Starch retrogradation and gelatinization are key processes influencing cereal quality, where gelatinization transforms starch granules into a gel-like structure during heating, enhancing texture and digestibility. Retrogradation occurs as gelatinized starch molecules realign and recrystallize upon cooling, affecting the firmness and shelf-life of cereal products. Balancing these processes is crucial for optimizing the sensory attributes and stability of cereal-based foods.

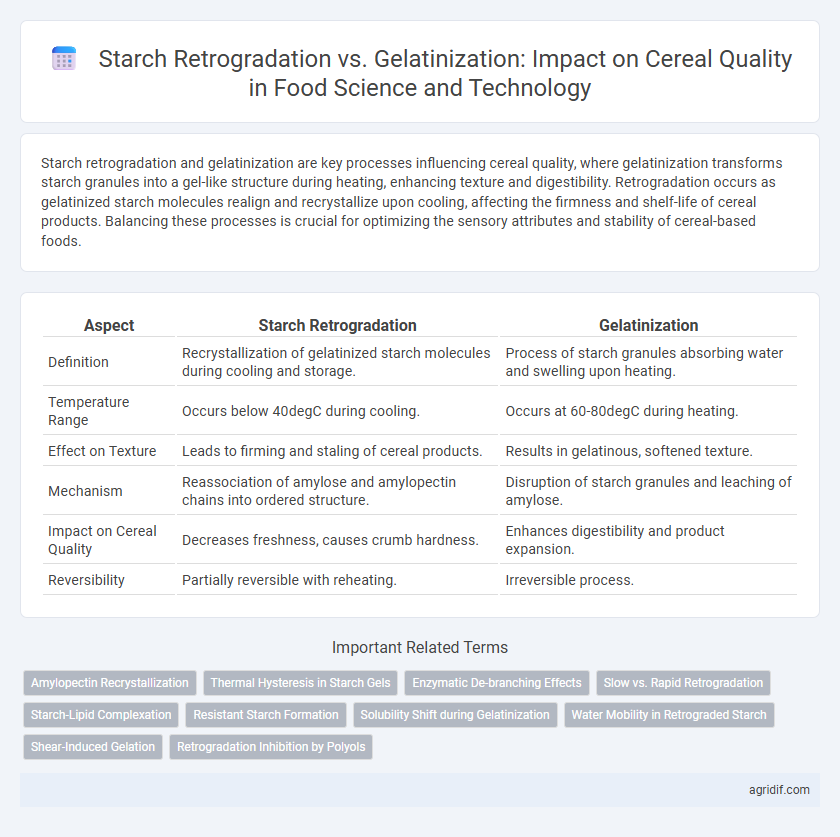

Table of Comparison

| Aspect | Starch Retrogradation | Gelatinization |

|---|---|---|

| Definition | Recrystallization of gelatinized starch molecules during cooling and storage. | Process of starch granules absorbing water and swelling upon heating. |

| Temperature Range | Occurs below 40degC during cooling. | Occurs at 60-80degC during heating. |

| Effect on Texture | Leads to firming and staling of cereal products. | Results in gelatinous, softened texture. |

| Mechanism | Reassociation of amylose and amylopectin chains into ordered structure. | Disruption of starch granules and leaching of amylose. |

| Impact on Cereal Quality | Decreases freshness, causes crumb hardness. | Enhances digestibility and product expansion. |

| Reversibility | Partially reversible with reheating. | Irreversible process. |

Introduction to Starch Functionality in Cereal Science

Starch functionality in cereal science critically influences product texture and shelf life through the processes of gelatinization and retrogradation. Gelatinization involves the swelling and disruption of starch granules upon heating in water, enhancing digestibility and texture, whereas retrogradation is the recrystallization of amylose and amylopectin molecules during cooling, leading to firmness and potential staling. Understanding the molecular changes in starch during these phases allows food scientists to optimize cereal quality for improved sensory attributes and storage stability.

Defining Starch Gelatinization: Mechanisms and Impact

Starch gelatinization occurs when cereal starch granules absorb water and swell upon heating, disrupting the crystalline structure and causing viscosity changes that are crucial for food texture. This process transforms raw starch into a gel-like state, directly influencing the sensory qualities and digestibility of cereal-based products. Understanding gelatinization mechanisms enables optimization of cooking conditions to enhance product quality and shelf-life in food science applications.

