Spray chilling offers a controlled cooling process that solidifies fat-based coatings at temperatures just below their melting point, resulting in smooth, uniform layers ideal for encapsulation and protection. Spray freezing rapidly freezes fat droplets using cryogenic agents, producing brittle coatings that may enhance the structural integrity but can lead to increased porosity. Choosing between spray chilling and spray freezing depends on the desired texture, stability, and release properties of the coated product in food applications.

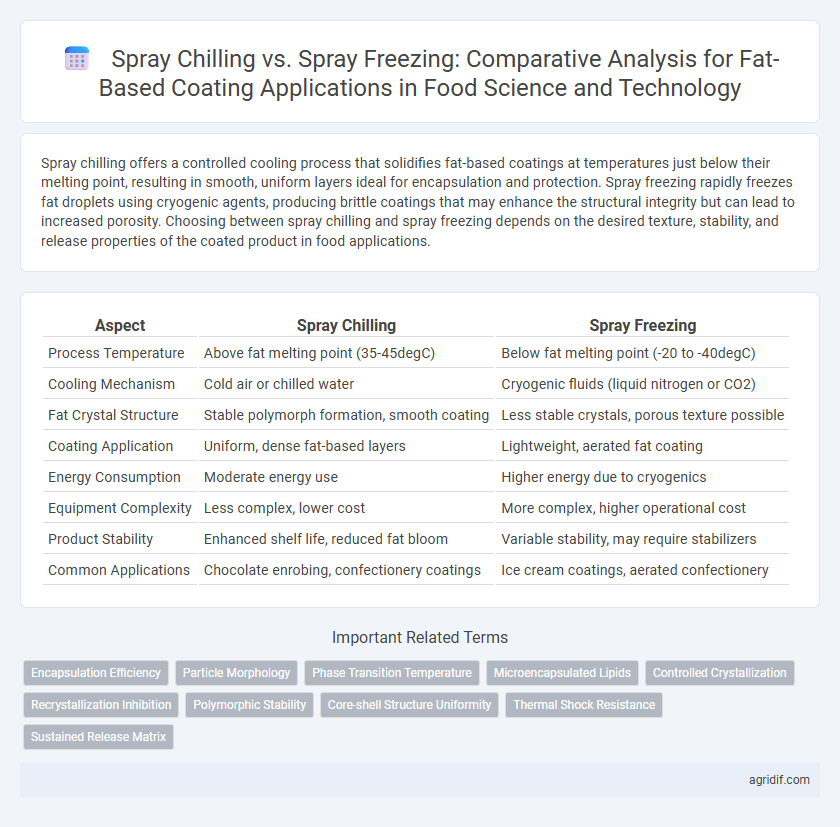

Table of Comparison

| Aspect | Spray Chilling | Spray Freezing |

|---|---|---|

| Process Temperature | Above fat melting point (35-45degC) | Below fat melting point (-20 to -40degC) |

| Cooling Mechanism | Cold air or chilled water | Cryogenic fluids (liquid nitrogen or CO2) |

| Fat Crystal Structure | Stable polymorph formation, smooth coating | Less stable crystals, porous texture possible |

| Coating Application | Uniform, dense fat-based layers | Lightweight, aerated fat coating |

| Energy Consumption | Moderate energy use | Higher energy due to cryogenics |

| Equipment Complexity | Less complex, lower cost | More complex, higher operational cost |

| Product Stability | Enhanced shelf life, reduced fat bloom | Variable stability, may require stabilizers |

| Common Applications | Chocolate enrobing, confectionery coatings | Ice cream coatings, aerated confectionery |

Introduction to Fat-Based Coating Technologies

Fat-based coating technologies utilize spray chilling and spray freezing to encapsulate flavors, oils, or active ingredients in food products. Spray chilling solidifies molten fat droplets by cooling them below their melting point, producing smooth, stable coatings ideal for controlled release and texture enhancement. Spray freezing rapidly freezes fat droplets using cryogenic agents, creating porous structures that enhance rehydration properties and protect sensitive bioactives during storage.

