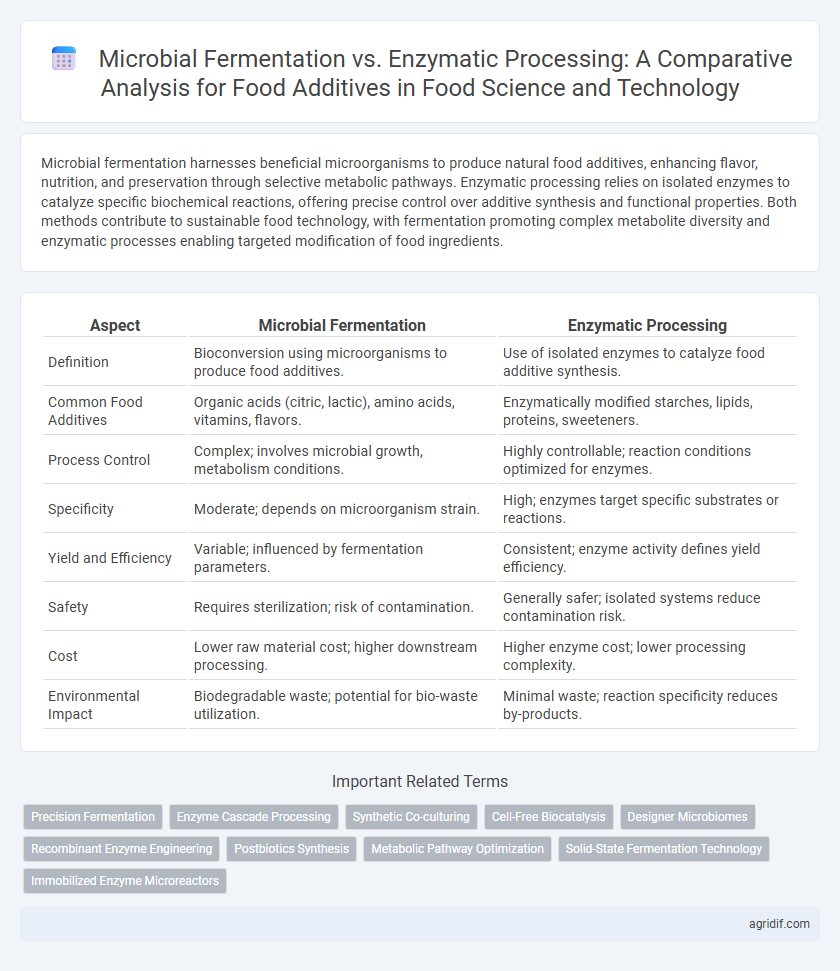

Microbial fermentation harnesses beneficial microorganisms to produce natural food additives, enhancing flavor, nutrition, and preservation through selective metabolic pathways. Enzymatic processing relies on isolated enzymes to catalyze specific biochemical reactions, offering precise control over additive synthesis and functional properties. Both methods contribute to sustainable food technology, with fermentation promoting complex metabolite diversity and enzymatic processes enabling targeted modification of food ingredients.

Table of Comparison

| Aspect | Microbial Fermentation | Enzymatic Processing |

|---|---|---|

| Definition | Bioconversion using microorganisms to produce food additives. | Use of isolated enzymes to catalyze food additive synthesis. |

| Common Food Additives | Organic acids (citric, lactic), amino acids, vitamins, flavors. | Enzymatically modified starches, lipids, proteins, sweeteners. |

| Process Control | Complex; involves microbial growth, metabolism conditions. | Highly controllable; reaction conditions optimized for enzymes. |

| Specificity | Moderate; depends on microorganism strain. | High; enzymes target specific substrates or reactions. |

| Yield and Efficiency | Variable; influenced by fermentation parameters. | Consistent; enzyme activity defines yield efficiency. |

| Safety | Requires sterilization; risk of contamination. | Generally safer; isolated systems reduce contamination risk. |

| Cost | Lower raw material cost; higher downstream processing. | Higher enzyme cost; lower processing complexity. |

| Environmental Impact | Biodegradable waste; potential for bio-waste utilization. | Minimal waste; reaction specificity reduces by-products. |

Introduction to Food Additive Production Methods

Microbial fermentation and enzymatic processing represent two pivotal methods in food additive production, each leveraging biological catalysts to enhance flavor, texture, and shelf-life. Microbial fermentation utilizes specific microorganisms to convert substrates into desired bioactive compounds, such as organic acids, vitamins, and probiotics, under controlled environmental conditions. Enzymatic processing involves purified enzymes that catalyze targeted reactions, enabling precise modification of food components to produce additives like emulsifiers, sweeteners, and preservatives with high specificity and efficiency.

