Enzymatic browning occurs when polyphenol oxidase enzymes react with oxygen, leading to discoloration and reduced quality in fresh fruits during storage. Non-enzymatic browning, such as the Maillard reaction, happens between reducing sugars and amino acids, resulting in color and flavor changes typically under heat or prolonged storage conditions. Controlling enzymatic browning involves enzyme inhibitors and low temperatures, while preventing non-enzymatic browning centers on moisture control and optimal storage environments.

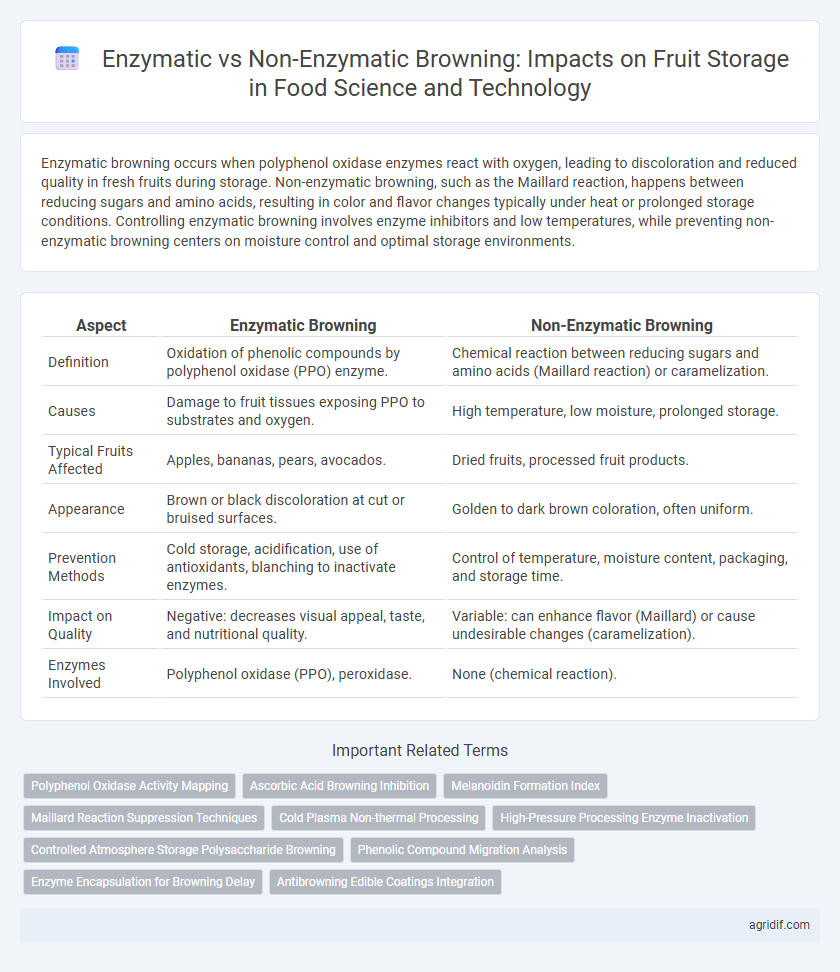

Table of Comparison

| Aspect | Enzymatic Browning | Non-Enzymatic Browning |

|---|---|---|

| Definition | Oxidation of phenolic compounds by polyphenol oxidase (PPO) enzyme. | Chemical reaction between reducing sugars and amino acids (Maillard reaction) or caramelization. |

| Causes | Damage to fruit tissues exposing PPO to substrates and oxygen. | High temperature, low moisture, prolonged storage. |

| Typical Fruits Affected | Apples, bananas, pears, avocados. | Dried fruits, processed fruit products. |

| Appearance | Brown or black discoloration at cut or bruised surfaces. | Golden to dark brown coloration, often uniform. |

| Prevention Methods | Cold storage, acidification, use of antioxidants, blanching to inactivate enzymes. | Control of temperature, moisture content, packaging, and storage time. |

| Impact on Quality | Negative: decreases visual appeal, taste, and nutritional quality. | Variable: can enhance flavor (Maillard) or cause undesirable changes (caramelization). |

| Enzymes Involved | Polyphenol oxidase (PPO), peroxidase. | None (chemical reaction). |

Introduction to Browning in Fruits: Enzymatic vs Non-Enzymatic

Enzymatic browning in fruits occurs when polyphenol oxidase catalyzes the oxidation of phenolic compounds to quinones, leading to brown pigments, significantly affecting the visual quality during storage. In contrast, non-enzymatic browning, primarily Maillard reactions and caramelization, involves chemical reactions between reducing sugars and amino acids or sugar decomposition under heat, influencing flavor and color development. Understanding these distinct browning mechanisms is crucial for optimizing fruit preservation methods and extending shelf life in food technology.