Principles of Spray Chilling and Spray Freezing

Spray chilling involves atomizing molten fat into a cold chamber where it solidifies upon contact with chilled air, resulting in solid fat particles used for coating applications that require smooth texture and controlled melting behavior. In contrast, spray freezing rapidly freezes fat droplets by spraying them into a cryogenic environment or cold air stream, preserving structural integrity and enhancing stability against oxidation for sensitive bioactive coatings. Both techniques provide distinct advantages in encapsulation efficiency and particle morphology tailored to specific functional requirements in fat-based food coatings.

Material Compatibility with Fat-Based Coatings

Spray chilling offers superior material compatibility with fat-based coatings by gently solidifying fats through controlled cooling, preserving their structural integrity and preventing phase separation. Spray freezing rapidly solidifies the material, which may cause crystallization defects and compromise the uniformity of fat coatings. Optimizing the cooling rate in spray chilling enhances the retention of desired functional properties in fat-based encapsulates, making it preferable for sensitive lipid formulations.

Process Parameters: Temperature and Cooling Rates

Spray chilling operates at temperatures just below the fat's melting point, typically between 30degC and 35degC, allowing controlled solidification through gradual cooling rates that preserve fat crystal structure and functionality. Spray freezing uses much lower temperatures, often below -40degC, inducing rapid solidification by fast cooling rates that create small, uniform fat crystals but may cause brittleness. Optimizing these process parameters is crucial for tailoring fat-based coating properties such as texture, gloss, and release characteristics in food applications.

Particle Morphology and Microstructure

Spray chilling produces fat-based coatings with dense, spherical particles exhibiting smooth surfaces and uniform microstructure, enhancing barrier properties and mechanical strength. Spray freezing yields porous, irregularly shaped particles with a porous microstructure that can increase surface area but may reduce stability and cohesiveness. Control over cooling rates and solidification dynamics in spray chilling results in consistent fat crystal networks, while spray freezing often leads to heterogeneous crystallization and variable particle morphology.

Encapsulation Efficiency and Stability

Spray chilling offers superior encapsulation efficiency for fat-based coatings by solidifying molten fats through rapid cooling, resulting in dense, uniform particles with enhanced structural integrity. Spray freezing, which freezes droplets rapidly before further drying, often yields lower stability due to ice crystal formation that can disrupt the encapsulant matrix. The stability of fat-based encapsulates is generally higher with spray chilling, as it minimizes moisture-induced degradation and preserves fat crystallinity, essential for controlled release and prolonged shelf-life in food applications.

Impact on Nutrient and Flavor Retention

Spray chilling solidifies fat-based coatings by cooling molten fat, preserving delicate nutrients and volatile flavor compounds better than spray freezing, which involves rapid freezing that can cause ice crystal formation and nutrient degradation. The slower solidification in spray chilling minimizes thermal and oxidative stress, enhancing the retention of lipophilic vitamins and maintaining flavor integrity in coated products. Consequently, spray chilling offers superior protection of bioactive compounds and sensory attributes compared to spray freezing in fat-based coating applications.

Industrial Applications in Food Science

Spray chilling and spray freezing are key techniques for fat-based coating applications in food science, impacting texture and release properties of products like confectionery and snacks. Spray chilling solidifies molten fat by cooling it just above its melting point, producing smooth, stable coatings ideal for controlled melting profiles and improved shelf life. Spray freezing rapidly freezes fat droplets using cryogenic agents, resulting in fine, porous coatings that enhance rapid dissolution and flavor release in industrial food manufacturing.

Comparative Advantages and Limitations

Spray chilling offers the advantage of producing smooth, uniform fat-based coatings with lower energy consumption and better control over particle size compared to spray freezing, which often results in a more crystalline and brittle structure. However, spray freezing excels in preserving heat-sensitive bioactives and maintaining functional properties due to rapid solidification at subzero temperatures. Limitations of spray chilling include potential fat bloom and lower encapsulation stability, whereas spray freezing may suffer from higher operational costs and challenges in scale-up.

