Ambient packaging preserves meat products by providing a stable environment that slows microbial growth without altering the food's atmosphere. Active packaging incorporates components such as oxygen scavengers or antimicrobial agents to extend shelf life and enhance safety by actively interacting with the meat. Comparing both, active packaging offers improved protection against spoilage and oxidation, making it a more advanced solution for maintaining meat quality during storage.

Table of Comparison

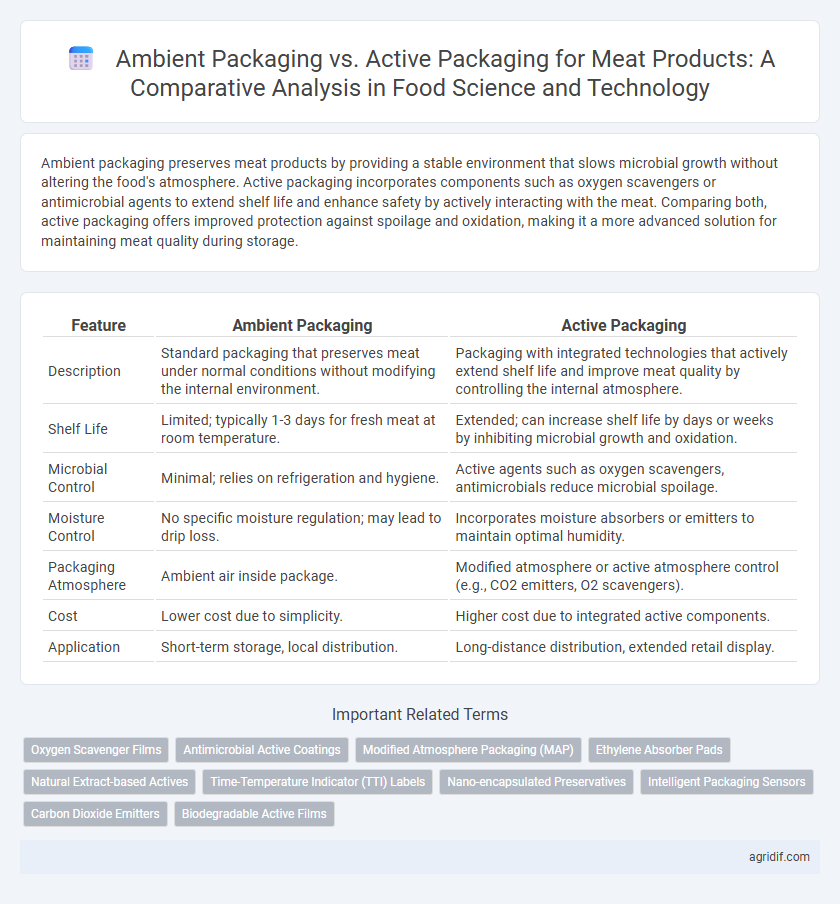

| Feature | Ambient Packaging | Active Packaging |

|---|---|---|

| Description | Standard packaging that preserves meat under normal conditions without modifying the internal environment. | Packaging with integrated technologies that actively extend shelf life and improve meat quality by controlling the internal atmosphere. |

| Shelf Life | Limited; typically 1-3 days for fresh meat at room temperature. | Extended; can increase shelf life by days or weeks by inhibiting microbial growth and oxidation. |

| Microbial Control | Minimal; relies on refrigeration and hygiene. | Active agents such as oxygen scavengers, antimicrobials reduce microbial spoilage. |

| Moisture Control | No specific moisture regulation; may lead to drip loss. | Incorporates moisture absorbers or emitters to maintain optimal humidity. |

| Packaging Atmosphere | Ambient air inside package. | Modified atmosphere or active atmosphere control (e.g., CO2 emitters, O2 scavengers). |

| Cost | Lower cost due to simplicity. | Higher cost due to integrated active components. |

| Application | Short-term storage, local distribution. | Long-distance distribution, extended retail display. |

Overview of Packaging Technologies in Meat Products

Ambient packaging for meat products relies on traditional methods such as vacuum sealing and modified atmosphere packaging (MAP) to extend shelf life by controlling oxygen and moisture levels. Active packaging incorporates innovative elements like oxygen scavengers, antimicrobial agents, and moisture absorbers to actively enhance preservation and inhibit microbial growth. These technologies differ in their approach to maintaining freshness, with active packaging offering dynamic interaction with the product environment compared to the passive nature of ambient packaging.

