Continuous flow sterilization offers more precise temperature control and uniform heat distribution compared to batch sterilization, enhancing the safety and quality of canned foods. This method reduces processing time and increases throughput, making it more efficient for large-scale production. While batch sterilization remains versatile for various product sizes, continuous flow systems improve consistency and minimize thermal degradation in canned food products.

Table of Comparison

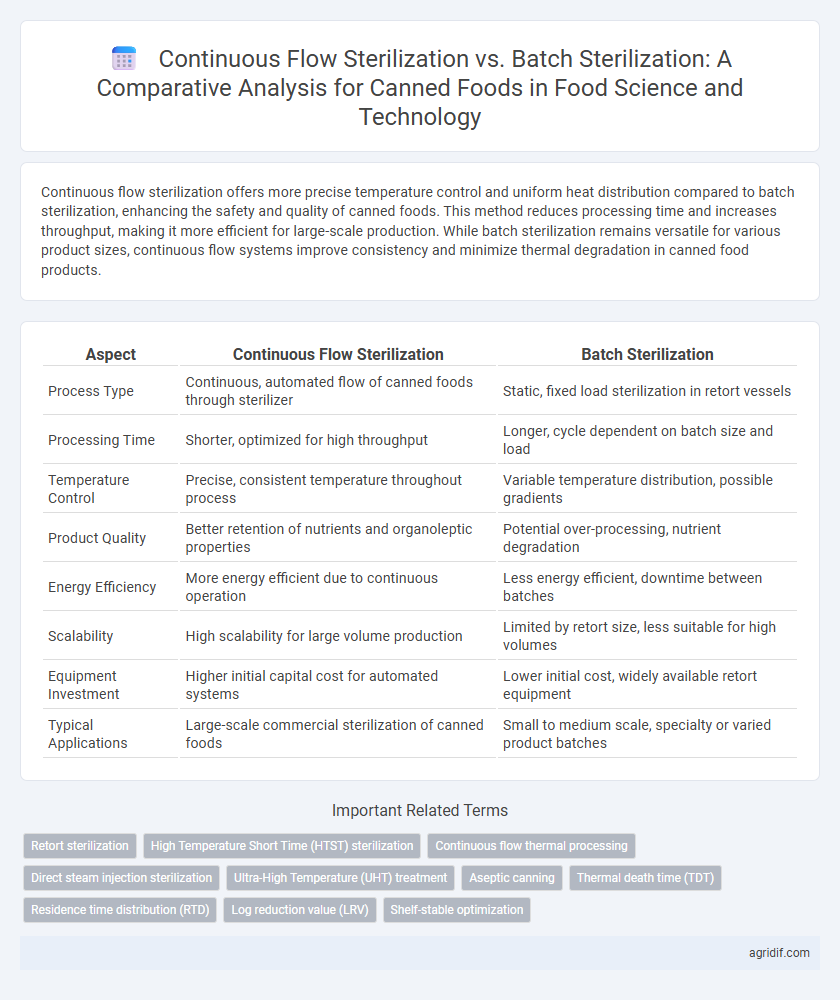

| Aspect | Continuous Flow Sterilization | Batch Sterilization |

|---|---|---|

| Process Type | Continuous, automated flow of canned foods through sterilizer | Static, fixed load sterilization in retort vessels |

| Processing Time | Shorter, optimized for high throughput | Longer, cycle dependent on batch size and load |

| Temperature Control | Precise, consistent temperature throughout process | Variable temperature distribution, possible gradients |

| Product Quality | Better retention of nutrients and organoleptic properties | Potential over-processing, nutrient degradation |

| Energy Efficiency | More energy efficient due to continuous operation | Less energy efficient, downtime between batches |

| Scalability | High scalability for large volume production | Limited by retort size, less suitable for high volumes |

| Equipment Investment | Higher initial capital cost for automated systems | Lower initial cost, widely available retort equipment |

| Typical Applications | Large-scale commercial sterilization of canned foods | Small to medium scale, specialty or varied product batches |

Introduction to Sterilization in Canned Food Processing

Continuous flow sterilization offers precise temperature and time control, enhancing microbial inactivation while preserving nutrient content in canned foods. Batch sterilization involves processing foods in sealed containers under high heat, ensuring safety but often resulting in longer processing times and potential quality degradation. Selecting the optimal sterilization method impacts microbial safety, nutrient retention, and overall product quality in canned food processing.