Principles of Microbial Fermentation in Food Additives

Microbial fermentation in food additives involves the metabolic conversion of substrates by microorganisms such as bacteria, yeast, or fungi to produce desired compounds like organic acids, vitamins, and flavor enhancers. This process relies on controlled environmental conditions, including temperature, pH, and oxygen levels, to optimize microbial growth and metabolite synthesis. Key examples include the production of lactic acid for preservatives and citric acid for acidity regulation, both essential in enhancing food quality and shelf life.

Fundamentals of Enzymatic Processing for Food Ingredients

Enzymatic processing utilizes specific enzymes to catalyze biochemical reactions, enhancing food ingredient functionality such as flavor development, texture modification, and nutritional improvement. This method offers precise control over reaction conditions, leading to consistent product quality and reduced production time compared to microbial fermentation. Key enzymes include proteases, lipases, and amylases, which target proteins, fats, and carbohydrates respectively, expanding the range of functional food additives.

Comparative Efficiency: Fermentation vs Enzymatic Processing

Microbial fermentation produces complex bioactive compounds through the metabolic activity of microorganisms, enabling the synthesis of diverse food additives with high specificity and natural origin. Enzymatic processing offers precise catalysis for targeted reactions, yielding additives with consistent quality and reduced byproducts, often at faster reaction rates and under milder conditions. Comparative efficiency depends on the desired additive type, process scalability, and cost-effectiveness, with fermentation excelling in producing novel metabolites and enzymatic methods optimizing purity and reaction control.

Raw Material Utilization and Sustainability Aspects

Microbial fermentation leverages renewable substrates, such as agricultural by-products, enhancing raw material efficiency and reducing waste in food additive production. Enzymatic processing offers precise biocatalysis with lower energy consumption but often depends on purified substrates, which may limit raw material flexibility. Sustainable food manufacturing increasingly favors microbial fermentation due to its ability to convert diverse raw materials into high-value additives while minimizing environmental impact.

Product Quality and Purity: Microbial vs Enzyme Approaches

Microbial fermentation in food additive production often yields high-purity compounds due to the selective metabolic pathways of microorganisms, enhancing product quality with fewer impurities. Enzymatic processing offers precise control over reaction conditions, resulting in consistent additive quality and minimal by-product formation. Comparatively, microbial methods may introduce complex matrices requiring extensive purification, whereas enzymatic approaches typically enable cleaner extraction and higher purity levels.

Safety and Regulatory Considerations

Microbial fermentation and enzymatic processing both play crucial roles in producing food additives, with microbial fermentation involving live microorganisms that can pose safety concerns related to contamination and allergenicity. Regulatory frameworks, such as those established by the FDA and EFSA, require rigorous safety assessments, including strain identification, toxin production tests, and genetic stability for microbial fermentation-derived additives. Enzymatic processing offers a more controlled environment with fewer risks of pathogenic contamination, often leading to streamlined regulatory approval based on the enzyme source's Generally Recognized As Safe (GRAS) status and purity verification.

Cost Analysis and Industrial Scalability

Microbial fermentation for food additives offers cost-effective production through renewable substrates and optimized microbial strains, reducing raw material expenses and energy consumption. Enzymatic processing, while providing high specificity and product purity, often incurs higher costs related to enzyme isolation, stabilization, and reuse limitations, impacting overall scalability. Industrial scalability favors microbial fermentation due to ease of large-scale bioreactor design, continuous processing capabilities, and lower capital investment compared to enzymatic systems that require stringent reaction conditions and enzyme replenishment.

Current Innovations and Future Trends

Microbial fermentation in food additives leverages genetically engineered microorganisms to enhance yield and specificity of bioactive compounds, enabling scalable production of natural preservatives and flavor enhancers. Enzymatic processing advances include immobilized enzymes and co-factor regeneration systems that improve operational stability and reduce cost in synthesizing functional ingredients. Emerging trends focus on integrating synthetic biology with bioprocess optimization to develop sustainable, precision fermentation platforms and novel enzyme cascades for next-generation food additive manufacturing.

