Microfiltration and ultrafiltration are critical membrane technologies used in dairy clarification to remove impurities and enhance product quality. Microfiltration employs larger pore sizes, ideal for removing bacteria and fat globules while retaining essential proteins, whereas ultrafiltration uses smaller pores to concentrate proteins and remove lactose and minerals more effectively. Choosing between these methods depends on the desired clarity and nutritional profile of the dairy product.

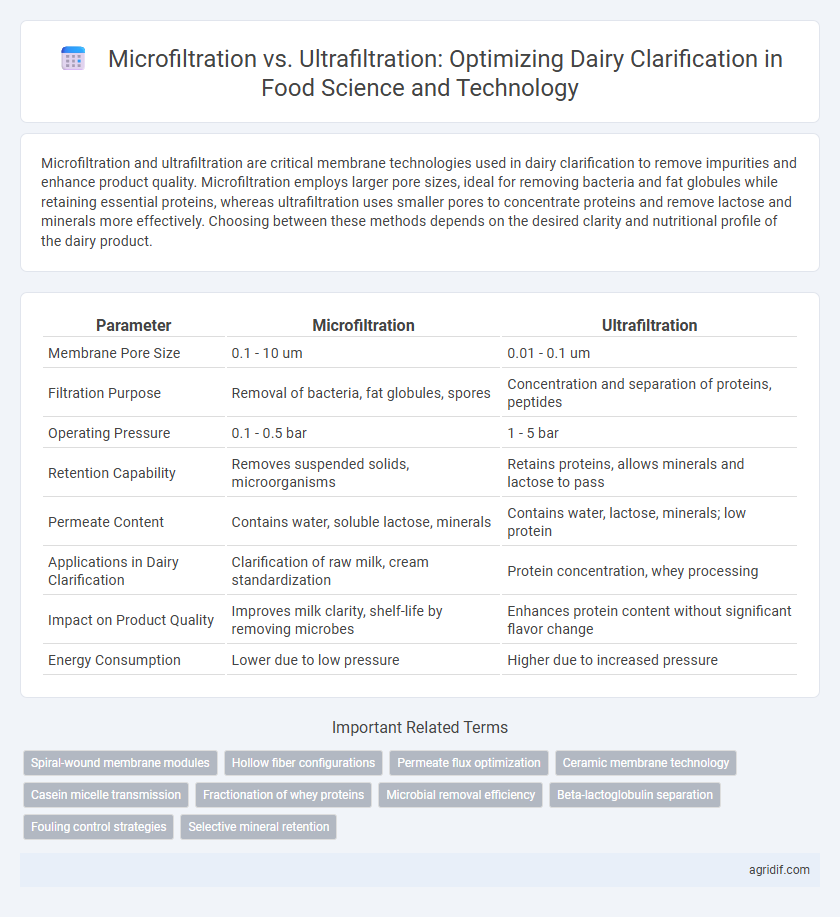

Table of Comparison

| Parameter | Microfiltration | Ultrafiltration |

|---|---|---|

| Membrane Pore Size | 0.1 - 10 um | 0.01 - 0.1 um |

| Filtration Purpose | Removal of bacteria, fat globules, spores | Concentration and separation of proteins, peptides |

| Operating Pressure | 0.1 - 0.5 bar | 1 - 5 bar |

| Retention Capability | Removes suspended solids, microorganisms | Retains proteins, allows minerals and lactose to pass |

| Permeate Content | Contains water, soluble lactose, minerals | Contains water, lactose, minerals; low protein |

| Applications in Dairy Clarification | Clarification of raw milk, cream standardization | Protein concentration, whey processing |

| Impact on Product Quality | Improves milk clarity, shelf-life by removing microbes | Enhances protein content without significant flavor change |

| Energy Consumption | Lower due to low pressure | Higher due to increased pressure |

Introduction to Dairy Clarification Processes

Dairy clarification processes utilize microfiltration and ultrafiltration to enhance milk purity by removing contaminants such as bacteria, fat globules, and somatic cells. Microfiltration membranes typically have pore sizes ranging from 0.1 to 10 micrometers, efficiently separating larger particles while preserving essential milk components. Ultrafiltration employs tighter membranes with pore sizes between 1 to 100 nanometers, concentrating proteins and removing smaller impurities, thus optimizing the quality and safety of dairy products.

