Homogenization and emulsification both enhance dairy stability by reducing particle size, but homogenization breaks down fat globules to create a uniform milk texture, while emulsification stabilizes mixtures of immiscible liquids such as oil and water. Homogenization improves the consistency and shelf life of milk by preventing cream separation, whereas emulsification ensures stable dairy-based sauces and dressings by maintaining dispersed fat droplets. Optimizing these processes is crucial for achieving desired texture, taste, and product stability in dairy formulations.

Table of Comparison

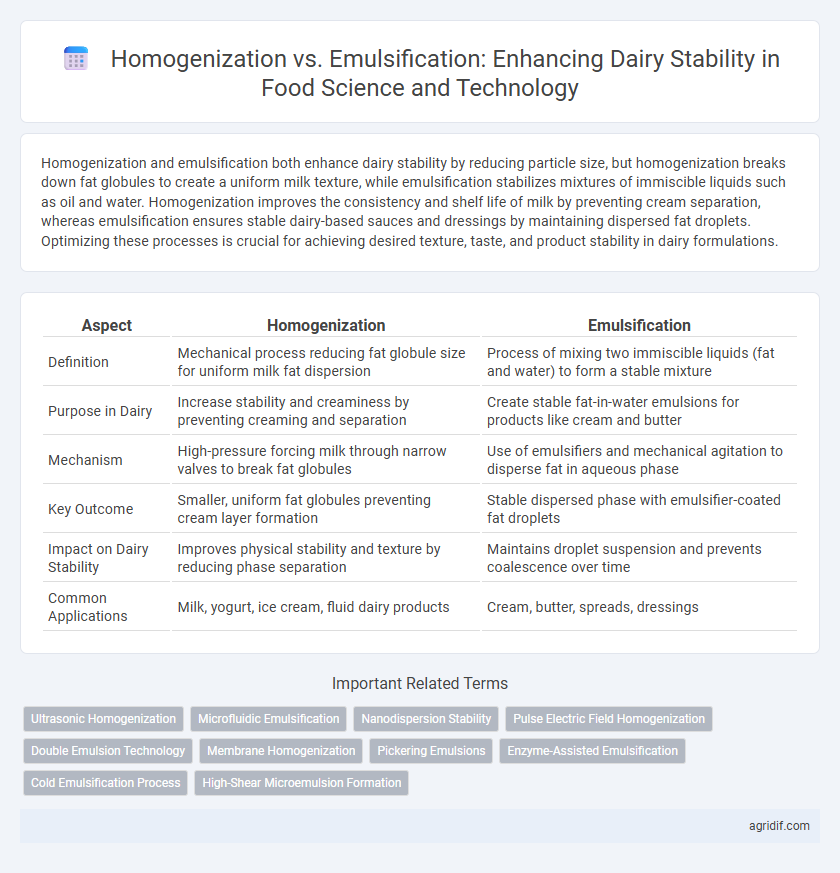

| Aspect | Homogenization | Emulsification |

|---|---|---|

| Definition | Mechanical process reducing fat globule size for uniform milk fat dispersion | Process of mixing two immiscible liquids (fat and water) to form a stable mixture |

| Purpose in Dairy | Increase stability and creaminess by preventing creaming and separation | Create stable fat-in-water emulsions for products like cream and butter |

| Mechanism | High-pressure forcing milk through narrow valves to break fat globules | Use of emulsifiers and mechanical agitation to disperse fat in aqueous phase |

| Key Outcome | Smaller, uniform fat globules preventing cream layer formation | Stable dispersed phase with emulsifier-coated fat droplets |

| Impact on Dairy Stability | Improves physical stability and texture by reducing phase separation | Maintains droplet suspension and prevents coalescence over time |

| Common Applications | Milk, yogurt, ice cream, fluid dairy products | Cream, butter, spreads, dressings |

Introduction to Dairy Stability in Food Science

Homogenization and emulsification are critical processes in dairy stability, enhancing texture, mouthfeel, and shelf life by reducing fat globule size and ensuring uniform fat dispersion. Homogenization mechanically breaks down milk fat globules to prevent creaming, while emulsification involves forming stable fat-in-water mixtures using emulsifiers and stabilizers. Effective control of these processes optimizes dairy product consistency and prevents phase separation during storage.

