Modified Atmosphere Packaging (MAP) enhances shelf life by altering the gas composition around food products, reducing oxygen levels to slow microbial growth and oxidation, thus preserving freshness and quality. Vacuum Packaging removes air entirely, effectively inhibiting aerobic spoilage organisms and oxidative reactions, but may cause anaerobic bacteria proliferation if not properly managed. Both techniques significantly extend shelf life in Food Science and Technology, with MAP offering more flexibility in gas mixtures tailored to specific food types compared to the simpler but highly effective vacuum method.

Table of Comparison

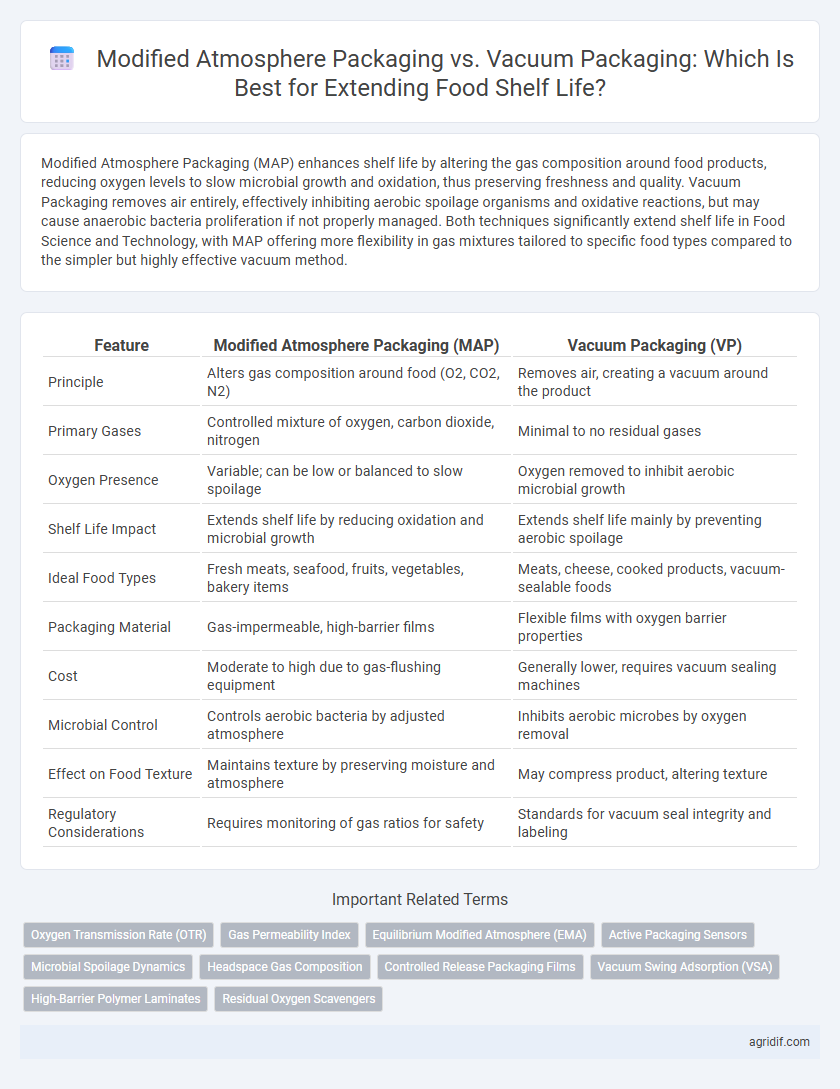

| Feature | Modified Atmosphere Packaging (MAP) | Vacuum Packaging (VP) |

|---|---|---|

| Principle | Alters gas composition around food (O2, CO2, N2) | Removes air, creating a vacuum around the product |

| Primary Gases | Controlled mixture of oxygen, carbon dioxide, nitrogen | Minimal to no residual gases |

| Oxygen Presence | Variable; can be low or balanced to slow spoilage | Oxygen removed to inhibit aerobic microbial growth |

| Shelf Life Impact | Extends shelf life by reducing oxidation and microbial growth | Extends shelf life mainly by preventing aerobic spoilage |

| Ideal Food Types | Fresh meats, seafood, fruits, vegetables, bakery items | Meats, cheese, cooked products, vacuum-sealable foods |

| Packaging Material | Gas-impermeable, high-barrier films | Flexible films with oxygen barrier properties |

| Cost | Moderate to high due to gas-flushing equipment | Generally lower, requires vacuum sealing machines |

| Microbial Control | Controls aerobic bacteria by adjusted atmosphere | Inhibits aerobic microbes by oxygen removal |

| Effect on Food Texture | Maintains texture by preserving moisture and atmosphere | May compress product, altering texture |

| Regulatory Considerations | Requires monitoring of gas ratios for safety | Standards for vacuum seal integrity and labeling |

Introduction to Packaging Technologies in Food Preservation

Modified Atmosphere Packaging (MAP) and Vacuum Packaging (VP) are advanced food preservation technologies that significantly extend shelf life by controlling the atmospheric conditions surrounding the product. MAP replaces the air inside packaging with specific gas mixtures, typically oxygen, carbon dioxide, and nitrogen, to slow microbial growth and oxidation, while VP removes air entirely to inhibit aerobic microorganisms. Both techniques effectively maintain food quality, freshness, and safety, with MAP often preferred for products requiring gas exchange and VP favored for liquid or solid foods sensitive to oxidation.

