Aseptic packaging preserves shelf-stable soups by sterilizing both the product and packaging separately, maintaining fresh taste and nutrient retention through minimal heat exposure. Retort packaging involves sealing soups in containers and subjecting them to high heat sterilization, which ensures long shelf life but may affect texture and flavor due to intense thermal processing. Choosing between aseptic and retort methods depends on desired product quality, shelf stability, and cost considerations in food science and technology.

Table of Comparison

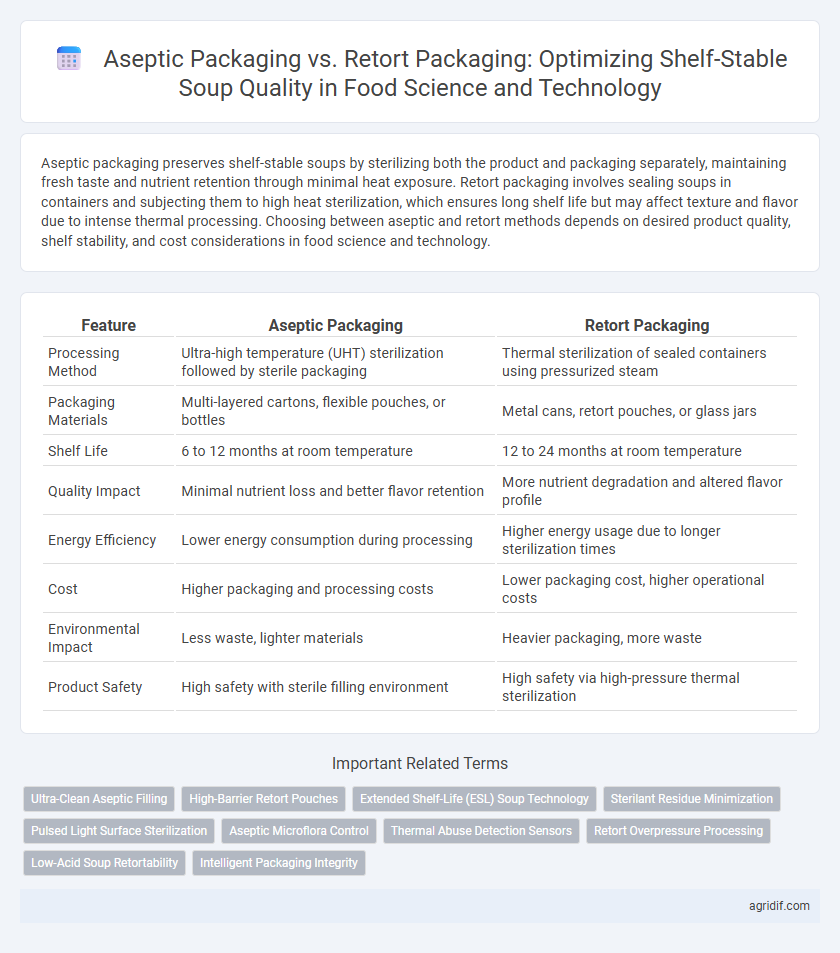

| Feature | Aseptic Packaging | Retort Packaging |

|---|---|---|

| Processing Method | Ultra-high temperature (UHT) sterilization followed by sterile packaging | Thermal sterilization of sealed containers using pressurized steam |

| Packaging Materials | Multi-layered cartons, flexible pouches, or bottles | Metal cans, retort pouches, or glass jars |

| Shelf Life | 6 to 12 months at room temperature | 12 to 24 months at room temperature |

| Quality Impact | Minimal nutrient loss and better flavor retention | More nutrient degradation and altered flavor profile |

| Energy Efficiency | Lower energy consumption during processing | Higher energy usage due to longer sterilization times |

| Cost | Higher packaging and processing costs | Lower packaging cost, higher operational costs |

| Environmental Impact | Less waste, lighter materials | Heavier packaging, more waste |

| Product Safety | High safety with sterile filling environment | High safety via high-pressure thermal sterilization |

Introduction to Shelf-Stable Soup Packaging Technologies

Aseptic packaging utilizes ultra-high temperature (UHT) processing to sterilize soup prior to filling in sterilized containers, preserving flavor and nutrients while enabling shelf stability without refrigeration. Retort packaging involves sealing soups in flexible pouches or cans followed by high-temperature steam sterilization, offering robust microbial safety but potentially affecting texture and taste due to prolonged heat exposure. Both technologies extend shelf life beyond 6 months, with aseptic systems favored for delicate flavors and retort preferred for cost-effective, high-volume production.