Fundamentals of Homogenization in Dairy Processing

Homogenization in dairy processing involves mechanical disruption of fat globules to create a uniform, stable milk emulsion by reducing fat particle size from 1-10 microns to less than 2 microns. This process enhances dairy stability by preventing creaming and improving texture, mouthfeel, and shelf life. Unlike emulsification, which relies on surfactants to stabilize immiscible liquids, homogenization mechanically achieves physical dispersion without added emulsifiers.

Principles of Emulsification in Dairy Technology

Emulsification in dairy technology involves the dispersion of fat droplets uniformly within the aqueous phase, stabilized by emulsifiers such as proteins and phospholipids that reduce interfacial tension and prevent coalescence. Homogenization mechanically disrupts fat globules into smaller sizes, enhancing emulsion stability by increasing surface area and promoting interaction with milk proteins. Effective emulsification principles improve dairy product texture, shelf life, and sensory attributes by maintaining a stable fat-in-water emulsion critical for quality and consumer acceptance.

Key Differences Between Homogenization and Emulsification

Homogenization mechanically reduces fat globule size in dairy products, creating a uniform fat distribution to enhance texture and prevent cream separation. Emulsification involves the stabilization of fat and water phases through emulsifiers, ensuring long-term stability and preventing phase separation in dairy formulations. Key differences include homogenization's physical disruption of fat globules versus emulsification's chemical stabilization using surface-active agents.

Impact on Milk and Cream Stability

Homogenization reduces the fat globule size in milk and cream, creating a uniform mixture that prevents cream separation and enhances product stability. Emulsification stabilizes mixtures of immiscible liquids by forming stable fat droplets surrounded by emulsifiers, maintaining shelf-life and texture in dairy products. Both processes are essential for improving the physical stability and sensory properties of milk and cream, reducing phase separation and extending freshness.

Effects on Nutrient Retention and Bioavailability

Homogenization improves dairy stability by reducing fat globule size, which enhances the uniform distribution of nutrients and prevents creaming, thereby maintaining nutrient retention. Emulsification stabilizes the fat-water interface through emulsifiers, promoting the bioavailability of fat-soluble vitamins such as A, D, E, and K in dairy products. Enhanced nutrient bioavailability from emulsified dairy ensures better absorption in the gastrointestinal tract, supporting improved nutritional efficacy.

Equipment and Technological Innovations

Homogenization employs high-pressure valves and piston pumps to mechanically reduce fat globule size, enhancing dairy product stability by preventing cream separation; advanced ultrasonic and microfluidizer equipment have further refined this process for uniform texture. Emulsification utilizes high-shear mixers and rotor-stator systems to disperse fat within aqueous phases, with recent innovations in nanotechnology and membrane emulsification improving emulsion stability and particle size control. Integration of inline sensors and real-time monitoring technologies enables precise control over homogenization and emulsification parameters, optimizing dairy product quality and shelf life.

Quality Control and Shelf Life Extension

Homogenization reduces the size of fat globules in milk, creating a uniform dispersion that enhances dairy product stability and texture, directly impacting quality control by preventing cream separation. Emulsification involves the creation of a stable oil-in-water mixture through emulsifiers, which improves the consistency and prolongs shelf life by inhibiting phase separation and microbial growth. The combined effect of homogenization and emulsification optimizes dairy product shelf life extension by maintaining physicochemical stability and preserving sensory attributes under various storage conditions.

Industrial Applications in Dairy Product Development

Homogenization reduces fat globule size uniformly through mechanical pressure, enhancing the physical stability and consistency of dairy products like milk and cream. Emulsification involves the stabilization of fat droplets by emulsifiers, critical in products such as butter and flavored milk to prevent phase separation. Industrial applications leverage homogenization for texture improvement, while emulsification ensures long-term stability and uniform distribution of fat in complex dairy formulations.

