High-pressure processing (HPP) extends juice shelf-life by inactivating spoilage microorganisms and enzymes without compromising flavor or nutritional quality, unlike traditional thermal processing which uses heat that can degrade sensory attributes and nutrients. HPP maintains fresh-like characteristics while ensuring safety, making it preferable for premium juice products requiring extended freshness. Thermal processing remains effective for long-term preservation but often results in cooked flavors and nutrient loss, limiting its appeal for fresh-tasting juices.

Table of Comparison

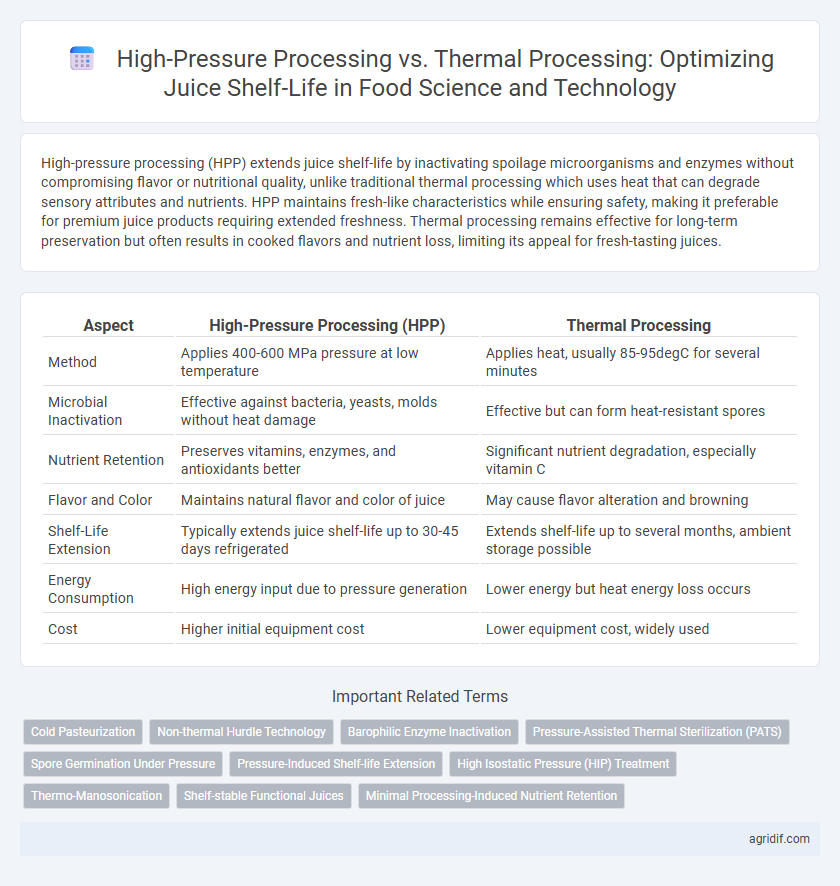

| Aspect | High-Pressure Processing (HPP) | Thermal Processing |

|---|---|---|

| Method | Applies 400-600 MPa pressure at low temperature | Applies heat, usually 85-95degC for several minutes |

| Microbial Inactivation | Effective against bacteria, yeasts, molds without heat damage | Effective but can form heat-resistant spores |

| Nutrient Retention | Preserves vitamins, enzymes, and antioxidants better | Significant nutrient degradation, especially vitamin C |

| Flavor and Color | Maintains natural flavor and color of juice | May cause flavor alteration and browning |

| Shelf-Life Extension | Typically extends juice shelf-life up to 30-45 days refrigerated | Extends shelf-life up to several months, ambient storage possible |

| Energy Consumption | High energy input due to pressure generation | Lower energy but heat energy loss occurs |

| Cost | Higher initial equipment cost | Lower equipment cost, widely used |

Introduction to Juice Preservation Methods

High-pressure processing (HPP) and thermal processing are widely used methods for extending juice shelf-life by inactivating spoilage microorganisms and enzymes. HPP preserves the nutritional and sensory qualities of juice better than thermal processing, which involves heating that can degrade vitamins and alter flavor profiles. Research indicates that HPP-treated juices maintain freshness and bioactive compounds longer, offering a superior alternative for juice preservation.

