UHT (Ultra-High Temperature) pasteurization heats milk to 135-150degC for a few seconds, extending shelf life up to six months without refrigeration by eliminating nearly all microorganisms and spores. HTST (High-Temperature Short Time) pasteurization heats milk to 72degC for 15 seconds, effectively reducing pathogenic bacteria while preserving taste and nutritional quality, but requires refrigeration and has a shorter shelf life. The choice between UHT and HTST depends on factors like desired shelf life, flavor retention, and storage conditions, impacting consumer acceptance and product distribution.

Table of Comparison

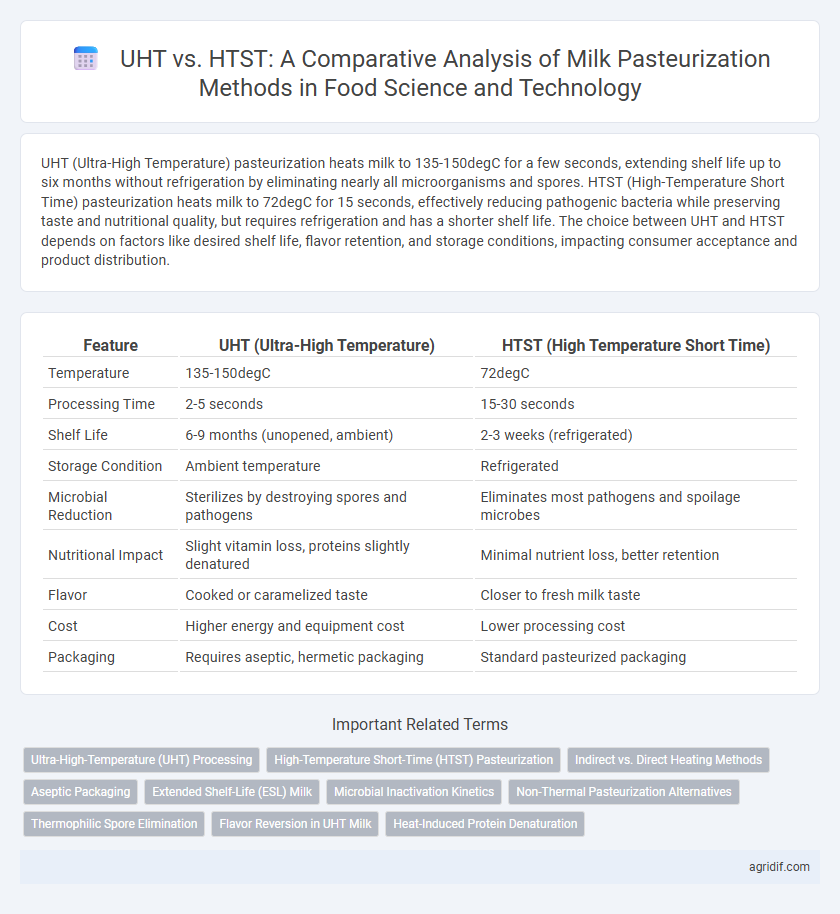

| Feature | UHT (Ultra-High Temperature) | HTST (High Temperature Short Time) |

|---|---|---|

| Temperature | 135-150degC | 72degC |

| Processing Time | 2-5 seconds | 15-30 seconds |

| Shelf Life | 6-9 months (unopened, ambient) | 2-3 weeks (refrigerated) |

| Storage Condition | Ambient temperature | Refrigerated |

| Microbial Reduction | Sterilizes by destroying spores and pathogens | Eliminates most pathogens and spoilage microbes |

| Nutritional Impact | Slight vitamin loss, proteins slightly denatured | Minimal nutrient loss, better retention |

| Flavor | Cooked or caramelized taste | Closer to fresh milk taste |

| Cost | Higher energy and equipment cost | Lower processing cost |

| Packaging | Requires aseptic, hermetic packaging | Standard pasteurized packaging |

Introduction to Milk Pasteurization Methods

UHT (Ultra-High Temperature) and HTST (High-Temperature Short-Time) are two primary milk pasteurization methods designed to eliminate pathogenic microorganisms and extend shelf life. HTST typically heats milk to 72degC for 15 seconds, preserving more of the milk's sensory and nutritional qualities, while UHT subjects milk to temperatures of about 135degC for 2-5 seconds, resulting in a sterile product with a longer shelf life but slightly altered taste. Both methods ensure safety and quality, with HTST favored for fresh milk and UHT preferred for ambient storage and extended durability.