Principles of Batch Sterilization

Batch sterilization for canned foods relies on heating a fixed volume of product in a sealed container under controlled temperature and pressure to eliminate microbial contaminants. This process maintains uniform thermal exposure throughout the batch, ensuring the destruction of spores and pathogens while preserving food quality. Temperature-time combinations are carefully optimized to achieve commercial sterility without compromising nutrient retention or sensory attributes.

Fundamentals of Continuous Flow Sterilization

Continuous flow sterilization employs high-temperature processing as canned foods continuously pass through a heated zone, ensuring uniform heat penetration and reduced processing time compared to batch sterilization. This method maintains product quality by minimizing overprocessing and thermal degradation while achieving commercial sterility. The principles of heat transfer, such as conduction and convection within the continuous flow system, optimize microbial inactivation and energy efficiency in large-scale production.

Comparison of Heat Transfer Efficiency

Continuous flow sterilization offers superior heat transfer efficiency compared to batch sterilization due to its consistent and controlled processing environment, which minimizes temperature fluctuations. The continuous system enables rapid heating and cooling rates, reducing thermal degradation of canned foods while ensuring uniform heat distribution. In contrast, batch sterilization often experiences uneven temperature profiles and longer processing times, leading to potential quality loss and lower energy efficiency.

Impact on Nutritional Quality and Sensory Attributes

Continuous flow sterilization preserves nutritional quality in canned foods more effectively than batch sterilization by minimizing heat exposure time, thereby reducing the degradation of heat-sensitive vitamins like vitamin C and B-complex. Sensory attributes such as texture, color, and flavor are better maintained due to uniform and controlled heating, which prevents overcooking and enzymatic browning commonly observed in batch processing. This method enhances product consistency and shelf-life while retaining desirable organoleptic properties crucial for consumer acceptance.

Microbial Inactivation: Efficacy and Safety

Continuous flow sterilization offers enhanced microbial inactivation by maintaining consistent high temperatures and reducing exposure time, which preserves food quality while ensuring safety. Batch sterilization provides uniform heat distribution but may result in uneven microbial kill due to temperature fluctuations within the retort. Continuous flow systems improve efficacy by minimizing thermal lag, reducing microbial survival risks, and supporting regulatory compliance for canned food safety.

Energy Consumption and Operational Costs

Continuous flow sterilization in canned foods significantly reduces energy consumption by maintaining steady-state thermal conditions, leading to enhanced heat transfer efficiency compared to batch sterilization. This method lowers operational costs through decreased processing time, reduced labor requirements, and minimized utility usage, optimizing production scalability. Batch sterilization exhibits higher energy usage due to repeated heating and cooling cycles, resulting in increased downtime and elevated maintenance expenses.

Scalability and Production Throughput

Continuous flow sterilization offers superior scalability and higher production throughput compared to batch sterilization, making it ideal for large-scale canned food manufacturing. This method enables constant processing with reduced downtime between batches, optimizing plant efficiency and meeting high demand. Batch sterilization, although flexible for smaller volumes, faces limitations in scalability due to longer cycle times and increased labor intensity.

Equipment Design and Maintenance Considerations

Continuous flow sterilization equipment for canned foods features automated, high-capacity systems with precise temperature and time controls, enabling consistent sterilization and increased throughput. Batch sterilization equipment requires robust, insulated retorts designed for uniform heat distribution and easy access for loading, unloading, and cleaning, emphasizing durability and corrosion resistance. Maintenance considerations for continuous flow systems focus on monitoring flow rates, heat exchangers, and sealing mechanisms, while batch systems demand regular inspection of pressure vessels, gaskets, and steam traps to ensure safety and efficiency.

