Pasteurization heats milk to a specific temperature below boiling, effectively reducing harmful pathogens while preserving essential nutrients and flavor. Sterilization involves subjecting milk to higher temperatures, eliminating all microorganisms but potentially altering taste and nutritional quality. Choosing between pasteurization and sterilization depends on shelf life requirements and the balance between safety and sensory attributes.

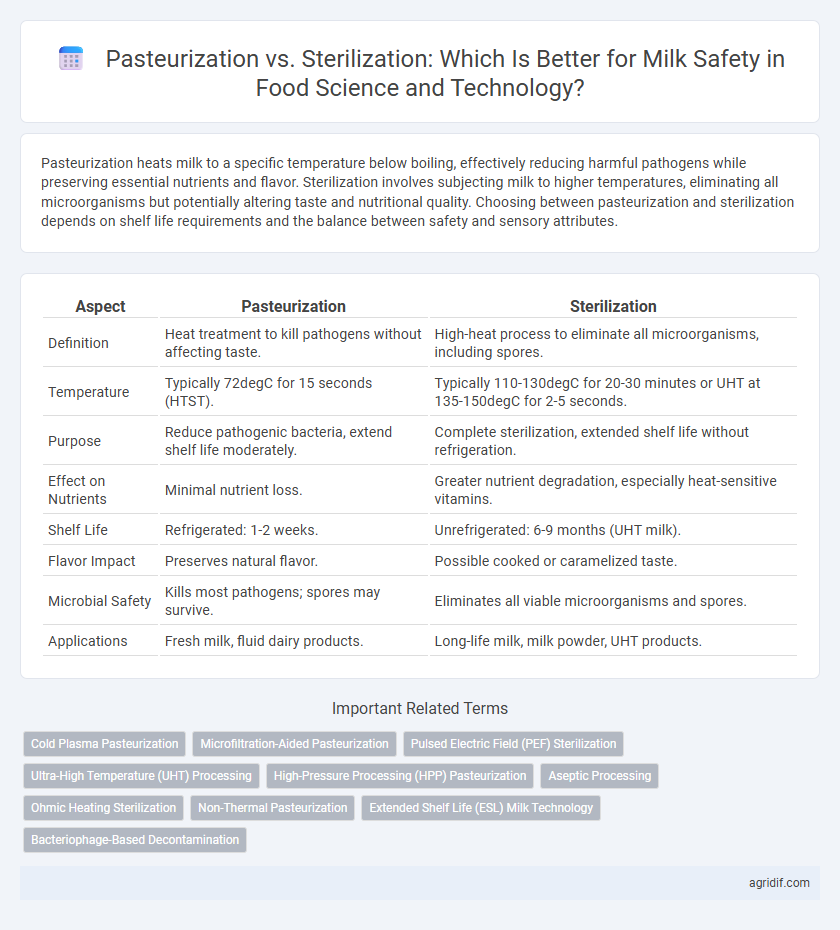

Table of Comparison

| Aspect | Pasteurization | Sterilization |

|---|---|---|

| Definition | Heat treatment to kill pathogens without affecting taste. | High-heat process to eliminate all microorganisms, including spores. |

| Temperature | Typically 72degC for 15 seconds (HTST). | Typically 110-130degC for 20-30 minutes or UHT at 135-150degC for 2-5 seconds. |

| Purpose | Reduce pathogenic bacteria, extend shelf life moderately. | Complete sterilization, extended shelf life without refrigeration. |

| Effect on Nutrients | Minimal nutrient loss. | Greater nutrient degradation, especially heat-sensitive vitamins. |

| Shelf Life | Refrigerated: 1-2 weeks. | Unrefrigerated: 6-9 months (UHT milk). |

| Flavor Impact | Preserves natural flavor. | Possible cooked or caramelized taste. |

| Microbial Safety | Kills most pathogens; spores may survive. | Eliminates all viable microorganisms and spores. |

| Applications | Fresh milk, fluid dairy products. | Long-life milk, milk powder, UHT products. |

Introduction to Milk Safety in Modern Agriculture

Milk safety in modern agriculture relies heavily on effective microbial control techniques such as pasteurization and sterilization to prevent contamination and extend shelf life. Pasteurization typically involves heating milk to 72degC for 15 seconds to eliminate pathogenic bacteria while preserving nutritional quality, making it the preferred method in many dairy processes. Sterilization, involving higher temperatures above 135degC for a few seconds, achieves commercial sterility but can alter flavor and reduce some heat-sensitive nutrients, serving specialized needs within the dairy industry.