Overview of High-Pressure Processing (HPP)

High-Pressure Processing (HPP) utilizes pressures up to 600 MPa to inactivate pathogens and spoilage microorganisms in juice, significantly extending shelf-life without the use of heat. Unlike thermal processing, HPP preserves the nutritional quality, flavor, and color of juice by avoiding high temperatures that degrade sensitive bioactive compounds such as vitamin C and antioxidants. This non-thermal technique achieves microbial safety and shelf stability while maintaining fresh-like sensory attributes, making it a preferred method in modern juice preservation.

Fundamentals of Thermal Processing in Juices

Thermal processing in juices involves applying controlled heat to inactivate spoilage microorganisms and enzymes, thereby extending shelf-life while maintaining safety. The process parameters such as temperature and time are optimized to balance microbial kill rates with retention of nutritional and sensory attributes, preventing quality degradation. Understanding thermal kinetics and heat transfer mechanisms is essential to designing effective thermal treatments that ensure juice safety and stability.

Effects on Juice Microbial Safety

High-pressure processing (HPP) preserves juice microbial safety by inactivating pathogens and spoilage microorganisms without significantly affecting nutritional and sensory qualities, extending shelf-life effectively. Thermal processing uses heat to destroy microbes but can degrade vitamins and alter flavor profiles, sometimes resulting in nutrient loss and off-flavors. HPP's ability to maintain juice freshness while ensuring microbial safety makes it a superior non-thermal preservation technique compared to conventional thermal methods.

Nutritional Retention: HPP vs Thermal Treatment

High-pressure processing (HPP) significantly preserves the nutritional quality of juices by retaining higher levels of vitamins, antioxidants, and enzymes compared to thermal processing, which often causes nutrient degradation due to elevated temperatures. Studies show HPP maintains vitamin C content up to 90% more effectively than conventional heat treatments, extending juice shelf-life without compromising essential nutrients. While thermal processing can lead to flavor and nutrient loss, HPP offers a non-thermal alternative that enhances juice safety and nutritional retention simultaneously.

Impact on Juice Sensory Qualities

High-pressure processing (HPP) preserves juice sensory qualities more effectively than thermal processing by maintaining fresh-like flavors, vibrant colors, and natural textures without significant heat-induced degradation. Thermal processing often causes flavor loss, color darkening, and texture changes due to Maillard reactions and enzymatic inactivation. Studies show that HPP extends juice shelf-life while retaining sensory attributes preferred by consumers, making it a superior method for high-quality juice preservation.

Shelf-Life Extension: Comparative Analysis

High-pressure processing (HPP) significantly extends juice shelf-life by inactivating spoilage microorganisms and enzymes without compromising nutritional quality, maintaining freshness for up to 30-45 days under refrigeration. In contrast, traditional thermal processing achieves microbial safety through heat, often leading to nutrient degradation and altering sensory attributes, with shelf-life typically ranging from 14-28 days. Comparative studies highlight HPP's superior ability to preserve bioactive compounds and sensory characteristics while providing extended shelf stability in fruit juices.

Energy Efficiency and Environmental Impacts

High-pressure processing (HPP) significantly reduces energy consumption by using isostatic pressure rather than prolonged heat, preserving juice quality with lower carbon emissions compared to thermal processing. Thermal processing relies on sustained high temperatures that demand substantial energy input, leading to greater greenhouse gas emissions and increased environmental footprint. Optimizing juice shelf-life with HPP supports sustainable production through decreased energy use and minimized environmental impacts while maintaining microbial safety.

Consumer Acceptance and Market Trends

High-pressure processing (HPP) extends juice shelf-life by preserving flavor, nutrients, and freshness better than traditional thermal processing, which often leads to nutrient degradation and altered taste. Consumer acceptance favors HPP due to its minimally processed nature and clean-label appeal, aligning with growing demand for natural and fresh products. Market trends indicate increasing adoption of HPP technologies in juice manufacturing, driven by health-conscious consumers and expanding premium beverage segments.

Future Directions in Juice Processing Technologies

High-pressure processing (HPP) significantly extends juice shelf-life by inactivating spoilage microorganisms at low temperatures, preserving sensory and nutritional qualities better than traditional thermal processing. Emerging technologies combine HPP with mild heat or pulsed electric fields to enhance microbial safety and reduce processing time, addressing consumer demand for fresh-like juices. Future research is focused on optimizing these hybrid methods for energy efficiency, scalability, and retention of bioactive compounds to meet sustainability goals in juice production.

