Cold plasma and UV-C treatment are both effective non-thermal technologies for microbial inactivation in food preservation, with cold plasma offering reactive species that disrupt microbial cell membranes and DNA. UV-C treatment relies on ultraviolet light to damage microbial nucleic acids, leading to cell death, but its effectiveness can be limited by surface shadowing and food matrix complexity. Cold plasma typically shows higher penetration and broader-spectrum antimicrobial efficacy, making it a promising alternative or complement to UV-C in enhancing food safety.

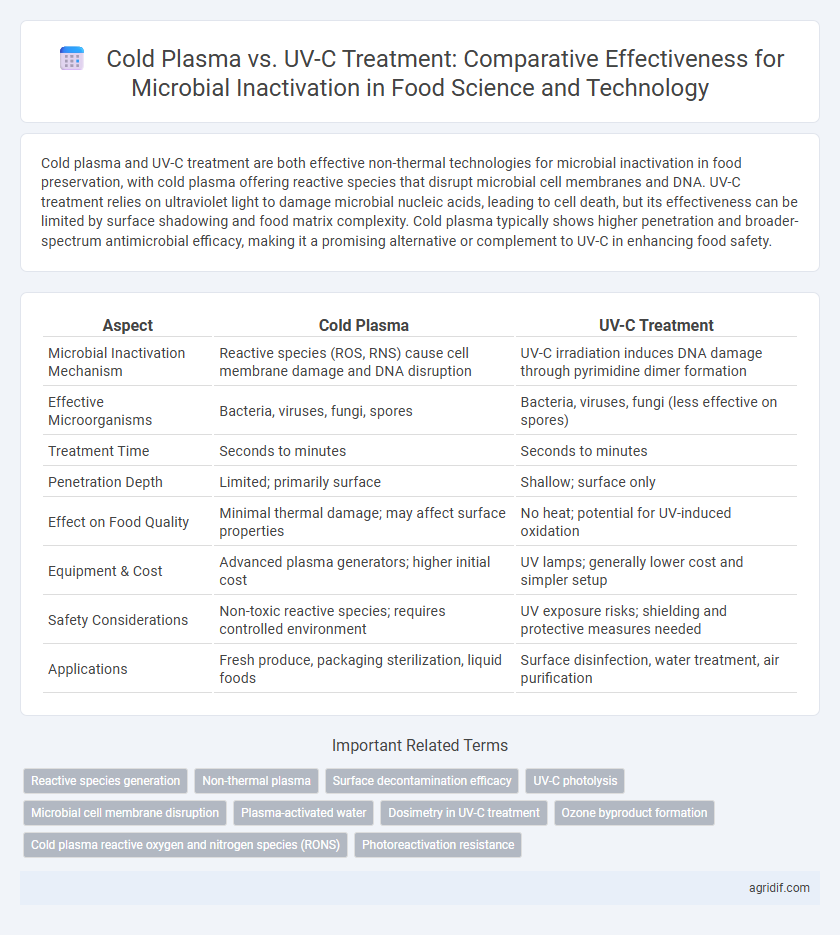

Table of Comparison

| Aspect | Cold Plasma | UV-C Treatment |

|---|---|---|

| Microbial Inactivation Mechanism | Reactive species (ROS, RNS) cause cell membrane damage and DNA disruption | UV-C irradiation induces DNA damage through pyrimidine dimer formation |

| Effective Microorganisms | Bacteria, viruses, fungi, spores | Bacteria, viruses, fungi (less effective on spores) |

| Treatment Time | Seconds to minutes | Seconds to minutes |

| Penetration Depth | Limited; primarily surface | Shallow; surface only |

| Effect on Food Quality | Minimal thermal damage; may affect surface properties | No heat; potential for UV-induced oxidation |

| Equipment & Cost | Advanced plasma generators; higher initial cost | UV lamps; generally lower cost and simpler setup |

| Safety Considerations | Non-toxic reactive species; requires controlled environment | UV exposure risks; shielding and protective measures needed |

| Applications | Fresh produce, packaging sterilization, liquid foods | Surface disinfection, water treatment, air purification |

Introduction to Non-Thermal Technologies in Food Safety

Cold plasma and UV-C treatment represent advanced non-thermal technologies in food safety that effectively inactivate microbial contaminants without compromising food quality. Cold plasma generates reactive species and charged particles that disrupt microbial cell membranes, while UV-C treatment employs germicidal ultraviolet light to damage microbial DNA and RNA. These methods offer sustainable, energy-efficient alternatives to traditional thermal processing, enhancing food safety by reducing pathogenic bacteria and spoilage microorganisms.

