Enzymatic browning occurs when polyphenol oxidase enzymes catalyze the oxidation of phenolic compounds, resulting in the formation of brown pigments in fruits and vegetables during processing. Non-enzymatic browning, including Maillard reactions and caramelization, involves the chemical interaction between reducing sugars and amino acids or heat-induced sugar decomposition, leading to complex color changes and flavor development in processed foods. Understanding the mechanisms of both browning types is essential for optimizing color stability and sensory attributes in food products.

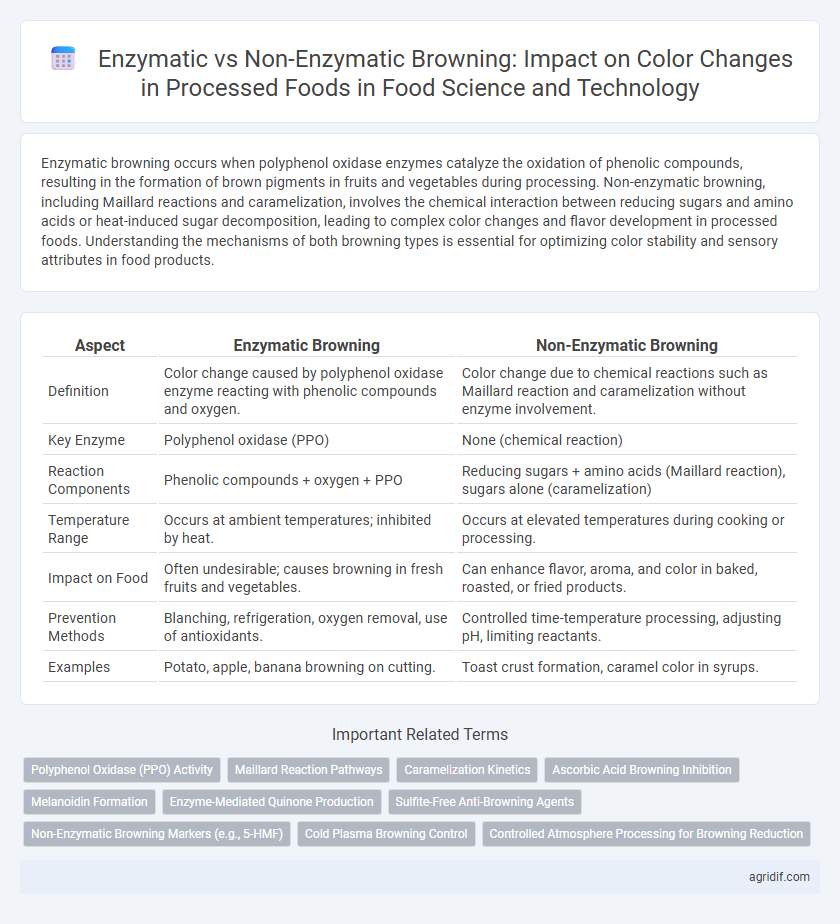

Table of Comparison

| Aspect | Enzymatic Browning | Non-Enzymatic Browning |

|---|---|---|

| Definition | Color change caused by polyphenol oxidase enzyme reacting with phenolic compounds and oxygen. | Color change due to chemical reactions such as Maillard reaction and caramelization without enzyme involvement. |

| Key Enzyme | Polyphenol oxidase (PPO) | None (chemical reaction) |

| Reaction Components | Phenolic compounds + oxygen + PPO | Reducing sugars + amino acids (Maillard reaction), sugars alone (caramelization) |

| Temperature Range | Occurs at ambient temperatures; inhibited by heat. | Occurs at elevated temperatures during cooking or processing. |

| Impact on Food | Often undesirable; causes browning in fresh fruits and vegetables. | Can enhance flavor, aroma, and color in baked, roasted, or fried products. |

| Prevention Methods | Blanching, refrigeration, oxygen removal, use of antioxidants. | Controlled time-temperature processing, adjusting pH, limiting reactants. |

| Examples | Potato, apple, banana browning on cutting. | Toast crust formation, caramel color in syrups. |

Introduction to Browning Reactions in Processed Foods

Browning reactions in processed foods significantly impact color, flavor, and quality, with enzymatic browning involving polyphenol oxidase catalyzing phenolic compounds into melanins, commonly seen in fresh-cut fruits and vegetables. Non-enzymatic browning, such as the Maillard reaction and caramelization, occurs through chemical interactions between reducing sugars and amino acids or heat-induced sugar degradation, influencing baked and roasted products. Understanding these mechanisms is crucial for controlling color development and maintaining sensory attributes in food processing.

