Conventional drying removes moisture through heat, effectively reducing water activity and inhibiting microbial growth but often causes nutrient loss and flavor deterioration in fruits. Freeze drying preserves fruit by sublimating ice directly into vapor at low temperatures, maintaining nutritional content, flavor, and texture more effectively than traditional methods. While freeze drying is more energy-intensive and costly, it produces superior quality products with longer shelf life compared to conventional drying techniques.

Table of Comparison

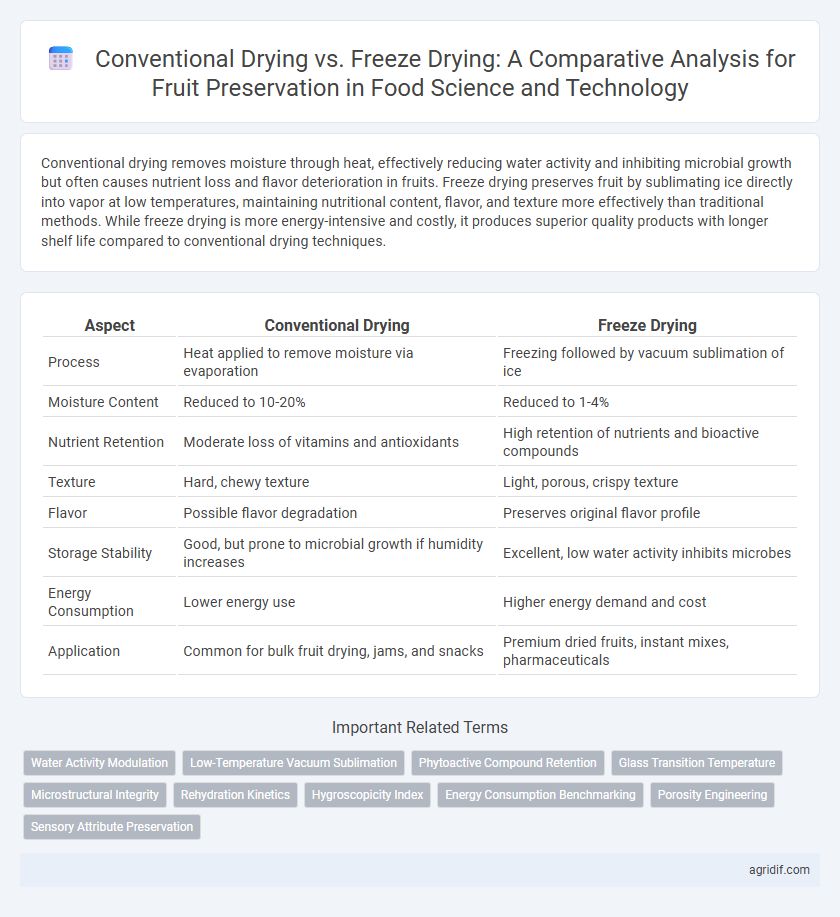

| Aspect | Conventional Drying | Freeze Drying |

|---|---|---|

| Process | Heat applied to remove moisture via evaporation | Freezing followed by vacuum sublimation of ice |

| Moisture Content | Reduced to 10-20% | Reduced to 1-4% |

| Nutrient Retention | Moderate loss of vitamins and antioxidants | High retention of nutrients and bioactive compounds |

| Texture | Hard, chewy texture | Light, porous, crispy texture |

| Flavor | Possible flavor degradation | Preserves original flavor profile |

| Storage Stability | Good, but prone to microbial growth if humidity increases | Excellent, low water activity inhibits microbes |

| Energy Consumption | Lower energy use | Higher energy demand and cost |

| Application | Common for bulk fruit drying, jams, and snacks | Premium dried fruits, instant mixes, pharmaceuticals |

Introduction to Fruit Preservation Techniques

Conventional drying methods for fruit preservation involve the removal of moisture through heat, reducing water activity to inhibit microbial growth and enzymatic reactions, while freeze drying uses sublimation to preserve fruit structure, nutrient content, and flavor more effectively. Conventional drying is cost-effective and widely accessible but may result in significant nutrient loss and texture changes, whereas freeze drying maintains higher quality and shelf life due to low-temperature processing. Understanding the differences between these techniques helps optimize fruit preservation for nutritional retention, sensory attributes, and storage stability in food science and technology.

