Batch processing enables precise control over juice quality by treating fixed quantities at a time, making it ideal for small-scale or specialty juice production. Continuous processing offers higher efficiency and consistency by maintaining a steady flow of raw materials through the system, suitable for large-scale commercial juice manufacturing. Selecting between these methods depends on production volume, cost considerations, and desired product uniformity in juice processing.

Table of Comparison

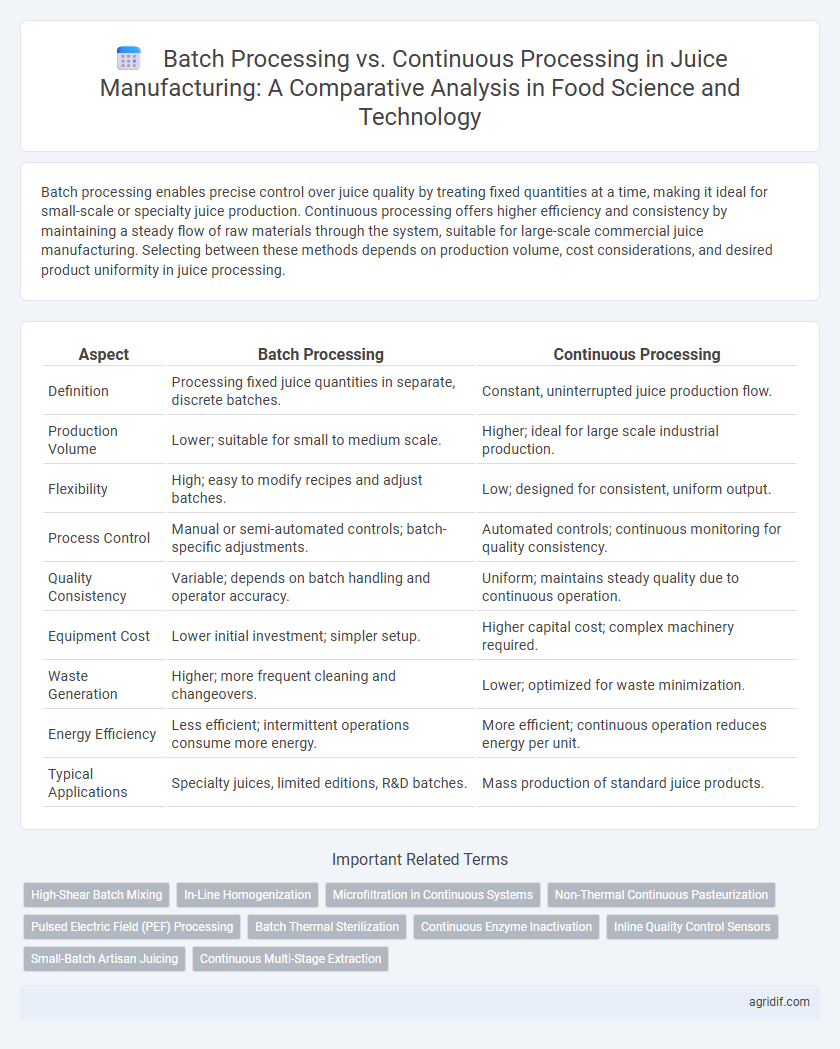

| Aspect | Batch Processing | Continuous Processing |

|---|---|---|

| Definition | Processing fixed juice quantities in separate, discrete batches. | Constant, uninterrupted juice production flow. |

| Production Volume | Lower; suitable for small to medium scale. | Higher; ideal for large scale industrial production. |

| Flexibility | High; easy to modify recipes and adjust batches. | Low; designed for consistent, uniform output. |

| Process Control | Manual or semi-automated controls; batch-specific adjustments. | Automated controls; continuous monitoring for quality consistency. |

| Quality Consistency | Variable; depends on batch handling and operator accuracy. | Uniform; maintains steady quality due to continuous operation. |

| Equipment Cost | Lower initial investment; simpler setup. | Higher capital cost; complex machinery required. |

| Waste Generation | Higher; more frequent cleaning and changeovers. | Lower; optimized for waste minimization. |

| Energy Efficiency | Less efficient; intermittent operations consume more energy. | More efficient; continuous operation reduces energy per unit. |

| Typical Applications | Specialty juices, limited editions, R&D batches. | Mass production of standard juice products. |

Introduction to Juice Manufacturing Processes

Juice manufacturing involves two primary production methods: batch processing, where juice is produced in discrete, controlled quantities, and continuous processing, which allows uninterrupted juice extraction and pasteurization. Batch processing offers flexibility for small-scale or varied product lines, while continuous processing enhances efficiency and consistency for large-scale operations. Process selection impacts juice quality, shelf life, and production costs, making it essential to align techniques with operational goals and market demands.

