Ambient drying preserves grain quality by slowly reducing moisture content at natural temperatures, minimizing nutrient loss and preventing microbial growth. Solar drying accelerates this process using sunlight, offering higher efficiency but requiring careful control to avoid overheating and uneven drying that can degrade grain quality. Both methods balance energy use and preservation efficacy, with solar drying providing a sustainable alternative where ambient conditions are insufficient.

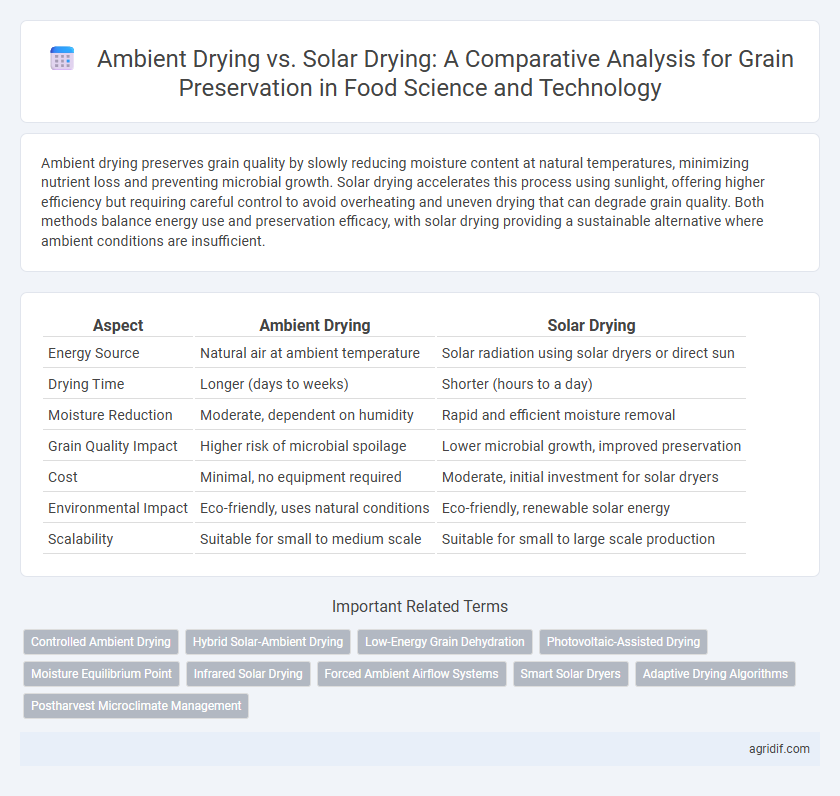

Table of Comparison

| Aspect | Ambient Drying | Solar Drying |

|---|---|---|

| Energy Source | Natural air at ambient temperature | Solar radiation using solar dryers or direct sun |

| Drying Time | Longer (days to weeks) | Shorter (hours to a day) |

| Moisture Reduction | Moderate, dependent on humidity | Rapid and efficient moisture removal |

| Grain Quality Impact | Higher risk of microbial spoilage | Lower microbial growth, improved preservation |

| Cost | Minimal, no equipment required | Moderate, initial investment for solar dryers |

| Environmental Impact | Eco-friendly, uses natural conditions | Eco-friendly, renewable solar energy |

| Scalability | Suitable for small to medium scale | Suitable for small to large scale production |

Introduction to Grain Preservation Methods

Ambient drying leverages natural air circulation at moderate temperatures to reduce grain moisture content, minimizing microbial growth and enzymatic activity for effective preservation. Solar drying uses solar energy to elevate temperature and expedite moisture removal, enhancing drying efficiency while reducing dependency on conventional energy sources. Both methods serve as sustainable grain preservation techniques, balancing drying time, cost, and quality retention in diverse climatic conditions.

Overview of Ambient Drying in Agriculture

Ambient drying in agriculture relies on natural air circulation at room temperature to reduce grain moisture content, preserving quality without the need for external energy sources. This method minimizes heat stress on grains, maintaining their nutritional value and germination potential compared to higher-temperature techniques. Despite slower moisture removal rates, ambient drying is cost-effective and environmentally sustainable for preserving grains post-harvest.

Fundamentals of Solar Drying Techniques

Solar drying techniques leverage renewable solar energy to reduce grain moisture content, enhancing preservation while minimizing microbial growth and enzymatic activity. Unlike ambient drying, which relies on natural air circulation and ambient temperature, solar drying systems incorporate solar collectors or greenhouse-like chambers to increase drying efficiency and reduce drying time. Key factors such as solar radiation intensity, airflow rate, and grain thickness significantly influence the drying kinetics and final grain quality during solar drying processes.

Comparative Analysis: Energy Efficiency

Ambient drying relies on natural air circulation at ambient temperatures, consuming minimal external energy but requiring longer drying times compared to solar drying. Solar drying employs solar energy to increase air temperature, significantly boosting drying rates and energy efficiency by reducing moisture content faster. Energy consumption analysis reveals solar drying offers up to 50% greater efficiency in grain moisture reduction, minimizing post-harvest losses and preserving grain quality more effectively than ambient drying.

Impact on Grain Quality and Safety

Ambient drying, conducted at natural environmental temperatures and humidity levels, generally preserves grain germination capacity but risks prolonged moisture exposure that can promote microbial growth and mycotoxin development. Solar drying accelerates moisture removal through controlled heat application, reducing drying time and inhibiting fungal contamination, thereby enhancing grain safety and reducing quality degradation such as discoloration or nutrient loss. However, uneven heating or excessive temperatures during solar drying may cause grain stress or shrinkage, emphasizing the need for optimized drying protocols to balance quality retention and microbial safety.