Overview of Conventional Drying Methods

Conventional drying methods for fruit preservation include sun drying, air drying, and hot air oven drying, which rely on applying heat to remove moisture from the fruit, reducing microbial activity and enzymatic reactions. These methods are cost-effective and widely accessible but may lead to significant nutrient loss, altered texture, and color changes due to prolonged heat exposure. Common challenges include uneven drying, microbial contamination risks, and reduced shelf life compared to advanced techniques like freeze drying.

Principles of Freeze Drying Technology

Freeze drying technology preserves fruit by sublimating ice directly from the frozen state to vapor under low pressure, minimizing cellular damage and nutrient loss. This low-temperature dehydration process maintains the fruit's structural integrity, flavor, and bioactive compounds better than conventional drying methods, which rely on heat and often cause shrinkage and nutrient degradation. The key principles involve freezing the fruit, reducing ambient pressure, and applying controlled heat to facilitate sublimation, resulting in lightweight, shelf-stable fruit products with extended preservation of vitamins and antioxidants.

Impact on Nutritional Quality: Conventional vs Freeze Drying

Conventional drying methods often degrade heat-sensitive vitamins such as vitamin C and impact the texture and flavor of fruits due to high-temperature exposure. Freeze drying preserves nutritional quality more effectively by removing moisture through sublimation at low temperatures, maintaining higher levels of antioxidants, vitamins, and minerals. Studies indicate freeze-dried fruits retain up to 90% of their original vitamin content compared to 60-70% in conventionally dried counterparts.

Effects on Fruit Texture and Sensory Properties

Conventional drying typically results in significant shrinkage and a tougher texture due to heat exposure, which can also alter the fruit's natural flavors and color. Freeze drying preserves the fruit's cellular structure by sublimating ice directly into vapor under low temperatures, maintaining a more natural texture and vibrant sensory attributes. This method retains higher levels of nutrients, aroma compounds, and original taste profiles compared to conventional drying.

Retention of Flavor and Aroma in Dried Fruits

Conventional drying methods often lead to significant loss of volatile compounds responsible for flavor and aroma in dried fruits due to the high temperatures used. Freeze drying preserves these sensory attributes more effectively by sublimating water under low temperatures and vacuum conditions, maintaining the fruit's original flavor profile. Studies show that freeze-dried fruits retain up to 90% of their natural aroma compounds compared to less than 50% retention in conventionally dried products.

Shelf Life and Microbial Safety Comparison

Conventional drying reduces fruit moisture content to inhibit microbial growth but often results in shorter shelf life due to residual enzymatic activity and texture degradation. Freeze drying preserves fruit by sublimating ice under low temperature and pressure, maintaining cellular structure and significantly extending shelf life while ensuring superior microbial safety. Studies show freeze-dried fruits retain over 90% of their nutritional quality and exhibit minimal microbial contamination compared to conventionally dried counterparts.

Energy Consumption and Environmental Considerations

Conventional drying methods for fruit preservation typically consume less energy but often lead to higher nutrient loss and environmental emissions due to prolonged heating. Freeze drying, although more energy-intensive due to the sublimation process in low-temperature vacuum conditions, better retains fruit quality and reduces waste by extending shelf life. Environmental considerations favor freeze drying when prioritizing product preservation and reduced chemical preservatives, despite its higher initial energy footprint.

Cost-Effectiveness and Industrial Applications

Conventional drying methods, such as air drying, offer lower initial equipment costs and faster throughput, making them more cost-effective for large-scale fruit preservation in industrial settings. Freeze drying, while significantly increasing product quality by preserving flavor, nutrients, and texture, involves higher energy consumption and capital investment, limiting its widespread use to high-value fruits and niche markets. Industrial applications often favor conventional drying for bulk processing, whereas freeze drying is preferred for premium products requiring extended shelf life and superior sensory attributes.

