Traditional curing of meat products relies on natural aging processes and longer timeframes to develop flavor and preservation, resulting in deeper texture and taste complexity. Accelerated curing utilizes advanced techniques such as vacuum tumbling, injection, and the addition of curing accelerators to significantly reduce processing time while maintaining product safety and quality. This innovative approach enhances production efficiency and consistency, meeting modern demand without compromising sensory attributes.

Table of Comparison

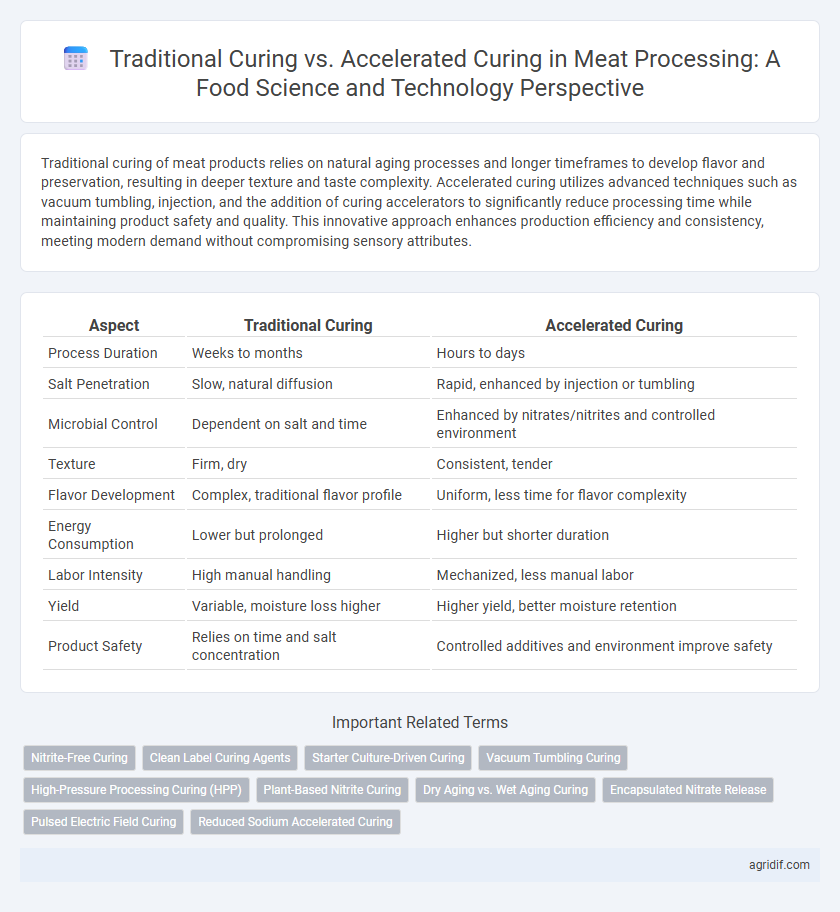

| Aspect | Traditional Curing | Accelerated Curing |

|---|---|---|

| Process Duration | Weeks to months | Hours to days |

| Salt Penetration | Slow, natural diffusion | Rapid, enhanced by injection or tumbling |

| Microbial Control | Dependent on salt and time | Enhanced by nitrates/nitrites and controlled environment |

| Texture | Firm, dry | Consistent, tender |

| Flavor Development | Complex, traditional flavor profile | Uniform, less time for flavor complexity |

| Energy Consumption | Lower but prolonged | Higher but shorter duration |

| Labor Intensity | High manual handling | Mechanized, less manual labor |

| Yield | Variable, moisture loss higher | Higher yield, better moisture retention |

| Product Safety | Relies on time and salt concentration | Controlled additives and environment improve safety |

Overview of Curing Methods in Meat Processing

Traditional curing in meat processing relies on natural aging and salt penetration over extended periods, enhancing flavor and preservation through slow moisture reduction and microbial control. Accelerated curing employs pressure, heat, or chemical agents like nitrites to significantly reduce curing time while maintaining safety and sensory qualities. Both methods use salt, nitrates, and spices, but accelerated curing optimizes efficiency to meet industrial-scale production demands in meat product manufacturing.