Principles of Aseptic Packaging in Food Processing

Aseptic packaging for shelf-stable soups involves sterilizing both the product and the packaging separately before filling and sealing in a sterile environment, preserving nutritional quality and flavor better than retort packaging, which uses heat sterilization after sealing. In aseptic processing, ultra-high temperature (UHT) treatment rapidly sterilizes the soup, minimizing thermal degradation. This method extends shelf life without refrigeration while maintaining sensory attributes, making it ideal for heat-sensitive, liquid foods.

Understanding Retort Packaging Methods

Retort packaging employs heat sterilization under high pressure to effectively inactivate microbial spores, extending the shelf life of soups without refrigeration. This method involves loading sealed pouches or cans into a retort chamber where controlled temperature and pressure ensure product safety and quality. Compared to aseptic packaging, retort processing maintains flavor and texture better in complex formulations but requires longer processing times and more robust packaging materials.

Material Composition: Aseptic vs Retort Packaging

Aseptic packaging for shelf-stable soups typically uses multilayer materials combining paperboard, polyethylene, and aluminum foil, providing lightweight, flexible barriers against oxygen and moisture. Retort packaging commonly relies on metal cans or retort pouches composed of flexible polyester, aluminum foil, and polypropylene layers designed to withstand high-temperature sterilization. The material composition in aseptic packaging prioritizes product lightness and convenience, whereas retort packaging emphasizes thermal resistance and durability for extended shelf life.

Impact on Soup Nutritional and Sensory Quality

Aseptic packaging preserves soup nutritional quality by minimizing heat exposure, maintaining higher levels of vitamins and antioxidants compared to retort packaging, which applies intensive thermal processing. Sensory attributes such as flavor, color, and texture are better retained in aseptic-packaged soups due to reduced thermal degradation and Maillard reactions. However, retort packaging offers superior microbial safety and longer shelf life, but often at the expense of slight nutrient loss and altered sensory profiles.

Comparative Shelf Life and Microbial Safety

Aseptic packaging extends shelf life of shelf-stable soups up to 6-12 months by sterilizing both product and packaging separately, preventing microbial contamination and preserving nutrient quality. Retort packaging uses high heat sterilization inside sealed pouches or cans, achieving similar microbial safety but often resulting in shorter shelf life of 6-9 months and slight nutrient degradation. Both methods ensure safety from pathogens, but aseptic packaging offers superior preservation of sensory and nutritional attributes due to lower thermal impact.

Energy Efficiency and Processing Time Differences

Aseptic packaging for shelf-stable soups utilizes high-temperature short-time (HTST) sterilization, significantly reducing processing time and energy consumption compared to retort packaging, which relies on prolonged heating in sealed containers. Energy efficiency in aseptic processing is markedly higher due to continuous sterilization and rapid cooling, minimizing thermal load on equipment and product. In contrast, retort packaging, involving batch processing with extended heat exposure, demands greater energy input and longer processing times, affecting operational costs and carbon footprint.

Packaging Sustainability and Environmental Considerations

Aseptic packaging for shelf-stable soups offers significant sustainability advantages by using lightweight materials that reduce transportation emissions and enable more efficient recycling compared to retort packaging, which relies on heavier multilayered cans and pouches with lower recyclability. The energy consumption during aseptic processing is generally lower than retort sterilization, contributing to a smaller carbon footprint over the product life cycle. However, retort packaging's thermal stability and extended shelf life remain valuable for reducing food waste, balancing environmental trade-offs.

Cost Implications for Manufacturers

Aseptic packaging requires higher initial investment in specialized equipment and sterile processing environments, but offers lower operational costs due to faster processing times and reduced energy consumption. Retort packaging involves lower upfront costs but incurs higher ongoing expenses from energy-intensive thermal sterilization and longer production cycles. Manufacturers must balance these cost implications against product shelf life, quality retention, and market demands when choosing packaging methods for shelf-stable soups.

