HTST (High-Temperature Short-Time) milk treatment heats milk to 72degC for 15 seconds, effectively reducing pathogenic microorganisms while preserving a fresh taste and nutritional value. UHT (Ultra High Temperature) processing heats milk above 135degC for 2-5 seconds, resulting in extended shelf life and sterilization but with slight changes in flavor and some nutrient degradation. Choosing between HTST and UHT depends on balancing shelf life requirements with maintaining sensory and nutritional quality in milk products.

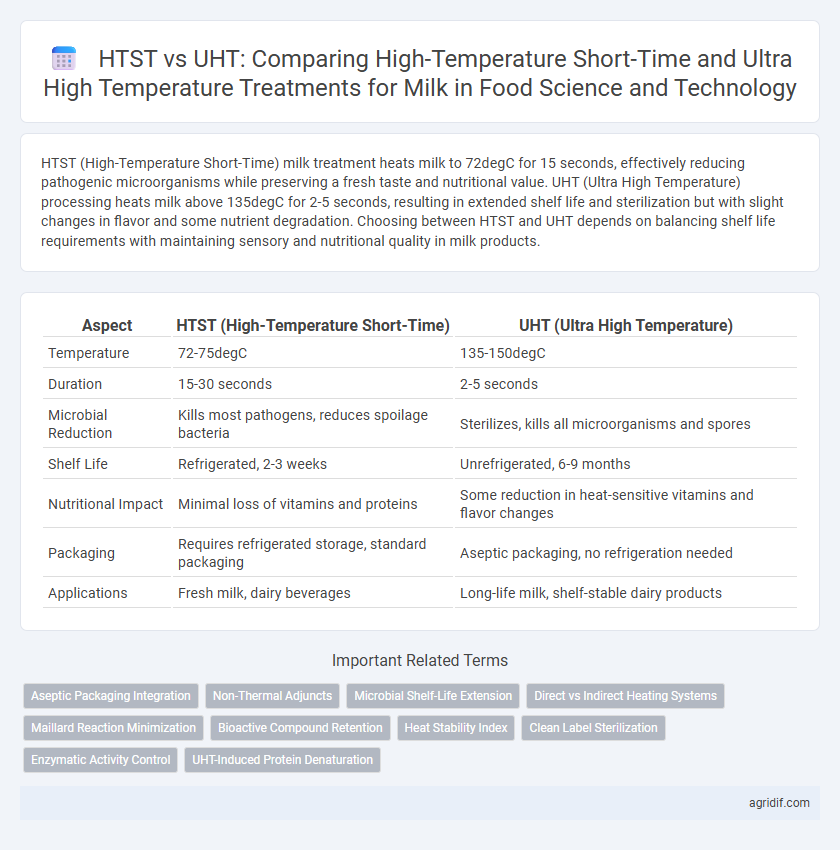

Table of Comparison

| Aspect | HTST (High-Temperature Short-Time) | UHT (Ultra High Temperature) |

|---|---|---|

| Temperature | 72-75degC | 135-150degC |

| Duration | 15-30 seconds | 2-5 seconds |

| Microbial Reduction | Kills most pathogens, reduces spoilage bacteria | Sterilizes, kills all microorganisms and spores |

| Shelf Life | Refrigerated, 2-3 weeks | Unrefrigerated, 6-9 months |

| Nutritional Impact | Minimal loss of vitamins and proteins | Some reduction in heat-sensitive vitamins and flavor changes |

| Packaging | Requires refrigerated storage, standard packaging | Aseptic packaging, no refrigeration needed |

| Applications | Fresh milk, dairy beverages | Long-life milk, shelf-stable dairy products |

Introduction to Milk Pasteurization Methods

HTST (High-Temperature Short-Time) pasteurization heats milk to 72degC for 15 seconds, effectively reducing pathogenic microorganisms while preserving flavor and nutritional quality. UHT (Ultra High Temperature) processing heats milk to 135-150degC for 2-5 seconds, ensuring extended shelf life and sterility but may cause slight changes in taste and nutrient content. Both methods are critical in milk pasteurization, balancing microbial safety with product quality in dairy technology.

Understanding HTST: Process and Applications

HTST (High-Temperature Short-Time) milk treatment involves heating milk to 72degC for at least 15 seconds, effectively reducing pathogenic microorganisms while preserving most of the milk's original flavor and nutrients. This method is widely used in commercial pasteurization due to its balance of microbial safety and minimal impact on milk's sensory and nutritional qualities. HTST-treated milk has a refrigerated shelf life of around 2-3 weeks, making it ideal for daily consumption and short-term storage.

