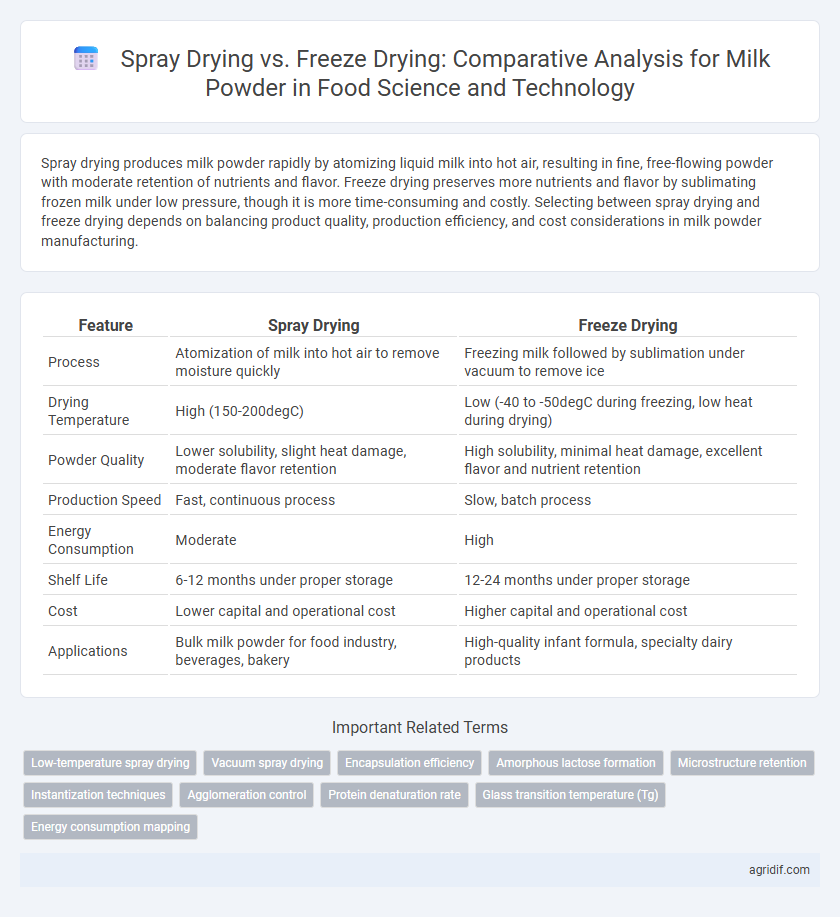

Spray drying produces milk powder rapidly by atomizing liquid milk into hot air, resulting in fine, free-flowing powder with moderate retention of nutrients and flavor. Freeze drying preserves more nutrients and flavor by sublimating frozen milk under low pressure, though it is more time-consuming and costly. Selecting between spray drying and freeze drying depends on balancing product quality, production efficiency, and cost considerations in milk powder manufacturing.

Table of Comparison

| Feature | Spray Drying | Freeze Drying |

|---|---|---|

| Process | Atomization of milk into hot air to remove moisture quickly | Freezing milk followed by sublimation under vacuum to remove ice |

| Drying Temperature | High (150-200degC) | Low (-40 to -50degC during freezing, low heat during drying) |

| Powder Quality | Lower solubility, slight heat damage, moderate flavor retention | High solubility, minimal heat damage, excellent flavor and nutrient retention |

| Production Speed | Fast, continuous process | Slow, batch process |

| Energy Consumption | Moderate | High |

| Shelf Life | 6-12 months under proper storage | 12-24 months under proper storage |

| Cost | Lower capital and operational cost | Higher capital and operational cost |

| Applications | Bulk milk powder for food industry, beverages, bakery | High-quality infant formula, specialty dairy products |

Introduction to Milk Powder Drying Techniques

Spray drying and freeze drying are prominent techniques in milk powder production, each offering distinct advantages in preserving nutritional content and particle properties. Spray drying utilizes rapid evaporation at elevated temperatures, resulting in cost-effective and high-throughput powder with fine granules but potential heat-induced nutrient loss. Freeze drying, involving sublimation under low temperature and pressure, maintains superior flavor and bioactive compounds, producing larger, more porous particles with extended shelf life.