Understanding Pasteurization: Definition and Process

Pasteurization involves heating milk to a specific temperature, usually 72degC for 15 seconds in the high-temperature short-time (HTST) method, to eliminate pathogenic bacteria while preserving nutritional quality. This process significantly reduces microbial load without significantly altering taste or nutritional content, making milk safe for consumption. Understanding the precise time-temperature parameters is essential to ensure effective microbial inactivation and maintain milk's sensory and nutritional properties.

Exploring Sterilization: Definition and Methods

Sterilization in milk safety refers to the process of eliminating all forms of microbial life, including spores, through high-temperature treatments such as ultra-high temperature (UHT) processing and autoclaving. Common sterilization methods include UHT heating at 135-150degC for 2-5 seconds and retort sterilization involving temperatures above 110degC under pressure for extended periods. These techniques ensure prolonged shelf life and safety by achieving commercial sterility without compromising essential milk nutrients significantly.

Key Differences Between Pasteurization and Sterilization

Pasteurization heats milk to 72degC for 15 seconds to eliminate most pathogenic bacteria while preserving nutritional quality and flavor. Sterilization involves heating milk above 100degC, often using ultra-high temperature (UHT) processing at 135-150degC for a few seconds, ensuring complete destruction of all microorganisms and spores for extended shelf life. Pasteurized milk requires refrigeration and has a shorter shelf life compared to sterilized milk, which can be stored unrefrigerated for several months.

Impact on Milk Nutritional Quality

Pasteurization preserves most milk nutrients by heating milk at lower temperatures (typically 72degC for 15 seconds), effectively reducing pathogenic microbes while maintaining vitamins like B complex and C. Sterilization involves higher temperatures (above 121degC) and longer durations, leading to significant nutrient degradation, including loss of heat-sensitive vitamins and changes in milk protein structure. The trade-off between microbial safety and nutrient retention makes pasteurization the preferred method for balancing milk safety and nutritional quality.

Effects on Microbial Inactivation and Safety

Pasteurization reduces microbial load by heating milk to 72degC for 15 seconds, effectively inactivating pathogenic bacteria like Listeria and Salmonella while preserving nutritional quality. Sterilization involves higher temperatures, typically 135-150degC for a few seconds, achieving complete microbial inactivation, including spores, thus extending shelf life significantly. The choice between pasteurization and sterilization balances milk safety, microbial inactivation efficiency, and retention of sensory attributes.

Shelf Life Extension: Pasteurized vs. Sterilized Milk

Pasteurization extends milk shelf life by reducing pathogenic bacteria while maintaining most nutritional qualities, typically allowing refrigerated storage for 7-14 days. Sterilization, through high-temperature processing such as Ultra-High Temperature (UHT) treatment, eliminates all microorganisms, enabling shelf-stable milk storage for several months without refrigeration. The choice between pasteurized and sterilized milk balances consumer preferences for taste and nutrient retention with the need for prolonged preservation and safety.

Equipment and Technology Innovations

Advanced pasteurization equipment utilizes rapid heating and cooling systems with digital temperature controls to ensure precise microbial inactivation while preserving milk quality. Sterilization technology innovations include ultra-high temperature (UHT) processing combined with aseptic packaging systems that extend shelf life without refrigeration. Integration of IoT sensors and automated monitoring enhances process reliability, traceability, and compliance with safety standards in both pasteurization and sterilization units.

Regulatory Standards for Milk Treatment

Regulatory standards for milk treatment establish strict guidelines to ensure safety and quality through pasteurization or sterilization processes. Pasteurization must achieve a minimum of 72degC for 15 seconds (HTST) to eliminate pathogenic microorganisms, complying with standards set by agencies like the FDA and Codex Alimentarius. Sterilization processes, such as UHT treatment at 135-150degC for 2-4 seconds, follow stringent regulations to guarantee commercial sterility while maintaining nutritional value.