Principles of Traditional Curing Techniques

Traditional curing techniques rely on osmotic dehydration and the slow diffusion of curing agents like salt, nitrites, and nitrates into meat, promoting flavor development and microbial inhibition over extended periods. These methods often involve dry curing or brining, where the curing agents penetrate through natural muscle fibers, enhancing preservation and color stability while allowing enzymatic and non-enzymatic reactions to develop complex taste profiles. The principles emphasize time-dependent biochemical changes and controlled moisture reduction to ensure safety and desirable sensory attributes in meat products.

Accelerated Curing: Modern Approaches and Technologies

Accelerated curing in meat products leverages advanced technologies such as high-pressure processing, ultrasound, and vacuum tumbling to significantly reduce curing time while enhancing flavor development and microbial safety. These modern methods optimize salt and nitrite diffusion by increasing mass transfer rates, resulting in uniform curing and improved product quality. Integration of these technologies aligns with food safety regulations and consumer demand for high-quality, minimally processed meat products.

Chemical and Physical Changes During Curing

Traditional curing involves slower diffusion of curing agents like salt and nitrites, resulting in gradual protein denaturation and oxidation processes that enhance flavor and color stability in meat products. Accelerated curing techniques use mechanical methods such as vacuum tumbling to increase mass transfer rates, promoting rapid penetration of curing compounds and more uniform chemical modifications, including faster myoglobin conversion to nitrosylmyoglobin. These chemical and physical changes affect moisture retention, texture, and microbial stability, with accelerated curing often improving processing efficiency while maintaining product quality.

Flavor Development: Traditional vs Accelerated Curing

Traditional curing enhances meat flavor through prolonged exposure to salt and nitrates, promoting complex chemical reactions such as Maillard browning and peptide breakdown, which develop rich, nuanced tastes. Accelerated curing uses higher concentrations of curing agents and elevated temperatures to speed up these reactions, resulting in faster flavor development but sometimes less depth and complexity compared to traditional methods. Sensory analysis often reveals that meats cured traditionally possess more intense and balanced flavor profiles, while accelerated curing prioritizes efficiency over intricate taste formation.

Impact on Texture and Color in Meat Products

Traditional curing processes enhance meat texture by promoting gradual protein denaturation and moisture loss, resulting in a firmer and more uniform product. Accelerated curing methods use higher concentrations of curing agents and injection techniques, which intensify color development through rapid nitrosomyoglobin formation but may lead to uneven texture and increased toughness. The choice between traditional and accelerated curing significantly influences the sensory quality, with implications for consumer preference and product consistency in meat processing.

Microbial Safety and Shelf-life Comparison

Traditional curing of meat products relies on natural fermentation and extended salt and nitrate exposure, which effectively inhibits microbial growth but requires longer processing times, resulting in enhanced shelf-life through gradual microbial stabilization. Accelerated curing methods use higher concentrations of curing agents, vacuum packaging, and controlled environments to achieve rapid microbial control, significantly reducing processing time while maintaining comparable shelf-life and ensuring microbial safety by targeting spoilage and pathogenic organisms. Studies show accelerated curing can achieve similar or improved suppression of Clostridium botulinum and Listeria monocytogenes compared to traditional methods, validating its efficacy in modern meat preservation.

Nutritional Implications of Different Curing Methods

Traditional curing methods for meat products often preserve nutrients such as proteins and minerals but may lead to nutrient degradation due to prolonged exposure to salt and air. Accelerated curing techniques utilize higher concentrations of curing agents and shorter processing times, which better retain water-soluble vitamins like B-complex vitamins and reduce the loss of essential amino acids. The choice between traditional and accelerated curing significantly impacts the nutritional quality, shelf life, and safety of the final meat product.

Consumer Perceptions and Acceptance

Traditional curing methods for meat products are often perceived by consumers as more authentic and natural, contributing to a preference for the characteristic flavors and textures developed over extended curing periods. Accelerated curing techniques, which use higher concentrations of curing agents and advanced technologies like vacuum tumbling or injection, offer faster production but may raise concerns about artificial additives and altered taste profiles among consumers. Studies in Food Science and Technology reveal that transparency in processing and clear labeling significantly influence consumer acceptance of accelerated curing, balancing efficiency with expectations for quality and safety.