Principles of Modified Atmosphere Packaging (MAP)

Modified Atmosphere Packaging (MAP) extends food shelf life by altering the gaseous environment surrounding the product, typically reducing oxygen and increasing carbon dioxide or nitrogen levels to inhibit microbial growth and oxidative reactions. Unlike vacuum packaging, MAP maintains product shape and texture by preventing package collapse and controlling respiration rates in fresh produce. This selective gas composition optimizes freshness retention, flavor preservation, and color stability, making MAP a preferred technology for perishable food items in the supply chain.

Fundamentals of Vacuum Packaging

Vacuum packaging extends shelf life by removing air and reducing oxygen availability, which slows down microbial growth and oxidation of food products. This method creates a tight, oxygen-free environment by sealing the package under low pressure, preserving sensory qualities and nutritional value effectively. Key factors in vacuum packaging include package material permeability, residual oxygen levels, and product handling to maximize preservation and maintain food safety.

Comparative Effects on Shelf Life Extension

Modified Atmosphere Packaging (MAP) extends shelf life by altering the gas composition around food products, typically increasing carbon dioxide and reducing oxygen levels to inhibit microbial growth and oxidative spoilage. Vacuum Packaging (VP) removes air from the package, significantly reducing oxygen exposure and slowing aerobic microbial activity and oxidation processes. Studies show MAP often provides longer shelf life for fresh produce and meats by balancing gas mixtures tailored to specific products, while VP is more effective for high-moisture foods and products sensitive to physical deformation.

Impact on Microbial Growth and Food Safety

Modified Atmosphere Packaging (MAP) controls oxygen, carbon dioxide, and nitrogen levels to inhibit aerobic microbial growth, effectively extending shelf life and enhancing food safety by slowing spoilage and pathogen proliferation. Vacuum Packaging removes air completely, creating anaerobic conditions that suppress aerobic bacteria but may promote the growth of anaerobic pathogens like Clostridium botulinum, requiring careful control of storage conditions. Both methods improve shelf life but must be optimized based on the specific microbial risks associated with the food product to ensure safety and quality.

Influence on Organoleptic Properties and Quality

Modified Atmosphere Packaging (MAP) enhances shelf life by selectively altering gas composition, preserving color, texture, and flavor more effectively than Vacuum Packaging (VP), which can sometimes induce product deformation and off-flavors due to oxygen removal. MAP maintains organoleptic properties by controlling oxygen, carbon dioxide, and nitrogen levels, reducing oxidative reactions and microbial growth, thus sustaining freshness and sensory quality. In contrast, VP may lead to anaerobic microbial risks and texture softening, limiting its suitability for certain perishable foods requiring high visual and flavor quality retention.

Suitability for Different Food Products

Modified Atmosphere Packaging (MAP) suits fresh produce, meats, and bakery items by adjusting gases like oxygen, carbon dioxide, and nitrogen to slow spoilage and maintain quality. Vacuum Packaging (VP) excels in extending shelf life of meats, cheeses, and cooked foods by removing air to inhibit aerobic microbial growth and oxidation. Selection depends on the food's respiration rate, sensitivity to anaerobic conditions, and desired shelf life extension.

Environmental and Economic Considerations

Modified Atmosphere Packaging (MAP) enhances shelf life by altering gas composition, reducing spoilage and food waste, but it typically incurs higher material costs and increased energy consumption for gas flushing and sealing compared to Vacuum Packaging (VP). VP reduces oxygen levels by removing air, offering lower packaging costs and simpler machinery, resulting in reduced environmental impact through decreased energy use and material waste. Evaluating the life cycle assessments reveals VP often has a smaller carbon footprint and better cost-efficiency, while MAP provides extended shelf life that can offset initial environmental and economic investments in high-value food products.

Recent Advances and Innovations in Packaging

Modified Atmosphere Packaging (MAP) utilizes advanced gas mixtures tailored to inhibit microbial growth and oxidative spoilage, significantly extending the shelf life of fresh produce and meat products compared to traditional vacuum packaging. Recent innovations in MAP include the integration of oxygen scavengers and humidity regulators within films, enhancing product quality and freshness retention under varying storage conditions. Emerging smart packaging technologies combined with modified atmospheres are developing real-time monitoring systems that track and optimize gas compositions, further improving shelf life and reducing food waste.

