Variable Rate Technology (VRT) in fertilizer spreading enables precise nutrient application tailored to specific soil conditions and crop needs, optimizing yield and reducing waste. Uniform Rate Application, by contrast, delivers the same amount of fertilizer across the entire field, potentially leading to over-application in some areas and under-application in others. Employing VRT enhances resource efficiency and environmental sustainability by minimizing nutrient runoff and maximizing plant health.

Table of Comparison

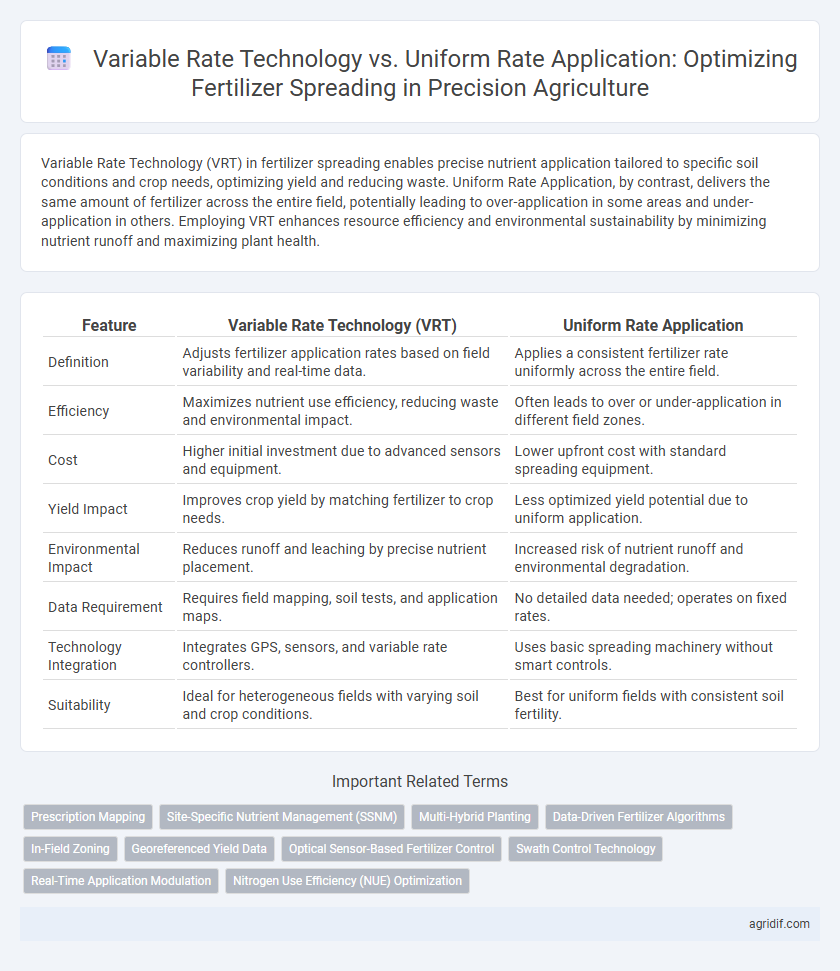

| Feature | Variable Rate Technology (VRT) | Uniform Rate Application |

|---|---|---|

| Definition | Adjusts fertilizer application rates based on field variability and real-time data. | Applies a consistent fertilizer rate uniformly across the entire field. |

| Efficiency | Maximizes nutrient use efficiency, reducing waste and environmental impact. | Often leads to over or under-application in different field zones. |

| Cost | Higher initial investment due to advanced sensors and equipment. | Lower upfront cost with standard spreading equipment. |

| Yield Impact | Improves crop yield by matching fertilizer to crop needs. | Less optimized yield potential due to uniform application. |

| Environmental Impact | Reduces runoff and leaching by precise nutrient placement. | Increased risk of nutrient runoff and environmental degradation. |

| Data Requirement | Requires field mapping, soil tests, and application maps. | No detailed data needed; operates on fixed rates. |

| Technology Integration | Integrates GPS, sensors, and variable rate controllers. | Uses basic spreading machinery without smart controls. |

| Suitability | Ideal for heterogeneous fields with varying soil and crop conditions. | Best for uniform fields with consistent soil fertility. |

Understanding Variable Rate Technology in Fertilizer Application

Variable Rate Technology (VRT) in fertilizer application uses GPS data and soil variability maps to optimize nutrient distribution, enhancing crop yield and reducing waste compared to uniform rate application. By adjusting fertilizer amounts based on specific field zones, VRT minimizes environmental impact and increases cost efficiency. Precision inputs tailored to soil conditions improve nutrient uptake and promote sustainable farming practices.