Overview of Spray Drying in Dairy Processing

Spray drying is a widely utilized method in dairy processing that transforms liquid milk into powder by atomizing the milk into a hot drying chamber, rapidly evaporating moisture while preserving nutritional qualities. This technique offers high throughput, cost-effectiveness, and consistent particle size distribution, making it ideal for large-scale production of milk powder with extended shelf life. Compared to freeze drying, spray drying achieves faster drying times and lower operational costs, although it may result in slight heat-induced changes to flavor and protein structure.

Fundamentals of Freeze Drying for Milk Powder

Freeze drying, or lyophilization, removes water from milk by sublimating ice under low temperature and pressure, preserving the milk's nutritional and sensory properties more effectively than spray drying. This method involves three primary stages: freezing, primary drying (sublimation), and secondary drying (desorption), which ensures minimal thermal degradation and maintains the functional proteins and enzymes in milk powder. Freeze drying results in a porous, lightweight powder with superior solubility and shelf life, making it ideal for high-quality milk powder production in food science and technology.

Comparative Efficiency: Spray Drying vs. Freeze Drying

Spray drying offers rapid moisture removal and high throughput, making it more energy-efficient and cost-effective for large-scale milk powder production compared to freeze drying. Freeze drying preserves nutritional quality and flavor by sublimating ice at low temperatures but requires longer processing times and higher energy consumption. The choice between spray drying and freeze drying depends on balancing efficiency, product quality, and production scale in milk powder manufacturing.

Impact on Nutritional Quality and Functional Properties

Spray drying of milk powder involves rapid water removal at high temperatures, which can cause some loss of heat-sensitive vitamins and denaturation of proteins, potentially reducing nutritional quality. Freeze drying preserves the nutritional integrity by sublimating ice under low temperature and pressure, maintaining heat-labile nutrients and bioactive compounds more effectively. Functional properties such as solubility and rehydration are generally superior in freeze-dried milk powders due to minimal structural changes, whereas spray-dried powders may exhibit reduced solubility and altered texture.

Energy Consumption and Cost Analysis

Spray drying milk powder typically consumes 20-30% less energy compared to freeze drying, making it more cost-effective for large-scale production due to its continuous operation and faster drying rates. Freeze drying, although requiring significantly higher energy input and longer processing time, preserves more nutrients and bioactivity, which can justify its higher cost in premium dairy products. Economic analysis reveals that spray drying reduces production costs by up to 40%, whereas freeze drying may lead to expenses two to three times greater, driven mainly by its energy-intensive sublimation process.

Effects on Milk Powder Solubility and Particle Morphology

Spray drying produces milk powder with spherical, porous particles that enhance rapid solubility due to increased surface area, while freeze drying yields irregular, porous structures that preserve sensitive nutrients but result in slower reconstitution. Milk powder from spray drying typically shows higher bulk density and consistent particle size distribution, which favors flowability and mixing properties. Freeze-dried milk powder maintains better flavor and nutritional retention but can have reduced solubility and a more fragile particle morphology.

Shelf Life and Microbial Stability Considerations

Spray drying of milk powder offers shorter processing times and forms amorphous particles that can be more hygroscopic, potentially reducing shelf life if not properly packaged. Freeze drying preserves milk powder with minimal thermal degradation, resulting in better microbial stability and an extended shelf life due to lower moisture content and porous structure. However, spray-dried powders typically require stricter moisture control to prevent microbial growth, whereas freeze-dried powders maintain stability even under less stringent storage conditions.

Environmental Sustainability of Drying Methods

Spray drying of milk powder consumes less energy than freeze drying, making it a more environmentally sustainable option for large-scale production. Freeze drying preserves nutritional quality but requires significantly higher electricity input due to low-temperature vacuum conditions. Innovations in energy-efficient spray drying technologies reduce greenhouse gas emissions and carbon footprint compared to conventional freeze drying processes.