Defining Ambient Packaging for Meat Preservation

Ambient packaging for meat preservation involves storing meat products at room temperature under controlled atmospheric conditions without actively modifying the packaging environment. This method relies on barrier materials that protect meat from oxygen, moisture, and microbial contamination, extending shelf life while maintaining the product's quality. Common materials include high-barrier films such as polyethylene terephthalate (PET) combined with vacuum or modified atmosphere packaging to slow spoilage and prevent oxidative degradation.

Understanding Active Packaging: Principles and Applications

Active packaging for meat products incorporates technologies such as oxygen scavengers, antimicrobials, and moisture absorbers to extend shelf life and maintain freshness by directly interacting with the product or its environment. Unlike ambient packaging, which provides a passive barrier against external contaminants, active packaging modifies internal conditions to inhibit microbial growth and oxidative spoilage. Applications in meat preservation demonstrate significant improvements in quality retention and safety by controlling factors like gas composition and moisture levels within the package.

Key Differences Between Ambient and Active Packaging

Ambient packaging preserves meat products under normal atmospheric conditions, relying on barriers that limit oxygen and moisture penetration to maintain freshness. Active packaging incorporates components such as oxygen scavengers, antimicrobial agents, or carbon dioxide emitters to interact dynamically with the meat environment, extending shelf life and enhancing safety. Key differences include the interaction level with the product, with active packaging modifying the internal atmosphere, while ambient packaging provides passive protection.

Effects on Shelf Life of Meat Products

Ambient packaging for meat products typically offers limited protection, resulting in shorter shelf life due to oxidative degradation and microbial growth. Active packaging incorporates antimicrobial agents, oxygen scavengers, and moisture regulators to significantly extend shelf life by inhibiting spoilage and maintaining meat quality. Studies report that active packaging can increase shelf life by 30-50% compared to conventional ambient packaging methods.

Impact on Food Safety and Quality

Ambient packaging for meat products maintains a stable environment but allows microbial growth and oxidation, potentially compromising food safety and shelf life. Active packaging incorporates antimicrobial agents, oxygen scavengers, or moisture absorbers to inhibit spoilage microorganisms and oxidative reactions, significantly enhancing meat quality and extending shelf life. The integration of active packaging technologies directly improves microbial safety and sensory attributes, reducing the risk of foodborne illnesses and preserving nutritional value.

Influence on Meat Sensory Attributes

Ambient packaging preserves meat by maintaining stable environmental conditions but may lead to moisture loss and oxidation, affecting texture and flavor negatively. Active packaging incorporates oxygen scavengers or antimicrobial agents that significantly enhance meat color retention, juiciness, and aroma stability during storage. Studies show active packaging extends shelf life while maintaining desirable sensory attributes, outperforming conventional ambient packaging in consumer acceptance.

Environmental and Economic Considerations

Ambient packaging for meat products generally offers lower initial costs and simpler recycling processes, reducing short-term environmental impact. Active packaging extends shelf life by incorporating antimicrobial or oxygen-scavenging materials, decreasing food waste and associated economic losses but often involves higher production expenses and complex disposal challenges. Balancing reduced food spoilage against increased material use is critical for sustainable, cost-effective meat packaging solutions in the food science industry.

Innovations and Trends in Meat Packaging

Active packaging for meat products incorporates oxygen scavengers, antimicrobial agents, and moisture regulators, enhancing shelf life and safety compared to traditional ambient packaging. Innovations in active packaging use nanotechnology and biopolymer films to improve barrier properties and enable real-time freshness monitoring. Current trends emphasize sustainable materials combined with smart packaging features, aligning meat preservation with environmental and consumer demands.

