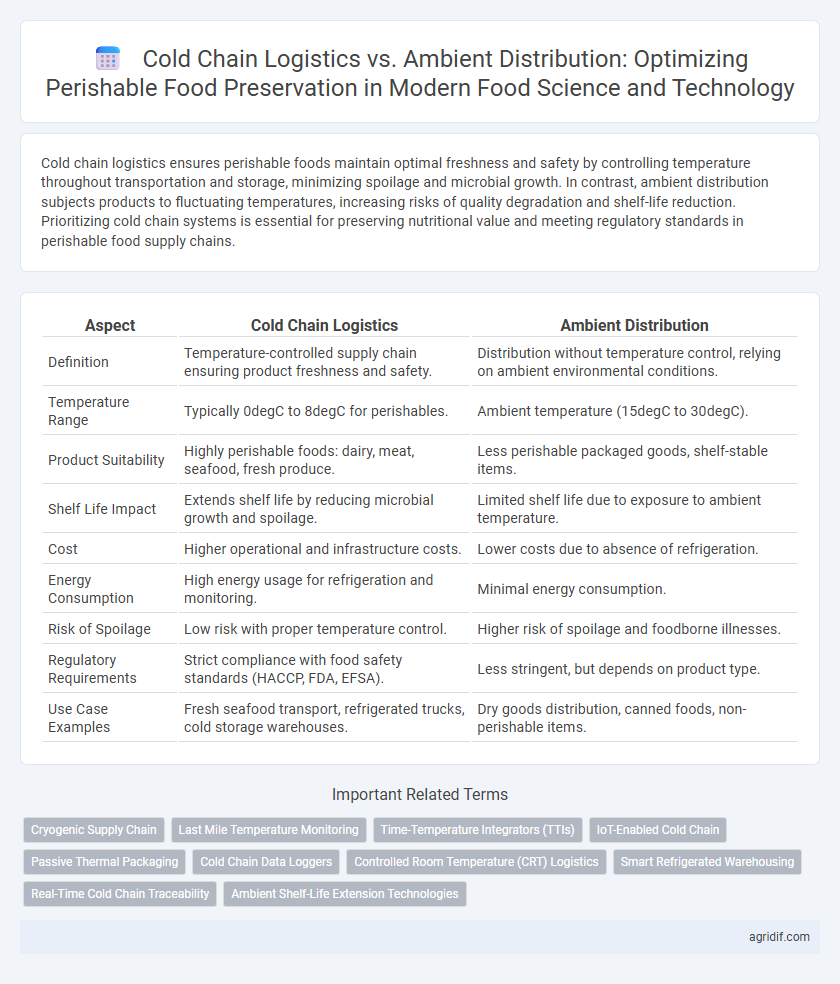

Cold chain logistics ensures perishable foods maintain optimal freshness and safety by controlling temperature throughout transportation and storage, minimizing spoilage and microbial growth. In contrast, ambient distribution subjects products to fluctuating temperatures, increasing risks of quality degradation and shelf-life reduction. Prioritizing cold chain systems is essential for preserving nutritional value and meeting regulatory standards in perishable food supply chains.

Table of Comparison

| Aspect | Cold Chain Logistics | Ambient Distribution |

|---|---|---|

| Definition | Temperature-controlled supply chain ensuring product freshness and safety. | Distribution without temperature control, relying on ambient environmental conditions. |

| Temperature Range | Typically 0degC to 8degC for perishables. | Ambient temperature (15degC to 30degC). |

| Product Suitability | Highly perishable foods: dairy, meat, seafood, fresh produce. | Less perishable packaged goods, shelf-stable items. |

| Shelf Life Impact | Extends shelf life by reducing microbial growth and spoilage. | Limited shelf life due to exposure to ambient temperature. |

| Cost | Higher operational and infrastructure costs. | Lower costs due to absence of refrigeration. |

| Energy Consumption | High energy usage for refrigeration and monitoring. | Minimal energy consumption. |

| Risk of Spoilage | Low risk with proper temperature control. | Higher risk of spoilage and foodborne illnesses. |

| Regulatory Requirements | Strict compliance with food safety standards (HACCP, FDA, EFSA). | Less stringent, but depends on product type. |

| Use Case Examples | Fresh seafood transport, refrigerated trucks, cold storage warehouses. | Dry goods distribution, canned foods, non-perishable items. |

Introduction to Temperature-Controlled Logistics in Perishable Food Supply

Temperature-controlled logistics play a critical role in preserving the quality and safety of perishable foods by maintaining optimal thermal conditions throughout the supply chain. Cold chain logistics involve refrigerated storage and transportation, effectively reducing microbial growth and enzymatic activity, which prolongs shelf life and minimizes spoilage. In contrast, ambient distribution exposes perishable products to fluctuating temperatures, increasing the risk of quality degradation and foodborne illnesses due to compromised temperature control.