Future Trends in Fruit Drying Technology

Emerging trends in fruit drying technology emphasize energy-efficient methods such as vacuum-microwave drying and infrared-assisted freeze drying to enhance nutrient retention and texture preservation. Integration of smart sensors and AI-driven process control optimizes drying parameters, reducing processing time and preventing quality loss during dehydration. Sustainable practices, including the use of renewable energy sources and biodegradable packaging, are becoming paramount in advancing both conventional drying and freeze drying techniques for fruit preservation.

Related Important Terms

Water Activity Modulation

Conventional drying reduces water activity by applying heat to evaporate moisture, which can impact flavor and nutrient retention, whereas freeze drying lowers water activity by sublimating ice under low pressure, preserving cellular structure and bioactive compounds more effectively. The modulation of water activity in freeze drying maintains fruit texture and extends shelf life with minimal quality degradation compared to heat-based conventional drying methods.

Low-Temperature Vacuum Sublimation

Low-temperature vacuum sublimation in freeze drying preserves fruit quality by removing moisture through direct ice-to-vapor transition, minimizing thermal degradation and nutrient loss compared to conventional drying methods. This process maintains cellular structure and bioactive compounds, ensuring superior texture, flavor, and shelf life in dried fruit products.

Phytoactive Compound Retention

Conventional drying methods often result in significant losses of phytoactive compounds such as vitamins, flavonoids, and antioxidants due to high heat exposure, while freeze drying preserves these bioactive molecules more effectively by removing moisture under low temperature and vacuum conditions. Scientific studies reveal that freeze-dried fruits retain up to 90% of their original antioxidant capacity and phenolic content, making this technique superior for preserving nutritional quality in fruit preservation.

Glass Transition Temperature

Conventional drying methods often exceed the glass transition temperature (Tg) of fruit tissues, leading to structural collapse and nutrient loss, whereas freeze drying operates below Tg, preserving cellular integrity and bioactive compounds. Maintaining temperatures below the glass transition point during freeze drying minimizes molecular mobility, resulting in superior texture retention and prolonged shelf life of dried fruits.

Microstructural Integrity

Conventional drying methods often cause significant shrinkage and cellular collapse in fruit tissues, leading to compromised microstructural integrity and nutrient loss. Freeze drying preserves the cellular architecture by sublimating ice directly into vapor under low temperature and pressure, maintaining fruit quality and extending shelf life.

Rehydration Kinetics

Freeze drying significantly enhances rehydration kinetics in fruit preservation by maintaining cellular structure and porosity, allowing rapid water uptake compared to conventional drying, which often causes cellular collapse and slower rehydration rates. Studies reveal freeze-dried fruits rehydrate up to 80% faster and retain superior texture and flavor due to minimal thermal degradation and better water retention capacity.

Hygroscopicity Index

Conventional drying methods increase the hygroscopicity index of fruits, leading to higher moisture absorption and reduced shelf life, while freeze drying significantly lowers hygroscopicity, preserving texture and nutritional quality by minimizing water activity. Freeze-dried fruits exhibit superior rehydration capacity and stability against environmental humidity compared to traditionally dried counterparts, enhancing long-term preservation in Food Science and Technology.

Energy Consumption Benchmarking

Conventional drying methods typically consume 30-50% less energy compared to freeze drying, primarily due to lower operational temperatures and shorter processing times. Freeze drying, while energy-intensive, offers superior retention of nutrients and flavor by sublimating moisture under low temperatures, making it a trade-off between energy efficiency and product quality in fruit preservation.

Porosity Engineering

Conventional drying methods reduce fruit moisture by applying heat, causing cell collapse and resulting in low porosity, which affects texture and rehydration efficiency. Freeze drying preserves fruit structure through sublimation, maintaining high porosity and superior rehydration properties, crucial for extended shelf life and nutrient retention.

Sensory Attribute Preservation

Conventional drying methods often result in significant loss of aroma, flavor, and color due to high temperatures causing volatile compound degradation and enzymatic browning. Freeze drying preserves sensory attributes more effectively by sublimating water under low temperature and pressure, maintaining the fruit's original texture, taste, and nutritional profile.

Conventional Drying vs Freeze Drying for Fruit Preservation Infographic

agridif.com

agridif.com