Section control in sprayer operations enhances precision by targeting specific field zones, reducing overlap and minimizing chemical waste. Whole field control applies treatments uniformly, which can lead to over-application in some areas and under-application in others, decreasing efficiency and increasing costs. Implementing section control technology improves crop health and environmental sustainability by optimizing input usage.

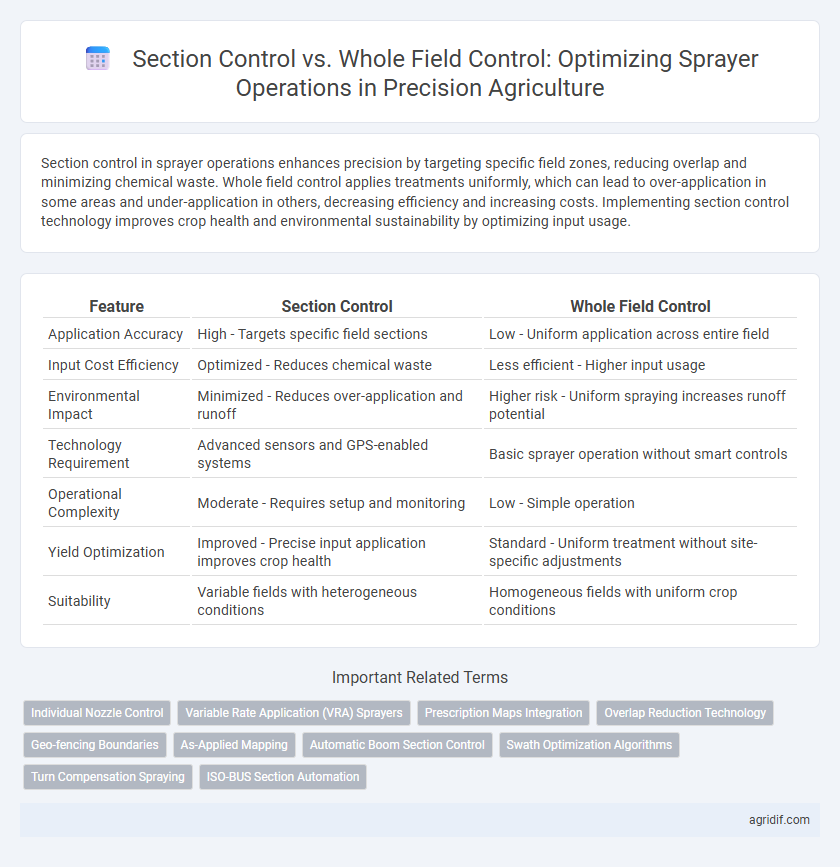

Table of Comparison

| Feature | Section Control | Whole Field Control |

|---|---|---|

| Application Accuracy | High - Targets specific field sections | Low - Uniform application across entire field |

| Input Cost Efficiency | Optimized - Reduces chemical waste | Less efficient - Higher input usage |

| Environmental Impact | Minimized - Reduces over-application and runoff | Higher risk - Uniform spraying increases runoff potential |

| Technology Requirement | Advanced sensors and GPS-enabled systems | Basic sprayer operation without smart controls |

| Operational Complexity | Moderate - Requires setup and monitoring | Low - Simple operation |

| Yield Optimization | Improved - Precise input application improves crop health | Standard - Uniform treatment without site-specific adjustments |

| Suitability | Variable fields with heterogeneous conditions | Homogeneous fields with uniform crop conditions |

Introduction to Sprayer Operations in Precision Agriculture

Section control technology in sprayer operations enhances precision agriculture by targeting specific field zones, reducing chemical waste, and minimizing environmental impact. In contrast, whole field control applies uniform treatments across the entire area, often leading to over-application and higher input costs. Implementing section control systems leverages GPS mapping and variable rate technology for optimized crop protection and sustainable resource management.

Understanding Section Control Technology

Section control technology in sprayer operations enhances precision agriculture by enabling automated on/off control of spray nozzles across different field zones, reducing chemical overlap and waste. This technology leverages GPS and variable rate application data to activate specific sprayer sections only where needed, improving input efficiency and minimizing environmental impact. By contrast, whole field control applies sprays uniformly, often resulting in unnecessary chemical usage and higher operational costs.

Defining Whole Field Control Methods

Whole Field Control methods in sprayer operations apply uniform rates of pesticides or fertilizers across the entire agricultural field without variation. This approach relies on predetermined application settings based on general field conditions, ignoring within-field variability detected by precision sensors or GPS technology. While simpler to implement, Whole Field Control lacks the site-specific adjustments that optimize input use and minimize environmental impact compared to Section Control systems.

Key Differences Between Section Control and Whole Field Control

Section Control in sprayer operations targets specific field zones based on GPS mapping and variable rate prescriptions, reducing overlaps and chemical waste. Whole Field Control applies uniform spraying across the entire field regardless of variability, often leading to over-application in certain areas. Key differences include precision in chemical usage, environmental impact, and cost efficiency, with Section Control enabling optimized input use and Whole Field Control exhibiting simpler but less resource-efficient management.

Advantages of Section Control in Modern Farming

Section control in sprayer operations significantly reduces chemical waste by precisely targeting treated areas only, enhancing cost-efficiency and environmental sustainability. This technology minimizes overlap and prevents over-application, which protects crops and soil health while optimizing input usage. Modern farming benefits from increased yield accuracy and regulatory compliance due to the sophisticated GPS-guided systems integrated into section control sprayers.