Understanding Cold Chain Logistics: Key Concepts and Components

Cold chain logistics involves temperature-controlled supply chain management crucial for preserving perishable foods like dairy, meat, and fresh produce, ensuring product safety and extending shelf life. Key components include refrigerated transportation, temperature-monitored storage facilities, and real-time data tracking systems to maintain consistent cold environments from production to consumer delivery. Effective cold chain management reduces microbial growth, prevents spoilage, and minimizes food waste, making it essential for quality assurance in food science and technology.

Ambient Distribution: Definition and Typical Use Cases in Food Supply

Ambient distribution involves transporting perishable foods without temperature control, relying on stable ambient conditions to maintain product quality. This method is commonly used for products with longer shelf lives such as shelf-stable snacks, canned goods, and certain types of fresh produce like bananas and tomatoes. Ambient distribution reduces costs and simplifies logistics but requires careful selection of products and packaging to prevent spoilage and ensure food safety.

Comparative Analysis: Cold Chain vs. Ambient Distribution Efficiency

Cold chain logistics significantly enhance the shelf life and safety of perishable foods by maintaining a controlled temperature environment from production to consumption, reducing microbial growth and spoilage rates. Ambient distribution often leads to accelerated quality degradation and increased food waste due to variable temperature exposure, especially for highly perishable items such as dairy, meat, and fresh produce. Energy consumption and operational costs are higher in cold chain systems, but the improved preservation efficiency results in better food quality retention and consumer satisfaction compared to ambient distribution methods.

Impact on Food Safety and Quality Preservation

Cold chain logistics ensures perishable foods are consistently maintained at low temperatures, significantly reducing microbial growth and enzymatic activity, which preserves both food safety and quality. Ambient distribution exposes products to fluctuating temperatures, accelerating spoilage and increasing the risk of foodborne pathogens. Maintaining a robust cold chain system is critical for extending shelf life and preventing contamination in highly perishable goods.

Energy Consumption and Carbon Footprint Considerations

Cold chain logistics for perishable foods significantly reduces spoilage rates by maintaining optimal low temperatures, though it demands higher energy consumption than ambient distribution, primarily due to refrigeration and freezing technologies. Energy-intensive cold storage and transport contribute to increased carbon footprints, but advancements in renewable energy integration and energy-efficient equipment are mitigating these impacts. In contrast, ambient distribution lowers energy use yet increases food waste risks, ultimately affecting the overall sustainability of perishable food supply chains.

Cost Implications for Producers and Distributors

Cold chain logistics for perishable foods require significant investment in refrigerated storage, temperature-controlled transport, and monitoring systems, leading to higher operational costs for producers and distributors compared to ambient distribution. While ambient distribution reduces energy expenses and infrastructure requirements, it increases the risk of spoilage, product loss, and shortened shelf life, potentially raising overall costs through waste and quality degradation. Balancing these cost implications involves assessing product sensitivity, shelf life, and market demands to optimize supply chain efficiency and profitability.

Regulatory Standards and Compliance in Perishable Food Distribution

Cold chain logistics for perishable foods must comply with stringent regulatory standards such as FDA's Food Safety Modernization Act (FSMA) and the EU's Cold Chain Compliance guidelines, ensuring temperature control from production to delivery to prevent microbial growth and spoilage. Ambient distribution requires adherence to regulations like the FDA's Hazard Analysis and Critical Control Points (HACCP) tailored to non-refrigerated supply chains, emphasizing packaging integrity and shelf-life monitoring to mitigate risks. Compliance with these standards is critical to maintaining food safety, traceability, and consumer protection throughout the perishable food distribution process.

Technological Innovations Shaping Cold and Ambient Logistics

Technological innovations such as IoT-enabled temperature sensors and blockchain traceability systems are revolutionizing cold chain logistics, ensuring precise temperature control and real-time monitoring to maintain the quality of perishable foods. In ambient distribution, advancements in modified atmosphere packaging (MAP) and smart humidity control systems extend shelf life by optimizing environmental conditions without refrigeration. These cutting-edge technologies enhance food safety, reduce spoilage, and improve supply chain transparency across both cold and ambient logistics.