Future Trends and Research Directions in Food Packaging

Emerging research in food science emphasizes integrating nanotechnology with Modified Atmosphere Packaging (MAP) to enhance antimicrobial properties and extend shelf life beyond traditional limits. Advances in sensor technologies embedded within packaging allow real-time monitoring of food quality and dynamic adjustment of atmospheric conditions, signaling a shift towards smart packaging solutions. Future trends highlight biodegradable MAP materials and hybrid systems combining vacuum packaging with controlled gas mixtures to optimize preservation while reducing environmental impact.

Related Important Terms

Oxygen Transmission Rate (OTR)

Modified Atmosphere Packaging (MAP) controls the Oxygen Transmission Rate (OTR) by replacing oxygen with inert gases, significantly reducing oxidative spoilage and extending shelf life of perishable foods. Vacuum Packaging minimizes OTR by removing air completely, creating an anaerobic environment that slows microbial growth and enzymatic reactions, enhancing product stability.

Gas Permeability Index

Modified Atmosphere Packaging (MAP) utilizes controlled gas permeability films with specific Gas Permeability Indices to regulate oxygen and carbon dioxide levels, optimizing microbial growth inhibition and enzymatic activity to extend shelf life. In contrast, Vacuum Packaging removes air entirely, creating minimal gas permeability, which effectively slows oxidative reactions but may not control anaerobic microbial growth as efficiently as MAP.

Equilibrium Modified Atmosphere (EMA)

Equilibrium Modified Atmosphere (EMA) packaging regulates gas composition inside the package by balancing the respiration rate of fresh produce with the permeability of packaging materials, thereby optimizing oxygen, carbon dioxide, and ethylene levels to extend shelf life while maintaining quality. Compared to Vacuum Packaging, which removes air entirely and can cause anaerobic spoilage or texture loss, EMA maintains partial atmospheres that reduce decay without compromising product integrity, making it ideal for fruits, vegetables, and other respiring foods.

Active Packaging Sensors

Active packaging sensors integrated into Modified Atmosphere Packaging (MAP) enable real-time monitoring of gas composition, humidity, and microbial activity, significantly enhancing shelf life control by providing dynamic feedback on food quality. Vacuum Packaging, while effective at reducing oxygen levels, lacks the advanced sensor technology found in MAP, limiting its ability to actively detect spoilage or environmental changes during storage.

Microbial Spoilage Dynamics

Modified Atmosphere Packaging (MAP) alters the gas composition around food products, typically reducing oxygen and increasing carbon dioxide levels, which inhibits aerobic microbial growth and slows spoilage, particularly effective for fresh produce and meat. Vacuum Packaging removes air entirely, creating anaerobic conditions that suppress aerobic bacteria but may promote anaerobic microorganisms, requiring careful selection for products prone to anaerobic spoilage to maximize shelf life extension.

Headspace Gas Composition

Modified Atmosphere Packaging (MAP) enhances shelf life by altering the headspace gas composition, typically increasing CO2 levels to inhibit microbial growth and balancing O2 and N2 to maintain product quality. Vacuum Packaging removes oxygen from the headspace, reducing oxidative spoilage and microbial activity but may cause product deformation due to the absence of cushioning gases.

Controlled Release Packaging Films

Controlled release packaging films in Modified Atmosphere Packaging (MAP) regulate gas exchange to optimize oxygen and carbon dioxide levels, significantly extending the shelf life of perishable foods compared to Vacuum Packaging, which removes air entirely but may cause product deformation. These films improve freshness retention and microbial safety by maintaining ideal atmospheric conditions, reducing oxidation and spoilage more effectively than traditional vacuum-sealed methods.

Vacuum Swing Adsorption (VSA)

Vacuum Swing Adsorption (VSA) enhances vacuum packaging by selectively adsorbing residual gases, creating a low-oxygen environment that significantly inhibits microbial growth and enzymatic activity, thereby extending food shelf life. This technology improves gas control over traditional vacuum packaging, optimizing preservation of fresh produce, meat, and dairy products by maintaining product quality and safety.

High-Barrier Polymer Laminates

High-barrier polymer laminates in Modified Atmosphere Packaging (MAP) provide controlled gas permeability to optimize oxygen and carbon dioxide levels, significantly extending the shelf life of perishable foods. In contrast, Vacuum Packaging removes air entirely but may not control residual gas interactions as effectively as MAP with high-barrier laminates, making MAP preferable for maintaining quality in oxygen-sensitive products.

Residual Oxygen Scavengers

Modified Atmosphere Packaging (MAP) combined with residual oxygen scavengers effectively reduces oxygen levels, significantly extending shelf life by minimizing oxidative spoilage and microbial growth in perishable foods. Vacuum Packaging removes air to create anaerobic conditions but may leave trace oxygen, making oxygen scavengers essential in MAP to maintain low residual oxygen and preserve product quality longer.

Modified Atmosphere Packaging vs Vacuum Packaging for Shelf Life Extension Infographic

agridif.com

agridif.com