Physical refining of vegetable oils involves removing impurities through steam distillation without using chemical solvents, preserving more natural antioxidants and flavors. Chemical refining employs neutralization with alkali to eliminate free fatty acids, resulting in higher oil yields but potential loss of minor nutrients. Choosing between physical and chemical refining depends on oil type, quality requirements, and desired nutritional properties.

Table of Comparison

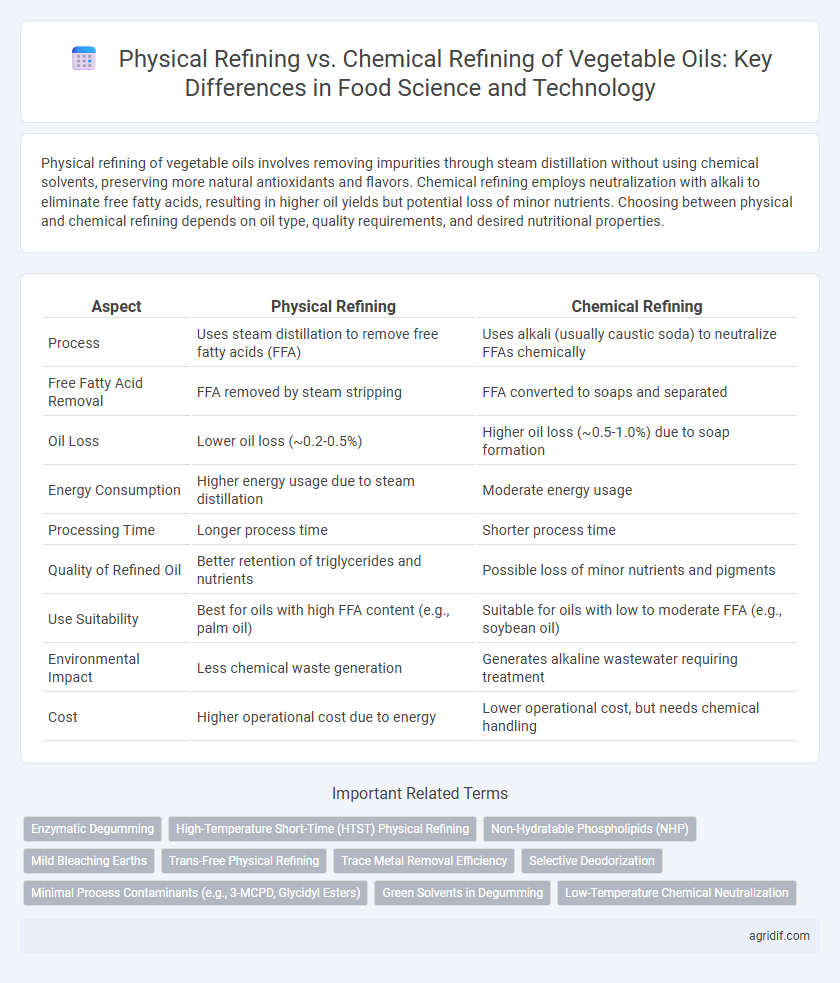

| Aspect | Physical Refining | Chemical Refining |

|---|---|---|

| Process | Uses steam distillation to remove free fatty acids (FFA) | Uses alkali (usually caustic soda) to neutralize FFAs chemically |

| Free Fatty Acid Removal | FFA removed by steam stripping | FFA converted to soaps and separated |

| Oil Loss | Lower oil loss (~0.2-0.5%) | Higher oil loss (~0.5-1.0%) due to soap formation |

| Energy Consumption | Higher energy usage due to steam distillation | Moderate energy usage |

| Processing Time | Longer process time | Shorter process time |

| Quality of Refined Oil | Better retention of triglycerides and nutrients | Possible loss of minor nutrients and pigments |

| Use Suitability | Best for oils with high FFA content (e.g., palm oil) | Suitable for oils with low to moderate FFA (e.g., soybean oil) |

| Environmental Impact | Less chemical waste generation | Generates alkaline wastewater requiring treatment |

| Cost | Higher operational cost due to energy | Lower operational cost, but needs chemical handling |

Overview of Vegetable Oil Refining Methods

Physical refining involves the removal of free fatty acids from vegetable oils through steam distillation at high temperatures, preserving natural antioxidants and minimizing chemical usage. Chemical refining employs neutralization with alkali solutions, followed by washing and drying, effectively reducing impurities but potentially causing higher nutrient loss. Both methods aim to improve oil quality by eliminating undesirable components like free fatty acids, phospholipids, and odors, with the choice depending on oil type, quality of raw material, and end-use requirements.