Overview of Batch Processing in Juice Production

Batch processing in juice manufacturing involves producing juice in discrete quantities, allowing precise control over ingredient mixing, pasteurization, and quality checks at each stage. This method offers flexibility for small to medium-scale production, enabling customization of flavors and rapid adaptation to changing consumer demands. Quality control measures ensure consistency and safety, although batch processing generally has lower throughput compared to continuous processing systems.

Principles of Continuous Processing in Juice Manufacturing

Continuous processing in juice manufacturing involves the uninterrupted flow of raw materials through a series of integrated equipment for extraction, clarification, pasteurization, and packaging, enhancing efficiency and consistency. This method relies on advanced sensors and automation to monitor parameters such as temperature, flow rate, and microbial load in real-time, ensuring product quality and safety. The seamless nature of continuous processing reduces downtime and waste, maximizing throughput and operational cost-effectiveness in large-scale juice production.

Key Differences Between Batch and Continuous Processing

Batch processing in juice manufacturing involves producing juice in discrete, separate quantities, allowing for flexibility in recipe adjustments and quality control at each stage. Continuous processing operates with an uninterrupted flow, enhancing efficiency and consistency by minimizing downtime and maintaining steady production rates. Key differences include scalability, production speed, equipment complexity, and suitability for large-scale, uniform juice production versus smaller, customized batches.

Juice Quality Control: Batch vs Continuous Methods

Batch processing in juice manufacturing allows precise control over juice quality through discrete, small-scale production runs, enabling easy adjustments to parameters like temperature and mixing time for each batch. Continuous processing provides consistent juice quality by maintaining steady-state conditions and automated monitoring, reducing variability but requiring robust system calibration to prevent quality deviations. Both methods impact nutrient retention and microbial stability differently, with batch processing offering flexibility and continuous processing enhancing efficiency and uniformity in juice quality control.

Efficiency and Throughput Comparison

Batch processing in juice manufacturing offers flexibility for small-scale production but generally results in lower throughput due to frequent start-up and cleaning times. Continuous processing maximizes efficiency by enabling uninterrupted juice extraction and pasteurization, leading to significantly higher throughput and reduced operational downtime. Equipment automation and real-time quality control in continuous systems further enhance productivity compared to batch methods.

Impact on Nutritional Value and Shelf Life

Batch processing in juice manufacturing allows for greater control over nutrient retention due to shorter exposure times to heat and oxygen, thus preserving vitamins like vitamin C and antioxidants more effectively. Continuous processing, while enabling higher throughput and consistent quality, may cause slightly increased nutrient degradation from prolonged thermal exposure but enhances shelf life through uniform pasteurization. Selecting between batch and continuous methods involves balancing nutrient preservation with extended shelf stability, crucial for optimizing juice quality in food science and technology.

Equipment and Automation Considerations

Batch processing in juice manufacturing utilizes flexible equipment suited for small to medium volumes, enabling easy cleaning and formulation changes, but often requires manual intervention and longer downtime between batches. Continuous processing employs highly automated, integrated machinery designed for large-scale production with consistent product quality and higher throughput, minimizing human error and operational delays. Equipment selection hinges on production scale, desired automation level, and cost-efficiency, with continuous systems favoring advanced sensors, programmable logic controllers (PLCs), and real-time monitoring technologies.

Sustainability and Resource Management

Batch processing in juice manufacturing allows for precise control over ingredient proportions and minimal waste due to small, manageable volumes, enhancing resource efficiency. Continuous processing optimizes energy consumption and water usage by maintaining steady production flows, leading to reduced overall environmental impact. Both methods can integrate sustainable practices like waste valorization and energy recovery systems to improve resource management in food technology.