Cost Implications for Farmers

Ambient drying requires minimal initial investment, relying on natural air flow and temperature, making it a cost-effective choice for small-scale farmers with limited resources. Solar drying systems, though involving higher upfront expenses for solar panels and drying chambers, offer enhanced drying efficiency and reduced post-harvest losses, potentially increasing farmers' profit margins over time. Evaluating the long-term cost-benefit ratio is crucial, as solar drying can lead to better grain quality preservation and lower storage costs compared to ambient drying.

Environmental Considerations

Ambient drying minimizes energy consumption by utilizing natural air circulation, reducing greenhouse gas emissions compared to solar drying systems that often require auxiliary power sources. Solar drying, while harnessing renewable solar energy, may involve materials and manufacturing processes with environmental footprints, including the use of plastics and metals. Selecting the optimal method depends on balancing local climate conditions, resource availability, and the overall environmental impact throughout the grain preservation lifecycle.

Technological Advances in Drying Systems

Technological advances in ambient drying include controlled airflow systems and humidity regulation that enhance grain moisture reduction while minimizing quality loss and energy consumption. Solar drying innovations incorporate photovoltaic-powered fans and hybrid greenhouse designs to improve drying efficiency and speed, ensuring optimal preservation under variable weather conditions. Integration of real-time monitoring sensors in both methods enables precise control of temperature and moisture, reducing spoilage and extending shelf life of stored grains.

Challenges and Limitations of Each Method

Ambient drying faces challenges such as slower moisture removal rates, which increase the risk of fungal growth and mycotoxin contamination in grains. Solar drying, while faster and more energy-efficient, is limited by weather dependency and the need for proper equipment to prevent dust and pest contamination. Both methods struggle with maintaining consistent drying conditions, impacting the overall quality and storability of the preserved grains.

Future Trends in Grain Drying Technologies

Emerging trends in grain drying technologies emphasize energy-efficient solutions like hybrid solar-assisted ambient drying systems that reduce moisture content while preserving nutritional quality. Advanced sensor integration and IoT-based monitoring optimize drying parameters, enhancing uniformity and minimizing post-harvest losses. Research in nanomaterials for coating grains during drying is also showing potential to improve moisture control and extend shelf life in scalable applications.

Related Important Terms

Controlled Ambient Drying

Controlled ambient drying enhances grain preservation by maintaining optimal temperature and humidity levels, reducing post-harvest losses and preserving nutritional quality better than traditional ambient drying. Solar drying, while faster due to higher temperatures, risks overheating and uneven drying, potentially compromising grain integrity without precise control systems.

Hybrid Solar-Ambient Drying

Hybrid solar-ambient drying combines the advantages of solar drying's accelerated moisture removal and ambient drying's energy efficiency, resulting in improved grain preservation by reducing drying time and minimizing quality degradation. This integrated approach enhances drying uniformity and reduces dependence on fuel, promoting sustainable post-harvest grain management.

Low-Energy Grain Dehydration

Ambient drying utilizes natural air temperature and humidity to reduce grain moisture with minimal energy input, ensuring cost-effective preservation under low-energy conditions. Solar drying accelerates moisture removal by harnessing solar radiation, offering a sustainable and efficient alternative for grain dehydration in energy-constrained environments.

Photovoltaic-Assisted Drying

Photovoltaic-assisted drying enhances grain preservation by combining solar drying's renewable energy use with controlled ambient conditions, resulting in faster moisture removal and improved product quality. This method optimizes energy efficiency and reduces reliance on conventional power sources, offering a sustainable alternative to traditional ambient drying techniques.

Moisture Equilibrium Point

Ambient drying maintains grains at a moisture equilibrium point by gradually removing moisture under natural airflow conditions, minimizing quality degradation and microbial growth. Solar drying achieves a faster reduction in grain moisture content by using controlled solar heat, but must carefully balance temperature to avoid surpassing the equilibrium point and risking grain quality loss.

Infrared Solar Drying

Infrared solar drying enhances grain preservation by using infrared radiation to accelerate moisture removal, reducing drying time compared to traditional ambient drying methods. This technology improves drying efficiency, maintains grain quality, and reduces microbial growth, making it a superior alternative for sustainable post-harvest grain management.

Forced Ambient Airflow Systems

Forced ambient airflow systems enhance grain preservation by accelerating moisture removal through controlled ventilation at ambient temperatures, reducing drying time while minimizing thermal damage. Compared to solar drying, these systems offer consistent airflow regardless of weather conditions, improving drying uniformity and lowering the risk of fungal growth in stored grains.

Smart Solar Dryers

Smart solar dryers enhance grain preservation by combining controlled temperature and humidity monitoring with renewable energy, reducing drying time and minimizing microbial growth compared to ambient drying. These systems optimize airflow and solar radiation absorption, ensuring consistent quality and extending shelf life while reducing post-harvest losses in grains.

Adaptive Drying Algorithms

Adaptive drying algorithms enhance both ambient and solar drying methods by dynamically adjusting temperature and humidity parameters to optimize grain moisture removal while minimizing nutrient loss and microbial growth. These intelligent systems utilize real-time sensor data and predictive models to improve drying uniformity, reduce energy consumption, and extend grain shelf life effectively.

Postharvest Microclimate Management

Ambient drying relies on natural air conditions with moderate temperature and humidity control, providing a cost-effective but slower grain preservation method in postharvest microclimate management. Solar drying enhances grain moisture reduction using controlled solar energy, accelerating drying rates and improving microbial safety by minimizing fungal growth and aflatoxin development under optimized temperature and humidity conditions.

Ambient drying vs Solar drying for grain preservation Infographic

agridif.com

agridif.com