Sustainability and Economic Considerations

Traditional curing methods rely on natural processes and extended aging periods, consuming more energy and resources, which can increase environmental impact and production costs. Accelerated curing techniques use advanced technologies such as vacuum tumbling and nitrite enhancers to reduce curing time, lowering energy usage and enhancing throughput, thereby offering improved sustainability and economic efficiency. Implementing accelerated curing can reduce waste and optimize resource utilization while meeting market demand more rapidly, balancing environmental concerns with cost-effectiveness in meat processing.

Related Important Terms

Nitrite-Free Curing

Traditional curing of meat products typically relies on natural salts and extended processing times, often resulting in a longer shelf life but with limitations in microbial control and color stability. Accelerated curing techniques for nitrite-free meat use alternative compounds like plant extracts rich in nitrate and microbial starter cultures to rapidly develop cured color and enhance safety without synthetic nitrites.

Clean Label Curing Agents

Traditional curing relies on natural salts and nitrates from sources such as celery powder and sea salt, which align with clean label demands by avoiding synthetic additives. Accelerated curing utilizes ingredients like cultured dextrose and natural nitrite generators to reduce processing time while maintaining color, flavor, and microbial safety in meat products.

Starter Culture-Driven Curing

Starter culture-driven curing enhances accelerated curing by rapidly generating nitric oxide, ensuring uniform color development and microbial safety in meat products, surpassing traditional curing methods. The use of selected bacteria like Staphylococcus carnosus optimizes nitrate reduction and flavor formation, reducing processing time and improving product consistency.

Vacuum Tumbling Curing

Vacuum tumbling curing significantly accelerates the diffusion of curing agents into meat by applying mechanical action under vacuum, enhancing flavor, texture, and shelf life compared to traditional curing methods. This technique reduces curing time from days to hours while ensuring uniform penetration and improved product quality in meat processing.

High-Pressure Processing Curing (HPP)

High-Pressure Processing Curing (HPP) significantly accelerates meat curing by applying intense hydrostatic pressure, enhancing salt and curing agent diffusion while inhibiting microbial growth, compared to traditional curing methods that rely on prolonged time and sodium nitrite absorption. This technology ensures improved texture and color stability, reduces processing time from days to hours, and maintains product safety without compromising sensory quality in meat products.

Plant-Based Nitrite Curing

Plant-based nitrite curing utilizes natural sources like celery powder and beet juice to achieve similar antimicrobial and color-stabilizing effects as traditional curing, while reducing reliance on synthetic nitrites. Accelerated curing methods incorporating plant-derived nitrites improve processing efficiency by shortening curing time and maintaining meat product safety and quality.

Dry Aging vs. Wet Aging Curing

Dry aging involves hanging meat in a controlled, refrigerated environment for several weeks, enhancing flavor and tenderness through natural enzymatic and microbial processes, which results in a more intense, concentrated taste. Wet aging, a form of accelerated curing, uses vacuum-sealed packaging to retain moisture and speed up enzymatic breakdown, producing a milder flavor and juicier texture while reducing shelf time and spoilage risk.

Encapsulated Nitrate Release

Encapsulated nitrate release in accelerated curing enhances the controlled delivery of curing agents, reducing curing time while maintaining meat product safety and quality. Traditional curing relies on slower nitrate conversion, resulting in extended processing durations and less precise nitrate utilization.

Pulsed Electric Field Curing

Pulsed Electric Field (PEF) curing enhances meat products by disrupting muscle cell membranes, allowing faster and more uniform penetration of curing agents compared to traditional curing methods, which rely on slow diffusion. This accelerated curing technique significantly reduces processing time, improves flavor uniformity, and maintains meat quality by minimizing heat-induced protein denaturation.

Reduced Sodium Accelerated Curing

Reduced sodium accelerated curing enhances meat product safety and shelf life by combining lower sodium content with rapid nitrite diffusion through vacuum tumbling and increased temperature, achieving comparable color development and microbial stability to traditional curing methods. This approach addresses health concerns related to high sodium intake while maintaining product quality and processing efficiency.

Traditional curing vs accelerated curing for meat products Infographic

agridif.com

agridif.com