Wet milling produces flour with finer particle size and higher starch damage, enhancing dough quality and fermentation, while dry milling offers a more energy-efficient process with lower moisture content and longer shelf life. Wet milling requires complex equipment and water management, making it more suitable for starch-rich grains, whereas dry milling is preferred for grains with lower moisture tolerance. The choice depends on nutritional goals, processing costs, and desired flour characteristics in food production.

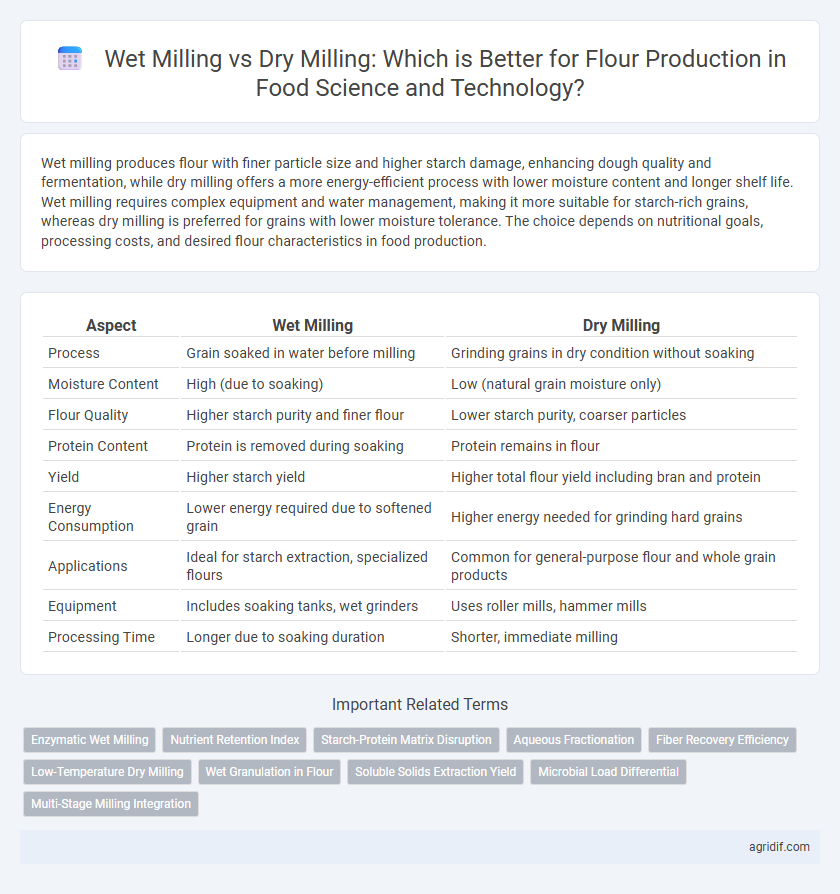

Table of Comparison

| Aspect | Wet Milling | Dry Milling |

|---|---|---|

| Process | Grain soaked in water before milling | Grinding grains in dry condition without soaking |

| Moisture Content | High (due to soaking) | Low (natural grain moisture only) |

| Flour Quality | Higher starch purity and finer flour | Lower starch purity, coarser particles |

| Protein Content | Protein is removed during soaking | Protein remains in flour |

| Yield | Higher starch yield | Higher total flour yield including bran and protein |

| Energy Consumption | Lower energy required due to softened grain | Higher energy needed for grinding hard grains |

| Applications | Ideal for starch extraction, specialized flours | Common for general-purpose flour and whole grain products |

| Equipment | Includes soaking tanks, wet grinders | Uses roller mills, hammer mills |

| Processing Time | Longer due to soaking duration | Shorter, immediate milling |

Introduction to Wet Milling and Dry Milling in Flour Production

Wet milling involves soaking grains in water to soften the kernels, enabling efficient separation of starch, fiber, and protein, which results in higher-quality flour with improved physicochemical properties and enhanced nutritional content. Dry milling, in contrast, processes dry grains through grinding and sieving, yielding flour with varying particle sizes but often retaining more bran and germ components, influencing texture and shelf life. Both methods impact flour functionality, with wet milling preferred for specialty flours requiring purity and dry milling commonly used for whole grain products.

Overview of Milling Processes in Food Science

Wet milling involves soaking grains in water to soften them before grinding, enhancing starch extraction and producing finer, more uniform flour particles with higher moisture content. Dry milling processes grains without moisture, resulting in coarser flour with lower enzymatic activity and longer shelf life, suitable for products requiring distinct texture. Both methods influence flour quality, particle size distribution, nutritional properties, and functional applications in food product development.

Mechanisms and Equipment Used in Wet Milling

Wet milling involves soaking grains in water to soften them before grinding, which facilitates the separation of starch, protein, and fiber components; this process employs equipment such as steep tanks, attrition mills, and hydrocyclones to enhance particle size reduction and component separation. In contrast to dry milling, wet milling utilizes the moisture-induced swelling of grains to optimize extraction efficiency and improve flour quality. Mechanical devices like continuous flow scrubbers and centrifuges enable precise purification and refinement of flour fractions, making wet milling ideal for producing starch-rich flours with high functional properties.

Mechanisms and Equipment Used in Dry Milling

Dry milling for flour production involves mechanical grinding methods such as roller mills and hammer mills that crush and shear grain kernels into fine particles. The process relies on the physical separation of bran, germ, and endosperm through sieving and aspiration systems to achieve desired flour purity. Key equipment includes roller mills with adjustable corrugated rolls for precise particle size reduction and plansifters that classify milled particles by size for optimal flour quality.