Understanding Starch Retrogradation: Causes and Consequences

Starch retrogradation occurs when gelatinized starch molecules, primarily amylose and amylopectin, realign and recrystallize during cooling, causing changes in texture and shelf life of cereal products. This process leads to increased firmness, reduced solubility, and potential staling in bread and other cereal-based foods, impacting quality and consumer acceptability. Understanding the molecular interactions and environmental factors influencing retrogradation is essential for optimizing cereal product formulations and storage conditions.

Molecular Transformations During Gelatinization and Retrogradation

Starch gelatinization involves the disruption of molecular order within starch granules as heat and water cause amylose and amylopectin chains to swell and leach out, resulting in increased viscosity and gel formation critical for cereal texture. Retrogradation occurs during cooling, where amylose and amylopectin molecules realign into more ordered, crystalline structures, affecting the firmness and shelf-life of cereal products. These molecular transformations directly influence starch digestibility, water retention, and overall quality attributes such as mouthfeel and staling in cereals.

Comparative Analysis: Gelatinization vs. Retrogradation in Cereals

Gelatinization in cereals occurs when starch granules absorb water and swell upon heating, leading to the loss of crystallinity and increased viscosity, which enhances texture and digestibility. Retrogradation, on the other hand, involves the reassociation of amylose and amylopectin molecules during cooling, resulting in recrystallization that affects firmness and shelf-life by increasing staling in products like bread and pasta. Comparative analysis reveals that while gelatinization improves initial cereal quality through gelatin-based gel formation, retrogradation negatively impacts sensory attributes and texture stability over time, highlighting the need to balance processing conditions for optimal cereal product quality.

Influence of Processing Conditions on Starch Transition Phases

Starch retrogradation and gelatinization critically impact cereal quality by altering texture, digestibility, and shelf life through their distinct phase transitions. Processing conditions such as temperature, moisture content, and cooling rate dictate the extent of starch granule swelling during gelatinization and the recrystallization rate during retrogradation. Controlling these parameters optimizes cereal product attributes by balancing starch mobility and crystallinity during thermal and storage phases.

Effects on Texture, Shelf-life, and Quality of Cereal-based Foods

Starch gelatinization disrupts granule structure, increasing water absorption and resulting in a soft, viscous texture essential for fresh cereal-based foods, while retrogradation leads to recrystallization of amylose and amylopectin, causing firming and staling that negatively affect texture and shelf-life. The degree of retrogradation influences crumb firmness and moisture migration, reducing the sensory quality and extending the shelf-life by slowing microbial growth due to reduced water activity. Controlling gelatinization and retrogradation through processing and formulation optimizes cereal quality by balancing desired texture with prolonged freshness.

Analytical Methods for Assessing Starch Changes

Starch gelatinization and retrogradation significantly influence cereal quality by affecting texture and shelf life, which can be precisely assessed using differential scanning calorimetry (DSC) to measure thermal transitions. X-ray diffraction (XRD) effectively analyzes crystallinity changes during retrogradation, while rapid visco analyzer (RVA) profiles viscosity alterations reflecting gelatinization behavior. Combining Fourier-transform infrared spectroscopy (FTIR) and nuclear magnetic resonance (NMR) spectroscopy provides detailed insights into molecular structure transformations during starch processing.

Technological Strategies to Control Starch Behavior

Controlling starch retrogradation and gelatinization is crucial for enhancing cereal product quality, as retrogradation leads to undesirable texture and shelf-life reduction while gelatinization improves digestibility and texture. Technological strategies such as enzyme modification, incorporating hydrocolloids, and optimizing thermal processing parameters effectively modulate starch behavior to maintain desirable product characteristics. Advanced techniques like controlled cooling rates and the use of starch-lipid complexes also minimize retrogradation, ensuring improved stability and sensory attributes in cereal-based foods.