Future Trends and Sustainable Practices in Perishable Food Distribution

Emerging trends in cold chain logistics emphasize the integration of IoT sensors and blockchain for real-time temperature monitoring and traceability, enhancing food safety and reducing spoilage. Sustainable practices prioritize eco-friendly refrigerants, energy-efficient refrigeration units, and biodegradable packaging materials to minimize carbon footprints. Ambient distribution innovations now include advanced modified atmosphere packaging (MAP) and natural preservatives, extending shelf life while reducing reliance on energy-intensive cold storage.

Related Important Terms

Cryogenic Supply Chain

Cryogenic supply chain technology leverages ultra-low temperature storage and transportation to preserve the quality and extend the shelf life of highly perishable foods by minimizing enzymatic and microbial activity. Compared to ambient distribution, cryogenic logistics reduce spoilage rates by up to 50% and maintain nutrient integrity, making them essential for sensitive products like seafood, pharmaceuticals, and frozen fruits.

Last Mile Temperature Monitoring

Last mile temperature monitoring in cold chain logistics ensures the integrity of perishable foods by maintaining precise thermal conditions, minimizing spoilage and foodborne risks. In contrast, ambient distribution lacks stringent temperature controls, increasing the likelihood of quality degradation and reduced shelf life during the final delivery phase.

Time-Temperature Integrators (TTIs)

Time-Temperature Integrators (TTIs) provide critical monitoring of temperature exposure and cumulative time in both cold chain logistics and ambient distribution, enabling enhanced quality control for perishable foods. By accurately tracking thermal history, TTIs help reduce spoilage, extend shelf life, and ensure compliance with safety standards during transportation and storage.

IoT-Enabled Cold Chain

IoT-enabled cold chain logistics leverage real-time temperature and humidity monitoring sensors to ensure optimal storage conditions for perishable foods, reducing spoilage and extending shelf life significantly compared to ambient distribution methods. Integrating IoT devices within cold chain systems enhances traceability, predictive maintenance, and compliance with food safety regulations, improving overall supply chain efficiency and quality control in food science and technology.

Passive Thermal Packaging

Passive thermal packaging in cold chain logistics ensures temperature stability for perishable foods by using insulated materials and phase change materials to maintain optimal conditions without external power. In contrast, ambient distribution relies on packaging designed to protect against environmental fluctuations but cannot guarantee the temperature-sensitive quality and safety that passive thermal packaging in cold chains provides.

Cold Chain Data Loggers

Cold chain data loggers play a critical role in maintaining the quality and safety of perishable foods by continuously monitoring temperature and humidity during transportation and storage, ensuring compliance with food safety standards. Unlike ambient distribution, cold chain logistics rely on these precise tracking devices to detect temperature fluctuations, prevent spoilage, and extend the shelf life of sensitive products such as dairy, seafood, and fresh produce.

Controlled Room Temperature (CRT) Logistics

Controlled Room Temperature (CRT) logistics maintains perishable foods within a precise range of 15-25degC, optimizing shelf life and quality without the high energy costs of cold chain systems. CRT distribution is particularly effective for pharmaceuticals and certain fruits, providing a stable environment that reduces spoilage compared to ambient distribution while avoiding the complexities of refrigerated transport.

Smart Refrigerated Warehousing

Smart refrigerated warehousing integrates IoT sensors and real-time temperature monitoring to optimize cold chain logistics for perishable foods, ensuring minimal spoilage and extended shelf life. Advanced data analytics in these warehouses enable precise climate control and rapid response to deviations, outperforming ambient distribution methods by preserving food quality and safety throughout storage and transit.

Real-Time Cold Chain Traceability

Real-time cold chain traceability enables continuous monitoring of temperature-sensitive perishable foods, ensuring quality and safety from production to consumption. Advanced IoT sensors and blockchain technology enhance data accuracy and transparency, reducing spoilage and compliance risks compared to ambient distribution systems.

Ambient Shelf-Life Extension Technologies

Ambient shelf-life extension technologies for perishable foods utilize advanced packaging materials, modified atmosphere packaging (MAP), and natural preservatives to inhibit microbial growth and enzymatic activity without refrigeration. These innovations reduce reliance on cold chain logistics by maintaining product quality and safety at ambient temperatures, significantly lowering energy consumption and distribution costs.

Cold Chain Logistics vs Ambient Distribution for Perishable Foods Infographic

agridif.com

agridif.com