Introduction to Physical Refining

Physical refining of vegetable oils involves the removal of free fatty acids by steam distillation under high temperature and vacuum, preserving the oil's natural antioxidants and flavor compounds. This method reduces chemical usage and environmental impact compared to chemical refining, which uses caustic alkali to neutralize free fatty acids. Physical refining is preferred for oils with high free fatty acid content, such as palm oil, due to its efficiency and lower processing costs.

Introduction to Chemical Refining

Chemical refining of vegetable oils involves a series of processes including degumming, neutralization, bleaching, and deodorization to remove free fatty acids, phospholipids, pigments, and odors. This method effectively improves oil stability, color, and flavor by using alkali treatment and heat in controlled conditions. It allows for higher oil yield and better control over oil quality compared to physical refining, making it suitable for a wide range of oil types.

Key Process Steps in Physical Refining

Physical refining of vegetable oils involves degumming, bleaching, and deodorization to remove impurities without chemical use, preserving oil quality and flavor. Degumming eliminates phospholipids through water or acid treatment, followed by bleaching with adsorbents like activated clay to absorb pigments and trace metals. The deodorization step uses steam distillation under vacuum to remove free fatty acids and volatile compounds, resulting in a neutral, high-quality oil suitable for food applications.

Process Steps in Chemical Refining

Chemical refining of vegetable oils involves multiple key process steps including degumming, neutralization, bleaching, and deodorization. Degumming removes phospholipids using water or acid treatments, while neutralization employs caustic soda to eliminate free fatty acids by forming soapstocks. Bleaching removes pigments and impurities with adsorbent clays, and deodorization uses high-temperature steam distillation to eliminate volatile compounds and improve oil flavor and stability.

Impact on Nutritional Quality and Oil Stability

Physical refining preserves more bioactive compounds such as tocopherols and phytosterols, enhancing the nutritional quality and antioxidant capacity of vegetable oils. Chemical refining involves neutralization and bleaching steps that can remove essential nutrients but improve oil stability by reducing free fatty acids and impurities. Both methods influence the shelf life and health benefits of oils, with physical refining favored for high-quality, minimally processed products.

Environmental Considerations in Refining Processes

Physical refining of vegetable oils reduces environmental impact by minimizing the use of chemicals and producing fewer hazardous effluents compared to chemical refining. Chemical refining involves multiple stages with chemical solvents and neutralizers, leading to higher energy consumption and wastewater generation. Adopting physical refining supports sustainable production by lowering emissions, waste, and resource utilization in vegetable oil processing.

Cost and Efficiency: Physical vs Chemical Refining

Physical refining of vegetable oils generally incurs lower operating costs due to fewer chemicals and simpler waste management procedures, enhancing overall cost efficiency. Chemical refining involves multiple stages such as degumming, neutralization, bleaching, and deodorization, increasing energy consumption and material expenses. Efficiency in physical refining is higher for oils with low free fatty acid content, while chemical refining is more versatile but often less cost-effective due to complex processing requirements.

Application Suitability for Different Oil Types

Physical refining suits oils with low free fatty acid content like palm oil and coconut oil, preserving natural antioxidants and flavor compounds. Chemical refining is effective for oils with high free fatty acids such as soybean and sunflower oil, removing impurities and improving oil stability. Selecting between physical and chemical refining depends on the oil's initial quality and intended application in food processing.

Future Trends in Vegetable Oil Refining Technologies

Future trends in vegetable oil refining technologies emphasize the shift towards physical refining due to its environmentally friendly profile and reduced chemical usage, enhancing oil quality by minimizing nutrient loss and preserving natural antioxidants. Advances in membrane filtration and enzymatic degumming are improving efficiency and sustainability, reducing wastewater generation and energy consumption compared to traditional chemical refining methods. Emerging technologies integrate sensor-based real-time monitoring to optimize refining processes, ensuring higher purity and stability in vegetable oils for food applications.

