Maillard reaction and caramelization are essential processes in food science that enhance flavor by producing complex taste profiles through heat-induced chemical changes. Maillard reaction involves amino acids and reducing sugars, creating savory, roasted, and nutty flavors, commonly found in baked, grilled, and roasted foods. Caramelization, on the other hand, occurs when sugars are heated to high temperatures, resulting in sweet, rich, and slightly bitter flavor notes typical of caramel, toffee, and browned desserts.

Table of Comparison

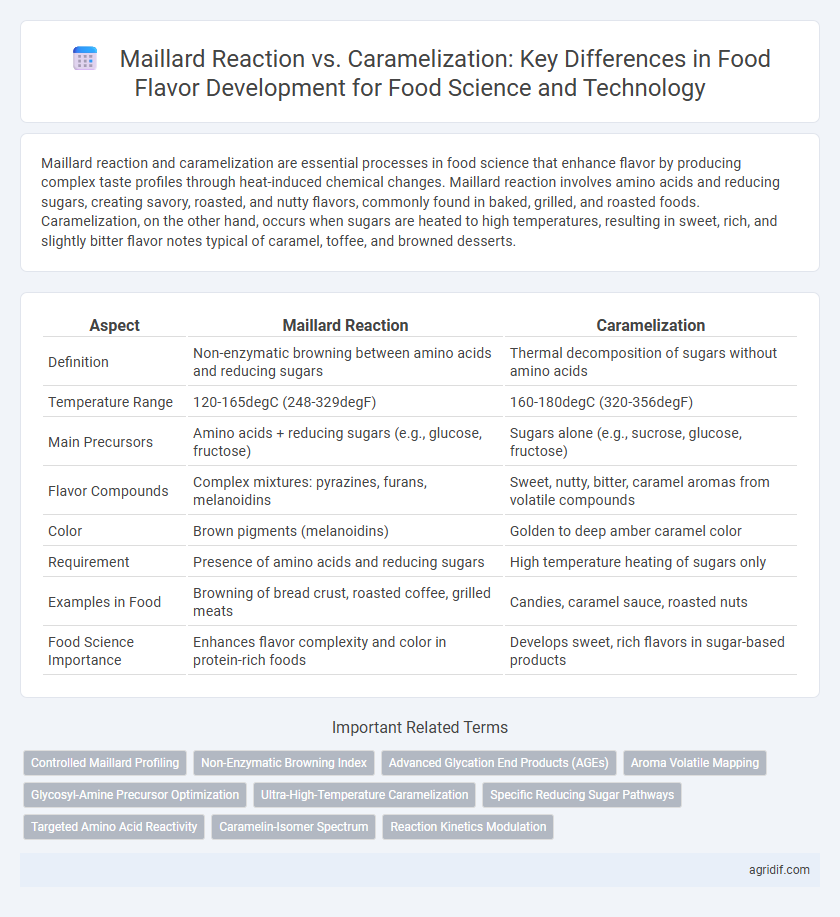

| Aspect | Maillard Reaction | Caramelization |

|---|---|---|

| Definition | Non-enzymatic browning between amino acids and reducing sugars | Thermal decomposition of sugars without amino acids |

| Temperature Range | 120-165degC (248-329degF) | 160-180degC (320-356degF) |

| Main Precursors | Amino acids + reducing sugars (e.g., glucose, fructose) | Sugars alone (e.g., sucrose, glucose, fructose) |

| Flavor Compounds | Complex mixtures: pyrazines, furans, melanoidins | Sweet, nutty, bitter, caramel aromas from volatile compounds |

| Color | Brown pigments (melanoidins) | Golden to deep amber caramel color |

| Requirement | Presence of amino acids and reducing sugars | High temperature heating of sugars only |

| Examples in Food | Browning of bread crust, roasted coffee, grilled meats | Candies, caramel sauce, roasted nuts |

| Food Science Importance | Enhances flavor complexity and color in protein-rich foods | Develops sweet, rich flavors in sugar-based products |

Overview of Maillard Reaction and Caramelization

The Maillard reaction is a complex chemical interaction between amino acids and reducing sugars that occurs at elevated temperatures, producing a diverse array of flavor compounds and brown pigments critical for savory and roasted food profiles. Caramelization involves the thermal decomposition of sugars alone, resulting in a sweet, nutty flavor and golden to dark brown coloration, without the involvement of proteins. Both processes are essential in food science for flavor development but differ fundamentally in reactants, temperature thresholds, and sensory outcomes.