Future Trends in Fat-Based Coating Technologies

Spray chilling and spray freezing represent advanced encapsulation techniques in fat-based coating applications, with spray chilling utilizing temperature reduction to solidify fats and spray freezing employing rapid freezing to improve structural integrity. Future trends emphasize integrating nano-encapsulation and bio-based lipid materials, enhancing stability and controlled release of bioactive compounds in functional foods. Innovations in process optimization and sustainability will drive improvements in encapsulation efficiency and scalability for industrial fat-based coatings.

Related Important Terms

Encapsulation Efficiency

Spray chilling achieves higher encapsulation efficiency in fat-based coating applications by solidifying lipid droplets through cooling, resulting in enhanced barrier properties and controlled release of active ingredients. Spray freezing, while effective for temperature-sensitive compounds, often results in lower encapsulation efficiency due to ice crystal formation, which can cause structural damage and increased permeability.

Particle Morphology

Spray chilling produces spherical, smooth, and dense fat particles with a uniform size distribution, enhancing flowability and controlled melting characteristics in coating applications. Spray freezing generates irregular, porous particles with higher surface area, leading to faster melting but reduced mechanical stability in fat-based coatings.

Phase Transition Temperature

Spray chilling utilizes the solidification of fats at temperatures just below their phase transition temperature, typically between 30degC and 40degC, enabling controlled crystallization and smooth coating formation. Spray freezing involves rapid cooling well below the fat's phase transition point, often below -20degC, resulting in amorphous or brittle coatings with distinct textural properties due to different crystal structures.

Microencapsulated Lipids

Spray chilling produces solid lipid coatings by cooling molten fat droplets, creating microencapsulated lipids with controlled melting points and enhanced stability, ideal for protecting sensitive bioactives. Spray freezing involves rapid freezing of lipid droplets, resulting in porous particles that impact release profiles and oxidative stability, making it suitable for specific controlled-release fat-based applications.

Controlled Crystallization

Spray chilling employs controlled crystallization by solidifying fat-based coatings at temperatures just below their melting point, resulting in uniform crystal structures that enhance texture and stability. In contrast, spray freezing rapidly solidifies coatings at much lower temperatures, often producing heterogeneous crystals that can compromise coating uniformity and functional performance in food applications.

Recrystallization Inhibition

Spray chilling utilizes controlled cooling to solidify fat-based coatings rapidly, effectively inhibiting fat recrystallization by forming stable crystalline structures that enhance texture and shelf-life. In contrast, spray freezing involves quick freezing to preserve amorphous fat phases, which may reduce recrystallization but often leads to less uniform coatings and potential structural instability.

Polymorphic Stability

Spray chilling enhances polymorphic stability in fat-based coatings by solidifying fats into a stable polymorph during cooling, reducing the risk of fat bloom and improving texture longevity. Spray freezing, while effective for rapid solidification, often leads to less stable fat polymorphs that may recrystallize during storage, compromising coating quality and shelf life.

Core-shell Structure Uniformity

Spray chilling produces a more uniform core-shell structure in fat-based coatings by solidifying fat droplets rapidly through cooling, enhancing barrier properties and controlled release, whereas spray freezing often leads to irregular shell formation due to ice crystal growth. Improved uniformity in spray chilling ensures better encapsulation stability and consistent texture in food applications.

Thermal Shock Resistance

Spray chilling provides superior thermal shock resistance in fat-based coating applications by gradually solidifying fats at controlled temperatures, preserving structural integrity and preventing cracking. In contrast, spray freezing induces rapid temperature drops that may cause brittleness and compromise the coating's durability under thermal stress.

Sustained Release Matrix

Spray chilling produces a solid lipid matrix by cooling molten fat, offering controlled release properties ideal for sustained release fat-based coatings, while spray freezing rapidly solidifies fat emulsions using cryogenic temperatures, resulting in porous structures with faster release rates. The choice between these techniques impacts the release profile, stability, and functional performance of encapsulated bioactives in food applications.

Spray chilling vs spray freezing for fat-based coating applications Infographic

agridif.com

agridif.com