Mechanisms of Microbial Inactivation: Cold Plasma vs UV-C

Cold plasma inactivates microbes through reactive species like ozone, reactive oxygen, and nitrogen species that damage cell membranes, proteins, and DNA, leading to oxidative stress and structural disruption. UV-C treatment primarily inactivates microorganisms by inducing DNA damage through thymine dimer formation, preventing replication and transcription processes. While cold plasma exerts multi-target biochemical stress on cells, UV-C specifically targets genetic material, making their mechanisms complementary in microbial control strategies.

Efficacy of Cold Plasma in Food Decontamination

Cold plasma demonstrates superior efficacy in microbial inactivation compared to UV-C treatment due to its ability to generate reactive species that penetrate food surfaces and disrupt microbial cell structures. Studies reveal that cold plasma effectively reduces pathogenic bacteria such as E. coli, Salmonella, and Listeria on fresh produce and meat products, achieving log reductions exceeding those of UV-C light. Its low-temperature operation preserves food quality while ensuring prolonged antimicrobial effects, making it a promising technology in food decontamination.

UV-C Treatment: Principles and Applications in Food Processing

UV-C treatment utilizes short-wavelength ultraviolet light (200-280 nm) to disrupt microbial DNA and RNA, effectively inactivating bacteria, viruses, and spores on food surfaces. Its application in food processing includes surface sterilization of fresh produce, decontamination of packaging materials, and extending shelf life by reducing microbial load without altering food quality. UV-C treatment offers a non-thermal, chemical-free alternative to traditional methods, making it suitable for heat-sensitive foods and ensuring safety in minimally processed products.

Comparative Analysis: Cold Plasma and UV-C on Microbial Reduction

Cold plasma generates reactive species that effectively disrupt microbial cell membranes, leading to higher inactivation rates compared to UV-C treatment, which primarily induces DNA damage in microorganisms. Studies show cold plasma can reduce bacterial populations by up to 5 log CFU/cm2, outperforming UV-C which typically achieves 2-3 log reductions under similar conditions. Cold plasma treatment also exhibits broader efficacy against spores and viruses, making it a more versatile option for food surface decontamination.

Impact on Food Quality and Sensory Attributes

Cold plasma treatment demonstrates effective microbial inactivation while preserving food quality by causing minimal changes in texture, color, and nutrient content compared to UV-C treatment, which can lead to oxidative damage and sensory attribute alterations such as off-flavors or discoloration. Studies indicate that cold plasma generates reactive species that inactivate microbes without significantly affecting the organoleptic properties of fresh produce and meats. UV-C treatment's higher energy exposure may degrade vitamins and proteins, negatively impacting food freshness and consumer acceptance.

Scalability and Industrial Implementation Challenges

Cold plasma offers scalable antimicrobial treatment by enabling uniform surface exposure and rapid microbial inactivation on various food products, but challenges include high equipment costs and energy consumption for large-scale operations. UV-C treatment is widely used due to its cost-effectiveness and ease of integration into conveyor systems, yet its limited penetration depth and shadowing effects restrict efficacy in complex food matrices. Integrating these technologies into industrial workflows requires optimizing treatment parameters and addressing safety regulations to ensure consistent microbial control without compromising product quality.

Environmental and Energy Considerations

Cold plasma technology offers microbial inactivation with lower energy consumption compared to UV-C treatment, reducing the environmental footprint in food processing. The generation of reactive species in cold plasma occurs at ambient temperature, minimizing greenhouse gas emissions often associated with UV-C lamp operation and cooling systems. Optimizing cold plasma parameters can further enhance energy efficiency while maintaining effective microbial kill rates, supporting sustainable food preservation strategies.

Regulatory Approvals and Consumer Acceptance

Cold plasma treatment is gaining regulatory approvals globally for microbial inactivation due to its chemical-free nature and effectiveness against a broad spectrum of pathogens. UV-C treatment has longstanding regulatory acceptance but faces consumer concerns over potential DNA damage and limited penetration in food matrices. Consumer acceptance of cold plasma is rising as more studies demonstrate its safety and minimal impact on food quality compared to UV-C irradiation.