Comparative Analysis: Yield and Flour Quality

Wet milling of grains results in higher flour yield due to better starch recovery and lower fiber content compared to dry milling, which often produces coarser flour with higher bran retention. Wet-milled flour exhibits superior functional properties, such as enhanced water absorption and improved dough elasticity, making it preferable for specialty baked goods. Dry milling, while more economical and faster, generally yields flour with lower purity and potential quality inconsistencies due to heat generation and starch damage.

Nutritional Impacts of Wet vs Dry Milling

Wet milling preserves higher levels of water-soluble vitamins and minerals in flour due to reduced heat and oxidation exposure compared to dry milling. Dry milling often results in nutrient loss, particularly in B vitamins and antioxidants, as it involves high-temperature grinding that degrades sensitive compounds. The choice between wet and dry milling significantly influences the micronutrient profile and bioavailability in the final flour product, impacting its nutritional quality.

Energy Consumption and Sustainability Considerations

Wet milling in flour production generally demands higher energy consumption due to extensive water usage and subsequent drying processes, whereas dry milling consumes less energy by avoiding moisture removal. From a sustainability perspective, dry milling reduces water usage, mitigating environmental impact and lowering wastewater treatment costs. However, wet milling can enhance flour quality and nutrient retention, presenting a trade-off between energy efficiency and product performance in sustainable food processing.

Application Suitability: Selecting the Appropriate Milling Method

Wet milling is ideal for producing flour with higher starch purity and finer particle size, making it suitable for applications requiring smooth textures like baby food and gluten-free products. Dry milling is preferred for whole grain flour production due to its efficiency in preserving fiber and nutrient content, benefiting whole wheat breads and baked goods. The choice between wet and dry milling depends on the desired flour characteristics and end-product requirements.

Technological Advances in Flour Milling Processes

Wet milling technology enhances flour production by extracting higher yields of starch and protein, enabling finer particle size and improved dough quality compared to dry milling. Innovations such as enzymatic treatment and ultrafiltration during wet milling optimize nutrient retention and functional properties of flour. Dry milling advances focus on precision grinding and moisture control, reducing energy consumption while preserving bioactive compounds and increasing overall milling efficiency.

Future Trends and Innovations in Flour Milling

Wet milling for flour production enhances starch modification and protein separation, enabling the development of tailored flour blends with improved functional properties. Emerging technologies utilize enzymatic treatments and ultrasonication during wet milling to boost yield and reduce energy consumption, aligning with sustainability goals. Dry milling innovations focus on precision grinding and sensor-based real-time quality control, facilitating the production of specialty flours with consistent particle size and enhanced nutritional profiles.

Related Important Terms

Enzymatic Wet Milling

Enzymatic wet milling uses specific enzymes to break down starch and fiber in grains, improving flour yield and quality compared to traditional dry milling. This method enhances starch recovery, reduces energy consumption, and produces flour with finer particle size and better functional properties for food applications.

Nutrient Retention Index

Wet milling for flour production generally achieves a higher Nutrient Retention Index compared to dry milling due to reduced heat generation and minimal nutrient degradation during processing. Enzymatic activity is better preserved in wet milled flour, resulting in improved retention of B vitamins, minerals, and phytochemicals essential for enhanced nutritional quality.

Starch-Protein Matrix Disruption

Wet milling significantly enhances starch-protein matrix disruption by using water to swell and soften grains, resulting in higher starch extraction and finer flour particle size compared to dry milling. In contrast, dry milling primarily relies on mechanical forces that cause less starch damage and protein denaturation, producing coarser flour with lower functional qualities for baking applications.

Aqueous Fractionation

Aqueous fractionation in wet milling enhances flour quality by selectively separating starch, protein, and fiber components through water-based processing, resulting in higher purity and functional properties compared to dry milling. Wet milling's use of water enables efficient removal of bran and germ, improving the nutritional profile and baking performance of the flour.

Fiber Recovery Efficiency

Wet milling enhances fiber recovery efficiency in flour production by utilizing water to separate fiber components more effectively, resulting in higher yields of dietary fiber compared to dry milling. Dry milling often leads to lower fiber retention due to mechanical separation processes that do not discriminate as finely between bran and endosperm fractions.

Low-Temperature Dry Milling

Low-temperature dry milling for flour production minimizes heat generation, preserving starch granule integrity and enhancing flour quality compared to traditional wet milling, which involves water usage and extended processing times. This technique improves particle size distribution and reduces energy consumption while maintaining nutritional value and functional properties essential for food applications.

Wet Granulation in Flour

Wet granulation in flour production enhances particle cohesion by using moisture to bind flour components, resulting in improved texture, uniformity, and reduced dust during processing compared to dry milling. This method preserves nutritional quality and promotes better hydration properties, essential for high-performance baking applications.

Soluble Solids Extraction Yield

Wet milling enhances soluble solids extraction yield by breaking down starch granules and facilitating enzymatic hydrolysis, resulting in higher yield compared to dry milling. Dry milling, while less effective in soluble solids recovery, offers advantages in energy efficiency and simpler process control for flour production.

Microbial Load Differential

Wet milling significantly reduces microbial load in flour production by incorporating moisture and heat, which inhibit pathogen growth, whereas dry milling tends to retain higher microbial contamination due to the absence of sanitizing conditions. Studies show that wet-milled flour exhibits lower total plate counts and fewer spoilage organisms, enhancing its safety and shelf life compared to dry-milled counterparts.

Multi-Stage Milling Integration

Multi-stage milling integration enhances flour production by combining wet milling's efficiency in separating starch, protein, and fiber fractions with dry milling's ability to finely grind and classify particles, resulting in improved flour yield and quality. This hybrid approach optimizes moisture control, particle size distribution, and nutrient retention, meeting diverse processing requirements and end-use functionalities.

Wet milling vs dry milling for flour production Infographic

agridif.com

agridif.com