Fundamentals of Enzymatic Browning

Enzymatic browning in processed foods occurs when polyphenol oxidase enzymes catalyze the oxidation of phenolic compounds to quinones, which polymerize into brown pigments called melanins. This reaction primarily affects fruits and vegetables with high phenolic content such as apples, potatoes, and bananas, leading to undesirable color changes during processing and storage. Controlling factors like pH, temperature, and oxygen exposure is critical in minimizing enzymatic browning and preserving product color quality.

Mechanisms of Non-Enzymatic Browning

Non-enzymatic browning in processed foods primarily involves the Maillard reaction, where reducing sugars react with amino acids under heat, leading to the formation of complex brown pigments called melanoidins. Caramelization, another key mechanism, occurs through the thermal decomposition of sugars, producing characteristic flavors and brown coloration without involving amino acids. These chemical pathways differ from enzymatic browning by not requiring polyphenol oxidase activity and significantly influence flavor, aroma, and color stability in food processing.

Key Enzymes Involved in Food Browning

Polyphenol oxidase (PPO) is the primary enzyme driving enzymatic browning, catalyzing the oxidation of phenolic compounds to quinones that polymerize into brown pigments. Peroxidase (POD) also contributes, particularly in the presence of hydrogen peroxide, enhancing pigment formation. In contrast, non-enzymatic browning involves Maillard reactions and caramelization, where heat-induced chemical reactions between reducing sugars and amino acids cause color changes without enzymatic involvement.

Chemical Pathways of Maillard and Caramelization Reactions

Enzymatic browning primarily involves polyphenol oxidases catalyzing the oxidation of phenolic compounds to quinones, leading to melanin formation and color changes in processed foods. Non-enzymatic browning includes Maillard and caramelization reactions, where Maillard reaction occurs between reducing sugars and amino acids, producing complex melanoidins responsible for brown pigments and flavor development under moderate heat and low moisture. Caramelization involves thermal decomposition of sugars at high temperatures, generating volatile compounds and brown polymers that contribute distinct flavors and colors independent of amino acids.

Factors Influencing Enzymatic Browning in Foods

Enzymatic browning in foods primarily results from the oxidation of phenolic compounds catalyzed by polyphenol oxidase, influenced by factors such as pH, temperature, oxygen availability, and substrate concentration. High pH levels and optimal temperatures between 20-35degC enhance enzymatic activity, while reducing oxygen exposure slows the browning process. Additionally, the presence of metal ions and the integrity of cell membranes also significantly affect the rate of enzymatic browning in processed foods.

Impact of Processing Conditions on Non-Enzymatic Browning

Non-enzymatic browning in processed foods is primarily influenced by temperature, pH, and moisture content during thermal treatments such as baking, roasting, and drying. Elevated temperatures and low moisture levels accelerate Maillard reactions and caramelization, leading to significant color development and flavor changes. Control of processing parameters is critical to optimize product quality by minimizing undesirable browning and maintaining nutritional value.

Strategies to Control Browning in Food Processing

Enzymatic browning in food processing can be effectively controlled using strategies such as lowering pH, applying heat treatments, and incorporating enzyme inhibitors like ascorbic acid or citric acid to prevent polyphenol oxidase activity. Non-enzymatic browning, primarily Maillard reaction and caramelization, can be managed by optimizing temperature, reducing sugar concentration, and controlling moisture levels during processing to minimize undesirable color changes. Implementing these targeted approaches preserves product quality and enhances the visual appeal of processed foods.

Effects of Browning on Nutritional and Sensory Quality

Enzymatic browning, catalyzed by polyphenol oxidase enzymes, leads to the formation of melanins that can reduce the nutritional quality by decreasing antioxidant levels and impair sensory attributes such as flavor and color uniformity. Non-enzymatic browning, including Maillard reactions and caramelization, enhances flavor complexity and color development but may generate advanced glycation end products (AGEs) that negatively impact nutritional value and pose potential health risks. Both browning mechanisms influence food quality by altering texture, aroma, and appearance, necessitating precise control during food processing to maintain optimal sensory and nutritional properties.