Future Prospects and Research Directions

Cold plasma technology offers promising potential for microbial inactivation with enhanced penetration and minimal heat damage compared to UV-C treatment, which is limited by its shallow surface action. Future research should focus on optimizing plasma generation parameters and combining cold plasma with UV-C to synergistically improve efficacy against resistant microbial strains in food matrices. Developing scalable, energy-efficient systems and assessing long-term effects on food quality and safety will be critical for commercial adoption in the food industry.

Related Important Terms

Reactive species generation

Cold plasma generates a diverse range of reactive species including reactive oxygen species (ROS) and reactive nitrogen species (RNS) that effectively disrupt microbial cell membranes and DNA, enhancing microbial inactivation. UV-C treatment primarily produces reactive oxygen species through photochemical reactions, but its efficacy is limited by lower penetration depth compared to cold plasma's surface and subsurface interaction capabilities.

Non-thermal plasma

Non-thermal cold plasma demonstrates superior efficacy in microbial inactivation compared to UV-C treatment due to its generation of reactive oxygen and nitrogen species that disrupt microbial cell membranes and DNA. This technology operates at ambient temperatures, preserving food quality while ensuring effective decontamination of pathogens such as Escherichia coli and Listeria monocytogenes.

Surface decontamination efficacy

Cold plasma treatment demonstrates superior surface decontamination efficacy compared to UV-C, achieving higher microbial inactivation rates on food surfaces due to its reactive species that penetrate biofilms and irregular surfaces. UV-C treatment primarily inactivates microorganisms through DNA damage but is limited by shadowing effects and lower penetration, reducing its effectiveness on complex surface topographies.

UV-C photolysis

UV-C photolysis effectively disrupts microbial DNA by generating thymine dimers, leading to inactivation of pathogens on food surfaces. Cold plasma, while also producing reactive species for microbial reduction, relies more on oxidative stress mechanisms compared to the direct DNA damage caused by UV-C treatment.

Microbial cell membrane disruption

Cold plasma generates reactive species that cause oxidative damage to microbial cell membranes, leading to lipid peroxidation and increased membrane permeability. UV-C treatment induces DNA damage but has limited direct impact on microbial cell membrane disruption compared to cold plasma's more pronounced effect on membrane integrity.

Plasma-activated water

Plasma-activated water demonstrates superior microbial inactivation compared to UV-C treatment by generating reactive oxygen and nitrogen species that disrupt microbial cell walls and DNA. Cold plasma technology offers a chemical-free, non-thermal antimicrobial approach, enhancing food safety while preserving sensory and nutritional quality.

Dosimetry in UV-C treatment

Dosimetry in UV-C treatment precisely measures the delivered ultraviolet dose to ensure effective microbial inactivation without damaging food quality. Cold plasma offers reactive species for decontamination but lacks standardized dosimetry protocols, making UV-C treatment's quantifiable dose delivery advantageous for controlled microbial reduction.

Ozone byproduct formation

Cold plasma treatment generates reactive oxygen species, including ozone, which can enhance microbial inactivation but may raise concerns about ozone byproduct accumulation. UV-C treatment effectively inactivates microbes with minimal ozone formation, making it a safer alternative for environments sensitive to ozone-related air quality issues.

Cold plasma reactive oxygen and nitrogen species (RONS)

Cold plasma generates reactive oxygen and nitrogen species (RONS) that disrupt microbial cell membranes and DNA, leading to efficient microbial inactivation in food preservation. Compared to UV-C treatment, cold plasma's RONS provide broader-spectrum antimicrobial effects without damaging food quality or inducing resistance.

Photoreactivation resistance

Cold plasma treatment demonstrates greater efficacy in microbial inactivation due to its reduced susceptibility to photoreactivation, unlike UV-C treatment where exposed microorganisms often regain viability through DNA repair mechanisms triggered by visible light. Studies indicate cold plasma induces irreversible oxidative damage to cellular components, leading to sustained microbial inactivation and enhanced food safety compared to UV-C methods.

Cold plasma vs UV-C treatment for microbial inactivation Infographic

agridif.com

agridif.com