Exploring UHT: Technology and Benefits

UHT (Ultra High Temperature) processing involves heating milk to temperatures above 135degC for 2 to 5 seconds, effectively sterilizing the product while preserving nutrients and flavor. This method extends shelf life up to six months without refrigeration, reducing spoilage and distribution costs. UHT technology also enhances microbial safety by eliminating heat-resistant pathogens, making it ideal for long-term storage and global transportation.

Comparative Analysis: HTST vs UHT

HTST (High-Temperature Short-Time) pasteurization heats milk to 72degC for 15 seconds, effectively reducing pathogenic bacteria while preserving most sensory and nutritional qualities. UHT (Ultra High Temperature) processing heats milk to 135-150degC for 2-5 seconds, achieving commercial sterility and extended shelf life but causing slight changes in taste and nutrient profile. Both methods ensure safety, but HTST is preferred for refrigerated milk with fresh taste, whereas UHT suits ambient storage and long distribution chains.

Nutritional Impact of HTST and UHT on Milk

HTST (High-Temperature Short-Time) treatment preserves more heat-sensitive vitamins and bioactive compounds in milk compared to UHT (Ultra High Temperature), which can cause greater nutrient degradation due to higher processing temperatures. While both methods effectively reduce microbial load, HTST better maintains the nutritional profile, particularly retaining higher levels of vitamin B complex and certain enzymes. UHT extends shelf life significantly but may lead to decreased levels of lactose, some proteins, and slight reductions in flavor quality.

Shelf Life and Storage Differences

HTST treatment heats milk to 72degC for 15 seconds, extending shelf life to about 2-3 weeks under refrigeration by effectively reducing pathogenic microorganisms while maintaining nutritional quality. UHT processing heats milk to 135-150degC for 2-5 seconds, achieving commercial sterility that enables shelf stability for 6-9 months without refrigeration due to the inactivation of spore-forming bacteria. Storage differences arise as HTST milk requires continuous refrigeration to prevent spoilage, whereas UHT milk can be stored at ambient temperatures until opened, making it ideal for regions with limited cold chain infrastructure.

Effects on Sensory Quality and Flavor

HTST (High-Temperature Short-Time) treatment preserves milk's natural flavor and sensory quality more effectively by using lower temperatures (typically 72degC for 15 seconds), minimizing protein denaturation and Maillard reactions. UHT (Ultra High Temperature) processing subjects milk to temperatures above 135degC for 2-5 seconds, causing greater flavor changes, such as cooked or caramelized notes, due to increased protein breakdown and non-enzymatic browning. Sensory evaluations consistently show that HTST-treated milk retains fresher taste profiles, while UHT milk has extended shelf life but altered flavor and diminished creaminess.

Safety and Microbial Reduction Efficiency

HTST (High-Temperature Short-Time) pasteurization heats milk to approximately 72degC for 15 seconds, effectively reducing common pathogens such as Listeria monocytogenes and Salmonella spp., ensuring microbial safety while preserving sensory qualities. UHT (Ultra High Temperature) treatment exposes milk to temperatures above 135degC for 2-5 seconds, achieving near-sterilization by inactivating all vegetative bacteria and spores, resulting in longer shelf life without refrigeration. The superior microbial reduction efficiency of UHT offers enhanced safety margins but may cause minor changes in flavor and nutrient profiles compared to HTST.

Environmental and Economic Implications

HTST milk treatment consumes less energy and water compared to UHT, leading to a smaller carbon footprint and reduced operational costs. UHT processing, while more energy-intensive due to higher temperatures (135-150degC for 2-5 seconds), offers longer shelf life, decreasing food waste and transportation frequency, which can offset some environmental impacts. Economically, HTST is favored for local dairy markets with rapid distribution, whereas UHT suits regions requiring extended storage and minimized refrigeration expenses.

Future Trends in Milk Processing Technologies

Emerging milk processing technologies emphasize enhancing nutritional retention and extending shelf life by optimizing thermal treatments like HTST and UHT. Innovations integrating membrane filtration and high-pressure processing alongside HTST and UHT aim to reduce heat exposure while maintaining microbial safety. Future trends prioritize sustainable, energy-efficient methods that preserve sensory qualities and bioactive components in milk, meeting growing consumer demand for minimally processed dairy products.