Related Important Terms

Enzymatic Degumming

Enzymatic degumming enhances physical refining of vegetable oils by effectively removing phospholipids and impurities without the use of harsh chemicals, preserving oil quality and nutrient content. Compared to chemical refining, enzymatic degumming reduces oil loss and environmental impact, aligning with sustainable food processing technologies.

High-Temperature Short-Time (HTST) Physical Refining

High-Temperature Short-Time (HTST) physical refining effectively removes free fatty acids from vegetable oils by applying intense heat for a brief period, preserving oil quality and nutrients compared to traditional chemical refining, which relies on caustic chemicals like sodium hydroxide. HTST physical refining enhances oxidative stability and maintains beneficial compounds such as tocopherols and phytosterols, optimizing both safety and nutritional profile in edible oils.

Non-Hydratable Phospholipids (NHP)

Physical refining effectively removes Non-Hydratable Phospholipids (NHP) through high-temperature degumming and steam distillation, minimizing oil loss and chemical residues. Chemical refining involves enzymatic or acid degumming followed by neutralization, which can increase oil loss and generate soapstock due to incomplete NHP removal.

Mild Bleaching Earths

Mild bleaching earths in physical refining of vegetable oils effectively remove impurities such as phospholipids and trace metals without excessive adsorption of beneficial carotenoids and tocopherols, preserving oil quality. Compared to chemical refining, physical refining with mild bleaching earths reduces oil losses and minimizes the formation of undesirable compounds, enhancing overall efficiency and sensory attributes.

Trans-Free Physical Refining

Physical refining of vegetable oils effectively removes free fatty acids through steam distillation, preserving natural antioxidants and minimizing nutrient loss, resulting in trans-free oils preferred for health benefits. Chemical refining involves neutralizing free fatty acids with alkali, which can produce trans fats and cause greater nutrient depletion, making physical refining a superior method for producing high-quality, trans-free vegetable oils.

Trace Metal Removal Efficiency

Physical refining of vegetable oils offers superior trace metal removal efficiency by utilizing high-temperature steam distillation to volatilize metals such as copper and iron, essential for preventing oil oxidation and improving shelf life. Chemical refining involves neutralization with alkali, which removes free fatty acids but is less effective in eliminating trace metals, leading to potential stability issues in the final product.

Selective Deodorization

Selective deodorization in physical refining of vegetable oils targets and removes volatile impurities like free fatty acids and off-flavors without the use of chemicals, preserving oil quality and nutritional value. Chemical refining relies on alkali treatments to neutralize free fatty acids, but may lead to higher oil loss and reduced bioactive compounds compared to the more precise, temperature-controlled selective deodorization process in physical refining.

Minimal Process Contaminants (e.g., 3-MCPD, Glycidyl Esters)

Physical refining of vegetable oils significantly reduces the formation of minimal process contaminants such as 3-MCPD esters and glycidyl esters compared to chemical refining, which involves harsher conditions that promote these harmful compounds. Selecting physical refining methods enhances oil safety by minimizing contaminants linked to potential health risks in food science and technology.

Green Solvents in Degumming

Physical refining of vegetable oils utilizes green solvents such as natural lecithins and enzymatic degumming agents to enhance the removal of phospholipids without harsh chemical use, preserving oil quality and environmental sustainability. Chemical refining relies on acid degumming with solvents like phosphoric acid, which can lead to higher chemical waste and less eco-friendly processing compared to green solvent applications in physical refining.

Low-Temperature Chemical Neutralization

Low-temperature chemical neutralization for vegetable oils involves treating crude oil with alkali at reduced temperatures to minimize thermal degradation and preserve sensitive bioactive compounds. This method contrasts with physical refining, which relies on steam distillation to remove free fatty acids, often leading to higher energy consumption and possible loss of minor nutrients.

Physical refining vs chemical refining for vegetable oils Infographic

agridif.com

agridif.com