Future Trends and Innovations in Starch Modification for Cereal Products

Emerging innovations in starch retrogradation and gelatinization focus on enhancing cereal product quality through engineered enzymatic treatments and novel physical processing methods such as pulsed electric fields and ultrasonication. Advanced biotechnological approaches enable precise control over molecular structure alterations, improving texture, shelf-life, and digestibility of cereal-based foods. Future trends emphasize sustainable starch modifications integrating nanotechnology and clean-label solutions to meet consumer demand for healthier and functional cereal products.

Related Important Terms

Amylopectin Recrystallization

Amylopectin recrystallization plays a critical role in starch retrogradation, directly affecting the textural quality and shelf-life of cereal-based products by causing firmness and staling. Gelatinization disrupts the crystalline structure of starch granules by swelling and solubilizing amylopectin, which enhances the initial viscosity and digestibility of cereal products.

Thermal Hysteresis in Starch Gels

Thermal hysteresis in starch gels reflects the energy difference between gelatinization and retrogradation, significantly impacting the textural quality and shelf life of cereal-based products. Control of this hysteresis through processing conditions can optimize starch crystallinity and water retention, enhancing product stability and consumer acceptability.

Enzymatic De-branching Effects

Enzymatic de-branching significantly influences starch retrogradation by breaking down amylopectin branches, enhancing the recrystallization process and improving cereal texture and shelf-life. In contrast, gelatinization disrupts starch granules through heat and moisture, with limited impact on enzymatic de-branching, thus affecting cereal quality primarily through viscosity changes rather than molecular restructuring.

Slow vs. Rapid Retrogradation

Starch gelatinization involves the disruption of granule structure and swelling during heating, enhancing cereal texture and digestibility, while retrogradation is the recrystallization of gelatinized starch molecules affecting shelf-life and firmness. Slow retrogradation improves cereal quality by maintaining softer texture and freshness over time, whereas rapid retrogradation leads to undesirable firmness and staling in cereal products.

Starch-Lipid Complexation

Starch retrogradation involves the re-association of amylose and amylopectin molecules, leading to changes in cereal texture and shelf-life, whereas gelatinization disrupts starch granules upon heating, improving digestibility and processing functionality. Starch-lipid complexation significantly influences both processes by stabilizing starch structures, reducing retrogradation rates, and modifying gelatinization temperatures, thereby enhancing the quality and functional properties of cereal-based products.

Resistant Starch Formation

Starch retrogradation in cereals enhances resistant starch formation by reorganizing amylose and amylopectin chains into crystalline structures less digestible by enzymes, improving dietary fiber content and glycemic response. In contrast, gelatinization disrupts starch granules during heating, increasing digestibility but reducing resistant starch levels, thereby affecting cereal texture and nutritional quality.

Solubility Shift during Gelatinization

During gelatinization, starch granules absorb water and swell, leading to a significant increase in solubility as amylose and amylopectin molecules leach out, which enhances cereal texture and digestibility. In contrast, retrogradation involves the reassociation of these starch molecules into more ordered, less soluble structures, negatively affecting cereal quality by reducing softness and increasing staling.

Water Mobility in Retrograded Starch

Water mobility in retrograded starch decreases due to the recrystallization of amylose and amylopectin, resulting in reduced water binding capacity and firmness in cereal products. This reduced water mobility contrasts with gelatinization, where starch granules swell and absorb water, enhancing viscosity and texture during processing.

Shear-Induced Gelation

Shear-induced gelation influences starch retrogradation and gelatinization by altering the molecular alignment and crystallinity within cereal matrices, directly impacting texture and shelf-life. Controlling shear rates during processing enhances gel network formation, optimizing cereal quality through improved water retention and structural stability.

Retrogradation Inhibition by Polyols

Starch retrogradation in cereals leads to undesirable texture changes and reduced shelf life, but polyols such as sorbitol and glycerol effectively inhibit this process by interacting with amylose and amylopectin chains, enhancing moisture retention and stability. Gelatinization disrupts starch granules through heat and water, crucial for cooking quality, while polyol addition during retrogradation modulates recrystallization, improving cereal product quality and consumer acceptability.

Starch retrogradation vs Gelatinization for cereal quality Infographic

agridif.com

agridif.com