Canning and aseptic processing are two prevalent methods for food preservation, each offering unique benefits in maintaining food safety and extending shelf life. Canning involves sealing food in containers followed by heat treatment to destroy microorganisms, resulting in a longer shelf life but often impacting texture and flavor due to high heat exposure. Aseptic processing sterilizes food and packaging separately before filling in a sterile environment, preserving nutritional quality and sensory attributes while ensuring microbial safety.

Table of Comparison

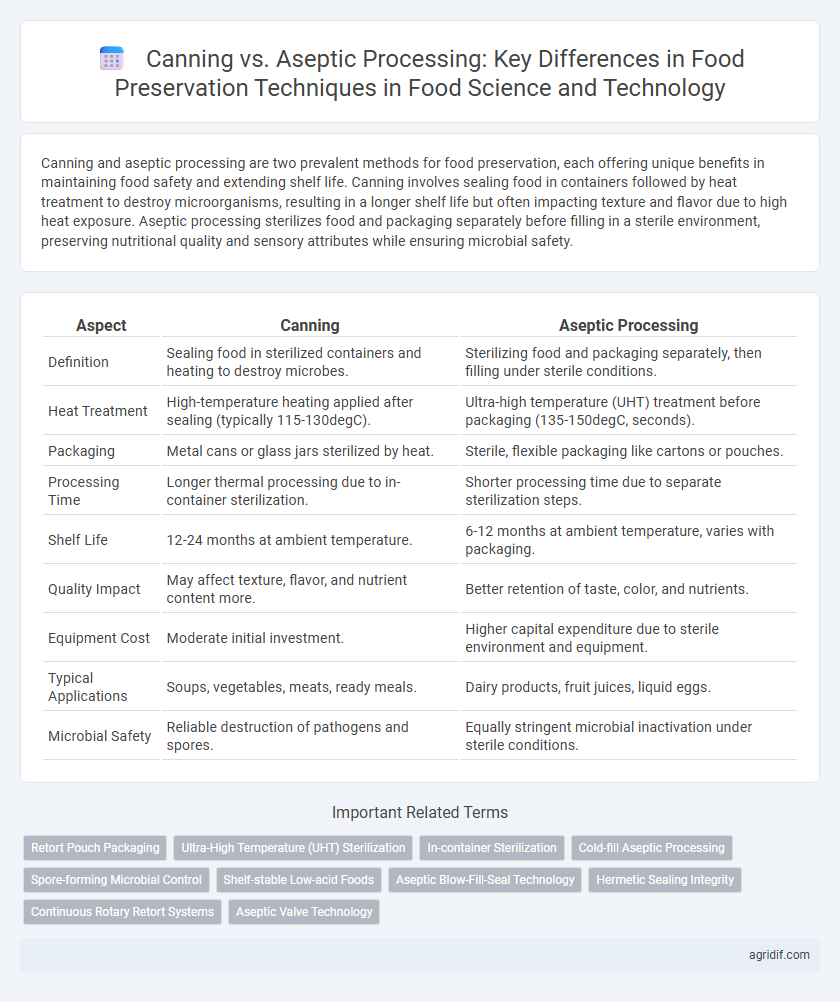

| Aspect | Canning | Aseptic Processing |

|---|---|---|

| Definition | Sealing food in sterilized containers and heating to destroy microbes. | Sterilizing food and packaging separately, then filling under sterile conditions. |

| Heat Treatment | High-temperature heating applied after sealing (typically 115-130degC). | Ultra-high temperature (UHT) treatment before packaging (135-150degC, seconds). |

| Packaging | Metal cans or glass jars sterilized by heat. | Sterile, flexible packaging like cartons or pouches. |

| Processing Time | Longer thermal processing due to in-container sterilization. | Shorter processing time due to separate sterilization steps. |

| Shelf Life | 12-24 months at ambient temperature. | 6-12 months at ambient temperature, varies with packaging. |

| Quality Impact | May affect texture, flavor, and nutrient content more. | Better retention of taste, color, and nutrients. |

| Equipment Cost | Moderate initial investment. | Higher capital expenditure due to sterile environment and equipment. |

| Typical Applications | Soups, vegetables, meats, ready meals. | Dairy products, fruit juices, liquid eggs. |

| Microbial Safety | Reliable destruction of pathogens and spores. | Equally stringent microbial inactivation under sterile conditions. |

Overview of Canning and Aseptic Processing

Canning preserves food by sealing it in airtight containers and heating to eliminate bacteria, extending shelf life without refrigeration. Aseptic processing sterilizes food and packaging separately before filling under sterile conditions, maintaining higher nutrient quality and flavor. Both methods enhance food safety, but aseptic processing offers faster production and better preservation of heat-sensitive nutrients.

