Emulsification enhances the stability of dairy beverages by uniformly dispersing fat globules in the aqueous phase, preventing separation and improving texture. Homogenization physically reduces the size of fat globules through high-pressure forcing, creating a finer, more stable emulsion that enhances mouthfeel and shelf life. Both processes are critical in dairy science to achieve consistent quality and sensory appeal in products such as milk and cream-based drinks.

Table of Comparison

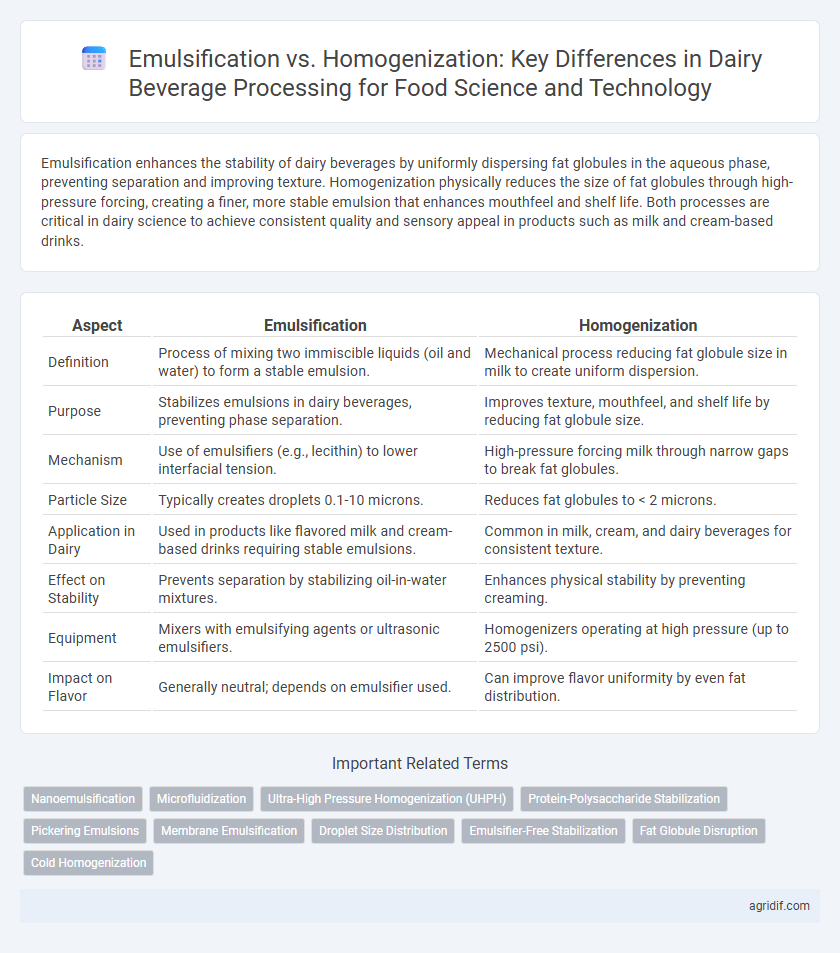

| Aspect | Emulsification | Homogenization |

|---|---|---|

| Definition | Process of mixing two immiscible liquids (oil and water) to form a stable emulsion. | Mechanical process reducing fat globule size in milk to create uniform dispersion. |

| Purpose | Stabilizes emulsions in dairy beverages, preventing phase separation. | Improves texture, mouthfeel, and shelf life by reducing fat globule size. |

| Mechanism | Use of emulsifiers (e.g., lecithin) to lower interfacial tension. | High-pressure forcing milk through narrow gaps to break fat globules. |

| Particle Size | Typically creates droplets 0.1-10 microns. | Reduces fat globules to < 2 microns. |

| Application in Dairy | Used in products like flavored milk and cream-based drinks requiring stable emulsions. | Common in milk, cream, and dairy beverages for consistent texture. |

| Effect on Stability | Prevents separation by stabilizing oil-in-water mixtures. | Enhances physical stability by preventing creaming. |

| Equipment | Mixers with emulsifying agents or ultrasonic emulsifiers. | Homogenizers operating at high pressure (up to 2500 psi). |

| Impact on Flavor | Generally neutral; depends on emulsifier used. | Can improve flavor uniformity by even fat distribution. |

Understanding Emulsification in Dairy Beverage Production

Emulsification in dairy beverage production involves the dispersion of fat droplets within an aqueous phase, creating a stable mixture through emulsifiers such as proteins and phospholipids. This process enhances the texture, mouthfeel, and shelf life of products like milk and cream by preventing fat coalescence and phase separation. Emulsification differs from homogenization, which mechanically reduces fat globule size to improve uniformity but relies on emulsification principles to maintain stability.