Future Trends in Canned Food Sterilization Technologies

Continuous flow sterilization in canned food processing offers enhanced efficiency and precise thermal control, reducing nutrient degradation compared to traditional batch sterilization methods. Emerging trends emphasize integration of advanced sensors, real-time monitoring, and automation to optimize sterilization parameters, ensuring food safety while preserving sensory and nutritional quality. Future developments focus on sustainable energy use and minimizing processing time to meet growing demands for high-quality, minimally processed canned foods.

Related Important Terms

Retort sterilization

Continuous flow sterilization enhances efficiency in canned food processing by maintaining consistent retort sterilization parameters, resulting in uniform microbial inactivation and improved product quality compared to batch sterilization. Retort sterilization in continuous systems reduces processing time and energy consumption while ensuring compliance with food safety standards such as F0 value monitoring.

High Temperature Short Time (HTST) sterilization

Continuous flow sterilization using High Temperature Short Time (HTST) achieves efficient microbial inactivation in canned foods by rapidly heating products to 121degC for 15 seconds, preserving sensory and nutritional quality compared to traditional batch sterilization. This method enhances process control and energy efficiency, minimizing thermal damage and extending shelf life without compromising food safety.

Continuous flow thermal processing

Continuous flow thermal processing provides precise temperature control and uniform heat distribution, significantly reducing nutrient degradation and processing time compared to batch sterilization for canned foods. This method enhances product quality and safety by enabling consistent microbial inactivation while maintaining sensory attributes and minimizing thermal damage.

Direct steam injection sterilization

Direct steam injection sterilization in continuous flow systems enhances heat transfer efficiency and reduces processing time compared to traditional batch sterilization of canned foods, resulting in improved product quality and shelf stability. This method minimizes thermal degradation and nutrient loss by rapidly achieving target temperatures through direct steam contact, optimizing microbial inactivation and energy consumption in food processing.

Ultra-High Temperature (UHT) treatment

Continuous flow sterilization using Ultra-High Temperature (UHT) treatment delivers rapid heating and cooling that preserves nutritional quality and extends shelf life of canned foods more efficiently than batch sterilization. This method enhances microbial safety by applying temperatures above 135degC for a few seconds, minimizing thermal damage while ensuring commercial sterility.

Aseptic canning

Continuous flow sterilization in aseptic canning offers precise control over temperature and time, ensuring uniform microbial inactivation and preserving food quality with higher efficiency compared to batch sterilization. This method reduces thermal degradation by minimizing exposure duration, thereby enhancing nutrient retention and extending shelf life of canned foods.

Thermal death time (TDT)

Continuous flow sterilization reduces thermal death time (TDT) more efficiently than batch sterilization by maintaining consistent temperature and heat distribution throughout canned foods, minimizing over-processing and nutrient degradation. This method enhances microbial inactivation kinetics, ensuring safer products with improved texture and flavor retention compared to traditional batch processes.

Residence time distribution (RTD)

Continuous flow sterilization in canned foods offers a more uniform Residence Time Distribution (RTD), minimizing overprocessing and ensuring consistent microbial inactivation compared to batch sterilization, where variable RTD can cause uneven heat exposure and affect food quality. Optimizing RTD in continuous flow systems enhances product safety and preserves nutritional and sensory attributes by reducing thermal degradation during processing.

Log reduction value (LRV)

Continuous flow sterilization achieves higher Log Reduction Values (LRV) in canned foods by maintaining precise temperature control and reduced processing times, resulting in more consistent microbial inactivation compared to batch sterilization. Batch sterilization often exhibits variability in LRV due to uneven heat distribution and longer exposure times, potentially compromising food safety and quality.

Shelf-stable optimization

Continuous flow sterilization enhances shelf stability of canned foods by providing uniform heat treatment and reducing processing time, which minimizes nutrient loss and preserves sensory qualities. This method enables precise control over thermal exposure, leading to optimized microbial inactivation and extended shelf life compared to traditional batch sterilization.

Continuous flow sterilization vs batch sterilization for canned foods Infographic

agridif.com

agridif.com