Historical Development of Food Preservation Methods

Canning, developed in the early 19th century by Nicolas Appert, revolutionized food preservation by using heat sterilization in sealed containers, enabling long-term storage without refrigeration. Aseptic processing, emerging in the mid-20th century, advanced preservation by sterilizing both the food product and packaging separately before filling, enhancing product quality and extending shelf life. These methods reflect significant milestones in food science, shifting from traditional preservation techniques to modern, industrial-scale processes ensuring safety and convenience.

Scientific Principles Behind Canning

Canning preserves food by heating it to destroy microorganisms and enzymes that cause spoilage, followed by sealing it in airtight containers to prevent recontamination. The process relies on thermal sterilization, where specific temperatures and times are applied to achieve commercial sterility while maintaining nutritional quality. Heat penetration and retort processing parameters are scientifically optimized to ensure safety and extend shelf life without compromising food texture or flavor.

Fundamentals of Aseptic Processing Technology

Aseptic processing technology involves sterilizing food and packaging separately before filling and sealing in a sterile environment, preserving nutrients and sensory qualities more effectively than traditional canning. This method reduces thermal exposure, preventing overcooking and maintaining food safety by minimizing microbial contamination. Sterilization techniques such as ultra-high temperature (UHT) treatment and cleanroom filling systems are critical components ensuring extended shelf life without preservatives.

Comparative Analysis: Shelf Life and Food Safety

Canning extends shelf life by creating a hermetically sealed environment that preserves food through heat sterilization, effectively eliminating microbial activity for up to 1-5 years depending on the product. Aseptic processing combines ultra-high temperature (UHT) treatment with sterile packaging, enabling shelf stability for 6-12 months without refrigeration while maintaining superior nutrient retention and flavor. Both methods ensure food safety by preventing contamination, but aseptic processing typically offers faster processing times and enhanced preservation of sensory and nutritional quality compared to traditional canning.

Nutritional Impact: Canning vs Aseptic Processing

Canning causes nutrient loss primarily through high heat and longer processing times, notably reducing heat-sensitive vitamins like vitamin C and B-complex. Aseptic processing preserves nutrients better by rapidly sterilizing food and packaging under sterile conditions, minimizing thermal degradation. Studies show aseptic processing retains 20-30% more vitamins and antioxidants compared to traditional canning methods.

Equipment and Process Requirements

Canning requires heavy-duty retorts capable of withstanding high pressure and temperature for thermal sterilization, along with robust sealing equipment to ensure container integrity. Aseptic processing demands sophisticated sterilization units for both the product and packaging materials, coupled with sterile filling machines operating in controlled environments to prevent contamination. Equipment for aseptic processing often involves advanced aseptic chambers and laminar flow hoods, which are critical for maintaining product sterility without the prolonged heat exposure seen in traditional canning.

Environmental Sustainability and Energy Usage

Canning involves heating and sealing food in containers, which consumes substantial energy due to prolonged high temperatures and generates more packaging waste, impacting environmental sustainability negatively. Aseptic processing sterilizes food and packages it in sterile containers at lower temperatures, significantly reducing energy usage and minimizing waste through lightweight, recyclable packaging. This makes aseptic processing a more environmentally sustainable option by lowering carbon emissions and resource consumption in food preservation.

Economic Considerations for Food Producers

Canning requires higher capital investment in machinery and energy due to prolonged heating, increasing operational costs for food producers. Aseptic processing offers faster production cycles and reduced energy consumption, enabling cost savings in labor and utilities. However, aseptic packaging materials are more expensive, affecting overall economic feasibility based on product type and scale.