Mechanisms of Enzymatic Browning in Fruit Storage

Enzymatic browning in fruit storage primarily occurs when polyphenol oxidase (PPO) catalyzes the oxidation of phenolic compounds into quinones, which polymerize to form brown pigments called melanins. This process is initiated by cellular damage or exposure to oxygen, leading to a significant impact on fruit quality, appearance, and shelf life. Controlling factors such as pH, temperature, and oxygen availability can effectively reduce the enzymatic browning reaction and enhance fruit storage stability.

Pathways and Factors in Non-Enzymatic Browning

Non-enzymatic browning in fruit storage primarily occurs through the Maillard reaction and caramelization, involving the interaction of reducing sugars with amino acids or the thermal decomposition of sugars, respectively. Factors influencing this pathway include temperature, pH, moisture content, and sugar concentration, which accelerate browning and affect color and flavor development. Controlling these variables is critical to minimizing undesirable browning and maintaining fruit quality during storage.

Key Enzymes Involved in Fruit Browning

Key enzymes involved in enzymatic browning during fruit storage include polyphenol oxidase (PPO), peroxidase (POD), and tyrosinase, which catalyze the oxidation of phenolic compounds to quinones that polymerize into brown pigments. Non-enzymatic browning primarily involves Maillard reactions and caramelization, occurring independently of enzymes and influenced by factors such as temperature and pH. Understanding the activity of PPO and related enzymes is crucial for controlling enzymatic browning and extending the shelf life of fresh fruits.

Impact of Storage Conditions on Browning Reactions

Enzymatic browning in fruits primarily occurs due to polyphenol oxidase activity, which is highly influenced by temperature, pH, and oxygen availability during storage. Non-enzymatic browning, such as the Maillard reaction and caramelization, accelerates under higher temperatures and low moisture conditions, leading to color changes independent of enzyme action. Controlling storage conditions like refrigeration and modified atmosphere packaging effectively reduces both enzymatic and non-enzymatic browning, preserving fruit quality and extending shelf life.

Effects of Browning on Nutritional and Sensory Quality

Enzymatic browning in fruits primarily affects the sensory quality by causing undesirable color changes and off-flavors due to polyphenol oxidase activity, leading to reduced consumer acceptance. Non-enzymatic browning, such as the Maillard reaction, can enhance flavor profiles but often results in nutrient loss, including the degradation of vitamin C and essential amino acids during storage. Both browning mechanisms compromise nutritional value and texture, making effective control measures crucial for maintaining fruit quality in food science and technology.

Methods to Inhibit Enzymatic Browning in Fruits

Methods to inhibit enzymatic browning in fruits primarily involve reducing the activity of polyphenol oxidase (PPO) enzymes through techniques such as blanching, application of antioxidants like ascorbic acid and citric acid, and controlled atmosphere storage to limit oxygen exposure. Packaging innovations utilizing oxygen scavengers and modified atmosphere packaging (MAP) create low-oxygen environments that further slow enzymatic reactions responsible for browning. Enzyme inhibitors like 4-hexylresorcinol and natural extracts from plants, along with genetic modification approaches that downregulate PPO expression, offer advanced control over enzymatic browning during fruit storage.

Strategies to Minimize Non-Enzymatic Browning during Storage

Non-enzymatic browning in fruit storage, primarily caused by the Maillard reaction and caramelization, can be minimized through controlled storage temperature and humidity to slow down chemical reactions. Utilization of low oxygen or modified atmosphere packaging reduces the availability of reactants involved in non-enzymatic browning. Incorporating antioxidants and adjusting pH levels in fruit coatings also effectively inhibit the progression of browning during prolonged storage.

Comparative Analysis: Enzymatic vs Non-Enzymatic Browning

Enzymatic browning in fruit storage involves polyphenol oxidase catalyzing phenolic compounds into brown pigments, impacting sensory qualities and shelf life. Non-enzymatic browning, primarily Maillard reaction and caramelization, occurs under heat or prolonged storage, affecting flavor and color without involving enzymes. Comparative analysis reveals enzymatic browning is more prevalent in fresh, cut fruits, while non-enzymatic browning dominates during thermal processing and extended storage periods.