Overview of Membrane Filtration Technologies

Microfiltration and ultrafiltration are membrane filtration technologies widely employed in dairy clarification for their ability to selectively separate particles based on size. Microfiltration membranes typically have pore sizes ranging from 0.1 to 10 microns, effectively removing bacteria, spores, and fat globules from milk, while ultrafiltration membranes with pore sizes between 1 to 100 nanometers concentrate proteins and retain valuable nutrients. These technologies enhance dairy product quality by improving shelf life, safety, and functional properties without compromising nutritional content.

Principles of Microfiltration in Dairy Applications

Microfiltration in dairy clarification utilizes membranes with pore sizes typically ranging from 0.1 to 10 micrometers to remove bacteria, spores, and fat globules while retaining essential milk components such as proteins and lactose. The process operates at low transmembrane pressures (0.1-2 bar) to minimize protein denaturation and ensure high permeate flux, making it suitable for cold microfiltration of raw milk. This selective separation improves product safety and extends shelf life by effectively reducing microbial load without altering the nutritional and sensory qualities of milk.

Ultrafiltration: Mechanism and Dairy Industry Uses

Ultrafiltration employs semi-permeable membranes with pore sizes ranging from 1 to 100 nanometers to separate milk components based on molecular size, effectively retaining proteins and fat while allowing water, lactose, and minerals to pass. This mechanism concentrates milk solids, enhances protein content, and improves product texture and shelf life in dairy processing. Ultrafiltration is widely used for milk protein standardization, whey protein recovery, and lactose reduction, making it essential for producing high-quality dairy products like cheese, yogurt, and protein-enriched beverages.

Key Differences between Microfiltration and Ultrafiltration

Microfiltration employs membrane pores ranging from 0.1 to 10 micrometers, primarily removing bacteria and suspended solids in dairy clarification, while ultrafiltration uses smaller pores between 0.01 and 0.1 micrometers, effectively retaining proteins and peptides. Microfiltration operates at lower transmembrane pressures compared to ultrafiltration, which requires higher pressure to force smaller molecules through the membrane. The choice between microfiltration and ultrafiltration impacts the separation efficiency, with microfiltration suited for clarifying milk by removing fat and microbes, whereas ultrafiltration concentrates proteins and peptides for enhanced dairy product functionality.

Impact on Dairy Product Quality and Safety

Microfiltration and ultrafiltration significantly enhance dairy product quality and safety by removing bacteria, spores, and suspended solids without compromising nutritional content. Microfiltration offers superior clarification by selectively eliminating microorganisms, thereby extending shelf life and reducing heat treatment requirements. Ultrafiltration concentrates proteins and minerals, improving texture and nutritional density while maintaining microbiological safety through effective contaminant retention.

Efficiency of Protein and Microorganism Removal

Ultrafiltration demonstrates higher efficiency in protein retention compared to microfiltration, capturing molecules typically ranging from 1,000 to 100,000 Daltons, essential for dairy protein concentration. Microfiltration excels in microorganism removal, effectively filtering bacteria and spores through membranes with pore sizes between 0.1 to 10 microns, critical for microbial stabilization in milk. Combined application of both techniques optimizes dairy clarification by preserving proteins while ensuring microbiological safety.

Operational Costs and Energy Consumption Comparison

Microfiltration typically requires lower operational pressures ranging from 0.1 to 0.5 bar compared to ultrafiltration's 1 to 5 bar, resulting in reduced energy consumption for dairy clarification processes. Operational costs for microfiltration membranes are generally lower due to less frequent cleaning cycles and extended membrane lifespan. Ultrafiltration provides finer separation but incurs higher energy and maintenance costs, impacting overall cost-efficiency in large-scale dairy applications.

Challenges and Limitations of Each Filtration Method

Microfiltration faces challenges such as membrane fouling and limited removal of dissolved solutes, which can reduce efficiency in dairy clarification. Ultrafiltration, while more effective at retaining proteins and larger molecules, struggles with higher energy consumption and potential denaturation of sensitive milk components. Both methods require careful balance between flux rates and membrane durability to optimize performance without compromising product quality.