Related Important Terms

Cold Pasteurization

High-pressure processing (HPP) extends juice shelf-life by inactivating spoilage microorganisms and enzymes at low temperatures, preserving fresh flavor and nutrients better than thermal pasteurization, which subjects juice to high heat causing nutrient degradation and flavor changes. Cold pasteurization via HPP maintains juice quality while achieving microbial safety, making it a superior alternative to conventional thermal methods for shelf-life enhancement.

Non-thermal Hurdle Technology

High-pressure processing (HPP) effectively extends juice shelf-life by inactivating spoilage microorganisms and enzymes without heat-induced nutrient degradation, preserving flavor and freshness unlike conventional thermal processing. As a non-thermal hurdle technology, HPP enhances microbial safety and quality retention while minimizing thermal damage, making it superior for maintaining bioactive compounds and sensory attributes in juices.

Barophilic Enzyme Inactivation

High-pressure processing (HPP) effectively inactivates barophilic enzymes in fruit juices, preserving nutritional quality and extending shelf-life without significant heat-induced degradation. Thermal processing requires higher temperatures that can denature enzymes but often compromises flavor and nutrient retention, resulting in a shorter shelf-life compared to HPP.

Pressure-Assisted Thermal Sterilization (PATS)

Pressure-Assisted Thermal Sterilization (PATS) combines high-pressure processing and mild heat to achieve superior microbial inactivation in juices while preserving nutritional and sensory qualities better than traditional thermal processing. This method extends juice shelf-life significantly by reducing thermal damage, maintaining bioactive compounds, and ensuring food safety through enhanced microbial lethality.

Spore Germination Under Pressure

High-pressure processing (HPP) effectively inactivates vegetative microbes while delaying or inhibiting spore germination under pressure, extending juice shelf-life without compromising nutritional quality. In contrast, thermal processing triggers spore germination followed by heat inactivation, which may result in nutrient degradation and altered flavor profiles.

Pressure-Induced Shelf-life Extension

High-pressure processing (HPP) significantly extends juice shelf-life by inactivating spoilage microorganisms and enzymes without the thermal degradation associated with pasteurization, preserving flavor and nutrients. Compared to thermal processing, HPP achieves microbial safety at lower temperatures, resulting in longer shelf stability and improved quality retention in fruit juices.

High Isostatic Pressure (HIP) Treatment

High Isostatic Pressure (HIP) treatment significantly extends juice shelf-life by inactivating spoilage microorganisms and enzymes without compromising nutritional and sensory qualities, unlike traditional thermal processing which often leads to nutrient degradation and flavor changes. Studies demonstrate that HIP-treated juices maintain freshness and bioactive compounds for longer periods, providing a superior alternative for preserving juice quality during storage.

Thermo-Manosonication

Thermo-manosonication (combining mild heat and ultrasonic waves) enhances juice shelf-life by inactivating spoilage microorganisms more effectively than traditional thermal processing, preserving sensory and nutritional qualities. High-pressure processing offers microbial inactivation at ambient temperatures but may not achieve the same synergistic effect on enzyme deactivation and shelf stability as thermo-manosonication.

Shelf-stable Functional Juices

High-pressure processing (HPP) preserves bioactive compounds and sensory attributes in shelf-stable functional juices more effectively than thermal processing, extending shelf-life by inactivating spoilage microorganisms without heat-induced nutrient degradation. Thermal processing, while effective for microbial safety, often reduces vitamin content and alters flavor profiles, limiting its suitability for maintaining functional juice quality over extended storage.

Minimal Processing-Induced Nutrient Retention

High-pressure processing (HPP) enhances juice shelf-life by inactivating pathogens while preserving vitamins and phytochemicals more effectively than traditional thermal processing, which often degrades heat-sensitive nutrients such as vitamin C and folate. Studies show HPP maintains antioxidant capacity and sensory qualities, making it a superior method for minimal processing-induced nutrient retention in fruit juices.

High-pressure processing vs Thermal processing for juice shelf-life Infographic

agridif.com

agridif.com