Related Important Terms

Aseptic Packaging Integration

HTST (High-Temperature Short-Time) processing heats milk to 72degC for 15 seconds, preserving flavor and nutrients but requiring immediate refrigeration, while UHT (Ultra High Temperature) treatment heats milk above 135degC for 2-5 seconds, allowing sterilization and extended shelf life without refrigeration when combined with aseptic packaging. Aseptic packaging integration with UHT milk involves filling sterilized milk into sterile containers in a germ-free environment, ensuring microbiological safety and enabling long-term ambient storage critical for global distribution and reduced cold chain dependence.

Non-Thermal Adjuncts

HTST (High-Temperature Short-Time) milk treatment combined with non-thermal adjuncts like pulsed electric fields or ultrasound enhances microbial inactivation while preserving nutritional and sensory quality better than UHT (Ultra High Temperature) processing alone. These non-thermal technologies assist HTST by reducing heat exposure, minimizing protein denaturation, and retaining vitamins, offering a superior alternative for milk pasteurization with extended shelf life and improved product integrity.

Microbial Shelf-Life Extension

HTST treatment heats milk to 72degC for 15 seconds, effectively reducing spoilage bacteria and extending microbial shelf-life to about 2-3 weeks under refrigeration. UHT processing involves heating milk to 135-150degC for 2-5 seconds, achieving commercial sterility that extends microbial shelf-life up to 6 months at ambient temperature.

Direct vs Indirect Heating Systems

HTST (High-Temperature Short-Time) milk treatment typically uses indirect heating systems involving heat exchangers, which provide precise temperature control and energy efficiency, preserving milk's sensory qualities. UHT (Ultra High Temperature) processing often employs direct heating methods such as steam injection or infusion, enabling rapid heating and cooling that ensures extended shelf life and sterilization without refrigeration.

Maillard Reaction Minimization

HTST (High-Temperature Short-Time) treatment heats milk to 72degC for 15 seconds, effectively reducing microbial load while minimizing Maillard reaction by exposing milk to moderate heat for a brief duration, preserving nutritional quality and flavor. In contrast, UHT (Ultra High Temperature) processing involves heating milk to 135-150degC for 2-5 seconds, which extends shelf life but increases the risk of Maillard reaction, causing browning and off-flavors due to prolonged exposure to higher temperatures.

Bioactive Compound Retention

HTST milk treatment preserves a higher level of bioactive compounds such as vitamins B2, C, and antioxidants compared to UHT due to shorter exposure to elevated temperatures around 72degC for 15 seconds. UHT, which heats milk up to 135-150degC for 2-5 seconds, leads to greater degradation of heat-sensitive bioactive compounds but offers extended shelf life without refrigeration.

Heat Stability Index

HTST processing preserves milk's Heat Stability Index by gently heating milk at 72degC for 15 seconds, maintaining protein and enzyme integrity essential for processing performance. UHT treatment exposes milk to temperatures above 135degC for 2-5 seconds, significantly altering the Heat Stability Index through protein denaturation and Maillard reactions, enabling extended shelf life but reducing heat stability.

Clean Label Sterilization

High-Temperature Short-Time (HTST) processing heats milk to 72degC for 15 seconds, preserving flavor and nutrients while ensuring microbial safety, making it favorable for clean label sterilization without added preservatives. Ultra High Temperature (UHT) treatment involves heating milk above 135degC for 2-5 seconds, achieving commercial sterility but often resulting in altered taste and nutrient degradation, challenging clean label transparency goals.

Enzymatic Activity Control

HTST (High-Temperature Short-Time) treatment effectively reduces enzymatic activity in milk by heating it to at least 72degC for 15 seconds, preserving nutritional quality while inactivating most spoilage enzymes. UHT (Ultra High Temperature) processing exposes milk to temperatures above 135degC for 2-5 seconds, achieving near-complete enzymatic deactivation and extended shelf life without refrigeration, but may cause slight changes in flavor and nutritional components.

UHT-Induced Protein Denaturation

UHT treatment exposes milk to temperatures exceeding 135degC for a few seconds, causing extensive protein denaturation, particularly of whey proteins like b-lactoglobulin, which alters texture and nutritional quality. This contrasts with HTST processing at 72degC for 15 seconds, where protein denaturation is minimal, preserving the milk's sensory characteristics and functional properties.

HTST (High-Temperature Short-Time) vs UHT (Ultra High Temperature) for milk treatment Infographic

agridif.com

agridif.com