Understanding UHT (Ultra-High Temperature) Pasteurization

Ultra-High Temperature (UHT) pasteurization involves heating milk to approximately 135-150degC for 2 to 5 seconds, effectively eliminating pathogenic microorganisms and spores, thereby extending shelf life up to 6 months without refrigeration. This process preserves key nutrients such as calcium and vitamin B12 while impacting certain heat-sensitive proteins and enzymes differently than High-Temperature Short-Time (HTST) pasteurization. UHT-treated milk undergoes aseptic packaging to maintain sterility, making it ideal for regions with limited cold chain infrastructure and enhancing global milk distribution efficiency.

Overview of HTST (High-Temperature Short-Time) Pasteurization

HTST (High-Temperature Short-Time) pasteurization involves heating milk to approximately 72degC for 15 seconds, effectively destroying pathogenic microorganisms while preserving sensory and nutritional qualities. This method balances microbial safety with milk freshness, maintaining essential proteins and vitamins better than more intense heat treatments. HTST is widely used in commercial dairy processing due to its efficiency and ability to extend shelf life without significant alterations in taste or nutritional value.

Key Differences Between UHT and HTST Techniques

UHT (Ultra-High Temperature) pasteurization heats milk to approximately 135-150degC for 2-5 seconds, enabling shelf stability of several months without refrigeration by eliminating all spores and pathogens. HTST (High-Temperature Short Time) pasteurization heats milk to 72degC for 15-20 seconds, effectively reducing microbial load while preserving more sensory and nutritional attributes but requiring refrigeration and having a shorter shelf life. The choice between UHT and HTST impacts milk quality, energy consumption, packaging requirements, and distribution logistics in the dairy industry.

Impact on Milk Nutritional Value: UHT vs HTST

UHT (Ultra-High Temperature) pasteurization exposes milk to temperatures above 135degC for a few seconds, causing more significant denaturation of heat-sensitive vitamins such as B12 and C compared to HTST (High-Temperature Short Time), which heats milk to 72degC for 15 seconds. HTST pasteurization better preserves the bioavailability of protein fractions and essential enzymes, maintaining a higher nutritional profile. Despite slight losses with UHT, its extended shelf life offers practical advantages without drastically compromising macronutrients like calcium and proteins.

Shelf Life and Storage Comparison

UHT (Ultra-High Temperature) pasteurization extends milk shelf life up to 6 months unopened at ambient temperature due to sterilization at 135-150degC for 2-5 seconds, killing all spores and microorganisms. HTST (High-Temperature Short Time) pasteurization, heating milk at 72degC for 15 seconds, requires refrigeration and provides a shelf life of about 2-3 weeks because it only eliminates pathogenic bacteria. UHT milk offers greater convenience in storage without refrigeration, making it ideal for long-term distribution, while HTST milk maintains fresher taste profiles but demands cold chain logistics.

Sensory Quality: Taste, Texture, and Appearance

UHT pasteurization produces milk with a slightly cooked flavor and a longer shelf life, but it can alter taste and texture by causing subtle caramelization and protein changes. HTST pasteurization better preserves the fresh taste and natural creaminess of milk, maintaining its smooth texture and white appearance. Sensory evaluation consistently shows HTST milk is preferred for its fresher taste and less cooked flavor compared to UHT milk.

Microbial Safety and Efficacy

UHT (Ultra-High Temperature) treatment heats milk to 135-150degC for 2-5 seconds, effectively eliminating all pathogenic microorganisms and spores, providing superior microbial safety compared to HTST (High Temperature Short Time) which heats milk to 72degC for 15 seconds. HTST pasteurization reduces common pathogens like Listeria monocytogenes and Salmonella but may not inactivate heat-resistant spores, making UHT more efficacious for extended shelf life and sterility. Both methods maintain nutritional quality, but UHT's sterilization process ensures a longer microbial safety margin, crucial for ambient storage without refrigeration.

Industrial Applications and Processing Efficiency

UHT (Ultra-High Temperature) processing sterilizes milk at 135-150degC for 2-5 seconds, enabling shelf-stable products without refrigeration, significantly reducing distribution costs in industrial applications. HTST (High-Temperature Short-Time) pasteurization heats milk to 72degC for 15 seconds, preserving more flavor and nutrients but requiring cold chain logistics, making it ideal for regional dairy production. UHT offers superior processing efficiency and extended shelf life, whereas HTST balances microbial safety with quality retention in large-scale dairy operations.

Consumer Preferences and Market Trends

UHT (Ultra-High Temperature) milk offers extended shelf life of up to six months without refrigeration, appealing to consumers seeking convenience and long-term storage. HTST (High-Temperature Short Time) pasteurization preserves more natural taste and nutritional qualities, attracting consumers prioritizing fresh flavor and health benefits. Market trends indicate a growing demand for UHT milk in regions with limited refrigeration, while HTST milk remains preferred in urban areas where freshness and taste drive purchasing decisions.