Future Trends in Dairy Stabilization Techniques

Emerging techniques in dairy stabilization focus on integrating ultrasonication with traditional homogenization to enhance fat globule dispersion and improve emulsion stability. Nanotechnology applications, such as nanoemulsions, are gaining traction to increase the bioavailability and shelf life of dairy products by preventing phase separation. Advances in natural emulsifiers, including plant-based proteins and biopolymers, offer sustainable alternatives to synthetic stabilizers, aligning with consumer demand for clean-label dairy products.

Related Important Terms

Ultrasonic Homogenization

Ultrasonic homogenization uses high-frequency sound waves to create intense cavitation forces that break down fat globules in dairy, enhancing emulsion stability more effectively than traditional emulsification methods. This advanced technique improves particle size reduction and distribution, resulting in superior creaminess, texture, and shelf-life of dairy products.

Microfluidic Emulsification

Microfluidic emulsification in dairy processing offers precise droplet size control and enhanced stability compared to traditional homogenization, resulting in uniform emulsions that improve creaminess and shelf life. This technique utilizes microchannels to generate monodisperse droplets, reducing coalescence and phase separation for superior product quality in milk and yogurt formulations.

Nanodispersion Stability

Homogenization reduces fat globule size in milk to create a uniform nanodispersion, enhancing dairy stability by preventing cream separation and improving texture. Emulsification stabilizes oil-in-water mixtures through surfactants, promoting prolonged nanodispersion stability critical for consistent dairy product quality.

Pulse Electric Field Homogenization

Pulse Electric Field (PEF) homogenization enhances dairy stability by using short bursts of high voltage to disrupt fat globules more uniformly than traditional mechanical homogenization, improving emulsification efficiency and reducing particle size. This non-thermal method preserves milk's nutritional quality and extends shelf life by minimizing microbial growth without affecting flavor or texture.

Double Emulsion Technology

Double emulsion technology enhances dairy stability by creating complex multiple emulsions that encapsulate oil droplets within water phases, improving texture and shelf-life compared to traditional homogenization. This method offers superior control over droplet size distribution and phase stability, reducing coalescence and phase separation in dairy products.

Membrane Homogenization

Membrane homogenization enhances dairy stability by reducing fat globule size and creating uniform dispersions, improving the texture and shelf-life of milk products. This process surpasses traditional emulsification methods by offering precise control over particle size distribution and minimizing energy consumption during dairy processing.

Pickering Emulsions

Pickering emulsions enhance dairy stability by using solid particles like protein aggregates to stabilize oil-water interfaces, offering superior resistance to coalescence compared to traditional surfactant-based emulsions. Homogenization reduces fat globule size through mechanical shear but does not provide the same long-term stability benefits as Pickering emulsions, which improve shelf life and texture in dairy products.

Enzyme-Assisted Emulsification

Enzyme-assisted emulsification enhances dairy stability by using specific enzymes like lipases and proteases to improve interfacial film formation around fat globules, promoting uniform droplet dispersion and preventing phase separation. This bio-catalytic approach offers superior control over droplet size and emulsion stability compared to conventional homogenization, resulting in improved texture, shelf life, and nutrient retention in dairy products.

Cold Emulsification Process

Cold emulsification in dairy processing enhances product stability by uniformly dispersing fat globules without heat-induced protein denaturation, preserving nutritional quality and texture. This technique uses high-pressure homogenization to create fine, stable emulsions that improve shelf life and sensory attributes compared to traditional thermal methods.

High-Shear Microemulsion Formation

High-shear microemulsion formation during homogenization disrupts fat globules in dairy products, resulting in uniform particle size distribution that enhances physical stability and prevents creaming. Emulsification primarily involves surfactants to reduce interfacial tension but lacks the intense mechanical forces required for the fine dispersion and persistent stability achieved through high-shear homogenization in dairy systems.

Homogenization vs Emulsification for dairy stability Infographic

agridif.com

agridif.com