Homogenization: A Key Process in Dairy Technology

Homogenization is a crucial process in dairy technology that reduces fat globule size to create a stable, uniform dairy beverage with enhanced texture and mouthfeel. By breaking down fat molecules under high pressure, homogenization prevents cream separation, improving product consistency and shelf life. This process also boosts the bioavailability of nutrients, making dairy beverages more palatable and nutritionally effective.

Mechanisms of Emulsification and Homogenization

Emulsification in dairy beverages involves the dispersion of fat droplets into a continuous aqueous phase, stabilized by emulsifiers that reduce interfacial tension, facilitating the formation of stable oil-in-water emulsions. Homogenization mechanically forces milk through narrow gaps under high pressure, breaking down fat globules into smaller, uniform sizes to prevent creaming and improve texture and mouthfeel. Both processes optimize fat distribution but differ as emulsification relies primarily on chemical agents while homogenization uses physical shear forces for droplet size reduction.

Comparative Analysis: Emulsification vs Homogenization

Emulsification creates stable mixtures by dispersing fat droplets in dairy beverages, enhancing texture and mouthfeel, while homogenization mechanically breaks down fat globules to prevent creaming and improve uniformity. Emulsification relies on surfactants to stabilize oil-in-water systems, whereas homogenization applies high-pressure forces to reduce particle size, influencing viscosity and sensory properties. Comparative analysis shows emulsification suits flavored dairy drinks needing consistent droplet size, whereas homogenization is essential for milk and cream products requiring uniform fat distribution and shelf stability.

Equipment and Techniques for Emulsification in Dairy

High-shear mixers and ultrasonic emulsifiers are commonly employed for emulsification in dairy beverages, ensuring uniform dispersion of fat droplets to enhance texture and stability. Rotor-stator systems create intense mechanical shear forces that break down oil and water phases, facilitating fine emulsions resistant to creaming. Membrane emulsification techniques offer precise droplet size control by forcing one phase through a porous membrane into another, improving consistency in dairy product formulation.

Homogenization Technologies in Modern Dairy Processing

Homogenization technologies in modern dairy processing utilize high-pressure systems to break down fat globules, creating a uniform and stable dairy beverage texture. Advanced equipment, such as high-pressure homogenizers and microfluidizers, enhances product consistency, shelf life, and sensory qualities by reducing particle size and ensuring even fat dispersion. These technologies outperform traditional emulsification by providing improved stability, preventing cream separation, and facilitating the production of low-fat and flavored dairy beverages.

Impact on Physical and Sensory Properties of Dairy Beverages

Emulsification and homogenization significantly influence the texture and stability of dairy beverages, where emulsification creates stable oil-in-water mixtures enhancing creaminess and mouthfeel. Homogenization reduces fat globule size, preventing creaming and improving uniformity, which results in a smoother, more consistent sensory profile. The choice between these processes affects viscosity, flavor release, and visual appeal, directly impacting consumer acceptance and product shelf life.

Effects on Product Stability and Shelf-Life

Emulsification enhances product stability by forming fine droplets that resist coalescence, improving the uniformity and texture of dairy beverages, while homogenization mechanically reduces fat globule size, which prevents cream separation and extends shelf-life. Both processes disrupt fat globule membranes but emulsification often involves emulsifiers that provide additional steric stabilization, making it more effective against creaming and phase separation. Homogenized dairy beverages typically exhibit longer shelf-life due to increased fat dispersion and enhanced microbial stability, crucial factors in commercial dairy processing.

Quality Control: Testing Emulsified and Homogenized Dairy Products

Emulsification and homogenization techniques are crucial in dairy beverage production, directly impacting particle size distribution and stability, which are key quality control parameters. Testing methods such as laser diffraction and microscopy assess emulsion uniformity and droplet size, while rheological measurements evaluate texture and viscosity consistency. Regular monitoring using these analytical tools ensures product stability, sensory attributes, and shelf-life meet industry standards.