Future Trends in Milk Powder Drying Technologies

Emerging trends in milk powder drying technologies emphasize energy-efficient methods and product quality preservation, with innovations in spray drying incorporating advanced atomization techniques and real-time moisture monitoring. Freeze drying advancements focus on reducing drying time and operational costs through vacuum and pressure optimization, enhancing retention of bioactive compounds and flavor. Hybrid drying systems combining spray and freeze drying are gaining interest for maximizing nutritional content and scalability in industrial milk powder production.

Related Important Terms

Low-temperature spray drying

Low-temperature spray drying of milk powder preserves heat-sensitive nutrients and flavors better than conventional high-temperature methods, while offering faster drying times and greater scalability than freeze drying. Although freeze drying retains superior nutritional quality and rehydration properties, low-temperature spray drying provides an efficient balance between cost, product stability, and bioactive retention in dairy powder production.

Vacuum spray drying

Vacuum spray drying combines spray drying's rapid moisture removal with reduced pressure to preserve milk powder's nutritional quality and flavor better than traditional spray drying. This method enhances powder solubility and reduces thermal damage compared to freeze drying, making it an efficient choice for high-quality milk powder production.

Encapsulation efficiency

Spray drying offers higher production speed and cost-effectiveness but typically results in lower encapsulation efficiency due to thermal exposure affecting sensitive milk powder compounds. Freeze drying preserves bioactive components better with superior encapsulation efficiency by maintaining structural integrity under low temperature and vacuum conditions.

Amorphous lactose formation

Spray drying of milk powder typically results in a higher content of amorphous lactose due to rapid moisture evaporation and heat exposure, enhancing solubility but increasing hygroscopicity. Freeze drying preserves lactose in a crystalline state through sublimation under low temperatures, which improves stability but may reduce instant reconstitution properties compared to spray-dried powders.

Microstructure retention

Spray drying of milk powder typically results in spherical particles with a porous surface, which facilitates rehydration but may cause partial denaturation of proteins and loss of microstructure integrity. Freeze drying preserves the native microstructure more effectively by sublimating ice directly from frozen milk, maintaining protein conformations and bioactive compounds, although it produces more fragile and irregularly shaped particles.

Instantization techniques

Spray drying is a rapid and cost-effective method that produces milk powder with fine particles suitable for instantization by agglomeration, enhancing solubility and rehydration properties. Freeze drying preserves nutritional quality and flavor better but results in porous, fragile particles that require additional instantization steps such as fluidized bed agglomeration to improve dispersion and reduce caking.

Agglomeration control

Spray drying is preferred for milk powder production due to its ability to produce fine, uniformly sized particles with controlled agglomeration, enhancing solubility and flowability. Freeze drying typically results in porous, fragile particles with less agglomeration control, which can lead to clumping and lower rehydration efficiency.

Protein denaturation rate

Spray drying of milk powder typically results in a higher protein denaturation rate due to exposure to elevated temperatures ranging from 150degC to 200degC, which can affect nutritional quality and functional properties. Freeze drying operates at low temperatures under vacuum, preserving protein structure with minimal denaturation, making it suitable for high-quality protein retention in milk powder.

Glass transition temperature (Tg)

Spray drying milk powder typically results in a lower glass transition temperature (Tg) due to rapid water removal and higher residual moisture content, affecting powder stability and caking tendency. Freeze drying preserves a higher Tg by retaining more amorphous structure and lower moisture, enhancing shelf life and solubility of the milk powder.

Energy consumption mapping

Spray drying milk powder typically consumes 4 to 10 MJ of energy per kilogram due to high-temperature evaporation, whereas freeze drying requires significantly more, often exceeding 15 to 25 MJ/kg, because of the prolonged sublimation process at low temperatures. Energy consumption in spray drying is dominated by thermal energy for water evaporation, while freeze drying heavily relies on electrical energy for vacuum generation and refrigeration systems.

Spray drying vs freeze drying for milk powder Infographic

agridif.com

agridif.com