Future Trends in Food Preservation Technologies

Emerging trends in food preservation technologies emphasize the integration of aseptic processing with advanced packaging materials to enhance shelf life and maintain nutritional quality. Innovations in canning techniques are focusing on energy-efficient thermal treatments and non-thermal methods like high-pressure processing to reduce nutrient degradation. Future developments prioritize sustainability, using biodegradable packaging and smart sensors for real-time quality monitoring to meet consumer demand for safe, fresh, and environmentally friendly food products.

Related Important Terms

Retort Pouch Packaging

Retort pouch packaging combines the high-temperature sterilization of canning with the convenience of flexible packaging, enabling extended shelf life without refrigeration. This method uses aseptic processing principles by sterilizing both food and pouch separately before sealing, preserving nutritional quality and sensory attributes better than traditional canning.

Ultra-High Temperature (UHT) Sterilization

Ultra-High Temperature (UHT) sterilization in aseptic processing involves heating food to 135-150degC for 2-5 seconds, ensuring rapid microbial inactivation while preserving nutritional and sensory qualities better than traditional canning, which uses longer heating times at lower temperatures. This method enables extended shelf life without refrigeration and reduces nutrient degradation, making it ideal for liquid foods like milk and juices.

In-container Sterilization

In-container sterilization during canning involves heating sealed containers to destroy microorganisms and enzymes, ensuring prolonged shelf life without refrigeration. Aseptic processing sterilizes food and packaging separately before filling under sterile conditions, minimizing thermal damage and preserving product quality more effectively than traditional canning methods.

Cold-fill Aseptic Processing

Cold-fill aseptic processing preserves food by sterilizing both the product and packaging separately before filling in a sterile environment, maintaining nutritional quality and flavor better than traditional canning. This method reduces thermal degradation and microbial contamination risks, making it ideal for heat-sensitive liquids like juices and dairy.

Spore-forming Microbial Control

Canning utilizes high heat treatment to effectively inactivate spore-forming microbes such as Clostridium botulinum, ensuring long-term food preservation by creating an anaerobic environment. Aseptic processing combines ultra-high temperature sterilization and sterile packaging to control spores while maintaining food quality and extending shelf life without refrigeration.

Shelf-stable Low-acid Foods

Shelf-stable low-acid foods require precise thermal processing to eliminate Clostridium botulinum spores, with canning involving in-container sterilization and aseptic processing using separate sterilization and sterile packaging to prevent contamination. Aseptic processing offers shorter heat exposure, preserving nutritional quality and flavor better than traditional canning while ensuring microbial safety and extended shelf life.

Aseptic Blow-Fill-Seal Technology

Aseptic Blow-Fill-Seal (BFS) technology combines sterilization and packaging in a continuous, automated process, significantly reducing microbial contamination and extending shelf life compared to traditional canning. This advanced method enhances food safety and product quality by sterilizing both the food product and packaging separately before aseptically filling and sealing in a sterile environment.

Hermetic Sealing Integrity

Hermetic sealing integrity is critical in both canning and aseptic processing to prevent microbial contamination and ensure long shelf life; canning relies on metal cans sealed with compound gaskets and double seaming, while aseptic processing uses sterile containers with advanced heat-sealing or induction sealing technologies. Maintaining vacuum conditions and proper sealing pressure are essential parameters that guarantee the hermetic barrier, thereby preserving food quality and safety in both preservation methods.

Continuous Rotary Retort Systems

Continuous rotary retort systems enhance food preservation by providing uniform heat distribution and efficient processing in canning and aseptic methods, significantly reducing microbial load and preserving nutritional quality. These systems optimize thermal treatment cycles, improving energy efficiency and throughput while maintaining the safety and shelf stability of packaged foods.

Aseptic Valve Technology

Aseptic valve technology enhances aseptic processing by providing sterile isolation of food products during filling, minimizing contamination risk and extending shelf life compared to traditional canning. These sophisticated valves ensure precise control of flow and maintain product integrity under high sterilization conditions, supporting efficient food preservation and quality retention.

Canning vs Aseptic Processing for Food Preservation Infographic

agridif.com

agridif.com