Consumer Perceptions and Market Trends

Pasteurization preserves milk's natural flavor and nutrients by heating it to around 72degC for 15 seconds, aligning with consumer preferences for fresh taste and perceived safety. Sterilization, involving higher temperatures above 135degC for several seconds, ensures longer shelf life but can alter taste and texture, often leading to lower consumer acceptance despite stronger microbial safety claims. Market trends indicate growing demand for pasteurized milk labeled with transparent safety standards, appealing to health-conscious buyers prioritizing freshness and natural qualities.

Related Important Terms

Cold Plasma Pasteurization

Cold plasma pasteurization employs reactive gases at low temperatures to inactivate pathogens in milk while preserving sensory and nutritional quality, unlike traditional thermal pasteurization which can degrade heat-sensitive nutrients. This advanced non-thermal technique enhances milk safety by effectively reducing microbial load without the nutrient losses associated with sterilization processes.

Microfiltration-Aided Pasteurization

Microfiltration-aided pasteurization enhances milk safety by combining low-temperature filtration to remove bacteria with traditional pasteurization, preserving nutritional and sensory qualities better than conventional heat treatments. This process reduces microbial load more effectively than pasteurization alone while avoiding the harsher thermal impact of sterilization that can degrade milk components.

Pulsed Electric Field (PEF) Sterilization

Pulsed Electric Field (PEF) sterilization in milk safety uses short bursts of high voltage to inactivate pathogens while preserving nutrients and sensory qualities, offering a non-thermal alternative to traditional pasteurization and thermal sterilization. This innovative technology enhances microbial safety and extends shelf life without the heat-induced alterations associated with conventional methods.

Ultra-High Temperature (UHT) Processing

Ultra-High Temperature (UHT) processing rapidly heats milk to 135-150degC for 2-5 seconds, effectively sterilizing it by destroying all pathogenic and spoilage microorganisms, thus extending shelf life without refrigeration. This method maintains nutritional quality better than traditional sterilization, while offering greater safety and longer storage compared to standard pasteurization at 72degC for 15 seconds.

High-Pressure Processing (HPP) Pasteurization

High-Pressure Processing (HPP) pasteurization effectively eliminates pathogenic microorganisms in milk while preserving its nutritional and sensory qualities, unlike traditional thermal pasteurization that may degrade heat-sensitive nutrients. HPP achieves microbial safety by subjecting milk to pressures up to 600 MPa, disrupting cellular structures without significant heat, thus extending shelf life and enhancing milk safety.

Aseptic Processing

Aseptic processing combines pasteurization and sterile packaging to ensure milk safety by eliminating harmful pathogens while preserving nutritional quality and extending shelf life without refrigeration. This method balances microbial inactivation with minimal heat exposure, optimizing both food safety and sensory attributes in milk products.

Ohmic Heating Sterilization

Ohmic heating sterilization utilizes electrical currents passed through milk to rapidly generate internal heat, effectively inactivating pathogens while preserving nutritional and sensory qualities compared to traditional pasteurization and sterilization methods. This innovative technique offers uniform heating, reduced processing times, and enhanced milk safety by preventing microbial contamination without overheating.

Non-Thermal Pasteurization

Non-thermal pasteurization methods for milk safety, such as high-pressure processing (HPP) and cold plasma, effectively inactivate pathogenic microorganisms while preserving nutritional and sensory qualities better than traditional thermal pasteurization. These innovative techniques extend shelf life and maintain bioactive compounds without the protein denaturation and vitamin loss commonly associated with sterilization.

Extended Shelf Life (ESL) Milk Technology

Extended Shelf Life (ESL) milk technology combines high-temperature short-time pasteurization with microfiltration to reduce microbial load, significantly extending milk's shelf life while preserving its fresh taste. Unlike traditional sterilization, ESL maintains more nutrients and sensory qualities, offering a safer and longer-lasting product without the cooked flavor typical of sterilized milk.

Bacteriophage-Based Decontamination

Bacteriophage-based decontamination in milk safety effectively targets and eliminates specific bacterial contaminants without affecting milk's nutritional quality, offering a precise alternative to traditional pasteurization and sterilization methods. This biocontrol approach reduces reliance on heat treatments, preserving milk's sensory properties while enhancing microbial safety through targeted bacterial lysis.

Pasteurization vs Sterilization for Milk Safety Infographic

agridif.com

agridif.com