Chemical Pathways in Flavor Formation

Maillard reaction involves the complex interaction between reducing sugars and amino acids, leading to the formation of melanoidins and a diverse range of flavor compounds such as pyrazines and aldehydes through Strecker degradation. Caramelization, a thermal decomposition of sugars, generates flavor molecules like furans, diacetyl, and maltol via pyrolysis and polymerization pathways without amino acid participation. Both processes significantly contribute to food flavor complexity, where Maillard reaction produces savory and roasted notes, while caramelization imparts sweet, nutty, and caramel-like aromas.

Key Differences Between Maillard Reaction and Caramelization

The Maillard reaction involves amino acids and reducing sugars interacting under heat, producing complex flavor compounds and brown pigments primarily in proteins and baked goods. Caramelization occurs through thermal decomposition of sugars alone, generating sweet, nutty flavors and deep amber colors without the need for amino acids. Maillard reaction typically requires lower temperatures (140-165degC) and results in more diverse flavor profiles, while caramelization demands higher temperatures (above 160degC) and yields simpler, sugar-focused flavor notes.

Factors Influencing Maillard Reaction in Foods

The Maillard reaction, a complex chemical process between amino acids and reducing sugars, is highly influenced by factors such as temperature, pH, water activity, and reactant concentration, all of which significantly impact flavor development in foods. Higher temperatures accelerate the reaction rate, while alkaline conditions promote browning and flavor complexity, contrasting with caramelization, which involves sugar dehydration without amino acids. Control of moisture levels is critical, as intermediate water activity enhances Maillard reaction efficiency, leading to desirable flavor profiles in processed foods.

Conditions Favoring Caramelization Processes

Caramelization primarily occurs at high temperatures above 160degC, favoring low moisture environments, which facilitate sugar degradation into complex flavor compounds and brown pigments. The absence of amino acids differentiates caramelization from the Maillard reaction, emphasizing the thermal decomposition of sugars like glucose and fructose in slightly acidic to neutral pH conditions. Industrial applications optimize heat and pH control to enhance desirable caramel flavors and colors in products such as baked goods, confectionery, and beverages.

Impact on Sensory Attributes: Aroma and Taste Profiles

The Maillard reaction generates complex aroma compounds such as pyrazines and furans, contributing to roasted, nutty, and savory flavors essential in baked and grilled foods. Caramelization produces sweet, buttery, and slightly bitter notes through the thermal decomposition of sugars, enhancing the overall sweetness and depth in confections and caramel-based products. Both processes significantly impact sensory profiles by developing distinctive tastes and aromas that define food quality and consumer preference.

Applications in Food Processing and Product Development

Maillard reaction, a chemical interaction between reducing sugars and amino acids, generates complex flavor compounds crucial in baking, roasting, and meat processing, contributing to savory, roasted, and browned tastes. Caramelization involves the thermal decomposition of sugars, producing sweet, nutty, and caramel-like flavors prominently in candy making, beverages, and baked goods. Applying these reactions strategically in food processing enhances sensory attributes, shelf life, and consumer appeal in product development.

Implications for Nutritional Quality and Safety

Maillard reaction and caramelization are critical non-enzymatic browning processes that enhance food flavor, texture, and color, profoundly impacting nutritional quality and safety. The Maillard reaction involves amino acids and reducing sugars, generating complex flavor compounds but potentially forming advanced glycation end-products (AGEs) and acrylamide, which raise health concerns. Caramelization, the thermal decomposition of sugars, primarily yields sweet and nutty notes with fewer harmful byproducts, making it a safer option for flavor development in food processing.

Real-World Examples in Popular Food Products

Maillard reaction contributes to the rich flavor and brown color in grilled steaks and roasted coffee due to the interaction of amino acids and reducing sugars at high temperatures. Caramelization, involving the pyrolysis of sugars, is responsible for the sweet, nutty taste and amber color in caramel candies and baked goods like creme brulee. Understanding these processes allows food scientists to manipulate flavor profiles and textures in products such as bread crusts and confectionery.

Future Perspectives in Flavor Enhancement Technologies

Emerging flavor enhancement technologies leverage precise control of Maillard reaction intermediates and caramelization pathways to create optimized taste profiles with reduced formation of undesirable compounds. Advanced enzymatic and non-thermal processing methods show potential in modulating Maillard reaction kinetics to enhance savory and roasted notes while minimizing acrylamide content. Integration of machine learning and metabolomics enables prediction and customization of flavor compounds,Tui Dong next-generation food products with tailored sensory attributes and improved health safety.

