nuanced human perception essential for complex flavor attributes, electronic noses enable high-throughput screening and consistency in monitoring product freshness and detecting adulteration in agricultural products.

Panelist-E-nose Data Fusion

Combining sensory panel evaluations with electronic nose technology through data fusion enhances flavor profiling accuracy by integrating human perception nuances and electronic sensor precision. This panelist-e-nose data fusion approach leverages multivariate analysis to correlate subjective sensory attributes with objective volatile compound patterns, optimizing flavor characterization in food science.

AI-driven Sensomics

AI-driven sensomics integrates sensory panel data with electronic nose outputs, enhancing flavor profiling accuracy by combining human perception nuances and machine precision. This hybrid approach accelerates flavor compound identification, enabling more objective and comprehensive analysis in Food Science and Technology.

Sensor-array Drift Correction

Sensor-array drift correction is critical in electronic noses to maintain accuracy and reliability in flavor profiling over time, compensating for sensor aging and environmental changes that can distort volatile compound detection. Sensory panels rely on human perception without such drift issues but are subject to variability and fatigue, making electronic noses with effective drift correction algorithms a valuable tool for consistent, scalable flavor analysis in food science.

Real-time Flavor Fingerprinting

Sensory panels provide nuanced human perception for flavor profiling but are limited by subjectivity and fatigue, while electronic noses offer real-time flavor fingerprinting through sensor arrays and machine learning algorithms, enabling rapid, objective analysis of volatile compounds. Combining sensory data with electronic nose outputs enhances accuracy in detecting subtle flavor changes and ensures consistent quality control in food science and technology.

Digital Twin Sensory Evaluation

Sensory panels provide nuanced flavor profiles through human perception, capturing complex taste and aroma attributes that electronic noses, relying on sensor arrays and pattern recognition algorithms, may struggle to fully replicate. Integrating electronic nose data into a Digital Twin Sensory Evaluation framework enhances predictive accuracy by combining objective sensor inputs with virtual sensory modeling to simulate and optimize flavor experiences efficiently.

Sensory panels vs electronic nose for flavor profiling Infographic

agridif.com

agridif.com