Future Trends in Membrane Filtration for Dairy Clarification

Emerging trends in membrane filtration for dairy clarification highlight advancements in nanostructured membrane materials that enhance selectivity and fouling resistance, significantly improving microfiltration and ultrafiltration efficiency. Integration of real-time monitoring systems employing AI and machine learning facilitates optimized membrane performance and predictive maintenance, reducing downtime and operational costs. Sustainable membrane technologies incorporating biodegradable polymers and energy-efficient processes are poised to revolutionize dairy clarification by minimizing environmental impact while maximizing product purity.

Related Important Terms

Spiral-wound membrane modules

Spiral-wound membrane modules in microfiltration offer effective removal of bacteria and fat globules from milk, ensuring improved clarity and shelf life while maintaining high flux rates. Ultrafiltration spiral-wound membranes provide selective protein concentration with smaller pore sizes, enhancing dairy product texture and nutritional value without compromising processing efficiency.

Hollow fiber configurations

Hollow fiber configurations in microfiltration utilize pore sizes typically around 0.1 to 10 microns, effectively removing bacteria and fat globules in dairy clarification while preserving essential proteins. Ultrafiltration hollow fibers, with smaller pores ranging from 0.01 to 0.1 microns, concentrate whey proteins and remove lactose and minerals, enhancing yield and milk quality in dairy processing.

Permeate flux optimization

Microfiltration achieves higher permeate flux rates in dairy clarification due to larger pore sizes (0.1-10 um), effectively removing suspended solids while preserving milk components. Ultrafiltration offers selective separation with smaller pores (0.01-0.1 um), optimizing protein retention but typically results in lower permeate flux, requiring sensitive operational control to balance flux and fouling rates.

Ceramic membrane technology

Ceramic membrane technology in microfiltration offers superior dairy clarification by efficiently removing suspended solids, bacteria, and fat globules while preserving essential proteins, resulting in higher product purity and extended shelf life. Ultrafiltration ceramic membranes provide enhanced selective separation of proteins and peptides, improving nutrient retention and functional properties in dairy products compared to microfiltration.

Casein micelle transmission

Microfiltration effectively removes bacteria and spores from dairy while allowing partial transmission of casein micelles, typically retaining particles above 0.1 microns. Ultrafiltration provides higher retention of smaller casein micelles below 0.01 microns, offering improved concentration and clarification in dairy processing.

Fractionation of whey proteins

Microfiltration utilizes membrane pores typically sized between 0.1 to 10 micrometers, enabling the removal of bacteria and fat globules while allowing most whey proteins to pass through, which results in minimal whey protein fractionation. Ultrafiltration employs smaller pore sizes ranging from 1 to 100 nanometers, effectively concentrating and fractionating whey proteins such as b-lactoglobulin and a-lactalbumin, enhancing protein recovery and purity in dairy clarification processes.

Microbial removal efficiency

Microfiltration offers superior microbial removal efficiency compared to ultrafiltration in dairy clarification, effectively eliminating bacteria and spores while preserving essential milk components. Its pore size typically ranges from 0.1 to 10 microns, enabling targeted retention of microorganisms without compromising nutritional quality.

Beta-lactoglobulin separation

Microfiltration effectively separates beta-lactoglobulin from milk by removing larger particles and impurities, maintaining protein integrity with pore sizes typically between 0.1 to 10 micrometers. Ultrafiltration, with smaller pore sizes around 0.01 to 0.1 micrometers, offers selective separation by concentrating beta-lactoglobulin and other whey proteins, enhancing dairy product clarity and nutritional value.

Fouling control strategies

Microfiltration and ultrafiltration membranes exhibit distinct fouling mechanisms during dairy clarification, with microfiltration primarily prone to pore blocking by larger particles and ultrafiltration susceptible to cake formation by smaller proteins and fats. Effective fouling control strategies include periodic backflushing, enzymatic cleaning protocols targeting proteinaceous deposits, and optimizing crossflow velocity to minimize deposit accumulation and maintain permeate flux in both processes.

Selective mineral retention

Microfiltration membranes effectively remove bacteria and suspended solids from dairy products while allowing essential minerals such as calcium and phosphorus to remain, preserving nutritional quality. Ultrafiltration, with smaller pore sizes, selectively retains higher molecular weight proteins and minerals, enhancing mineral content concentration but potentially altering the ionic balance in dairy clarification processes.

Microfiltration vs Ultrafiltration for Dairy Clarification Infographic

agridif.com

agridif.com