The Principles of Uniform Rate Application

Uniform Rate Application in fertilizer spreading applies a consistent amount of nutrients across the entire field, based on average soil and crop requirements. This method simplifies equipment calibration and management but may lead to over-application or under-application in areas with varying soil fertility and crop needs. While easier to implement, Uniform Rate Application often lacks the site-specific precision that Variable Rate Technology provides for optimizing fertilization efficiency and minimizing environmental impact.

Key Differences Between VRT and Uniform Methods

Variable Rate Technology (VRT) enables precise fertilizer application by adjusting rates based on soil variability, crop needs, and real-time data, significantly enhancing nutrient use efficiency. Uniform rate application distributes a constant fertilizer amount across the entire field, often leading to over-application in some areas and under-application in others, reducing overall crop yield potential. VRT's site-specific management improves environmental sustainability and cost-effectiveness compared to the blanket approach of uniform methods.

Benefits of Variable Rate Technology for Farmers

Variable Rate Technology (VRT) enhances fertilizer use efficiency by applying precise amounts tailored to specific field zones, reducing waste and lowering input costs. This targeted application improves crop yield variability by addressing soil nutrient heterogeneity, leading to optimized plant growth and increased profitability. Farmers experience environmental benefits through minimized nutrient runoff, contributing to sustainable agriculture and compliance with environmental regulations.

Challenges Associated with Uniform Rate Application

Uniform rate application of fertilizers often leads to inefficient nutrient usage due to soil variability across agricultural fields, causing over-application in some areas and under-application in others. This inefficiency results in increased input costs, nutrient runoff, and environmental pollution, impacting crop yield and sustainability. In contrast, Variable Rate Technology enables site-specific nutrient management, optimizing fertilizer use and minimizing adverse environmental effects.

Impact on Crop Yields: VRT vs Uniform Rate

Variable Rate Technology (VRT) for fertilizer spreading significantly enhances crop yields by applying nutrients precisely based on soil variability, optimizing nutrient use and reducing waste. Uniform rate application often leads to over-fertilization in some areas and under-fertilization in others, resulting in suboptimal crop performance and lower overall yields. Studies show fields managed with VRT can increase yields by up to 15% compared to uniform rate applications due to improved nutrient distribution tailored to specific crop needs.

Economic Analysis: Cost-Efficiency Comparison

Variable Rate Technology (VRT) in fertilizer spreading enhances cost-efficiency by applying nutrients precisely where needed, reducing waste and lowering input costs compared to Uniform Rate Application, which disperses fertilizer evenly regardless of soil variability. Economic analyses demonstrate that VRT can increase return on investment by optimizing fertilizer use, minimizing over-application, and improving crop yield quality. Studies indicate cost savings ranging from 10% to 30% on fertilizer expenses with VRT, making it a financially advantageous choice for large-scale precision agriculture operations.

Environmental Implications of Variable and Uniform Application

Variable Rate Technology (VRT) in fertilizer spreading minimizes environmental impact by precisely matching nutrient application to specific soil and crop needs, reducing runoff and leaching that contribute to water pollution. Uniform rate application often leads to over-application in some areas, increasing the risk of nutrient leaching, greenhouse gas emissions, and soil degradation. By optimizing fertilizer use with VRT, farms enhance nutrient efficiency, protect ecosystems, and promote sustainable agriculture practices.

Precision Data Requirements for VRT

Variable Rate Technology (VRT) for fertilizer spreading relies heavily on precise agronomic data, including soil nutrient maps, crop yield variability, and GPS-guided machinery to optimize input application. Unlike uniform rate application that applies a constant fertilizer rate across the field, VRT adjusts fertilizer doses in real time based on spatial data, enhancing nutrient use efficiency and reducing environmental impact. Accurate soil sampling, advanced sensors, and robust data analytics are essential components for effective VRT implementation in precision agriculture.