Related Important Terms

Controlled Maillard Profiling

Controlled Maillard profiling enables precise manipulation of amino acid and reducing sugar interactions to enhance complex flavor compounds with rich, roasted, and savory notes, distinct from the simpler, sweet, and nutty profiles formed by caramelization. Optimizing temperature, pH, and reaction time during Maillard reactions provides superior control over flavor development and color formation in food processing compared to the non-enzymatic browning of caramelization.

Non-Enzymatic Browning Index

The Maillard reaction and caramelization are key non-enzymatic browning processes that contribute to food flavor development, with the Maillard reaction involving amino acids and reducing sugars producing complex flavor compounds, while caramelization strictly involves sugar pyrolysis generating caramel notes. The Non-Enzymatic Browning Index quantifies the extent of these browning reactions by measuring absorbance changes, serving as a critical indicator for flavor intensity and color development in food science applications.

Advanced Glycation End Products (AGEs)

Maillard reaction generates Advanced Glycation End Products (AGEs) through the non-enzymatic reaction between reducing sugars and amino acids, significantly enhancing savory, roasted, and complex flavors in cooked foods. In contrast, caramelization involves the thermal decomposition of sugars without amino acids, producing sweeter, nutty, and caramel-like flavors, but does not contribute to AGEs formation, making it distinct in its impact on both flavor profile and potential health effects.

Aroma Volatile Mapping

The Maillard reaction produces a complex array of aroma volatile compounds such as pyrazines, furans, and aldehydes, which contribute to roasted, nutty, and meaty flavors in food. Caramelization generates volatile compounds like maltol and diacetyl, leading to sweet, buttery, and caramel-like aromas distinct from the nitrogen-containing volatiles of the Maillard reaction.

Glycosyl-Amine Precursor Optimization

Optimizing glycosyl-amine precursors enhances Maillard reaction efficiency, promoting complex flavor and aroma compounds critical in food flavor development. Unlike caramelization, which involves sugar pyrolysis, Maillard glycosyl-amine pathways generate diverse heterocyclic compounds that enrich sensory profiles.

Ultra-High-Temperature Caramelization

Ultra-high-temperature caramelization involves heating sugars above 170degC, triggering complex pyrolytic reactions that generate rich, nutty, and caramel-like flavors distinct from the amino acid-dependent Maillard reaction. This process enhances flavor depth in foods such as caramel syrups and roasted nuts by producing volatile compounds like hydroxymethylfurfural and maltol, which contribute to characteristic caramel notes without the protein involvement seen in Maillard browning.

Specific Reducing Sugar Pathways

Maillard reaction involves specific reducing sugars such as glucose and fructose reacting with amino acids to form complex flavor compounds through glycosylamine intermediates, while caramelization occurs when sugars like sucrose and fructose undergo thermal decomposition without amino acids, producing distinct caramel flavors via polymerization and fragmentation pathways. The Maillard reaction's pathway dependence on reducing sugars enhances savory and roasted notes, whereas caramelization's sugar-specific thermal breakdown generates sweet, nutty, and bitter flavor profiles.

Targeted Amino Acid Reactivity

Maillard reaction selectively targets amino acids like lysine and arginine, producing complex flavor compounds through interactions with reducing sugars, while caramelization involves the thermal decomposition of sugars without amino acid participation, yielding distinct caramel-like aromas. The specific reactivity of lysine's amino group in Maillard reaction drives the formation of flavorful melanoidins, crucial for savory and roasted notes in cooked foods.

Caramelin-Isomer Spectrum

Caramelization involves the thermal degradation of sugars, producing a complex Caramelin-Isomer spectrum responsible for rich, nutty, and sweet flavors distinct from the amino acid-dependent Maillard reaction. This spectrum of isomers, formed through sugar dehydration and fragmentation, significantly enhances the sensory profile of foods like caramel, baked goods, and roasted vegetables.

Reaction Kinetics Modulation

The Maillard reaction exhibits complex reaction kinetics influenced by temperature, pH, and reactant concentration, leading to diverse flavor compound formation through amino acid-sugar interactions. Caramelization kinetics primarily depend on sugar type and heating rate, resulting in distinct volatile profiles via thermal decomposition and polymerization of sugars.

Maillard Reaction vs Caramelization for Food Flavor Development Infographic

agridif.com

agridif.com