Future Trends in Shelf-Stable Soup Packaging Technologies

Future trends in shelf-stable soup packaging technologies emphasize innovations in aseptic packaging that enhance product sterility and extend shelf life without refrigeration. Retort packaging advances focus on improving barrier materials and reducing thermal processing times to preserve nutrient quality and flavor. Emerging smart packaging solutions integrating sensors for real-time freshness monitoring are also gaining prominence in both aseptic and retort packaging systems.

Related Important Terms

Ultra-Clean Aseptic Filling

Ultra-clean aseptic filling employs sterile processing and filling under hygienic conditions, significantly extending shelf life of soups without refrigeration while preserving flavor and nutrients better than retort packaging. Retort packaging uses high-temperature sterilization post-packaging, which can negatively affect texture and nutrient content, making ultra-clean aseptic methods preferable for premium shelf-stable soup products.

High-Barrier Retort Pouches

High-barrier retort pouches offer superior oxygen and moisture resistance compared to traditional retort packaging, enhancing the shelf life and quality retention of shelf-stable soups. Aseptic packaging maintains soup freshness through ultra-high temperature sterilization before sealed packaging, while high-barrier retort pouches provide thermal stability and mechanical strength during retort sterilization, combining convenience with extended preservation.

Extended Shelf-Life (ESL) Soup Technology

Aseptic packaging uses sterile processing and hermetically sealed containers to extend shelf life of soups up to 6 months without refrigeration, preserving sensory and nutritional quality more effectively than retort packaging. Retort packaging employs high-temperature sterilization inside sealed pouches or cans, achieving shelf stability for 12-18 months but often leading to textural and flavor degradation in ESL soups.

Sterilant Residue Minimization

Aseptic packaging significantly reduces sterilant residue in shelf-stable soups by using high-temperature, short-time sterilization of both product and packaging separately, minimizing chemical exposure. Retort packaging involves in-package sterilization with steam or chemical agents, often leaving higher residual sterilants, which may affect flavor and safety profiles.

Pulsed Light Surface Sterilization

Pulsed Light Surface Sterilization enhances aseptic packaging by rapidly inactivating surface microorganisms without heat, preserving the sensory qualities and nutrients of shelf-stable soups. In contrast, retort packaging relies on high-temperature thermal processing that can degrade flavor and texture, making pulsed light a superior non-thermal sterilization method for maintaining product quality and safety.

Aseptic Microflora Control

Aseptic packaging achieves superior aseptic microflora control for shelf-stable soups by sterilizing both the product and packaging separately before filling in a sterile environment, effectively minimizing microbial contamination. In contrast, retort packaging relies on high-temperature and pressure treatments post-filling, which can compromise texture and nutrient retention while providing robust microbial inactivation.

Thermal Abuse Detection Sensors

Aseptic packaging for shelf-stable soups offers superior protection against thermal abuse through integrated time-temperature indicators that monitor heat exposure, preserving product quality and safety. In contrast, retort packaging relies on rigid containers that endure higher thermal processing but lack advanced sensor integration, limiting real-time thermal abuse detection.

Retort Overpressure Processing

Retort overpressure processing applies high pressure during thermal sterilization to prevent packaging deformation in shelf-stable soups, maintaining product integrity and safety. Compared to aseptic packaging, this method ensures uniform heat penetration and effective microbial inactivation, extending shelf life while preserving flavor and nutritional quality.

Low-Acid Soup Retortability

Low-acid soups require retort packaging due to their need for high-temperature sterilization to ensure microbial safety and shelf stability, while aseptic packaging is less effective for these products because it cannot achieve the necessary thermal processing conditions. Retort packaging provides uniform heat penetration essential for low-acid soups, preventing spoilage and maintaining product quality over extended shelf life.

Intelligent Packaging Integrity

Aseptic packaging for shelf-stable soups utilizes advanced Intelligent Packaging Integrity systems with embedded sensors that continuously monitor oxygen levels and temperature fluctuations, ensuring optimal freshness and safety by detecting package breaches in real-time. Retort packaging relies on thermal sterilization but lacks integrated smart sensors, making aseptic packaging superior for proactive quality assurance and reducing food spoilage risks in supply chains.

Aseptic packaging vs retort packaging for shelf-stable soups Infographic

agridif.com

agridif.com