Future Innovations in Emulsification and Homogenization for Dairy

Emerging nanotechnology and microfluidization techniques enhance emulsification and homogenization processes by producing finer and more stable dairy beverage textures, improving mouthfeel and shelf life. Integration of artificial intelligence enables precise control over particle size distribution and energy consumption, driving efficiency and product consistency. Innovations in enzyme-assisted emulsification offer sustainable alternatives, reducing reliance on synthetic emulsifiers and promoting clean-label dairy products.

Related Important Terms

Nanoemulsification

Nanoemulsification in dairy beverages creates stable, uniform dispersions of fat and water at the nanoscale, enhancing bioavailability and sensory properties compared to traditional emulsification and homogenization. This advanced technique improves the shelf life and texture by reducing droplet size below 100 nm, resulting in superior stability and enhanced delivery of nutrients in milk-based products.

Microfluidization

Microfluidization in dairy beverages enhances emulsification by applying high-pressure shear forces that create uniformly small fat globules, improving stability and texture more effectively than traditional homogenization. This technique promotes better protein-fat interactions and extends shelf life by producing finer emulsions with reduced particle size distribution.

Ultra-High Pressure Homogenization (UHPH)

Ultra-High Pressure Homogenization (UHPH) significantly improves the stability and shelf life of dairy beverages by reducing fat globule size more effectively than traditional emulsification, resulting in enhanced texture and mouthfeel. This process employs pressures above 200 MPa to disrupt fat and protein aggregates, promoting uniform dispersion and inhibiting microbial growth, which is critical for high-quality, extended-shelf-life dairy products.

Protein-Polysaccharide Stabilization

Emulsification in dairy beverages involves the dispersion of fat droplets stabilized by protein-polysaccharide complexes that enhance interfacial film formation and prevent coalescence, optimizing texture and shelf life. Homogenization mechanically reduces fat globule size, promoting uniform distribution and facilitating protein-polysaccharide interactions that improve stability against phase separation and creaming in milk-based drinks.

Pickering Emulsions

Pickering emulsions in dairy beverages utilize solid particles as stabilizers, offering enhanced stability and resistance to coalescence compared to traditional emulsification methods that rely on surfactants. Homogenization mechanically reduces fat globule size to create uniform dispersions, whereas Pickering emulsification leverages particle adsorption at interfaces, improving texture and shelf-life while minimizing additives.

Membrane Emulsification

Membrane emulsification in dairy beverages offers precise control over droplet size distribution, enhancing product stability and texture compared to traditional homogenization methods. This technique reduces energy consumption and shear stress, preserving sensitive bioactive compounds while producing uniform emulsions crucial for high-quality dairy formulations.

Droplet Size Distribution

Emulsification in dairy beverages produces a broader droplet size distribution, enhancing stability by preventing rapid coalescence, while homogenization achieves a narrower, more uniform droplet size distribution, resulting in improved texture and mouthfeel. Controlled droplet size reduction through high-pressure homogenization is critical for consistent particle dispersion and shelf-life extension in milk-based drinks.

Emulsifier-Free Stabilization

Emulsification creates a stable mixture of immiscible liquids traditionally relying on emulsifiers, while homogenization physically reduces fat globule size in dairy beverages to enhance stability without added emulsifiers. Emulsifier-free stabilization in dairy leverages advanced homogenization techniques, such as high-pressure homogenization, to achieve uniform fat dispersion and creaminess, improving shelf life and sensory properties without chemical additives.

Fat Globule Disruption

Emulsification involves creating a stable mixture of fat and water phases by dispersing fat globules into small droplets, while homogenization mechanically disrupts fat globules in dairy beverages, reducing their size to prevent creaming and improve texture. Fat globule disruption during homogenization enhances the stability and mouthfeel of milk by producing uniform, finely dispersed fat particles resistant to separation.

Cold Homogenization

Cold homogenization in dairy beverages reduces fat globule size without heat application, preserving flavor and nutritional quality while ensuring stable emulsification. This technique enhances texture and mouthfeel by creating a uniform fat dispersion, differentiating it from traditional emulsification methods that rely on thermal processes.

Emulsification vs Homogenization for Dairy Beverages Infographic

agridif.com

agridif.com