Future Prospects of Meat Product Packaging Technologies

Advancements in meat product packaging emphasize integrating smart materials in active packaging to enhance shelf life through antimicrobial and oxygen-scavenging properties, surpassing traditional ambient packaging limitations. Emerging technologies focus on biodegradable active films embedded with nanomaterials or natural extracts to reduce environmental impact while maintaining meat quality. Future prospects highlight the convergence of nanotechnology, biosensors, and controlled atmosphere systems for real-time monitoring and preservation of meat freshness and safety.

Related Important Terms

Oxygen Scavenger Films

Oxygen scavenger films in active packaging significantly extend the shelf life of meat products by reducing oxidative spoilage and microbial growth, unlike ambient packaging which relies solely on passive barriers. These films absorb residual oxygen, maintaining meat color and freshness, thereby enhancing product safety and quality in comparison to conventional packaging methods.

Antimicrobial Active Coatings

Antimicrobial active coatings in active packaging significantly extend the shelf life of meat products by inhibiting microbial growth, outperforming ambient packaging that relies solely on passive protection. These coatings integrate natural or synthetic antimicrobial agents, offering targeted microbial control and reducing spoilage while maintaining meat quality and safety.

Modified Atmosphere Packaging (MAP)

Modified Atmosphere Packaging (MAP) enhances meat product shelf life by altering the gas composition within ambient packaging, typically reducing oxygen and increasing carbon dioxide to inhibit microbial growth and oxidative spoilage. Active packaging further extends preservation by incorporating oxygen scavengers or antimicrobial agents that interact dynamically with the meat environment, offering superior quality retention compared to traditional ambient MAP systems.

Ethylene Absorber Pads

Ethylene absorber pads in active packaging effectively reduce ethylene levels, slowing spoilage and extending the shelf life of meat products compared to ambient packaging, which lacks such control mechanisms. This technology enhances meat quality by minimizing oxidative reactions and microbial growth linked to ethylene accumulation.

Natural Extract-based Actives

Natural extract-based actives in active packaging for meat products enhance shelf life and microbial safety by releasing antioxidants and antimicrobials, effectively reducing spoilage compared to ambient packaging. These bioactive compounds, such as essential oils and plant phenolics, target lipid oxidation and pathogenic bacteria, offering a sustainable alternative to synthetic preservatives in food preservation.

Time-Temperature Indicator (TTI) Labels

Time-Temperature Indicator (TTI) labels in active packaging provide real-time monitoring of meat product freshness by reacting to temperature fluctuations and signaling potential spoilage, enhancing quality control beyond the static protection offered by ambient packaging. Incorporating TTI labels enables dynamic risk management, reducing food waste and ensuring safety through precise indication of thermal abuse during storage and distribution.

Nano-encapsulated Preservatives

Nano-encapsulated preservatives in active packaging for meat products enhance shelf life by releasing antimicrobial agents in response to environmental triggers, contrasting with ambient packaging, which lacks such controlled preservation mechanisms. This technology improves meat safety and quality by minimizing microbial growth and oxidative spoilage without altering product appearance or texture.

Intelligent Packaging Sensors

Intelligent packaging sensors in active packaging for meat products significantly enhance shelf life and safety by detecting spoilage indicators such as pH, temperature, and gas composition, unlike ambient packaging which offers only passive protection. These sensors provide real-time monitoring, ensuring timely intervention and reducing food waste through improved quality management.

Carbon Dioxide Emitters

Carbon dioxide emitters in active packaging for meat products significantly extend shelf life by inhibiting microbial growth and oxidation, outperforming traditional ambient packaging that lacks these controlled gas release capabilities. This technology enhances meat freshness, safety, and overall quality by maintaining optimal CO2 levels, which ambient packaging fails to regulate effectively.

Biodegradable Active Films

Biodegradable active films in meat packaging enhance shelf life by incorporating antimicrobial and antioxidant agents, effectively reducing spoilage and microbial growth compared to traditional ambient packaging. These eco-friendly films minimize environmental impact while maintaining meat freshness through controlled gas exchange and moisture regulation.

Ambient packaging vs Active packaging for meat products Infographic

agridif.com

agridif.com