Related Important Terms

Ultra-High-Temperature (UHT) Processing

Ultra-High-Temperature (UHT) processing heats milk to approximately 135-150degC for 2-5 seconds, effectively eliminating microbial spores and extending shelf life up to six months without refrigeration. This method differs from High-Temperature Short-Time (HTST) pasteurization, which heats milk to 72degC for 15 seconds, offering shorter shelf life and requiring refrigeration due to less comprehensive microbial inactivation.

High-Temperature Short-Time (HTST) Pasteurization

High-Temperature Short-Time (HTST) pasteurization heats milk to 72degC for 15 seconds, effectively reducing pathogenic microorganisms while preserving most of the milk's nutritional and sensory qualities. Compared to Ultra-High Temperature (UHT) processing, HTST offers better retention of vitamins and a fresher taste, making it the preferred method for refrigerated pasteurized milk.

Indirect vs. Direct Heating Methods

Indirect heating methods in UHT pasteurization use heat exchangers to raise milk temperature rapidly without direct contact with steam, preserving flavor and extending shelf life, while HTST typically employs indirect plate heat exchangers for efficient pasteurization with minimal nutrient loss. Direct heating in UHT involves injecting steam into milk or mixing it with heated milk, allowing ultra-fast heating and cooling that enhances microbial kill rates and maintains quality but requires more complex equipment.

Aseptic Packaging

UHT pasteurization heats milk at 135-150degC for 2-5 seconds, enabling aseptic packaging that extends shelf life up to 6 months without refrigeration, whereas HTST pasteurization uses 72degC for 15 seconds and requires cold storage post-processing. Aseptic packaging in UHT-treated milk prevents microbial contamination and preserves nutritional quality, supporting long-term distribution and storage efficiency.

Extended Shelf-Life (ESL) Milk

Ultra-high temperature (UHT) pasteurization heats milk at 135-150degC for 2-5 seconds, achieving sterilization that extends shelf life up to 6 months without refrigeration, whereas high-temperature short-time (HTST) pasteurization heats at 72degC for 15 seconds, ensuring microbial safety but only extending shelf life to 2-3 weeks under refrigeration. Extended Shelf-Life (ESL) milk typically employs microfiltration combined with HTST or slightly higher temperature treatments to extend refrigerated shelf life up to 30-45 days, balancing microbial safety with minimal changes to flavor and nutritional quality.

Microbial Inactivation Kinetics

UHT (Ultra-High Temperature) pasteurization exposes milk to temperatures above 135degC for 2-5 seconds, achieving near-complete microbial inactivation by rapidly denaturing heat-sensitive enzymes and spores, while HTST (High-Temperature Short-Time) pasteurization uses 72degC for 15 seconds primarily targeting vegetative microbial cells. The kinetic rate constants for microbial inactivation in UHT processes are significantly higher, ensuring extended shelf life through more efficient destruction of pathogens and spoilage organisms compared to HTST treatment.

Non-Thermal Pasteurization Alternatives

Non-thermal pasteurization alternatives such as high-pressure processing (HPP) and pulsed electric fields (PEF) offer promising methods for milk preservation by effectively inactivating pathogens while maintaining nutritional and sensory qualities better than traditional UHT and HTST methods. These technologies reduce thermal damage, retain vitamins and enzymes, and extend shelf life without the flavor alterations typically caused by ultra-high temperature processing or high-temperature short-time pasteurization.

Thermophilic Spore Elimination

UHT (Ultra-High Temperature) pasteurization achieves superior elimination of thermophilic spores in milk by heating it above 135degC for 2-5 seconds, effectively inactivating spore-forming bacteria compared to HTST (High-Temperature Short Time) pasteurization, which operates at 72degC for 15 seconds and may not fully destroy thermophilic spores. The enhanced thermal treatment in UHT extends shelf life and ensures microbial safety by targeting heat-resistant spores that survive lower HTST temperatures.

Flavor Reversion in UHT Milk

UHT milk undergoes ultra-high temperature processing at 135-150degC for 2-5 seconds, which extends shelf life but often causes flavor reversion due to Maillard reaction products and lipid oxidation, resulting in a cooked or caramelized taste. In contrast, HTST milk pasteurization at 72degC for 15 seconds better preserves sensory qualities by minimizing these chemical changes, maintaining fresher milk flavor.

Heat-Induced Protein Denaturation

UHT (Ultra-High Temperature) pasteurization exposes milk to temperatures above 135degC for a few seconds, causing more extensive heat-induced protein denaturation, which alters whey protein structures and affects milk's functional properties. HTST (High-Temperature Short Time) pasteurization uses lower temperatures around 72degC for 15 seconds, resulting in less protein denaturation and better retention of milk's native protein composition and nutritional quality.

UHT vs HTST for Milk Pasteurization Infographic

agridif.com

agridif.com