Choosing the Right Processing Technique for Juice Manufacturers

Batch processing in juice manufacturing offers precise control over ingredient quality and recipe flexibility, making it ideal for small to medium-scale production and specialty juices. Continuous processing maximizes efficiency and consistency through automated, large-scale operations, reducing labor costs and minimizing contamination risks. Juice manufacturers should evaluate production volume, product variety, and quality standards to determine the most cost-effective and scalable processing technique.

Related Important Terms

High-Shear Batch Mixing

High-shear batch mixing in juice manufacturing allows precise control over ingredient blending and particle size reduction, enhancing juice quality and consistency. Unlike continuous processing, batch mixing enables customization for small-scale production and formulation adjustments, critical for maintaining optimal flavor and nutrient retention.

In-Line Homogenization

In juice manufacturing, in-line homogenization integrated within continuous processing enhances product consistency by uniformly reducing particle size during fluid flow, unlike batch processing where homogenization occurs in discrete volumes leading to variable texture and stability. Continuous in-line homogenization improves efficiency, reduces contamination risk, and maintains sensory quality, making it preferable for large-scale juice production requiring consistent emulsion and shelf life.

Microfiltration in Continuous Systems

Microfiltration in continuous juice processing enhances product clarity and microbial safety by consistently removing suspended solids and bacteria without interrupting flow, increasing throughput and operational efficiency. Compared to batch processing, continuous microfiltration maintains steady quality control and reduces contamination risks through uninterrupted filtration cycles, optimizing juice manufacturing scalability.

Non-Thermal Continuous Pasteurization

Non-thermal continuous pasteurization in juice manufacturing utilizes advanced technologies such as high-pressure processing (HPP) and pulsed electric fields (PEF) to preserve nutrients and flavors while ensuring microbial safety, offering significant advantages over traditional batch processing. This method enhances production efficiency by enabling continuous flow treatment, reducing processing time, and maintaining high product quality and shelf life without thermal degradation.

Pulsed Electric Field (PEF) Processing

Pulsed Electric Field (PEF) processing enhances juice manufacturing by improving microbial inactivation and preserving sensory qualities more effectively in continuous processing compared to batch processing, which often involves longer treatment times and inconsistent electric field distribution. Continuous PEF systems increase throughput and energy efficiency, making them ideal for large-scale juice production while maintaining high nutritional and organoleptic properties.

Batch Thermal Sterilization

Batch thermal sterilization in juice manufacturing involves processing fixed quantities of juice in discrete vessels, allowing precise control over temperature and time to ensure microbial safety and quality retention. This method contrasts with continuous processing by offering flexibility for small-scale production and diverse product formulations but may result in longer cycle times and higher energy consumption per unit.

Continuous Enzyme Inactivation

Continuous enzyme inactivation in juice manufacturing uses precise heat treatment to rapidly deactivate enzymes, preserving juice quality and extending shelf life more efficiently than batch processing. This method enhances operational throughput, reduces energy consumption, and enables consistent product quality across large production volumes.

Inline Quality Control Sensors

Inline quality control sensors in juice manufacturing provide real-time monitoring of parameters such as pH, Brix, and turbidity, enhancing the accuracy and consistency of both batch and continuous processing methods. Continuous processing benefits from these sensors by enabling immediate adjustments that minimize product variation, while batch processing relies on sensor data to verify product quality between stages, ensuring compliance with safety and flavor standards.

Small-Batch Artisan Juicing

Small-batch artisan juicing in juice manufacturing leverages batch processing to maintain precise control over flavor profiles, nutrient retention, and product customization, which are critical for premium quality and unique recipes. This method contrasts with continuous processing by allowing small volumes to be handled with minimal thermal degradation and oxidation, preserving freshness and artisanal characteristics in each batch.

Continuous Multi-Stage Extraction

Continuous multi-stage extraction in juice manufacturing enhances efficiency by maximizing yield and minimizing processing time through a series of sequential extraction steps within a single, integrated system. This method offers superior control over parameters such as temperature and solvent concentration, resulting in higher-quality juice with consistent flavor and nutritional content compared to traditional batch processing.

Batch Processing vs Continuous Processing for Juice Manufacturing Infographic

agridif.com

agridif.com