Conclusion: Choosing the Optimal Processing Path

Microbial fermentation offers complex biochemical transformations generating diverse food additives with enhanced functional properties, while enzymatic processing provides precise control and specificity for targeted modifications. Selection depends on factors like desired product complexity, processing time, cost-effectiveness, and scalability in industrial food production. Optimal processing aligns with product goals, raw material characteristics, and sustainability considerations to maximize additive quality and functionality.

Related Important Terms

Precision Fermentation

Precision fermentation leverages genetically engineered microorganisms to produce specific food additives with higher consistency and reduced environmental impact compared to traditional microbial fermentation, which relies on natural microbial communities. Enzymatic processing uses isolated enzymes to catalyze chemical reactions in food production but lacks the customization and scalability provided by precision fermentation for tailoring complex additives.

Enzyme Cascade Processing

Enzyme cascade processing in food additives leverages sequential enzymatic reactions to enhance product specificity, yield, and functionality compared to microbial fermentation, which often involves complex microbial communities and slower bioconversions. This approach enables precise control over reaction pathways, reducing byproducts and improving the efficiency of producing bioactive compounds, flavors, and texturizers in food technology.

Synthetic Co-culturing

Synthetic co-culturing in microbial fermentation leverages the synergistic interactions between multiple microbial strains to enhance the production of complex food additives with improved yield and functional properties compared to enzymatic processing. This biotechnological approach enables precise control of metabolic pathways, resulting in novel additive profiles that are difficult to achieve through isolated enzyme reactions.

Cell-Free Biocatalysis

Cell-free biocatalysis leverages isolated enzymes to produce food additives, offering higher specificity and controlled reaction conditions compared to microbial fermentation, which relies on live cells and complex metabolic pathways. This method enhances product purity and yield while minimizing by-products and contamination risks, making it a superior technique for sustainable and efficient food additive manufacturing.

Designer Microbiomes

Designer microbiomes in microbial fermentation offer tailored metabolic pathways for producing complex food additives with enhanced flavor profiles and functional properties compared to enzymatic processing that relies on isolated enzymes with limited substrate specificity. These engineered microbial consortia optimize yield, reduce production costs, and enable sustainable synthesis of bioactive compounds that improve food safety and nutritional value.

Recombinant Enzyme Engineering

Recombinant enzyme engineering enhances microbial fermentation by enabling the production of highly specific, stable enzymes tailored for food additive applications, improving yield and functionality compared to traditional enzymatic processing. This approach allows precise genetic modifications in microorganisms, resulting in efficient biosynthesis of novel enzymes that optimize reaction conditions and reduce production costs in food technology.

Postbiotics Synthesis

Microbial fermentation utilizes specific bacterial strains to produce postbiotics such as short-chain fatty acids, bacteriocins, and exopolysaccharides with enhanced bioactivity and stability in food additives. Enzymatic processing offers controlled and targeted synthesis of postbiotic compounds by catalyzing biochemical reactions, optimizing yield and purity while reducing production time and variability.

Metabolic Pathway Optimization

Metabolic pathway optimization in microbial fermentation enhances the yield and specificity of food additives through targeted genetic modifications that improve substrate utilization and product synthesis. Enzymatic processing relies on engineered enzymes with optimized catalytic efficiency and stability, enabling selective conversion of raw materials into high-purity additives under controlled conditions.

Solid-State Fermentation Technology

Solid-state fermentation technology enhances microbial fermentation by using minimal free water on solid substrates, producing high yields of enzymes and bioactive compounds essential for food additives. This method offers advantages over enzymatic processing including lower costs, higher product concentration, and sustainability, making it a preferred choice in the food science industry for natural additive production.

Immobilized Enzyme Microreactors

Immobilized enzyme microreactors enhance enzymatic processing in food additives by increasing enzyme stability, reusability, and reaction efficiency, outperforming traditional microbial fermentation methods in controlled product specificity and reduced processing time. These microreactors enable precise control over reaction conditions, facilitating scalable production of high-purity flavors, preservatives, and bioactive compounds with minimal contamination risk.

Microbial Fermentation vs Enzymatic Processing for Food Additives Infographic

agridif.com

agridif.com