Recent Advances in Browning Prevention Technologies

Recent advances in enzymatic browning prevention include the use of natural inhibitors such as ascorbic acid, citric acid, and novel polyphenolic compounds that effectively inhibit polyphenol oxidase activity. Non-enzymatic browning control has progressed through precise temperature and moisture regulation during processing, alongside the development of innovative antioxidants and enzyme deactivation techniques using high-pressure processing or pulsed light treatments. These technologies enhance color stability and extend shelf life in fruits, vegetables, and processed food products by minimizing discoloration while preserving nutritional and sensory quality.

Related Important Terms

Polyphenol Oxidase (PPO) Activity

Enzymatic browning in processed foods primarily involves the activity of Polyphenol Oxidase (PPO), which catalyzes the oxidation of phenolic compounds to quinones, leading to the formation of brown pigments. Non-enzymatic browning, such as the Maillard reaction, occurs independently of PPO and involves interactions between reducing sugars and amino acids, resulting in distinct color changes and flavor development.

Maillard Reaction Pathways

Maillard reaction pathways play a crucial role in non-enzymatic browning, where reducing sugars react with amino acids under heat, producing complex flavor compounds and brown pigments integral to food color and taste. Enzymatic browning, in contrast, involves polyphenol oxidase catalyzing the oxidation of phenolic compounds, primarily affecting surface color in fruits and vegetables without the formation of Maillard reaction products.

Caramelization Kinetics

Caramelization kinetics, a key non-enzymatic browning reaction, involves the thermal degradation of sugars at temperatures above 110degC, leading to complex color and flavor formation in processed foods. Unlike enzymatic browning catalyzed by polyphenol oxidase, caramelization depends on temperature and sugar concentration, significantly influencing the color intensity and stability during cooking and storage.

Ascorbic Acid Browning Inhibition

Enzymatic browning occurs through polyphenol oxidase activity on phenolic compounds, leading to undesirable color changes in processed foods, whereas non-enzymatic browning involves Maillard reactions and caramelization affecting flavor and color. Ascorbic acid acts as a potent browning inhibitor by reducing quinones back to phenols, effectively delaying enzymatic browning and preserving the color quality of fruits and vegetables during processing.

Melanoidin Formation

Melanoidin formation in processed foods is primarily a result of non-enzymatic browning through the Maillard reaction, involving reducing sugars and amino acids that produce complex brown pigments and enhance flavor profiles. In contrast, enzymatic browning, catalyzed by polyphenol oxidase enzymes on phenolic compounds, leads to color changes that are generally less stable and do not produce melanoidins.

Enzyme-Mediated Quinone Production

Enzymatic browning in processed foods primarily involves polyphenol oxidase catalyzing the oxidation of phenolic compounds to quinones, which polymerize to form brown pigments, significantly impacting product color and quality. In contrast, non-enzymatic browning, such as the Maillard reaction, occurs through the chemical interaction between reducing sugars and amino acids, independent of enzyme activity, leading to different color and flavor profiles in food products.

Sulfite-Free Anti-Browning Agents

Sulfite-free anti-browning agents such as ascorbic acid, citric acid, and calcium chloride effectively inhibit enzymatic browning by reducing polyphenol oxidase activity and chelating copper ions, preserving the natural color of processed foods. Non-enzymatic browning, mainly through the Maillard reaction and caramelization, requires different control strategies like temperature management and sugar reduction, as sulfite-free agents do not prevent these chemical changes.

Non-Enzymatic Browning Markers (e.g., 5-HMF)

Non-enzymatic browning in processed foods primarily involves Maillard reactions and caramelization, leading to the formation of color compounds and flavor changes, with 5-hydroxymethylfurfural (5-HMF) serving as a key marker for heat-induced sugar degradation. The quantification of 5-HMF provides critical insight into the extent of thermal processing and product quality, influencing color stability and potential nutritional impacts in food science applications.

Cold Plasma Browning Control

Cold plasma treatment effectively inhibits enzymatic browning by deactivating polyphenol oxidase enzymes, while its impact on non-enzymatic browning remains minimal, preserving the natural color of processed foods. This innovative technology offers a promising approach for maintaining visual quality and extending shelf life without chemical additives in food processing.

Controlled Atmosphere Processing for Browning Reduction

Controlled atmosphere processing effectively reduces enzymatic browning in processed foods by limiting oxygen exposure, thereby inhibiting polyphenol oxidase activity responsible for discoloration. This method also slows non-enzymatic browning reactions such as Maillard reactions and caramelization by regulating temperature, oxygen, and humidity levels to preserve color quality.

Enzymatic Browning vs Non-Enzymatic Browning for Color Changes in Processed Foods Infographic

agridif.com

agridif.com