Innovations and Future Trends in Browning Control for Fruit Storage

Recent innovations in enzymatic browning control for fruit storage leverage natural enzyme inhibitors and genetically modified organisms to reduce polyphenol oxidase activity, enhancing shelf life and preserving nutritional quality. Emerging non-enzymatic browning strategies focus on optimizing storage conditions and employing novel antioxidants to minimize Maillard reaction progression, thereby maintaining fruit freshness and appearance. Future trends include integrating smart packaging technologies with real-time monitoring systems to dynamically regulate browning factors and improve postharvest fruit quality.

Related Important Terms

Polyphenol Oxidase Activity Mapping

Polyphenol oxidase (PPO) activity mapping reveals higher enzymatic browning in fruits due to oxidation of phenolic compounds during storage, leading to quality degradation. In contrast, non-enzymatic browning occurs through Maillard reactions and caramelization, which are independent of PPO activity but influenced by temperature and sugar content.

Ascorbic Acid Browning Inhibition

Ascorbic acid effectively inhibits enzymatic browning in fruit storage by reducing quinones back to their original phenolic forms, thereby preventing the formation of brown melanins. In contrast, non-enzymatic browning, such as Maillard reactions, proceeds independently of enzymatic activity and is less influenced by ascorbic acid application.

Melanoidin Formation Index

Enzymatic browning in fruit storage involves polyphenol oxidase catalyzing phenolic compounds to form melanins, significantly increasing the Melanoidin Formation Index (MFI). Non-enzymatic browning, primarily through Maillard reactions, also contributes to MFI by producing melanoidins via sugar-amino acid interactions during thermal processing and storage.

Maillard Reaction Suppression Techniques

Enzymatic browning in fruit storage is catalyzed by polyphenol oxidase, while non-enzymatic browning occurs primarily through the Maillard reaction between reducing sugars and amino acids. Maillard reaction suppression techniques include lowering storage temperature, reducing pH, controlling water activity, and applying specific inhibitors such as sulfites or natural antioxidants to maintain fruit quality and extend shelf life.

Cold Plasma Non-thermal Processing

Cold plasma non-thermal processing effectively inhibits enzymatic browning in fruit storage by inactivating polyphenol oxidase enzymes without compromising fruit quality, while it also slows non-enzymatic browning reactions such as Maillard reactions by reducing reactive oxygen species and microbial load. This technology extends shelf life and maintains nutritional and sensory attributes better than conventional thermal treatments in fresh and minimally processed fruits.

High-Pressure Processing Enzyme Inactivation

High-Pressure Processing (HPP) effectively inactivates polyphenol oxidase enzymes responsible for enzymatic browning in fruits, extending shelf life and preserving color without using heat. Non-enzymatic browning, primarily Maillard reactions, remains minimal under HPP conditions due to low temperatures and short processing times, maintaining fruit quality during storage.

Controlled Atmosphere Storage Polysaccharide Browning

Controlled Atmosphere Storage (CAS) reduces enzymatic browning in fruits by limiting oxygen exposure, thereby inhibiting polyphenol oxidase activity responsible for browning reactions. Non-enzymatic polysaccharide browning, such as the Maillard reaction, proceeds independently of oxygen levels and is influenced primarily by temperature and sugar concentration during fruit storage.

Phenolic Compound Migration Analysis

Phenolic compound migration analysis reveals that enzymatic browning in fruit storage is primarily driven by polyphenol oxidase catalyzing the oxidation of phenolics, leading to quinone formation and subsequent browning. Non-enzymatic browning, such as the Maillard reaction, involves the interaction of reducing sugars and amino acids without enzyme involvement, resulting in different phenolic compound transformations and browning dynamics.

Enzyme Encapsulation for Browning Delay

Enzyme encapsulation techniques effectively inhibit enzymatic browning in fruit storage by controlling polyphenol oxidase (PPO) activity and limiting oxygen access, which preserves visual quality and nutritional value. This method contrasts with non-enzymatic browning, such as Maillard reactions, where enzyme activity is not involved, highlighting encapsulation's targeted approach to prolong shelf life and maintain fruit freshness.

Antibrowning Edible Coatings Integration

Enzymatic browning in fruits involves polyphenol oxidase catalyzing the oxidation of phenolic compounds, leading to undesirable color changes, whereas non-enzymatic browning results from Maillard reactions between reducing sugars and amino acids during storage. Integration of antibrowning edible coatings containing natural antioxidants or enzyme inhibitors effectively reduces both enzymatic and non-enzymatic browning, enhancing fruit shelf life and visual quality.

Enzymatic browning vs non-enzymatic browning for fruit storage Infographic

agridif.com

agridif.com