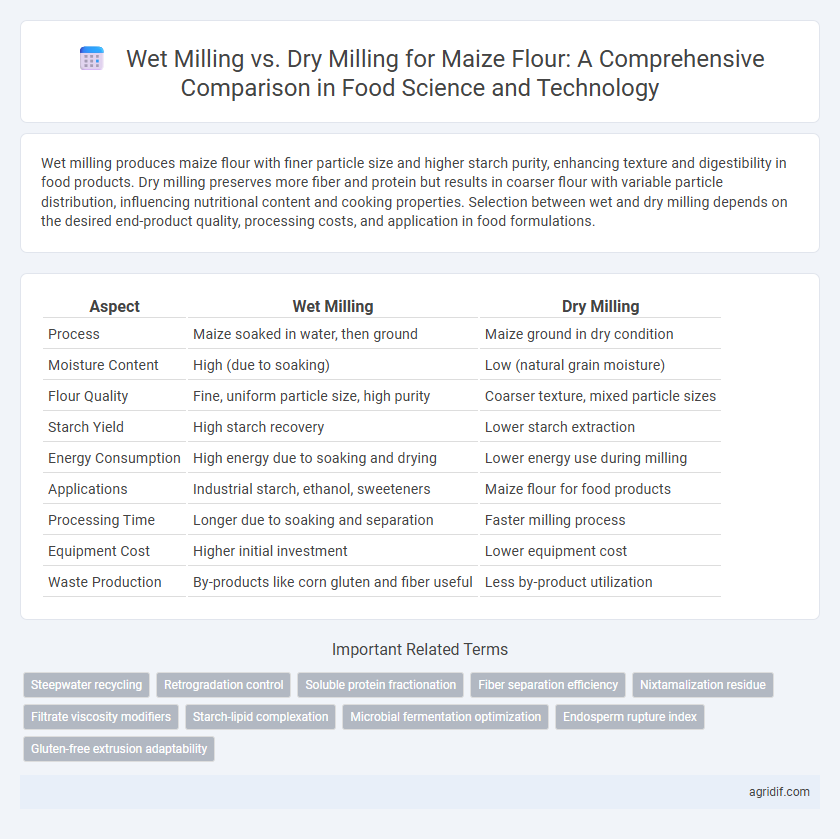

Wet milling produces maize flour with finer particle size and higher starch purity, enhancing texture and digestibility in food products. Dry milling preserves more fiber and protein but results in coarser flour with variable particle distribution, influencing nutritional content and cooking properties. Selection between wet and dry milling depends on the desired end-product quality, processing costs, and application in food formulations.

Table of Comparison

| Aspect | Wet Milling | Dry Milling |

|---|---|---|

| Process | Maize soaked in water, then ground | Maize ground in dry condition |

| Moisture Content | High (due to soaking) | Low (natural grain moisture) |

| Flour Quality | Fine, uniform particle size, high purity | Coarser texture, mixed particle sizes |

| Starch Yield | High starch recovery | Lower starch extraction |

| Energy Consumption | High energy due to soaking and drying | Lower energy use during milling |

| Applications | Industrial starch, ethanol, sweeteners | Maize flour for food products |

| Processing Time | Longer due to soaking and separation | Faster milling process |

| Equipment Cost | Higher initial investment | Lower equipment cost |

| Waste Production | By-products like corn gluten and fiber useful | Less by-product utilization |

Introduction to Maize Milling Processes

Wet milling and dry milling are the two primary processes used in maize flour production, each impacting nutrient retention and product texture differently. Wet milling involves soaking maize kernels in water to separate starch, protein, and fiber, resulting in finer flour with higher moisture content and enhanced functional properties. Dry milling mechanically grinds dried maize kernels, producing coarser flour with longer shelf life but lower extraction efficiency of maize components.

Overview of Wet Milling Method

Wet milling of maize flour involves soaking the kernels in water to soften them, facilitating the separation of starch, protein, and fiber components with minimal damage. This method enhances yield and purity of starch, producing finer, more consistent flour suitable for specialized food applications. It also allows recovery of valuable by-products such as corn gluten and oil, improving overall process efficiency.

Overview of Dry Milling Method

Dry milling of maize involves mechanically grinding kernels without soaking, resulting in coarse flour with higher particle size variability and lower starch damage compared to wet milling. This method is energy-efficient and cost-effective, preserving the natural flavor and extended shelf life of maize flour but yields lower protein and fiber separation. Predominantly used in regions with limited water resources, dry milling supports large-scale production of maize flour for diverse culinary applications.

Comparison of Yield: Wet vs Dry Milling

Wet milling of maize typically yields higher flour output compared to dry milling due to the separation of starch, protein, and fiber during the soaking process. Dry milling often results in lower yield with higher fiber content in the final product, impacting texture and nutritional value. The efficiency of wet milling makes it preferable for industrial-scale flour production where maximum starch recovery is essential.

Nutritional Impact of Milling Techniques

Wet milling of maize flour preserves higher levels of essential nutrients such as vitamins B and E, proteins, and minerals due to reduced heat generation and lower oxidation compared to dry milling. Dry milling often results in a loss of nutrient density, particularly in fibers and lipids, as the process involves higher temperatures and longer exposure to air, which degrade sensitive compounds. Studies indicate that wet milled maize flour maintains better bioavailability of carotenoids and phytochemicals, enhancing its nutritional profile for human consumption.