Future Trends in Fertilizer Application Technology

Variable Rate Technology (VRT) enhances fertilizer efficiency by precisely applying nutrients based on real-time soil and crop data, reducing waste and environmental impact compared to Uniform Rate Application. Future trends in fertilizer application technology emphasize integration of AI-driven analytics, drone-assisted monitoring, and IoT sensors to optimize nutrient delivery dynamically. Advancements in smart machinery and predictive modeling are set to revolutionize fertilizer management, promoting sustainable and cost-effective agricultural practices.

Related Important Terms

Prescription Mapping

Variable Rate Technology (VRT) utilizes GPS-guided prescription mapping to apply precise fertilizer amounts tailored to specific field zones, enhancing nutrient efficiency and reducing waste compared to Uniform Rate Application. Prescription maps integrate soil data, crop needs, and yield history to optimize fertilizer distribution, improving crop yield and environmental sustainability.

Site-Specific Nutrient Management (SSNM)

Variable Rate Technology (VRT) enhances Site-Specific Nutrient Management (SSNM) by precisely adjusting fertilizer application based on real-time soil fertility and crop needs, improving nutrient use efficiency and reducing environmental impact. Uniform Rate Application applies a consistent fertilizer amount across fields, often leading to over- or under-fertilization, which can decrease crop yield and increase nutrient runoff compared to VRT's targeted nutrient management.

Multi-Hybrid Planting

Variable Rate Technology (VRT) enables precise fertilizer application tailored to soil variability and crop needs, significantly enhancing nutrient use efficiency in multi-hybrid planting systems. Uniform rate application often leads to nutrient wastage and suboptimal yields by ignoring spatial differences in soil fertility and crop hybrid requirements.

Data-Driven Fertilizer Algorithms

Variable Rate Technology (VRT) employs data-driven fertilizer algorithms that utilize real-time soil and crop data to optimize nutrient application, enhancing crop yield while minimizing waste and environmental impact. In contrast, Uniform Rate Application applies a consistent fertilizer amount across fields regardless of variability, often resulting in inefficient nutrient use and suboptimal crop performance.

In-Field Zoning

Variable Rate Technology (VRT) optimizes fertilizer application by creating in-field zones based on soil properties and crop needs, enhancing nutrient efficiency and minimizing environmental impact compared to uniform rate application. In-field zoning enables precise management of variable soil fertility, improving crop yield and reducing input costs through targeted fertilizer distribution.

Georeferenced Yield Data

Variable Rate Technology leverages georeferenced yield data to optimize fertilizer application by tailoring nutrient input to specific field zones, enhancing crop productivity and reducing waste. Uniform Rate Application applies a consistent fertilizer amount across the entire field, often overlooking spatial variability and potentially leading to over- or under-fertilization in areas with differing nutrient needs.

Optical Sensor-Based Fertilizer Control

Optical sensor-based fertilizer control in variable rate technology (VRT) enables precise nutrient application by assessing real-time crop health and biomass, maximizing fertilizer efficiency and minimizing environmental impact compared to uniform rate application. This technology adjusts fertilizer distribution dynamically across fields, optimizing input use according to spatial variability and improving overall crop yield and sustainability.

Swath Control Technology

Variable Rate Technology (VRT) enhances fertilizer efficiency by adjusting application rates in real-time based on soil and crop variability, reducing waste compared to Uniform Rate Application, which spreads fertilizer evenly regardless of field conditions. Swath Control Technology complements VRT by preventing overlap and skips during fertilizer spreading, optimizing field coverage and minimizing environmental impact.

Real-Time Application Modulation

Variable Rate Technology enables real-time application modulation by using GPS and sensor data to adjust fertilizer distribution precisely according to field variability, enhancing nutrient efficiency and crop yield. Uniform Rate Application lacks this adaptability, applying fertilizer at a constant rate regardless of soil fertility differences, often leading to nutrient waste and environmental runoff.

Nitrogen Use Efficiency (NUE) Optimization

Variable Rate Technology (VRT) enhances Nitrogen Use Efficiency (NUE) by tailoring fertilizer application to specific soil nutrient profiles and crop needs, reducing nitrogen losses compared to Uniform Rate Application (URA), which applies a consistent fertilizer amount regardless of field variability. Studies indicate VRT can improve NUE by 20-30%, leading to increased crop yield and reduced environmental impact through optimized nitrogen distribution.

Variable Rate Technology vs Uniform Rate Application for Fertilizer Spreading Infographic

agridif.com

agridif.com