Limitations of Whole Field Control Approaches

Whole field control approaches for sprayer operations often lead to inefficient pesticide and fertilizer use by applying uniform rates regardless of field variability, increasing environmental risks and operational costs. This method ignores soil type, crop health, and pest hotspots, resulting in over-application in some areas and under-application in others, which can reduce crop yield and increase input waste. Precision agriculture data from GPS, sensors, and variable rate technology highlight these limitations, emphasizing the need for targeted section control to optimize resource use and improve sustainability.

Impact on Input Costs: Section vs Whole Field Control

Section control in sprayer operations significantly reduces input costs by precisely targeting pesticide and fertilizer applications only to affected field sections, minimizing chemical waste and environmental runoff. Whole field control applies inputs uniformly, often leading to over-application in healthy areas and increased expenses due to excess chemical use. Adopting section control technology enhances resource efficiency and lowers overall input costs by optimizing application rates based on real-time field variability.

Precision Application and Environmental Benefits

Section control in sprayer operations enables targeted application of fertilizers and pesticides, significantly reducing chemical overlap and waste compared to whole field control. This precision application minimizes environmental impact by limiting runoff and soil contamination, promoting sustainable farming practices. Utilizing GPS-guided section control systems also enhances operational efficiency and cost savings while preserving ecosystem health.

ROI and Yield Outcomes: Section Control vs Whole Field Control

Section control in sprayer operations reduces chemical overlap and minimizes input costs, leading to higher return on investment (ROI) compared to whole field control methods. Precision application with section control improves yield outcomes by targeting specific areas based on crop variability and weed distribution, enhancing overall field productivity. Whole field control often results in excessive input use and lower efficiency, diminishing potential yield gains and ROI.

Choosing the Right Sprayer Control System for Your Farm

Section control optimizes chemical application by activating and deactivating sprayer sections based on GPS data, reducing overlap and minimizing input costs. Whole field control applies chemicals uniformly across the entire field, which may lead to higher expenses and environmental impact due to unnecessary application. Selecting an advanced section control system tailored to your farm's size and variability enhances efficiency, promotes sustainability, and improves crop health.

Related Important Terms

Individual Nozzle Control

Individual nozzle control in precision agriculture significantly enhances spray accuracy by targeting specific zones within a field, reducing chemical waste and environmental impact compared to whole field control. This technology enables real-time adjustments based on crop variability and terrain, optimizing resource use and improving overall crop health management.

Variable Rate Application (VRA) Sprayers

Section control in Variable Rate Application (VRA) sprayers minimizes overlap and reduces chemical waste by activating or deactivating specific spray sections based on field variability, optimizing input usage. In contrast, whole field control applies a uniform rate across the entire area, often leading to inefficiencies and increased environmental impact due to over-application in less needy zones.

Prescription Maps Integration

Section control technology enhances sprayer efficiency by using GPS-guided systems to activate and deactivate spray nozzles precisely according to prescription maps, reducing chemical waste and overlap. Whole field control applies uniform spray rates across an entire field, lacking the targeted application benefits that prescription map integration provides for optimized input use and environmental sustainability.

Overlap Reduction Technology

Section control technology in sprayer operations uses GPS mapping and sensor data to activate and deactivate spray nozzles precisely, minimizing chemical overlap and reducing input costs by up to 20%. Whole field control applies treatments uniformly, often causing excess application in overlap zones that leads to wasted resources and potential crop damage.

Geo-fencing Boundaries

Section control in sprayer operations uses GPS-based geo-fencing boundaries to precisely activate and deactivate spray nozzles within defined field zones, reducing overlap and chemical waste. Whole field control applies chemicals uniformly across entire fields without regard to boundary zones, resulting in higher input costs and increased environmental impact.

As-Applied Mapping

Section control in sprayer operations enhances efficiency by applying chemicals only to targeted zones identified through as-applied mapping, reducing overlap and minimizing waste. Whole field control lacks this precision, resulting in uniform application that can lead to excessive input costs and increased environmental impact.

Automatic Boom Section Control

Automatic boom section control in sprayer operations enhances precision agriculture by selectively activating spray nozzles only in targeted field zones, minimizing pesticide overlap and reducing chemical usage. This technology improves crop yield and environmental sustainability by adapting spray application to variable field conditions compared to whole field control's uniform application.

Swath Optimization Algorithms

Swath optimization algorithms in Section Control enhance sprayer efficiency by dynamically adjusting spray sections based on real-time GPS and field boundary data, minimizing overlap and reducing chemical waste. Whole Field Control applies uniform spray rates regardless of variability, often leading to excess input use and lower environmental sustainability compared to the precision offered by Section Control systems.

Turn Compensation Spraying

Turn compensation spraying in precision agriculture enhances Section Control by adjusting spray output during field turns to prevent overlap and gaps, improving chemical application efficiency. Whole Field Control lacks this dynamic adjustment, often resulting in uneven coverage and increased input costs.

ISO-BUS Section Automation

ISO-BUS section control technology enables precise activation and deactivation of sprayer nozzles to minimize overlap and reduce chemical waste, significantly improving efficiency compared to whole field control which applies inputs uniformly across the entire area. By integrating GPS data and implement-specific algorithms, ISO-BUS section automation enhances resource management and environmental sustainability in precision agriculture sprayer operations.

Section Control vs Whole Field Control for Sprayer Operations Infographic

agridif.com

agridif.com