Quality and Functional Properties of Maize Flour

Wet milling of maize flour enhances starch gelatinization, resulting in superior water absorption capacity and improved paste viscosity compared to dry milling. The wet-milled flour exhibits higher protein solubility and better functional properties such as emulsification and foaming, which are critical for diverse food applications. Conversely, dry milling preserves phenolic compounds and dietary fiber, contributing to nutritional quality but often yields coarser particles that may affect texture and rehydration properties.

Industrial Applications of Wet and Dry Milled Maize

Wet milling of maize separates starch, protein, and fiber, producing high-purity starch used extensively in the food, paper, and pharmaceutical industries. Dry milling primarily yields whole-grain products such as corn flour and grits, preferred for animal feed and traditional food products. Industrial applications favor wet milling for starch-based products and dry milling for whole-grain flours with retained nutritional components.

Environmental and Economic Considerations

Wet milling of maize flour consumes significantly more water and energy compared to dry milling, increasing environmental footprints through higher wastewater generation and energy demand. Dry milling offers economic advantages due to lower operational costs, reduced water use, and simpler infrastructure, making it more sustainable for small to medium-scale production. However, wet milling yields higher-quality starch and by-products, influencing market value and economic viability in industrial settings.

Technological Advances in Maize Milling

Wet milling of maize flour enhances starch extraction efficiency and preserves nutritional components through controlled steeping and grinding, aided by enzymatic treatments improving yield and product quality. Dry milling advancements leverage precise tempering and advanced grinding technologies to optimize particle size distribution and reduce energy consumption, enabling gluten-free flour production tailored for diverse food applications. Integration of sensor-based monitoring and automation in both milling processes facilitates real-time quality control, maximizing throughput and consistent moisture content adjustment.

Future Trends in Maize Flour Processing

Emerging trends in maize flour processing emphasize wet milling due to its superior ability to preserve nutritional content and enhance functional properties compared to dry milling. Advances in enzyme-assisted wet milling and membrane technologies are driving higher efficiency and yield, catering to the growing demand for gluten-free and biofortified maize products. Innovations in sustainability, such as water recycling systems and energy-efficient equipment, are expected to redefine future maize flour production methods.

Related Important Terms

Steepwater recycling

Wet milling of maize enables the recovery and recycling of steepwater, which contains valuable nutrients and soluble solids crucial for fermentation and process efficiency, reducing water consumption and operating costs. Dry milling lacks steepwater recycling opportunities, resulting in higher water usage and less environmental sustainability in maize flour production.

Retrogradation control

Wet milling of maize flour significantly enhances starch gelatinization and reduces retrogradation by maintaining higher moisture levels during processing, which leads to improved texture and shelf-life in end products. Dry milling, with lower moisture content, often results in increased starch crystallinity and faster retrogradation, negatively affecting product quality and storage stability.

Soluble protein fractionation

Wet milling of maize flour enhances soluble protein fractionation by disrupting cell walls and promoting protein solubilization, whereas dry milling often leads to lower soluble protein yield due to limited cell disruption and protein extraction. The increased solubility of proteins in wet-milled maize flour improves functional properties such as emulsification and foaming in food applications.

Fiber separation efficiency

Wet milling of maize flour achieves higher fiber separation efficiency by utilizing water to soften and break down kernels, allowing for more precise isolation of fiber components such as bran and cellulose. Dry milling, while faster and less resource-intensive, tends to result in lower fiber purity and retention due to mechanical grinding without hydration, leading to fiber contamination with starch and protein fractions.

Nixtamalization residue

Wet milling of maize flour preserves Nixtamalization residue, enhancing fiber content and nutrient retention, whereas dry milling removes these residues, resulting in lower dietary fiber and reduced bioavailability of key minerals. The presence of Nixtamalization residue in wet-milled flour improves dough elasticity and flavor, making it preferable for traditional foods like tortillas.

Filtrate viscosity modifiers

Wet milling of maize flour enhances filtrate viscosity by preserving starch granules and increasing soluble polysaccharides, which improve dough consistency and texture. Dry milling, lacking moisture, results in lower viscosities due to reduced solubilization of starch and proteins, affecting the functional properties of maize flour in food applications.

Starch-lipid complexation

Wet milling of maize flour enhances starch-lipid complexation, improving functional properties such as gelatinization and digestibility by promoting better interaction between starch molecules and lipids. In contrast, dry milling results in less starch-lipid complex formation due to limited moisture, leading to lower thermal stability and altered pasting characteristics.

Microbial fermentation optimization

Wet milling of maize flour enhances microbial fermentation by maintaining higher moisture content and nutrient availability, promoting optimal growth conditions for beneficial microbes. Dry milling, with lower moisture levels, may limit fermentation efficiency due to reduced microbial activity and slower substrate breakdown.

Endosperm rupture index

The endosperm rupture index is significantly higher in wet milling compared to dry milling for maize flour, indicating enhanced starch granule swelling and gelatinization during wet processing. This difference in endosperm integrity affects the flour's water absorption capacity, texture, and suitability for various food applications.

Gluten-free extrusion adaptability

Wet milling improves maize flour's starch gelatinization and particle uniformity, enhancing hydration properties crucial for gluten-free extrusion processes. Dry milling yields coarser particles with lower water absorption, limiting dough extensibility and extrusion adaptability in gluten-free maize-based products.

Wet milling vs dry milling for maize flour Infographic

agridif.com

agridif.com